Numerical control diamond wire sapphire slicing machine

A diamond wire and sapphire technology, applied in the field of CNC diamond wire sapphire slicer, can solve the problems of difficult slicing process, decreased product quality, difficult sapphire processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

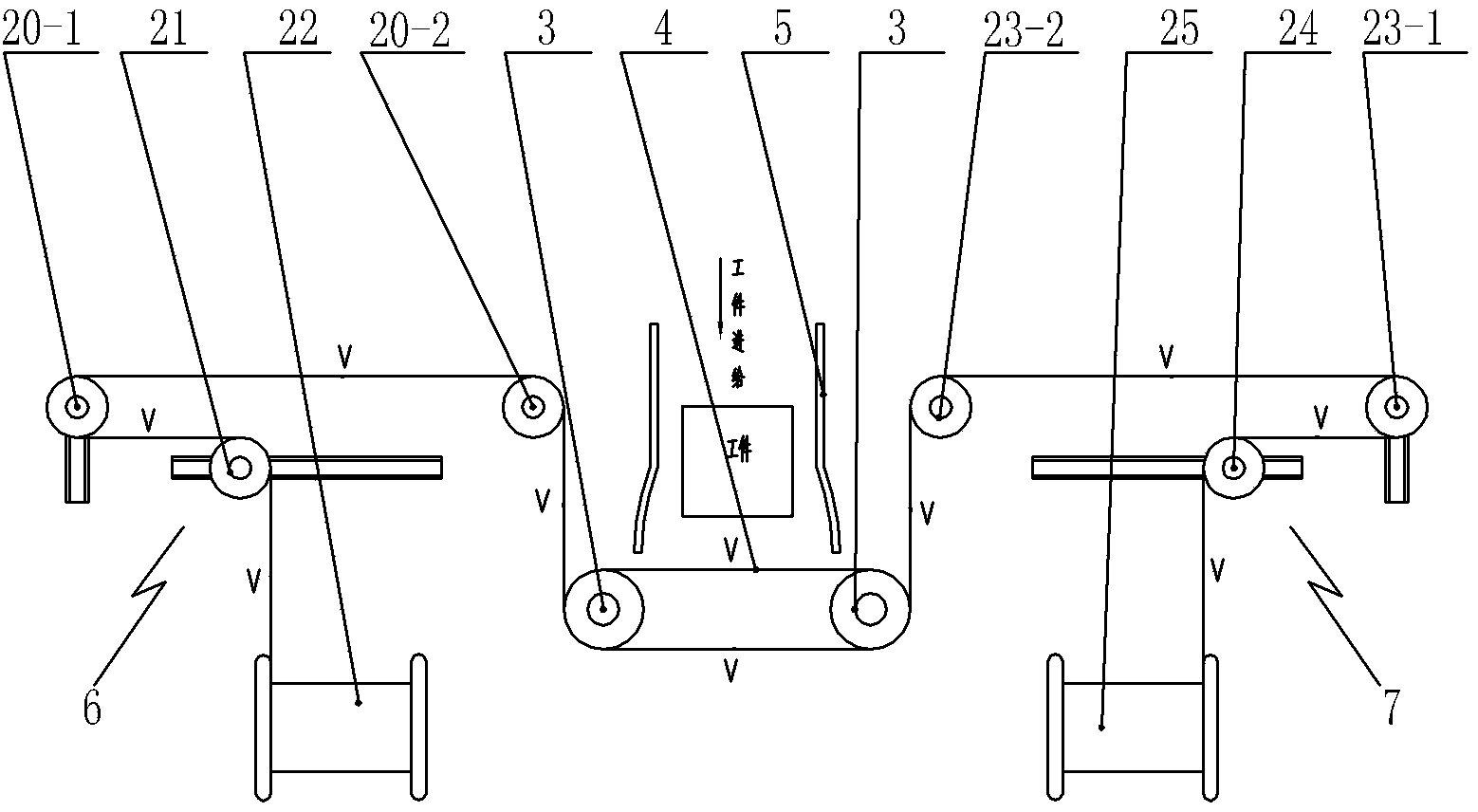

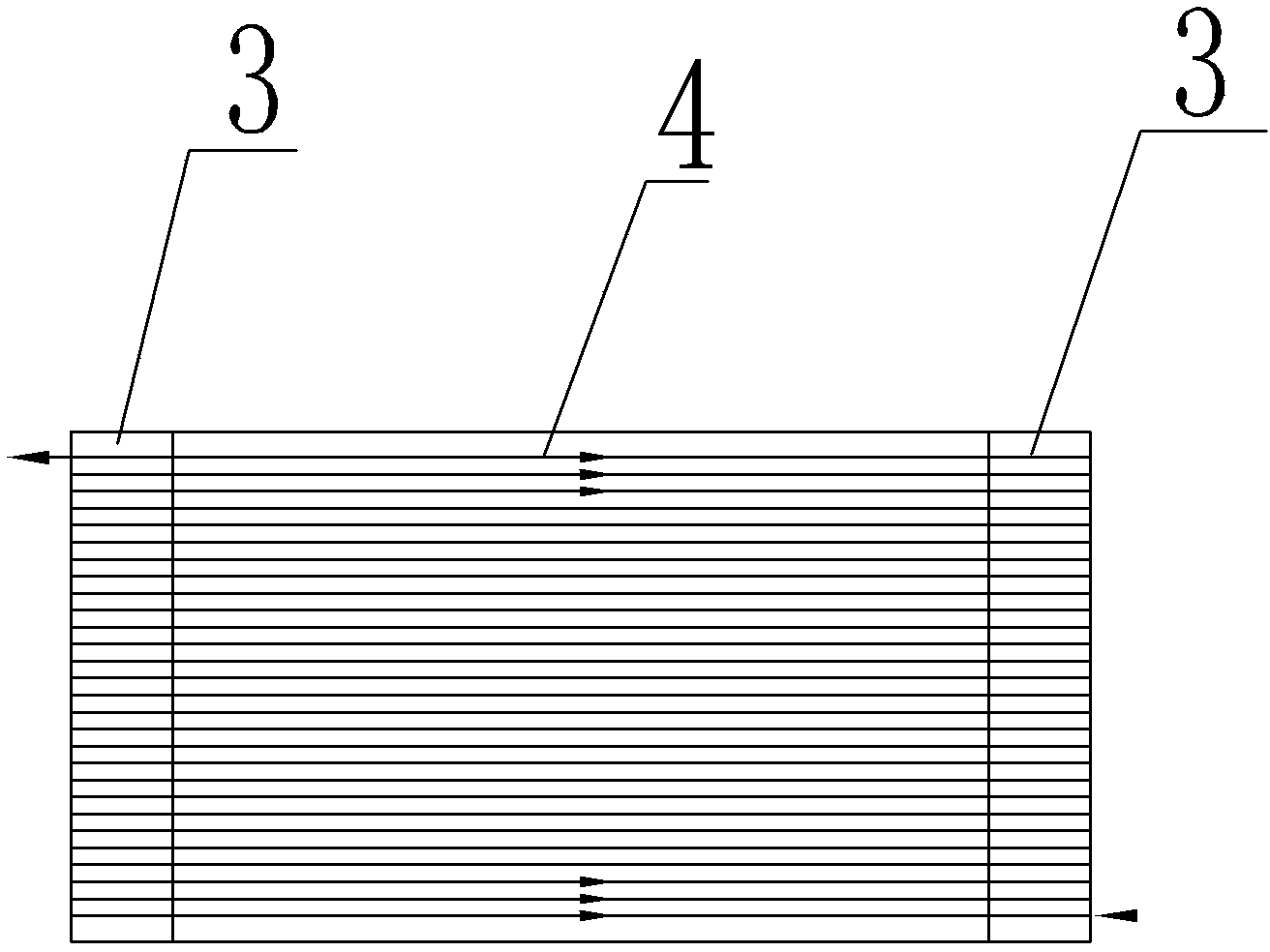

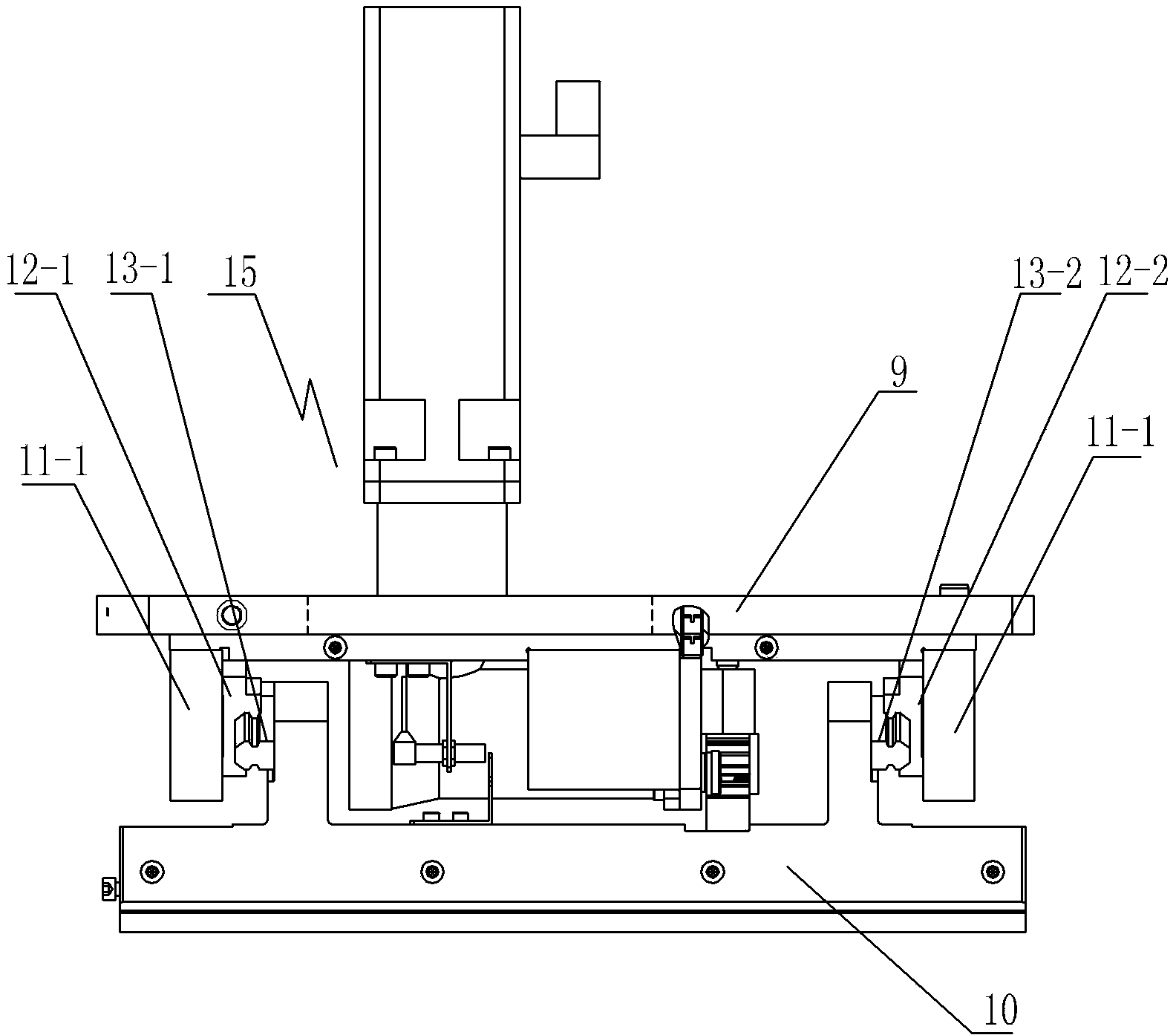

[0022] See figure 1 , figure 2 , image 3 , a numerical control diamond wire sapphire slicer, which includes a frame 1, a feed mechanism 2 is arranged on the frame, two lead wire guide wheel structures 3 are arranged on the frame 1 corresponding to the feed mechanism 2, and the diamond wire 4 maintains a distance The ground is wound on the two lead wire guide wheel structures 3 successively multiple times, and the cooling and lubricating nozzle 5 is correspondingly installed above the lead wire guide wheel structures 3 on the frame 1, and the two sides of the lead wire guide wheel structures 3 on the frame 1 are respectively provided with receiving The wire winding device 6 , the wire winding device 7 , and the feed mechanism 2 are provided with a swing mechanism 8 .

[0023] See figure 1 , figure 2 , The take-up winding device 6 includes the fixed wire pulley 20-1, 20-2, the wire take-up sliding wire pulley 21 and the wire take-up reel 22, and the pay-off winding device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com