Patents

Literature

160results about How to "Improve sawing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

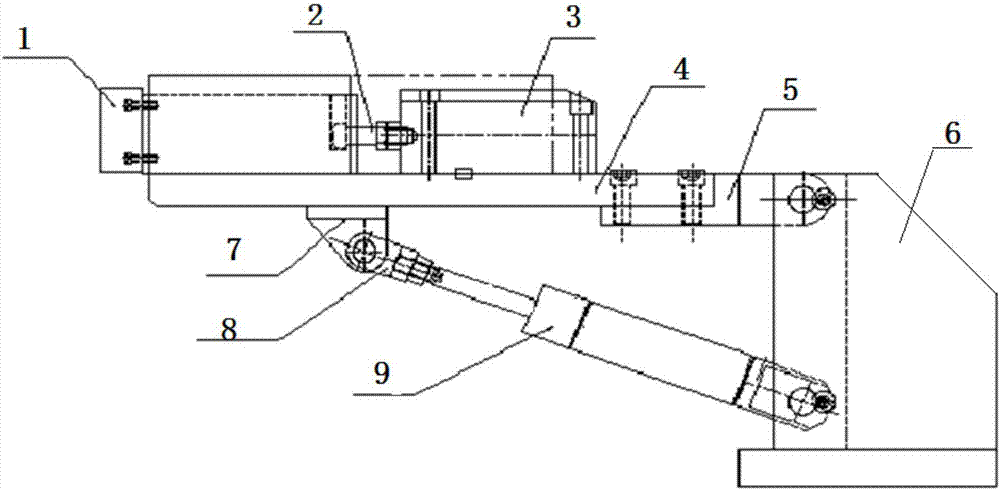

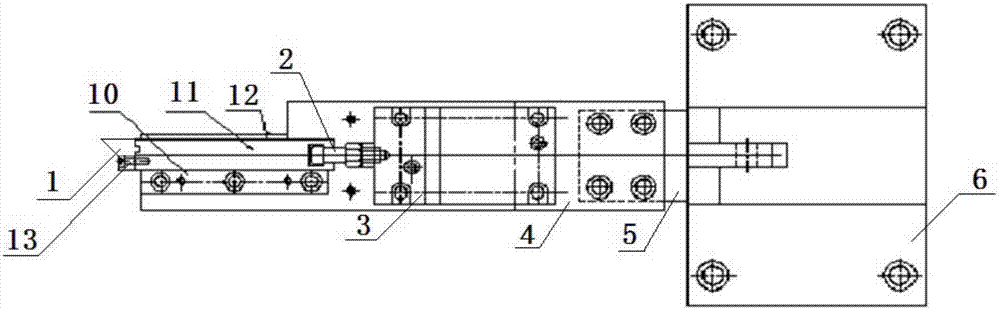

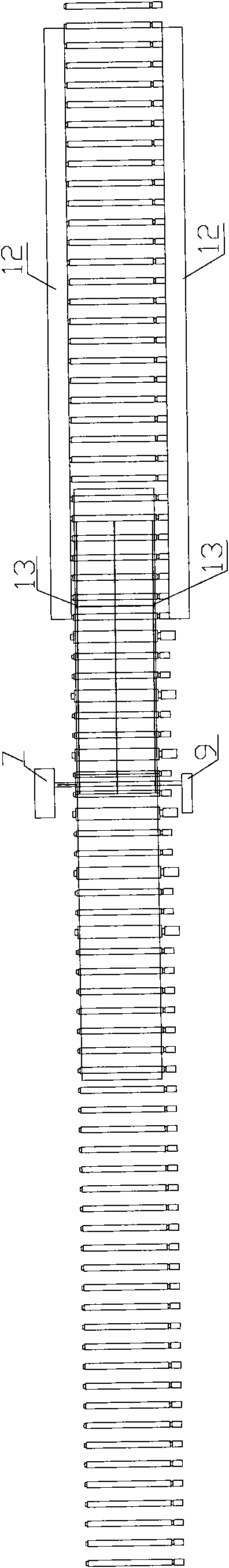

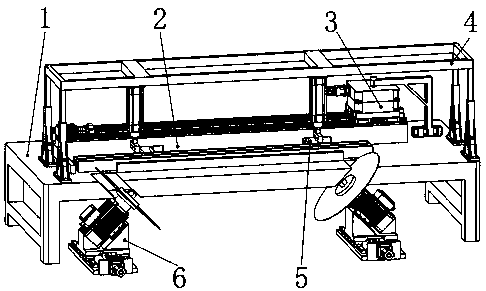

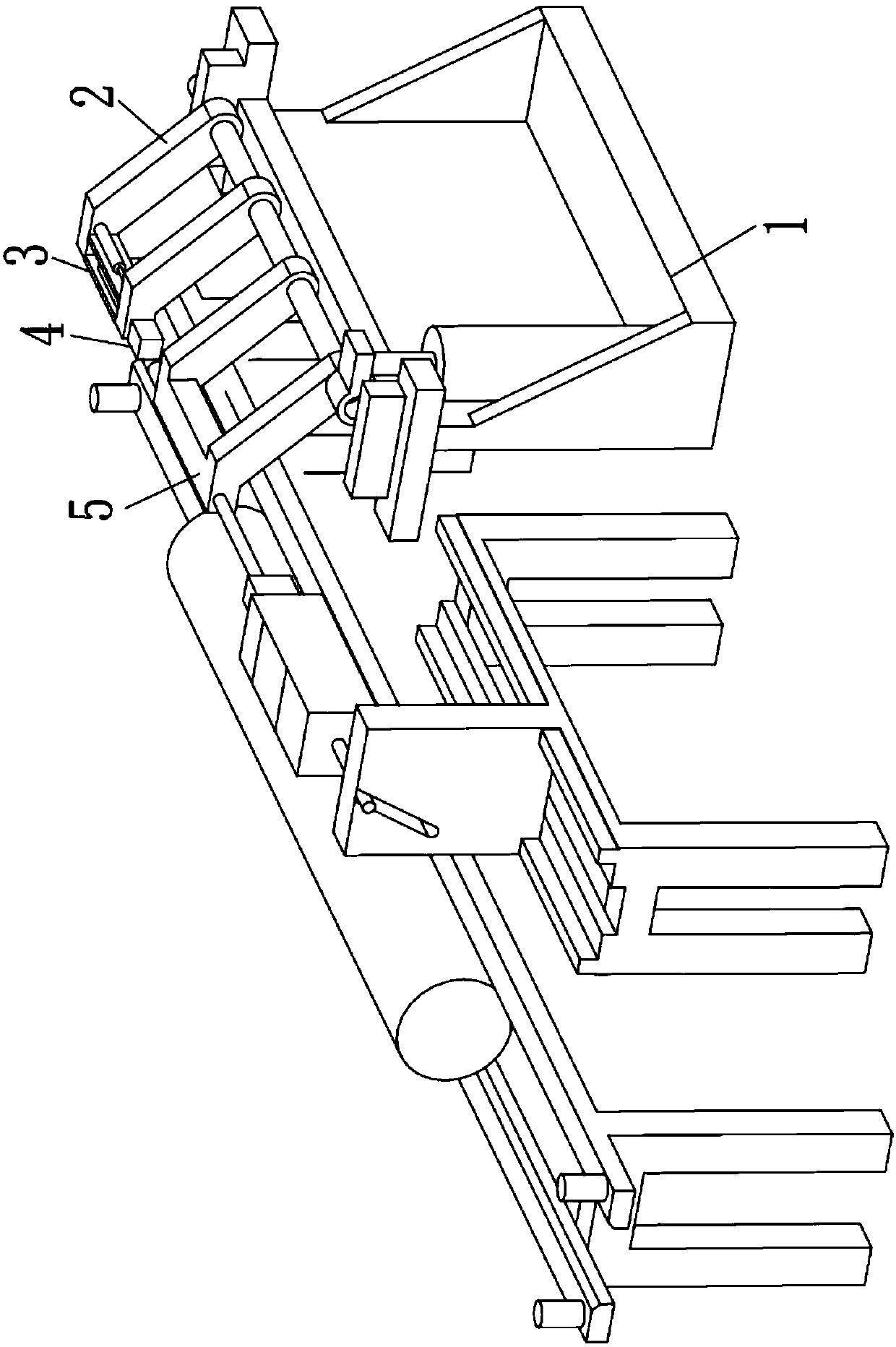

Automatic steel bar cutting device

The invention relates to the technical field of steel bar cutting, in particular to an automatic steel bar cutting device used for reducing the error generated during steel bar cutting. The automatic steel bar cutting device comprises a conveying assembly, a clamping assembly, a guiding assembly, a cutting assembly and a measuring assembly. The conveying assembly mainly comprises a first support and conveying rollers, and the multiple conveying rollers are connected with a stepping motor through a transmission mechanism, wherein the stepping motor is arranged on the first support. A second support is arranged on one side of the first support, two vertical first air cylinders are fixedly installed at the bottom of the second support, and a tray is fixedly installed at the free ends of piston rods of the two first air cylinders. A motor is fixedly installed on the tray, and the output end of the motor is connected with a cutting saw through a speed reducer. A fixing frame of a gantry structure is arranged over the cutting saw, and blocking curtains are fixedly arranged at the two ends of the fixing frame respectively. A third support is arranged on one side of the second support, and the measuring assembly is arranged on the third support. The automatic steel bar cutting device is easy to operate, accurate in positioning and high in saw cutting efficiency, and the work efficiency can be greatly improved.

Owner:STATE GRID SHANDONG SHANGHE POWER SUPPLY +1

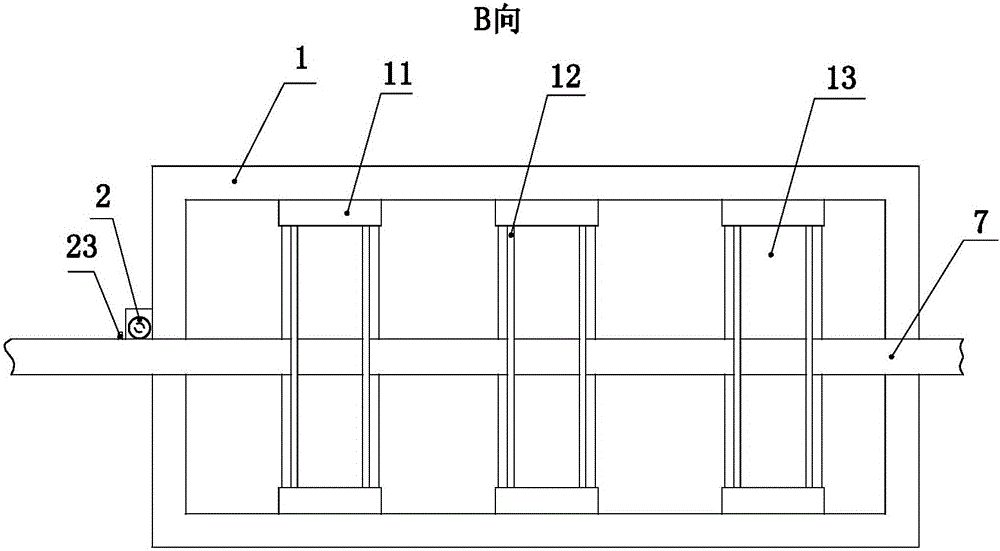

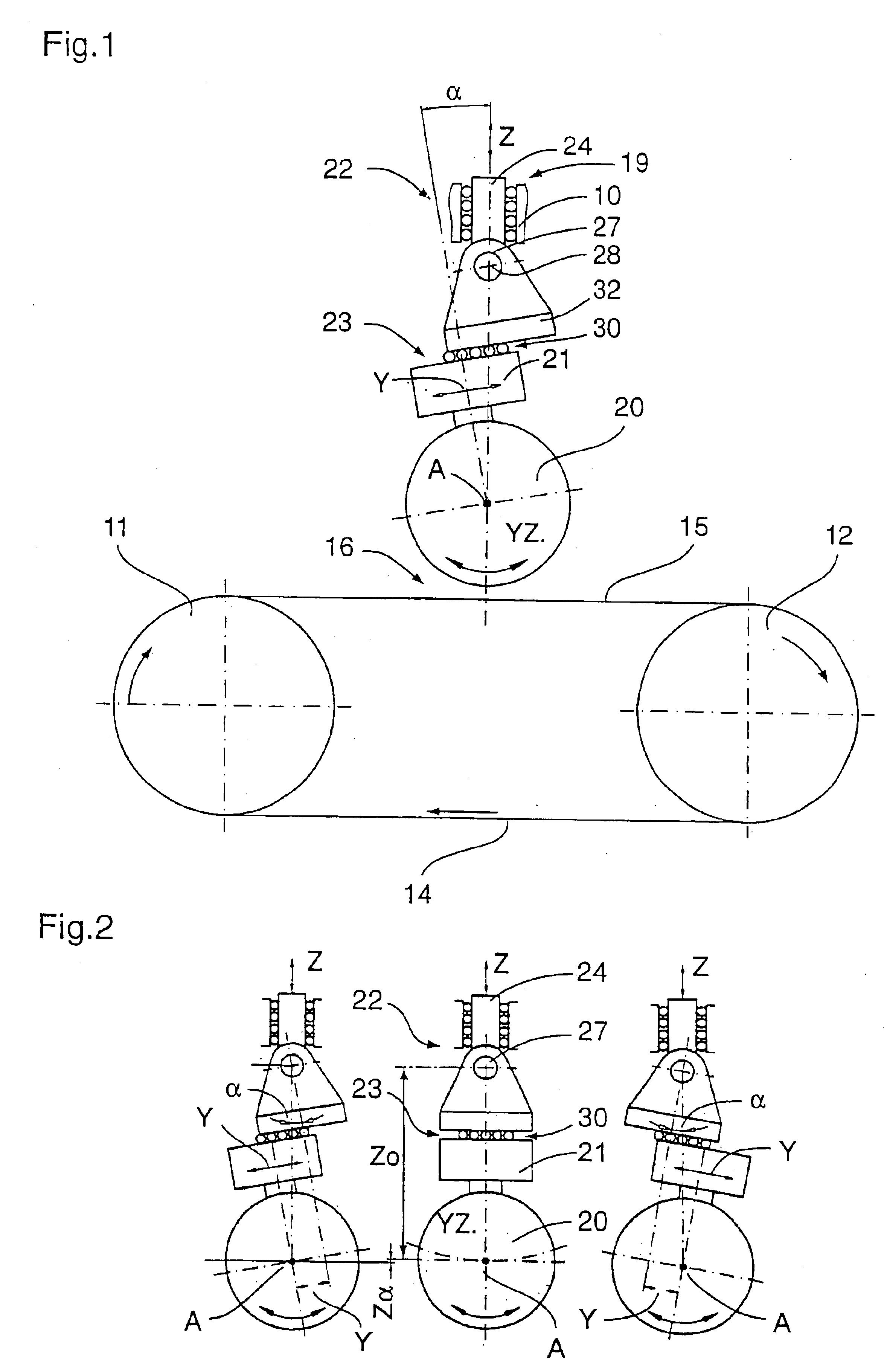

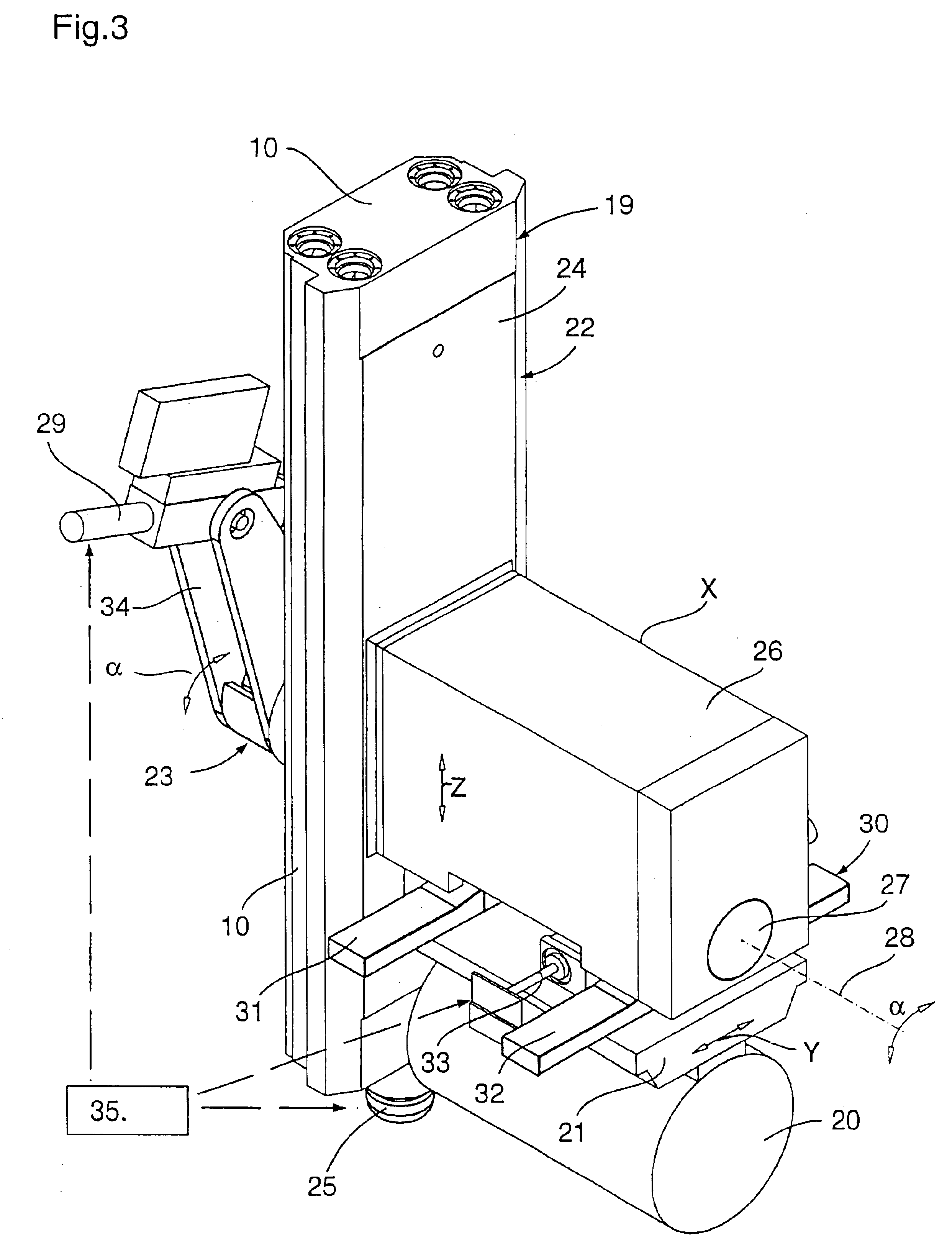

Wire saw with means for producing a relative reciprocating motion between the workpiece to be sawn and the wire

InactiveUS6886550B2High precisionAvoid roughnessMetal sawing devicesWorking accessoriesRotational axisWire rod

A sawing device includes a wire assembly (15) supported on wire-guiding rolls (11, 12) and pressed against a workpiece to be sawn (20) fixed on a support table (21). An oscillating device (23) produces a relative reciprocating movement between the workpiece and the wire assembly (15) around an oscillation axis (A) whereof the spatial position can be adjusted and programmed so that the oscillation axis (A) is at a programmable and adjustable distance from an effective axis of rotation (28) of the oscillating device (23).

Owner:APPLIED MATERIALS SWITZERLAND

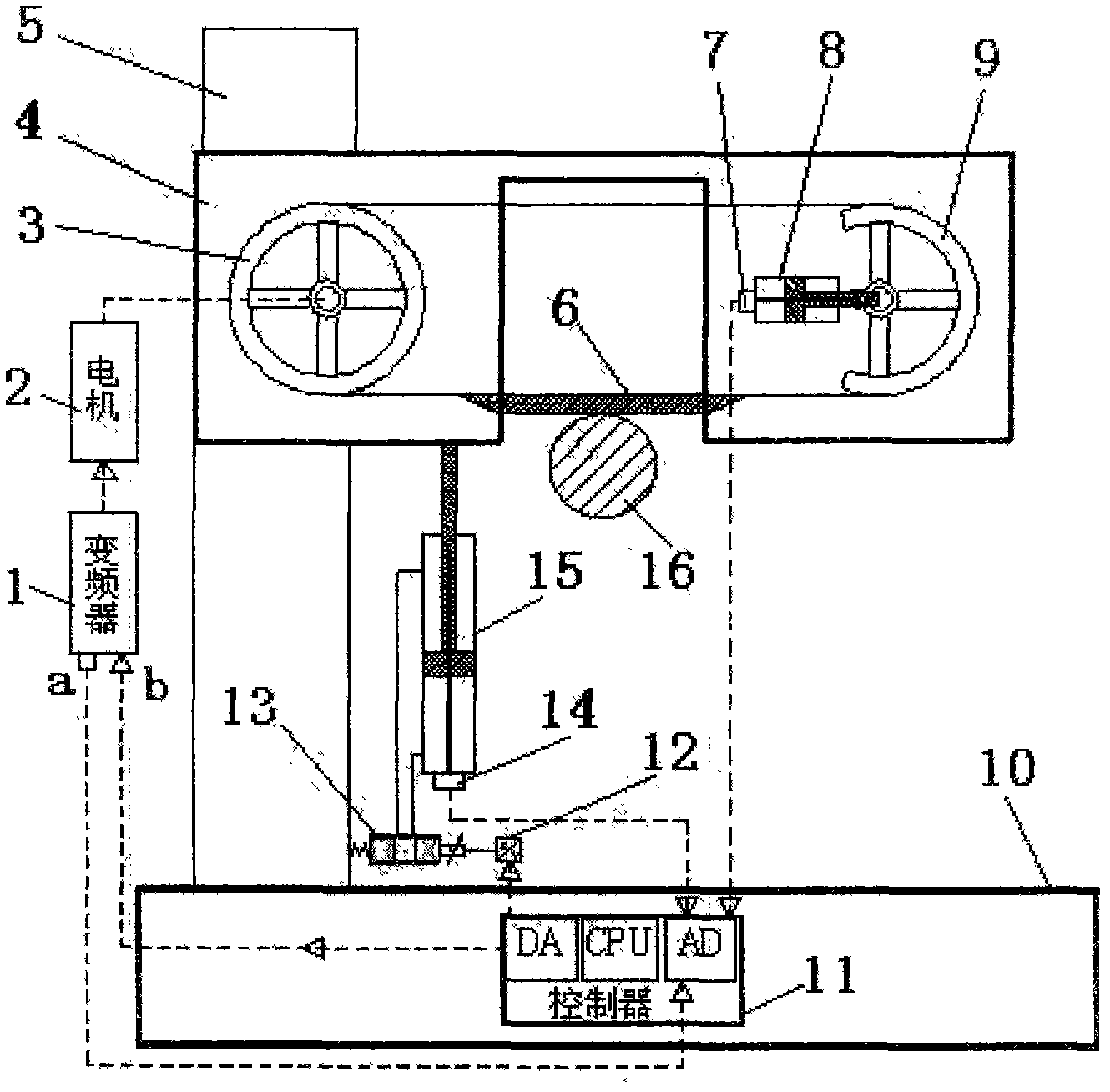

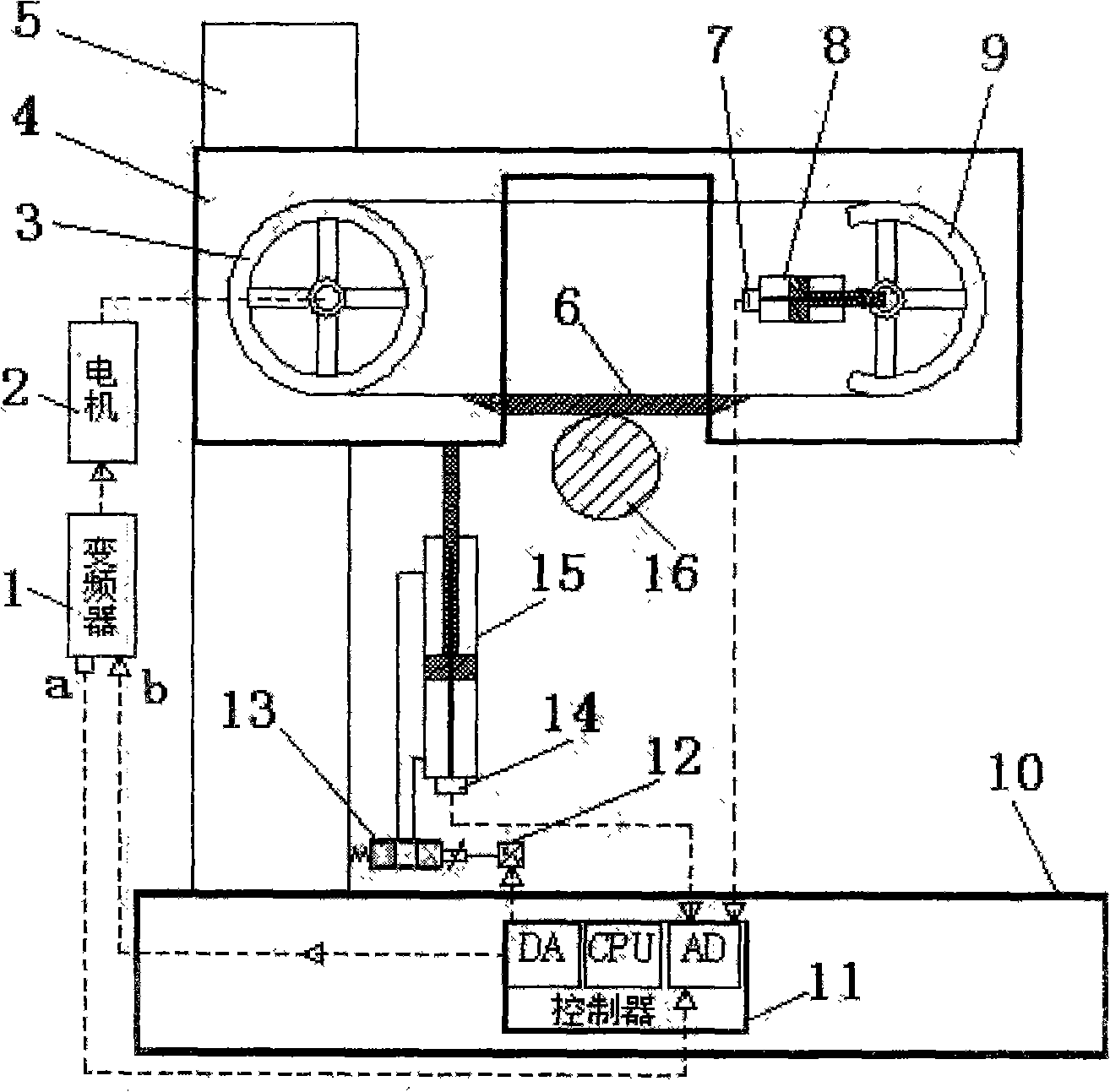

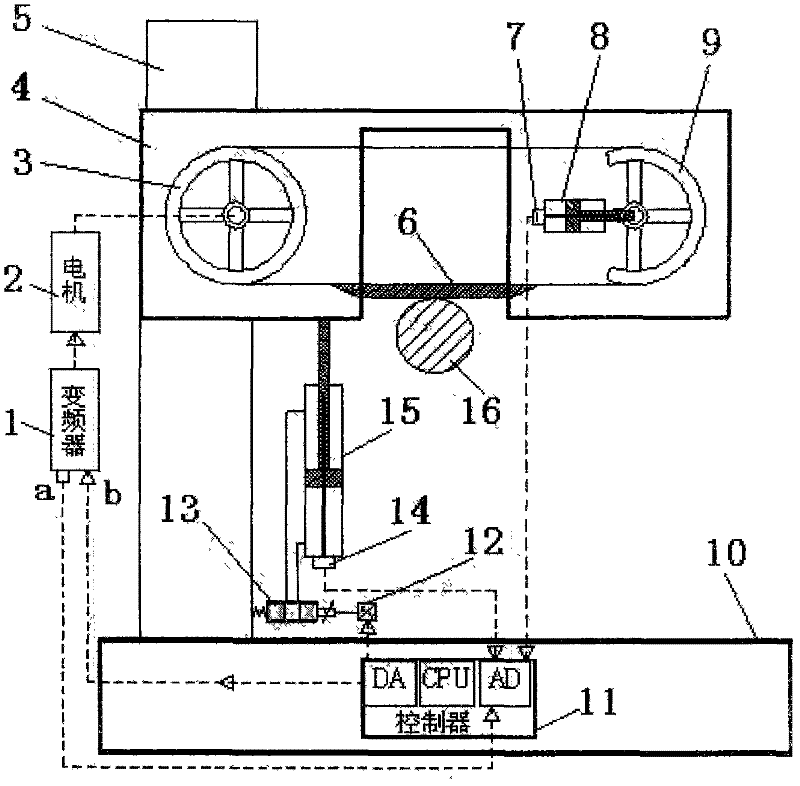

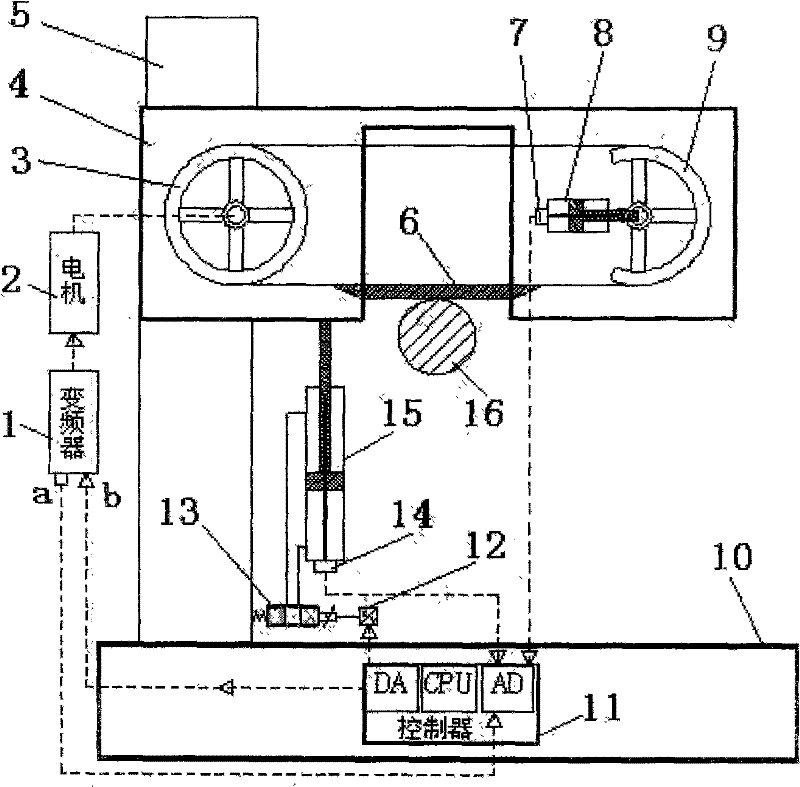

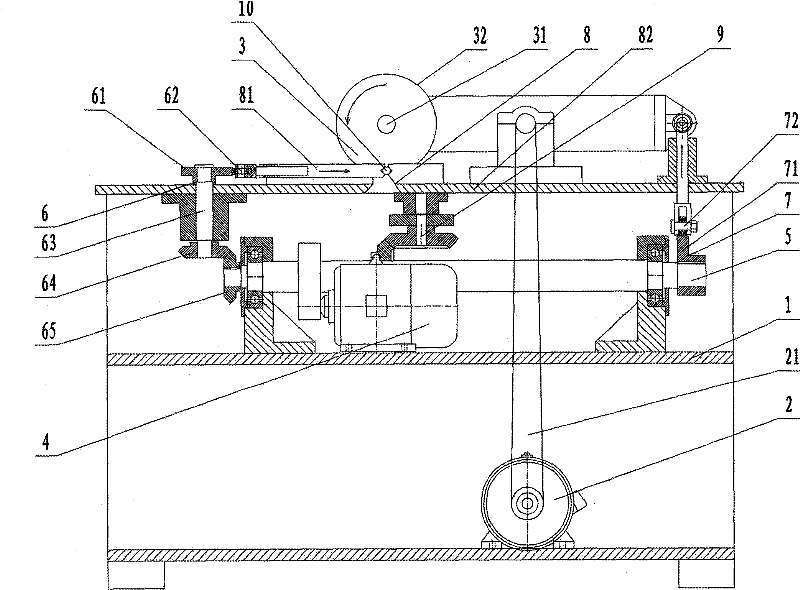

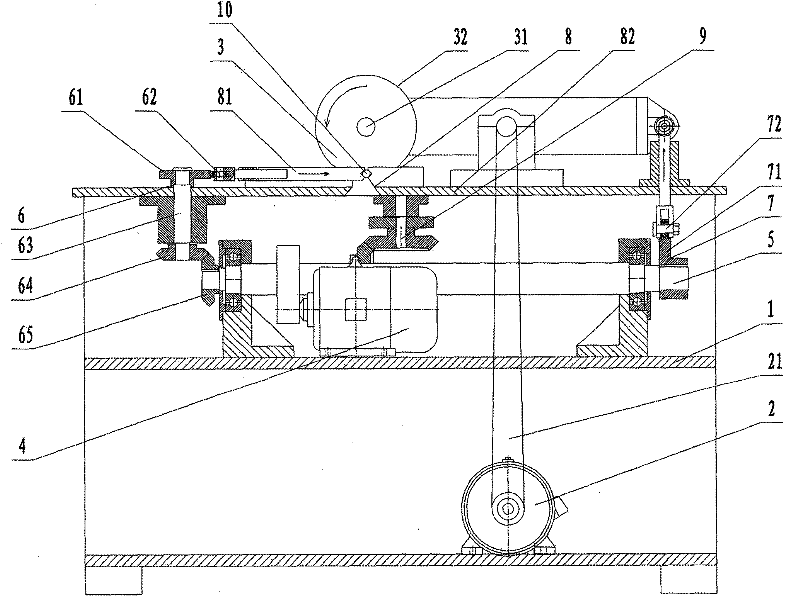

Intelligent sawing band sawing machine

ActiveCN102151899AExtended service lifeImprove sawing efficiencyMetal sawing devicesMeasurement/indication equipmentsNumerical controlHydraulic cylinder

The invention relates to an intelligent sawing band sawing machine. On the basis of the variable-frequency driver of a saw disc, a driving torque detecting device, a saw blade tension detecting device and an electro-hydraulic servo feeding device are added to a common numerical control band sawing machine, wherein the driving torque detecting device consists of an output current interface of the variable-frequency driver of the saw disc and an AD (analog-digital) conversion unit; the saw blade tension detecting device consists of a pressure sensor of a saw blade tension hydraulic cylinder and an AD conversion unit; and the electro-hydraulic servo feeding device consists of a displacement sensor of the saw frame feeding hydraulic cylinder, a whole machine controller, a three-position four-way electro-hydraulic proportional valve and a driving amplification circuit board. Therefore, the sawing power born by a band saw blade in the whole sawing process is constant, and the sawing efficiency of the sewing machine and the service life of the band saw blade are improved.

Owner:ZHEJIANG WEIYE SAWING MACHINE

Square tube multi-angle saw cutting machine

ActiveCN106862652AEasy to adjust the angleImprove sawing efficiencyMetal sawing devicesEngineeringMechanical engineering

The invention discloses a square tube multi-angle saw cutting machine. The square tube multi-angle saw cutting machine comprises a rotary saw cutting machine head, a feeding conveyance device and a discharging device. The rotary saw cutting machine head comprises a machine box. A saw cutting platform is arranged at the upper end of the machine box. A rotating box body driven by a rotating servo motor is installed inside the machine box in a rotating mode. A lifting pedestal driven by a lifting power device is installed inside the rotating box body. A saw blade is installed on the lifting pedestal in a rotating mode. A through hole is formed in the rotating box body. The saw cutting platform is provided with an upstream positioning clamp and a downstream positioning clamp. The upstream positioning clamp and the downstream positioning clamp transversely clamp a square tube and position the same side face of the square tube. The saw cutting platform is vertically provided with an upper pressing plate used for tightly pressing the square tube from the upper side in a sliding mode, the upper pressing plate is driven by an upper pressing power device, and the bottom of the upper pressing plate is detachably provided with an upper cushion block. The square tube multi-angle saw cutting machine is reasonable in structure, the saw cutting angle can be adjusted by rotating the angle of the saw blade, and thus the square tube can be sawed from different angles.

Owner:苏州斯马拓智能化装备有限公司

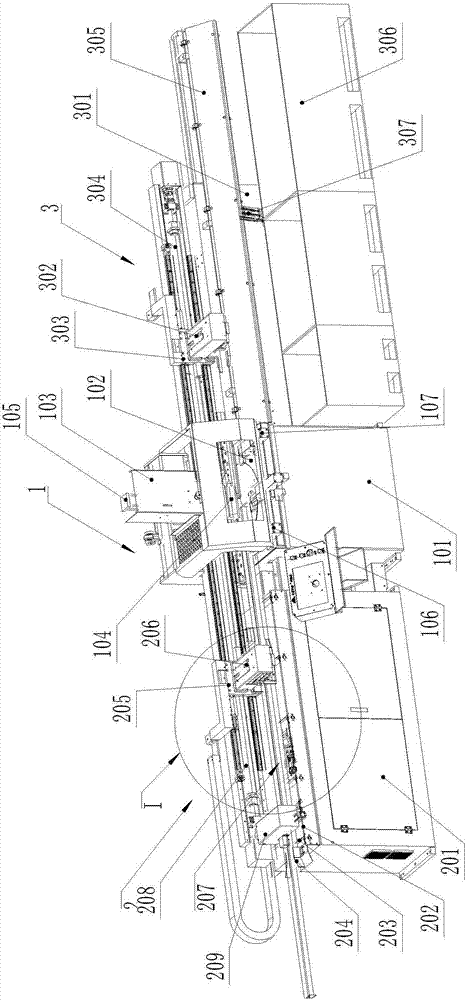

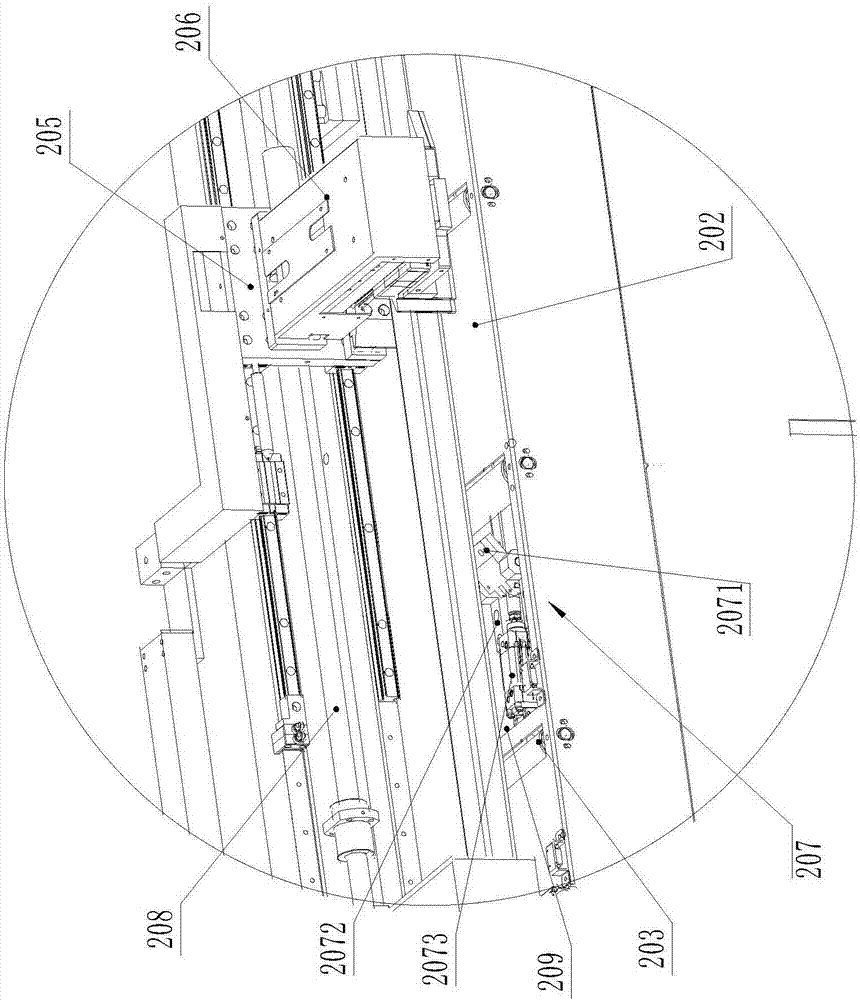

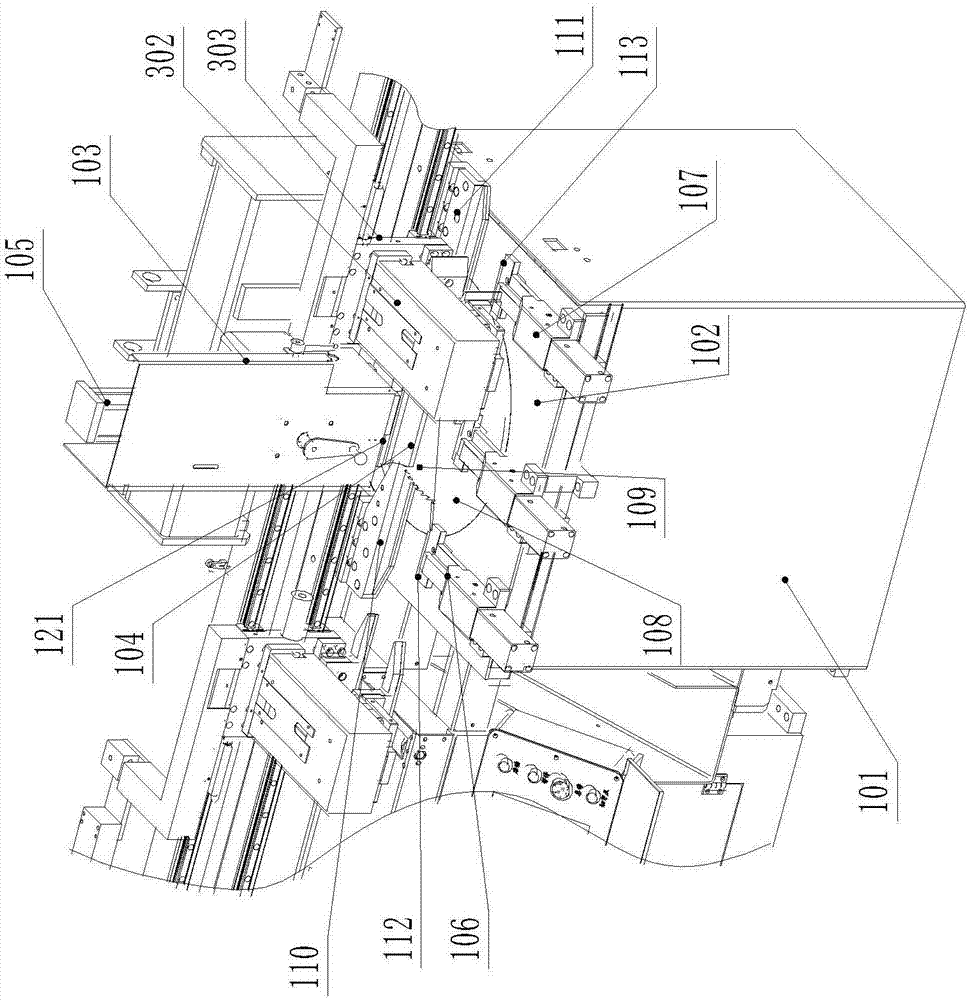

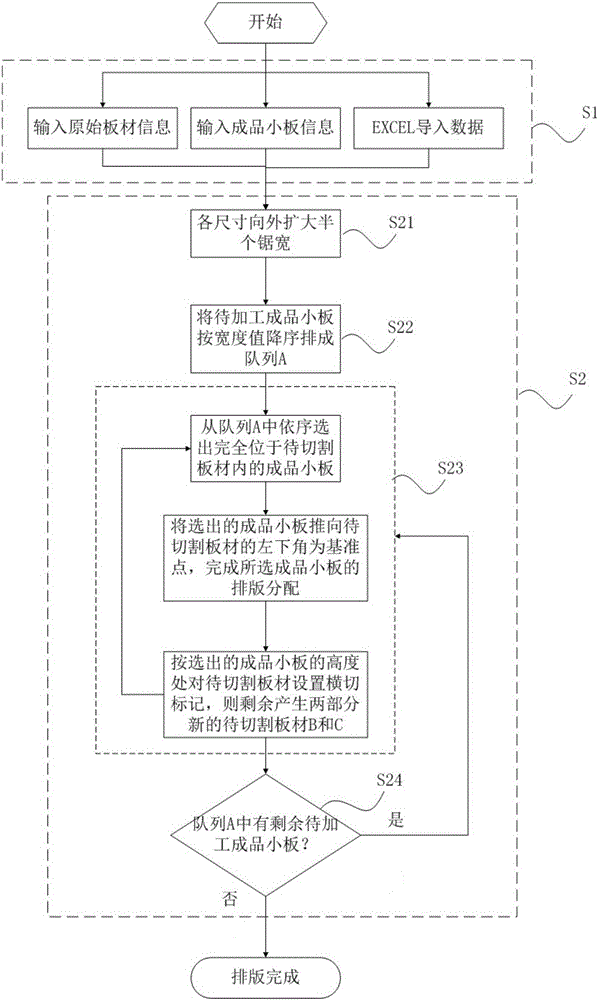

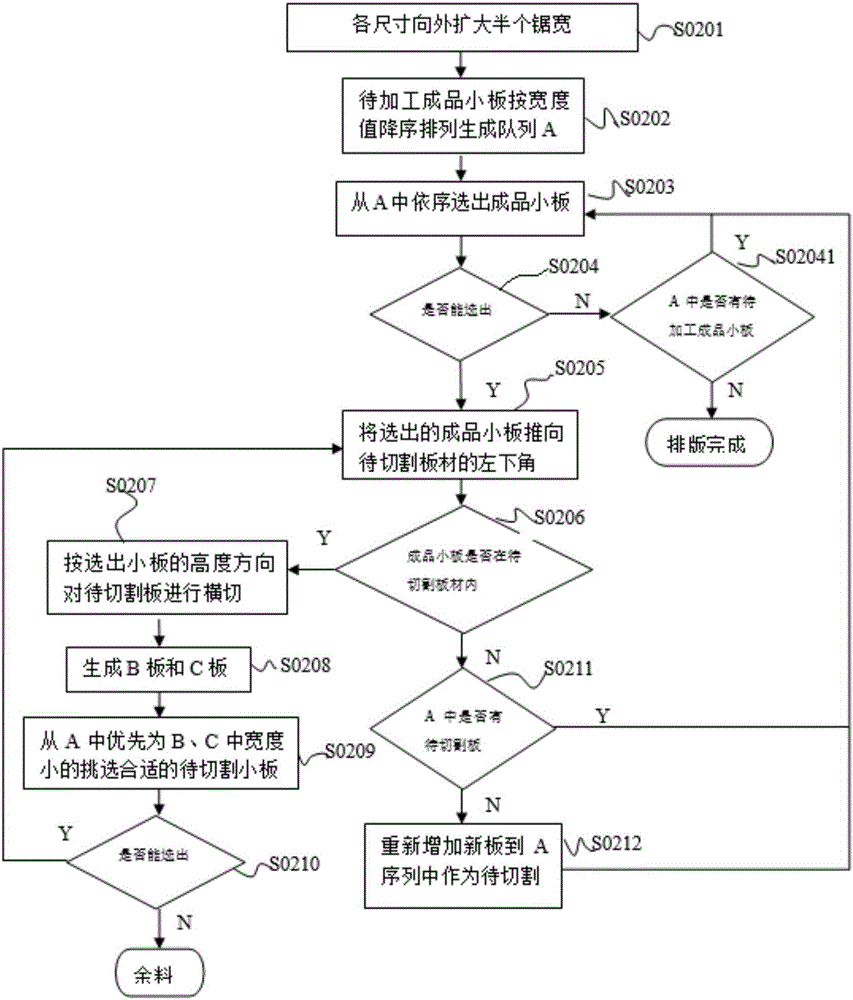

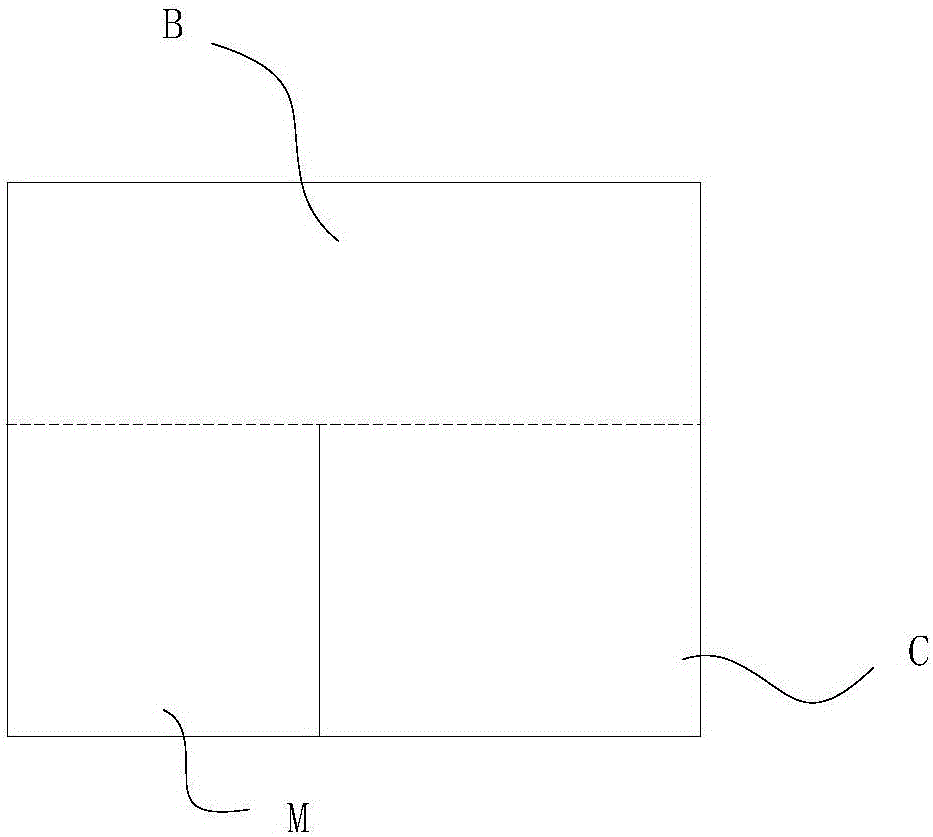

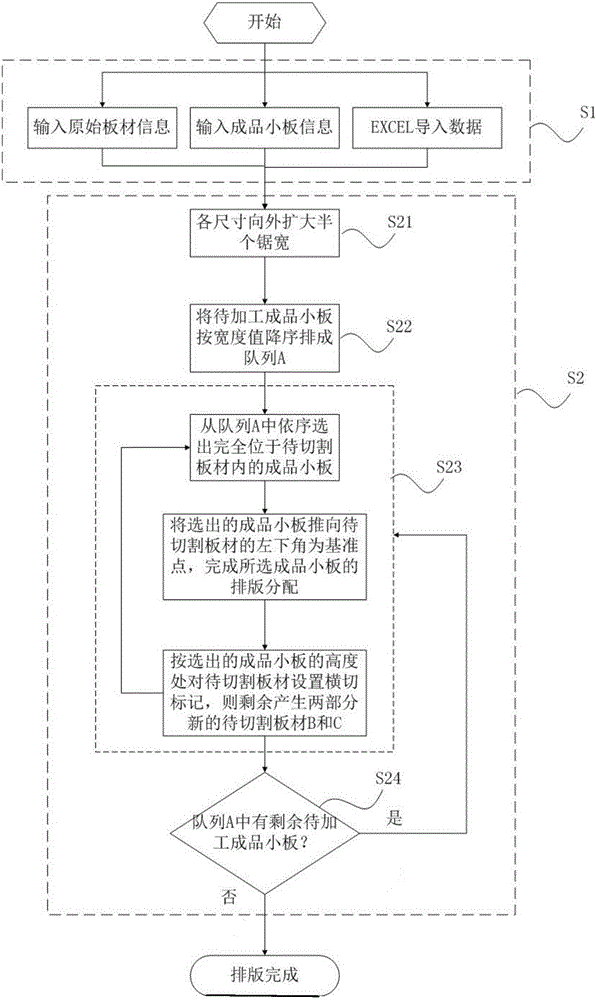

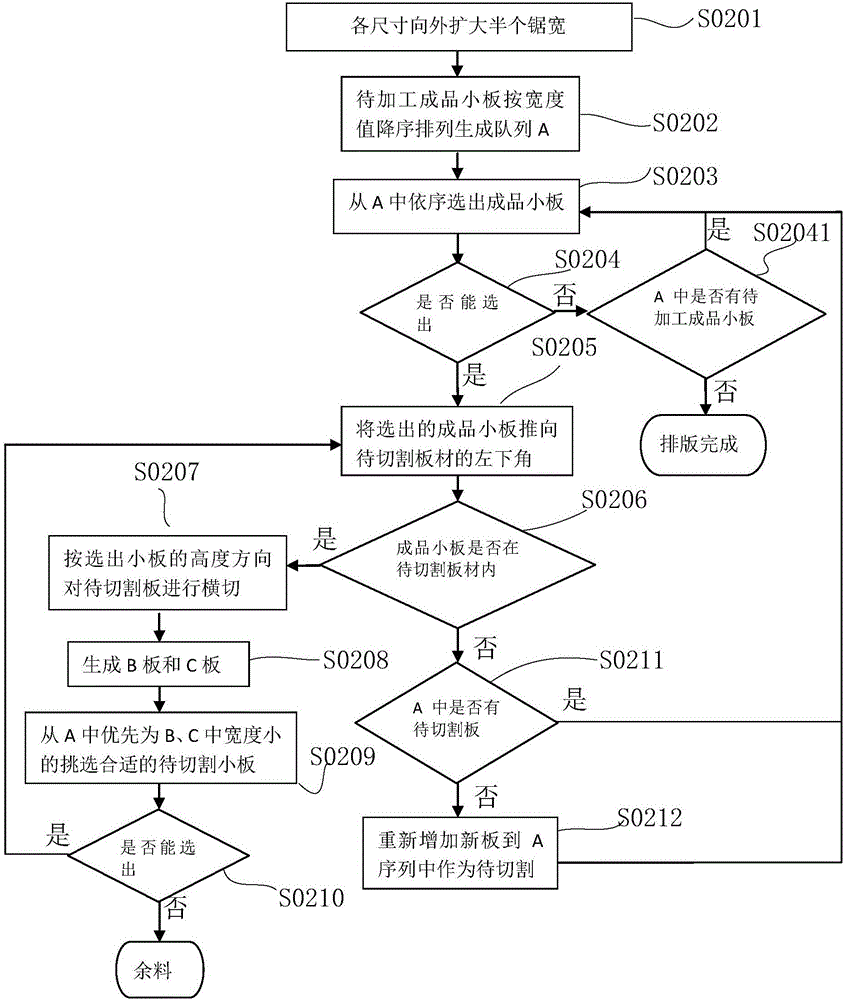

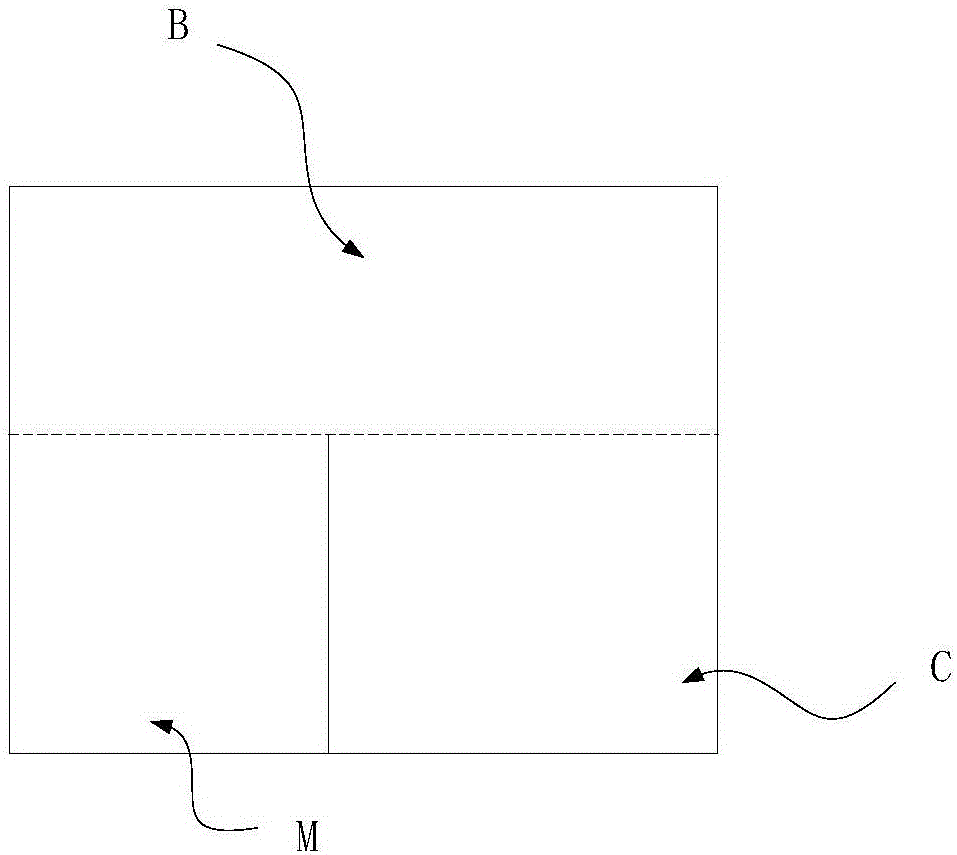

Control method and control system for numerically-controlled sliding table saw

InactiveCN105856332AImprove sawing efficiencySave human effortCircular sawsNumerical controlControl systemHuman power

The present invention proposes a control method and control system for a numerically controlled sliding table saw, comprising the following steps: A. Obtain parameter information of plates to be cut and each finished small plate; B. Obtain typesetting scheme; C. Automatically drive the ruler to be cut according to the typesetting scheme Plate cutting operation. The present invention realizes the precise positioning of the right side ruler automatically through typesetting, improves the sawing efficiency of the numerical control sliding table saw, greatly saves manpower and reduces the cost.

Owner:青岛金岭电器有限公司

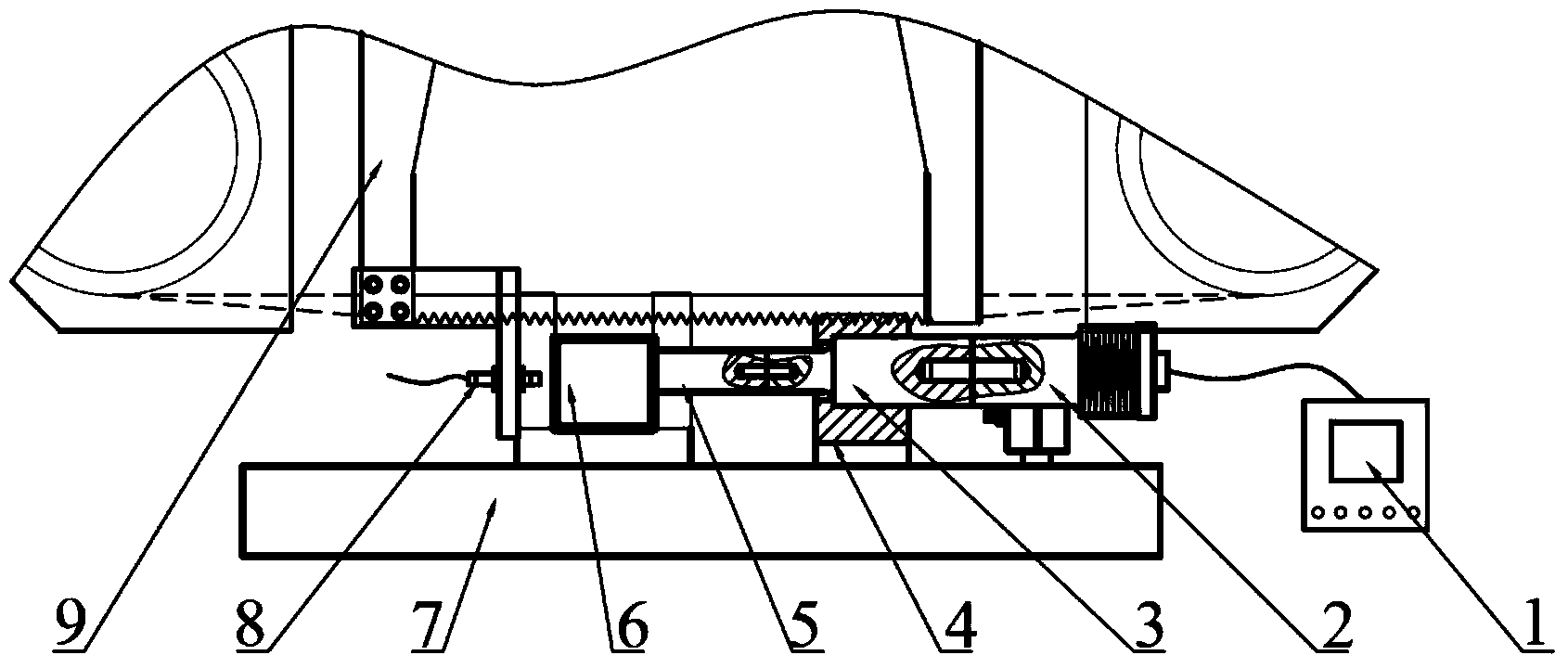

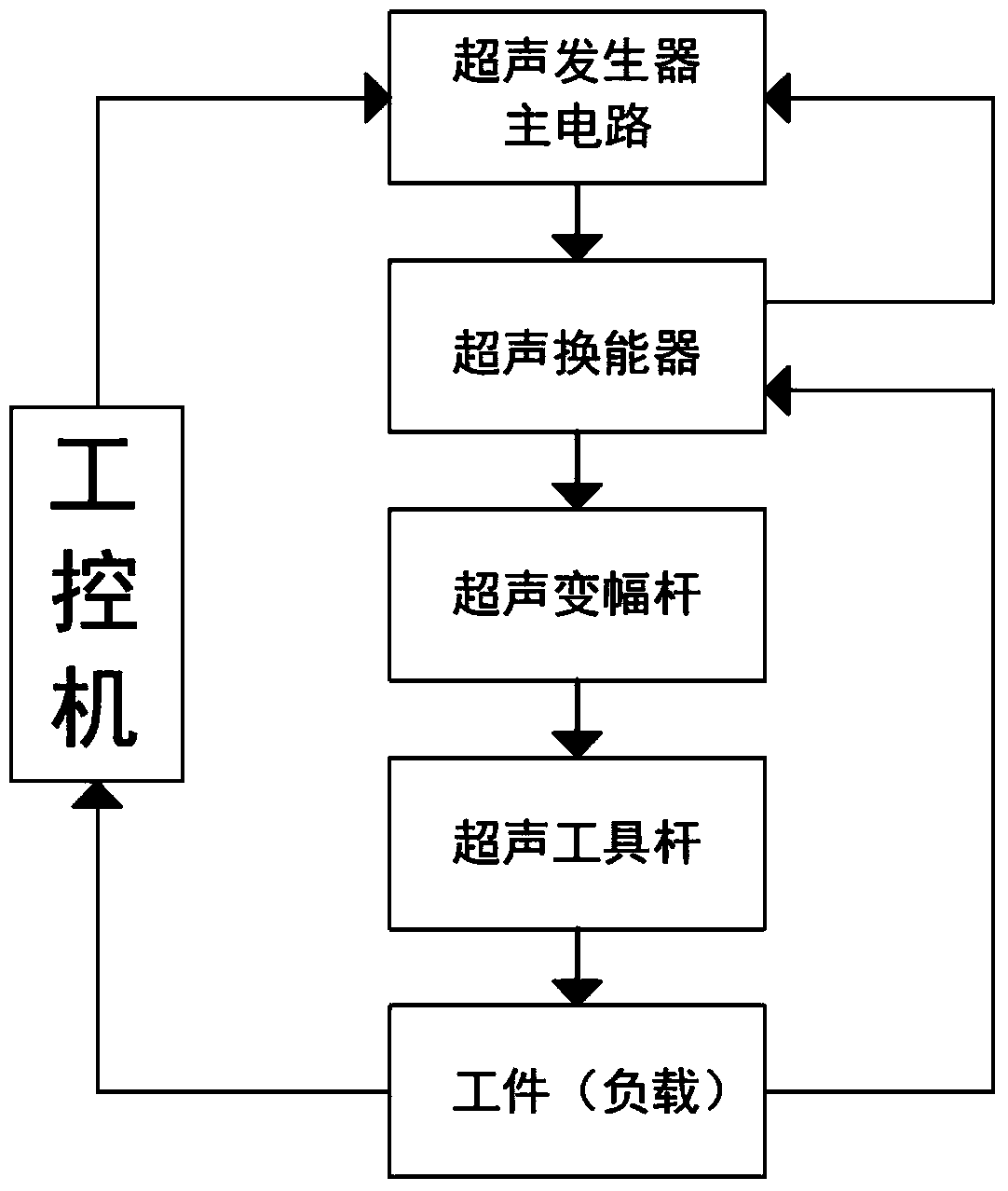

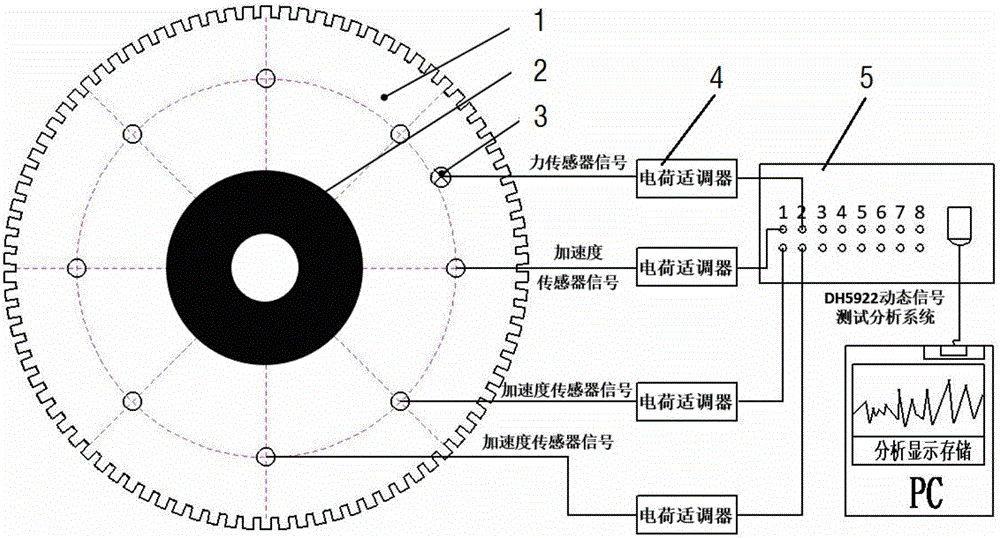

Metal band saw ultrasound saw cutting machining method and device

InactiveCN103962642AExtended service lifeLighten the sawing loadMetal sawing devicesMetal sawing accessoriesTransformerUltrasonic vibration

The invention discloses a metal band saw ultrasound saw cutting machining method and device. In current metal band saw machining, the shortcomings that the saw cutting range is narrow, efficiency is low, and filings can adhere to saw teeth easily exist. The device comprises an ultrasonic generator, an ultrasonic transducer, an ultrasonic amplitude transformer, an ultrasonic mechanism support, an ultrasonic tool rod, a workpiece, a sawing machine base, an electric vortex sensor and a sawing machine body. The compatibility with a sawing machine is good, the method and device can be adaptive to workpieces with various specifications, cost is low, and effect is obvious. The output frequency of the generator can carry out tracking changing along with load changing, and the fact that amplitude is largest all the time is guaranteed. Ultrasonic vibration is added, so that the workpiece generates vibration parallel to the saw cutting direction, the saw cutting length of the saw teeth is enlarged, and saw cutting efficiency and the surface quality of the saw cutting workpiece are greatly improved.

Owner:HANGZHOU DIANZI UNIV

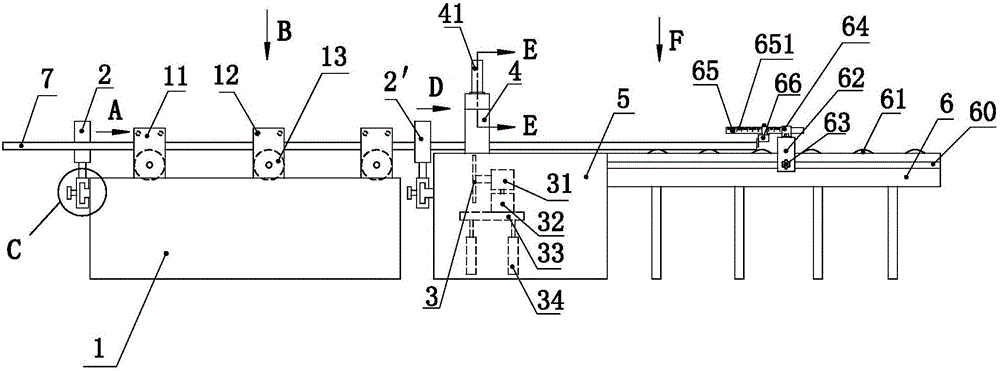

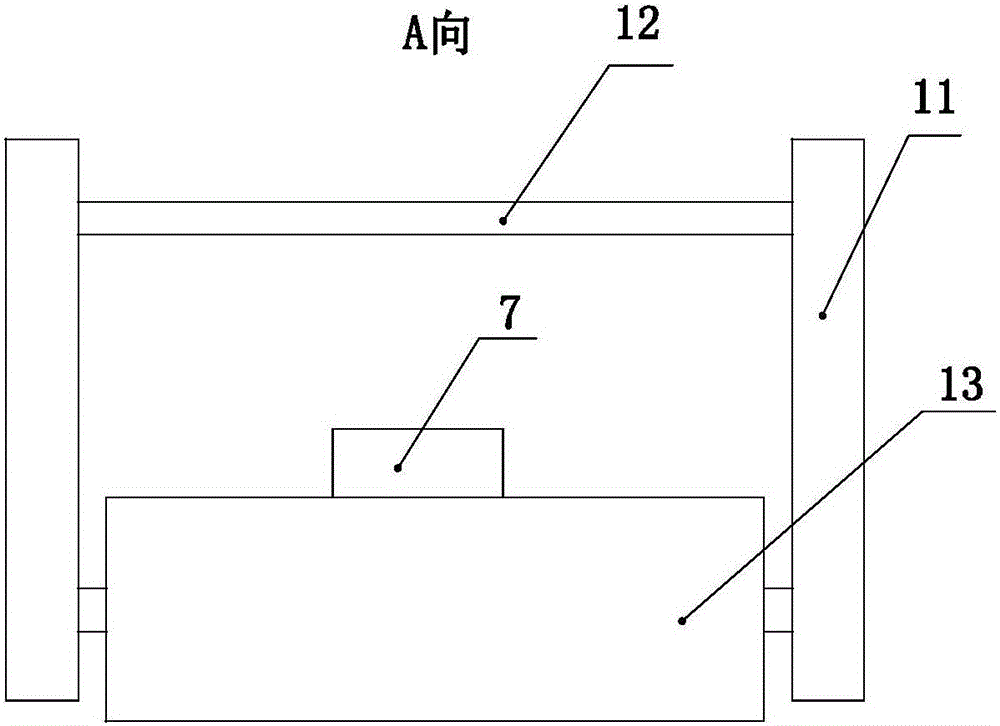

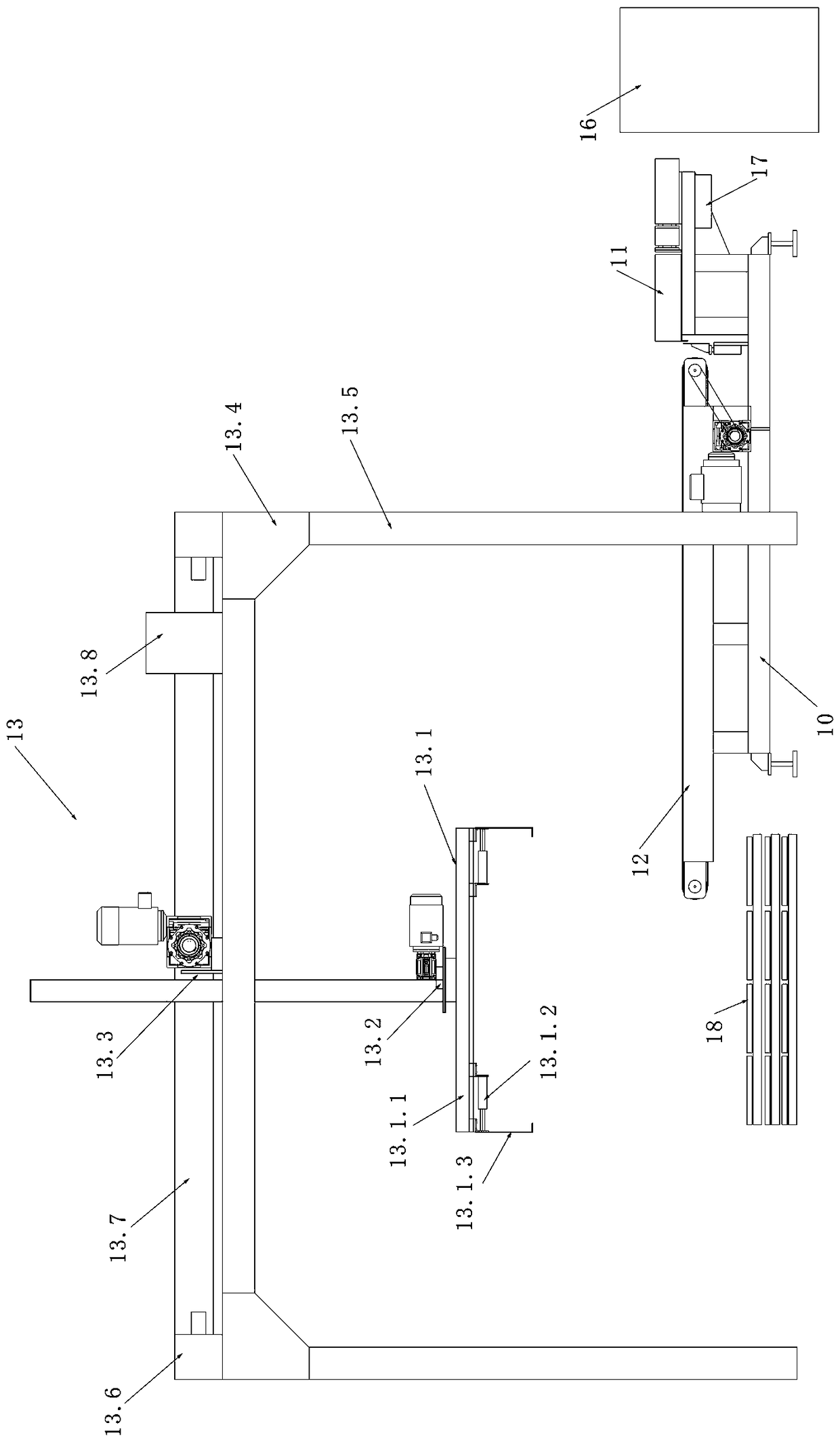

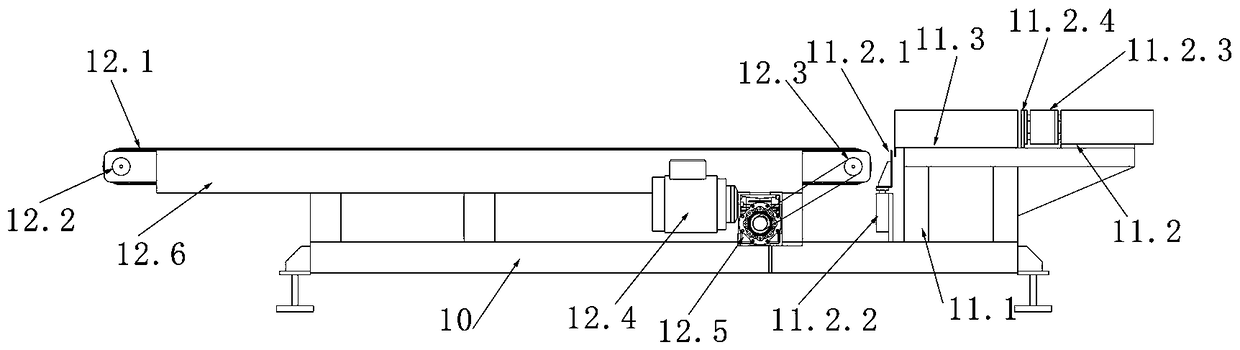

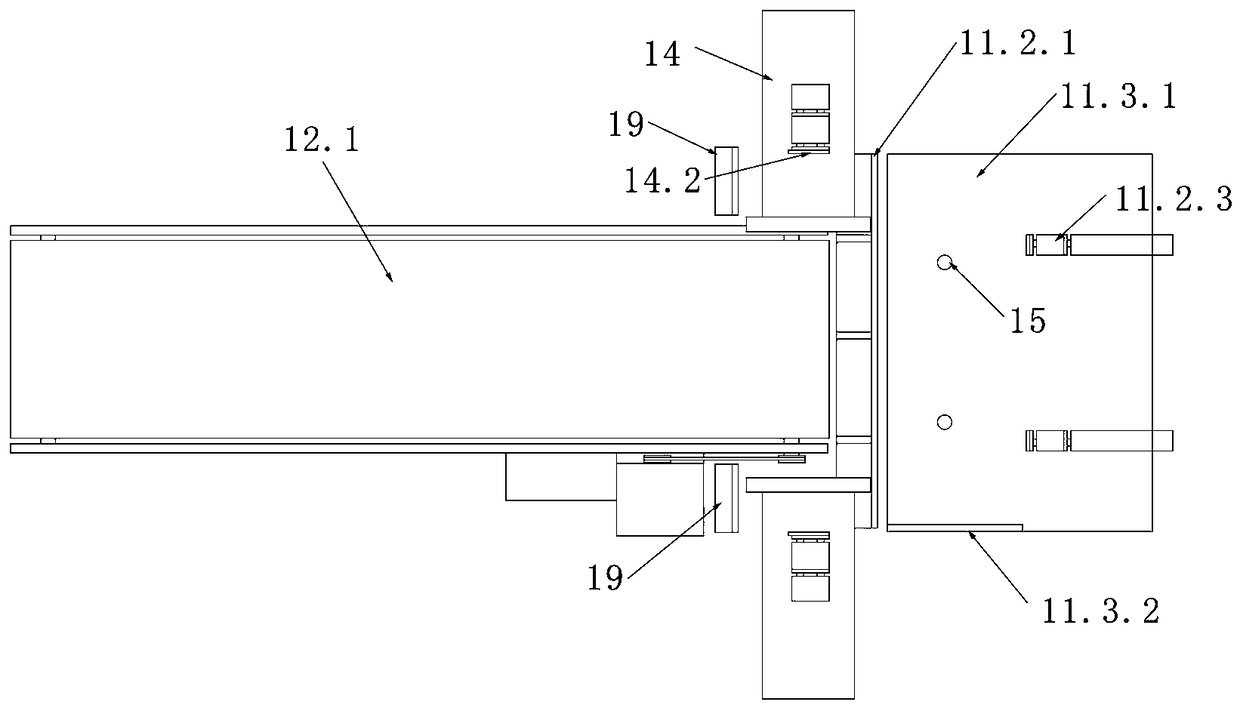

Wood floor stacking machine and floor cutting production line

ActiveCN108582266AIncrease heightEasy to useFeeding devicesPile receiversProduction lineStack machine

The invention relates to a wood floor stacking machine. The front end of a floor conveying mechanism serves as a conveying end, and the rear end of the floor conveying mechanism serves as an output end. A floor bearing mechanism is located on the front side of the output end of the floor conveying mechanism, and a stacking mechanism is located above the output end of the floor conveying mechanism.The floor bearing mechanism comprises a bearing platform frame, a first alignment device and a front bearing platform. The first alignment device and the front bearing platform are installed on the bearing platform frame, and the front bearing platform and an alignment push plate A push device are installed on the upper surface of the bearing platform frame. A first alignment baffle lifting device which is vertically arranged is installed on one side of the bearing platform frame, and a first alignment baffle is arranged on the first alignment baffle lifting device. An alignment push plate Ais arranged on the alignment push plate A push device. The invention further discloses a floor cutting production line. The wood floor stacking machine and the floor cutting production line have the following beneficial effects that the wood floor stacking machine is beneficial to increase the stacking speed and improve the stacking effect; and by the adoption of an upper-and-lower multifunctionaladjustable seamless saw, the saw cutting efficiency is improved, and the labor intensity of workers is reduced.

Owner:SHANDONG ZHONGXIN MACHINERY

Computer numerical control saw

InactiveCN106827070AImprove sawing efficiencyNo human interventionFeeding devicesCircular sawsNumerical controlElectric control

The invention relates to a computer numerical control saw which comprises a frame, a working table, an electric control cabinet, wherein the working table and the electric control cabinet are arranged on the frame. A saw blade driving system, a device capable of detecting the height of feeding materials and a device capable adjusting the height of a saw blade are arranged on the frame of the computer numerical control saw, the saw blade driving system can push the saw blade to move and comprises a saw blade driving motor, the saw blade driving motor is connected with a connecting rod, the connecting rod is hinged onto a motor mounting platform, a side push cylinder is connected in the middle of the connecting rod, a rack is arranged below the motor mounting platform, rollers are parallelly arranged on two sides of the motor mounting platform, the motor mounting platform is arranged on a motor mounting beam, and sliding rails corresponding to the rollers are arranged on the motor mounting beam. The system can drive the saw blade to linearly move in a reciprocating manner, rise and fall, so that saw cutting actions are finished, and the height of the saw blade is adjusted.

Owner:SICHUAN HENGXIN YOUBANG FURNITURE CO LTD

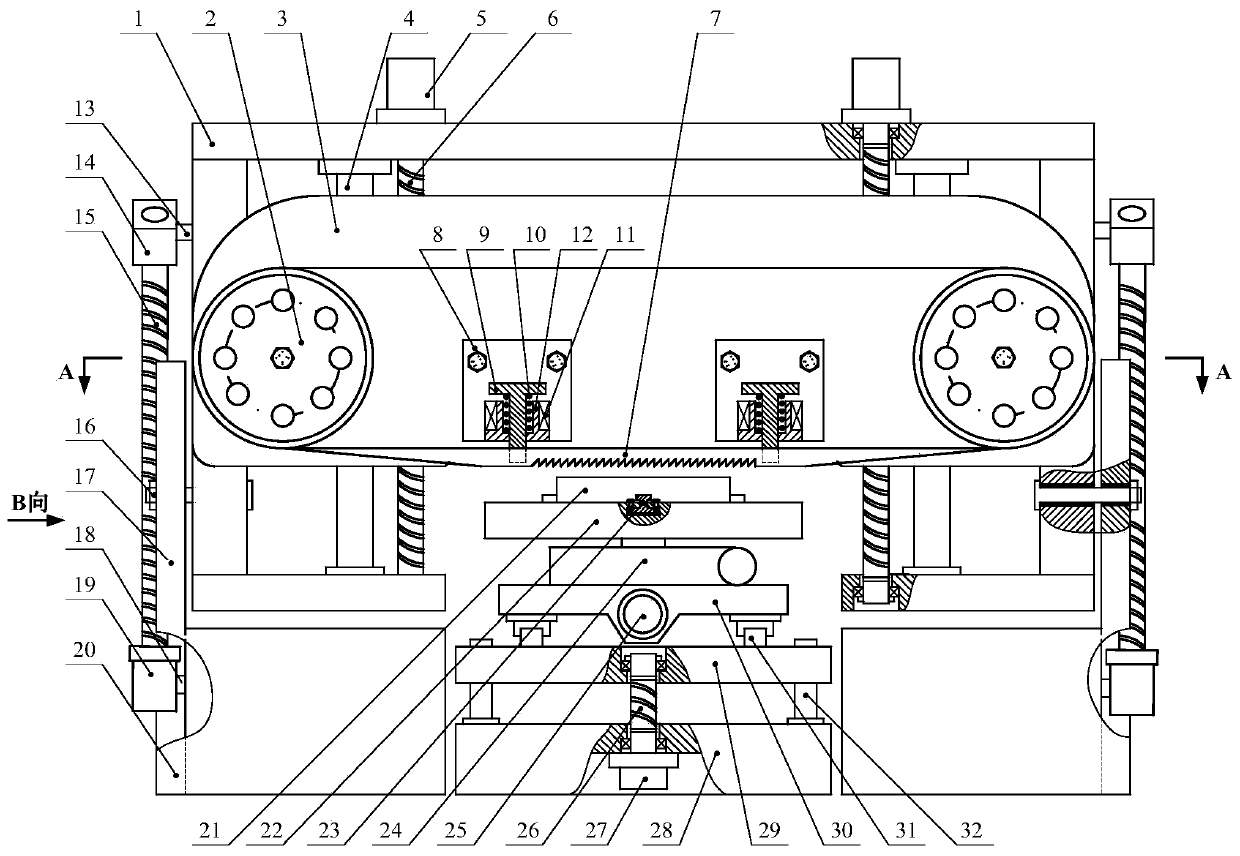

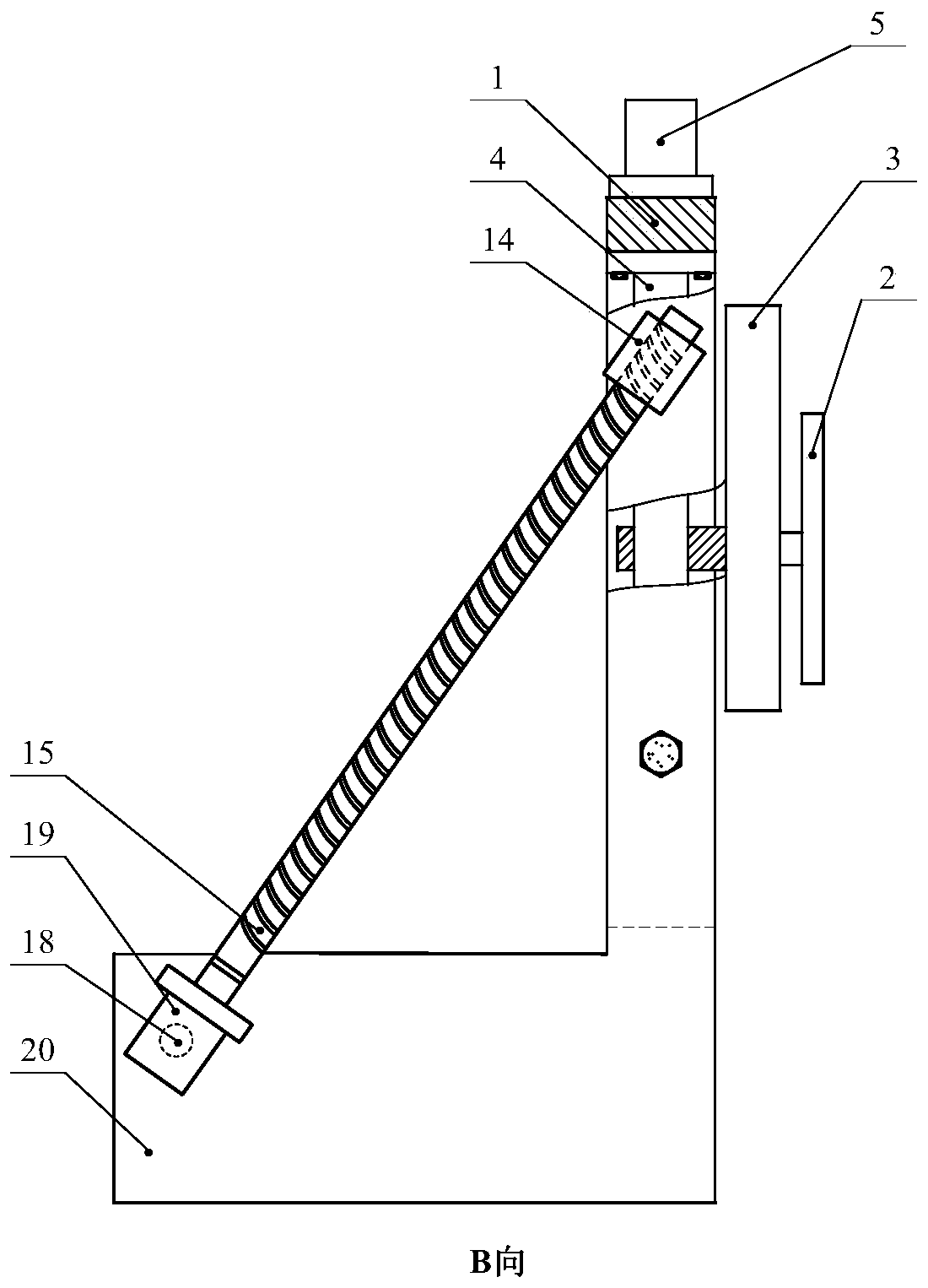

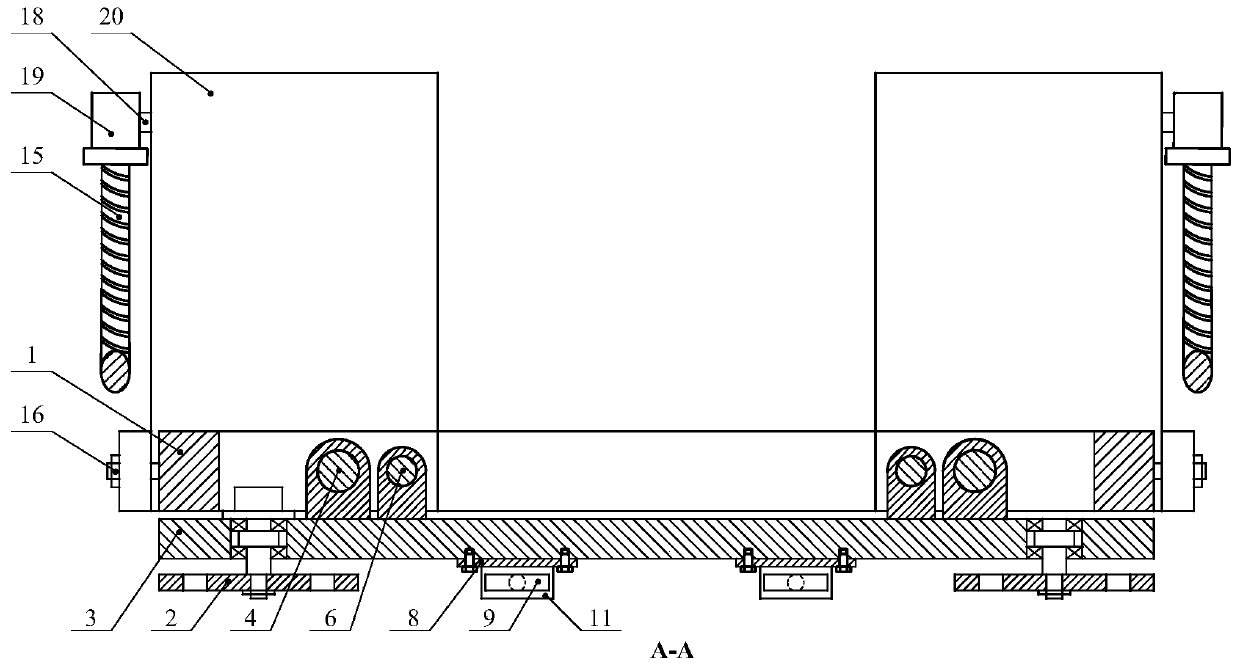

Intelligent sawing band sawing machine

ActiveCN102151899BExtended service lifeImprove sawing efficiencyMetal sawing devicesMeasurement/indication equipmentsNumerical controlHydraulic cylinder

The invention relates to an intelligent sawing band sawing machine. On the basis of the variable-frequency driver of a saw disc, a driving torque detecting device, a saw blade tension detecting device and an electro-hydraulic servo feeding device are added to a common numerical control band sawing machine, wherein the driving torque detecting device consists of an output current interface of the variable-frequency driver of the saw disc and an AD (analog-digital) conversion unit; the saw blade tension detecting device consists of a pressure sensor of a saw blade tension hydraulic cylinder andan AD conversion unit; and the electro-hydraulic servo feeding device consists of a displacement sensor of the saw frame feeding hydraulic cylinder, a whole machine controller, a three-position four-way electro-hydraulic proportional valve and a driving amplification circuit board. Therefore, the sawing power born by a band saw blade in the whole sawing process is constant, and the sawing efficiency of the sewing machine and the service life of the band saw blade are improved.

Owner:ZHEJIANG WEIYE SAWING MACHINE

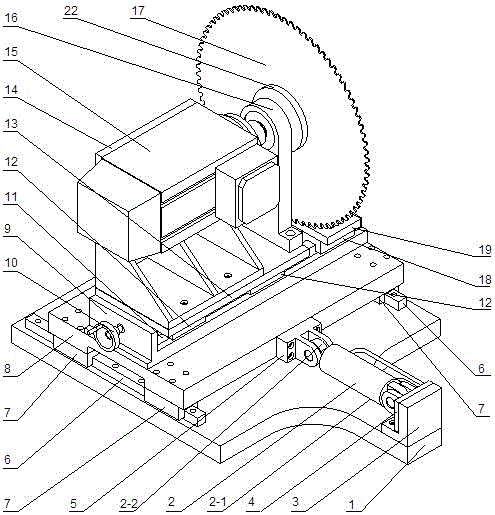

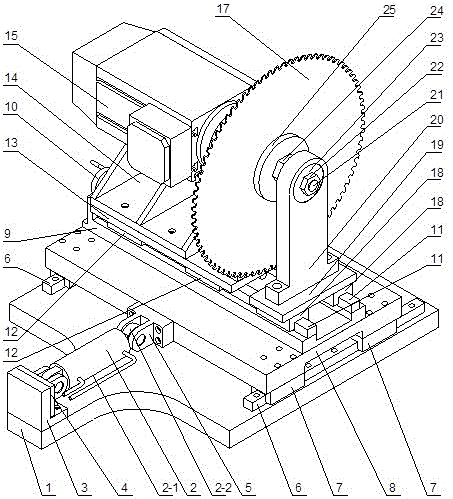

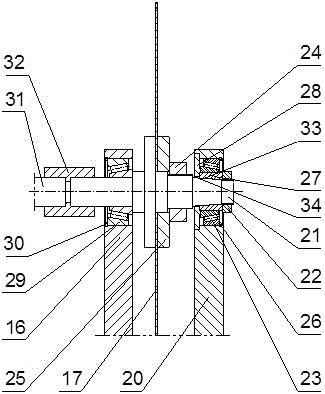

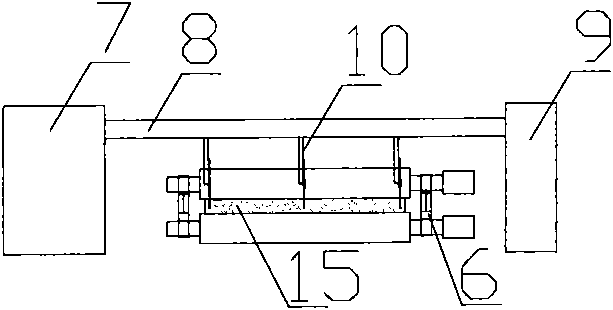

Efficient sawing component

ActiveCN105750635AImprove support stiffnessEasy to adjustMetal sawing devicesHydraulic cylinderCoupling

The invention relates to an efficient sawing component.The efficient sawing component comprises a base, a hydraulic cylinder, a supporting frame, a rear support, a front support, a Y-direction guide rail bar, a Y-direction guide rail sliding block, a Y-direction sliding table, a support base, a lead screw component, an X-direction guide rail bar, an X-direction guide rail sliding block, an X-direction sliding table, a motor support, a sawing motor, a left supporting frame, a saw web, a guide rail sliding block, an auxiliary sliding table, a right supporting frame, a center spindle, a round nut, a right tapered roller bearing, a nut, a pressing piece, a right check ring for hole, a sleeve, an end cover, a left tapered roller bearing, a left check ring for hole and a coupler.The efficient sawing component is characterized in that the Y-direction sliding table is driven by the hydraulic cylinder to move back and forth in the Y-direction, the X-direction sliding table moves leftwards and rightwards in the X direction under the driving of the lead screw component, the auxiliary sliding table can move leftwards and rightwards in the X direction, the central spindle is connected with an output shaft of the sawing motor through the coupler, and the saw web rotates under the driving of the central spindle.According to the efficient sawing component, the support stiffness of the saw web is improved greatly, so that sawing feeding rate is increased, and then sawing efficiency is improved.

Owner:SHANDONG UNIV OF TECH

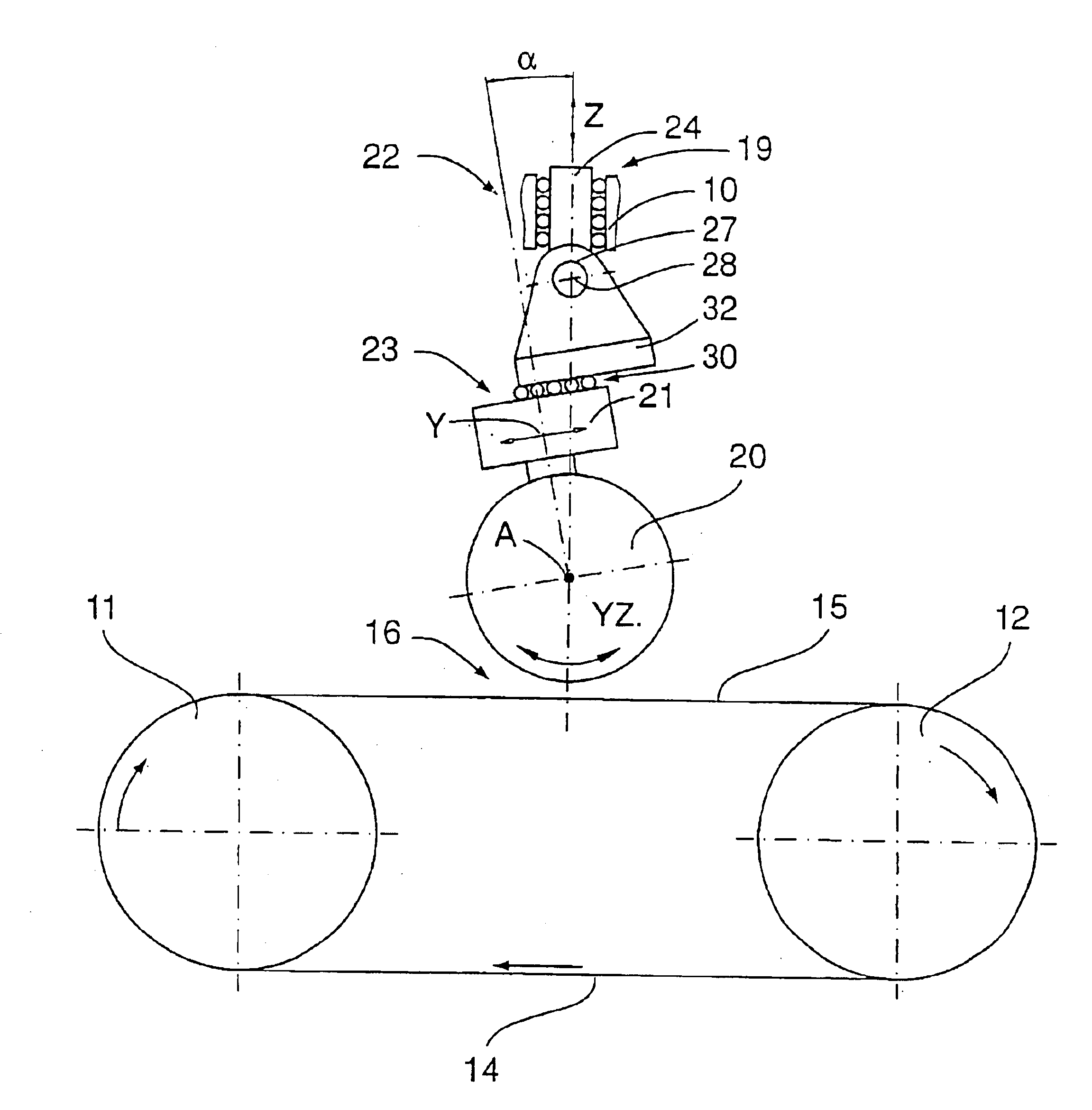

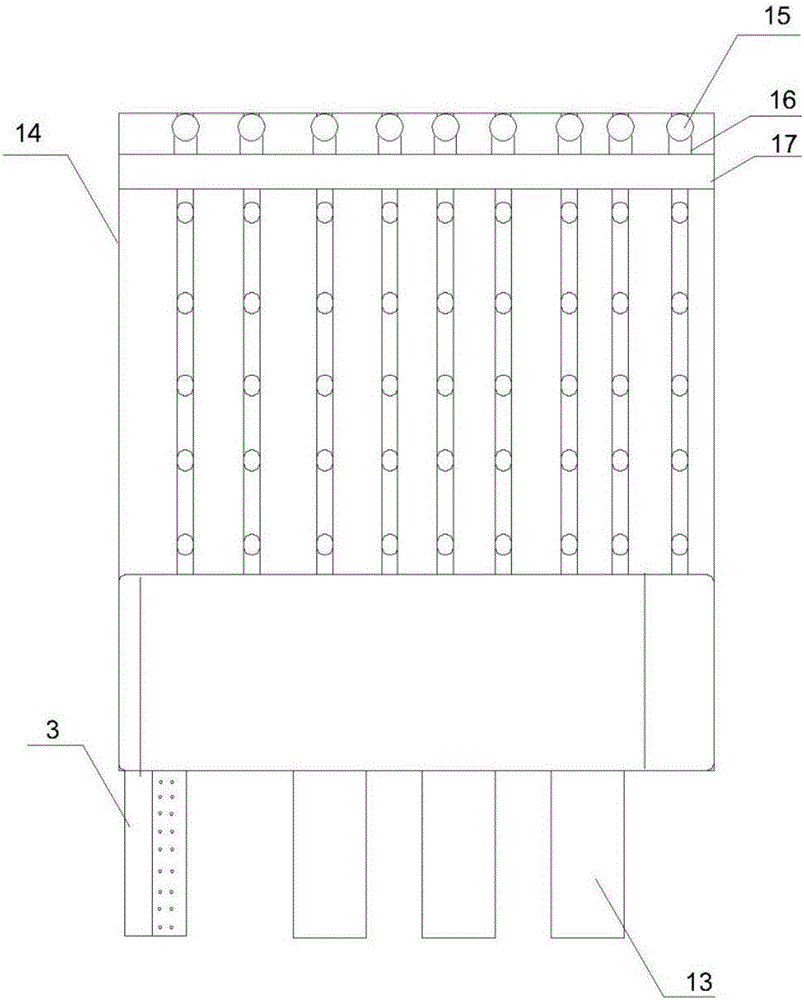

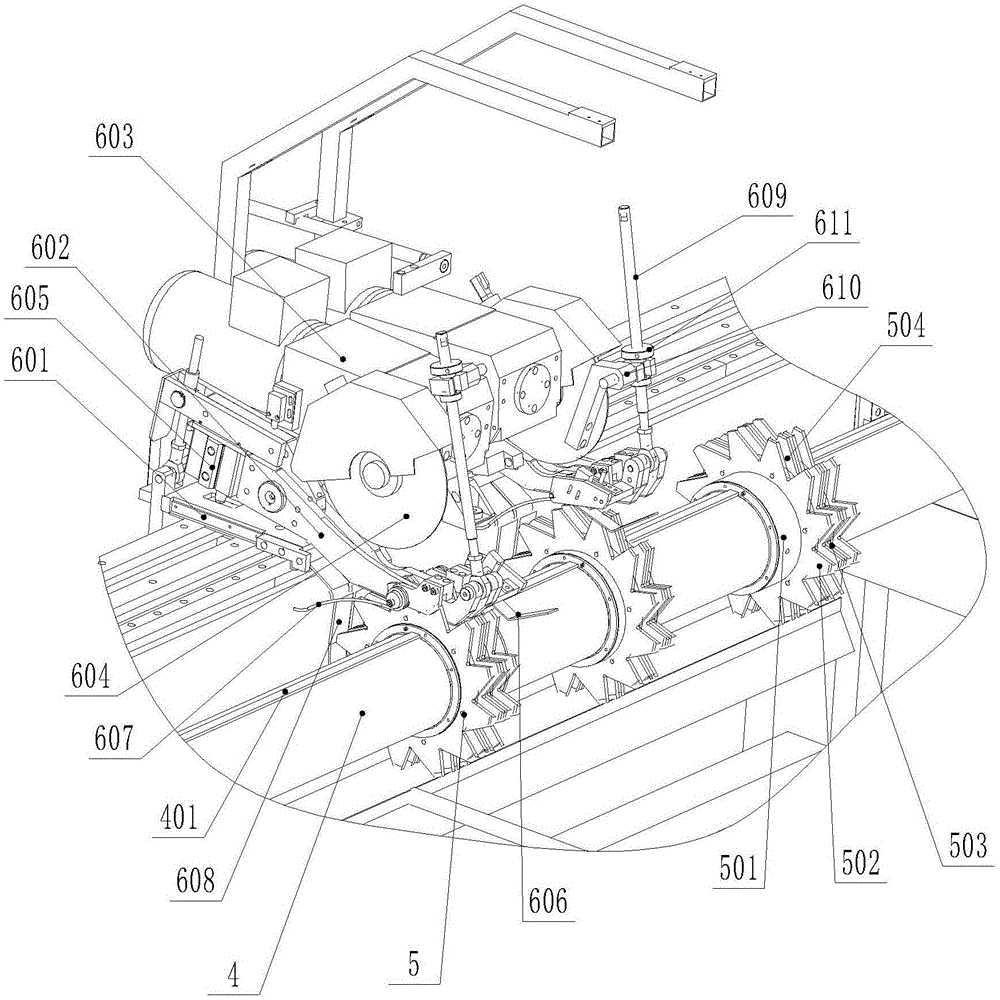

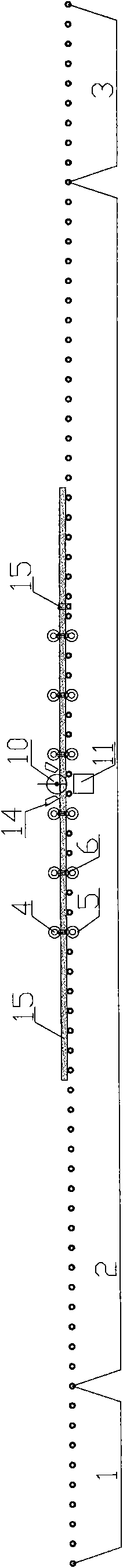

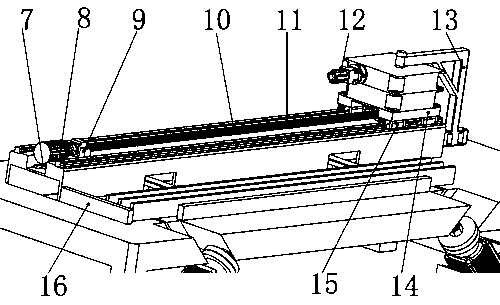

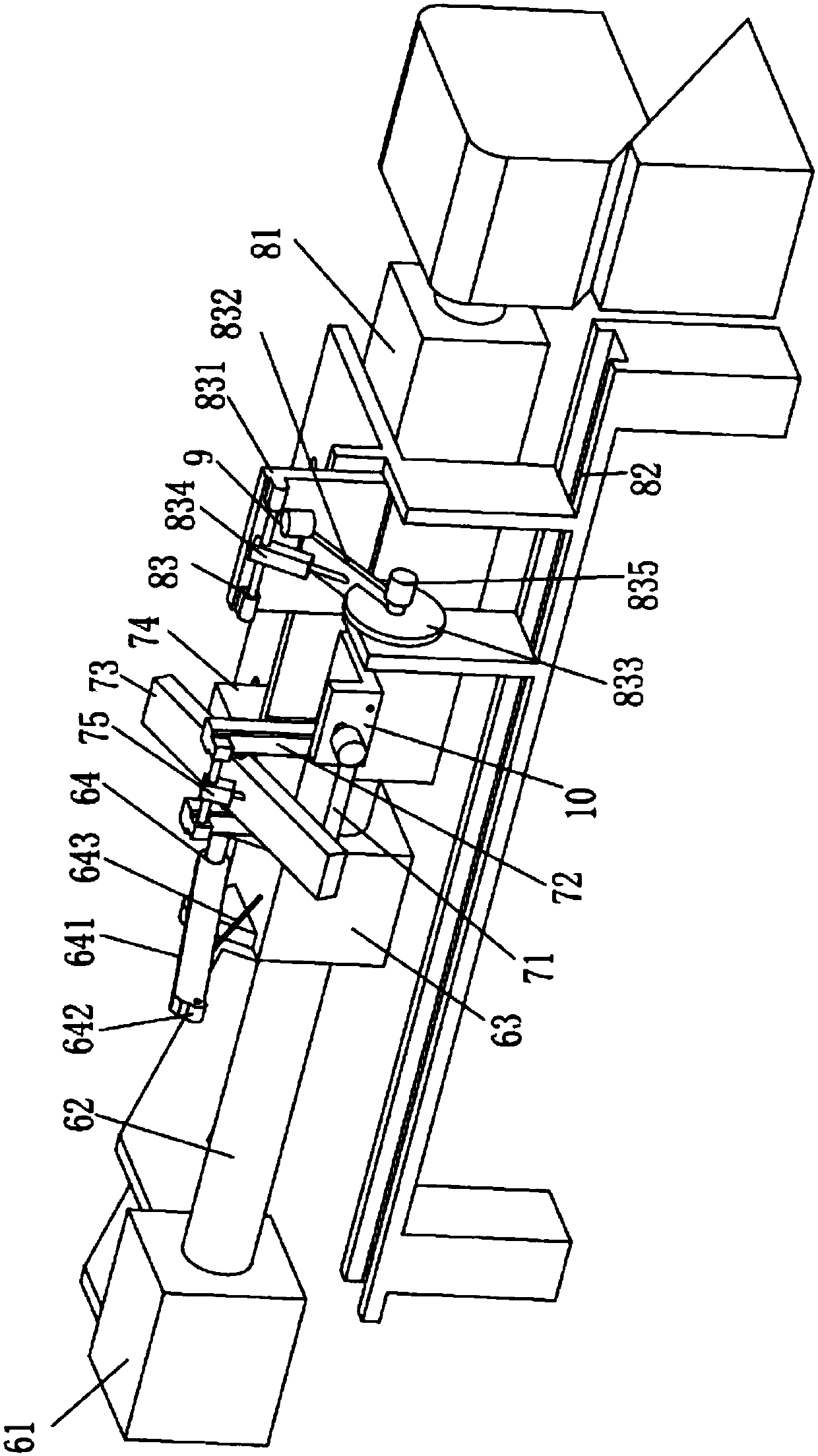

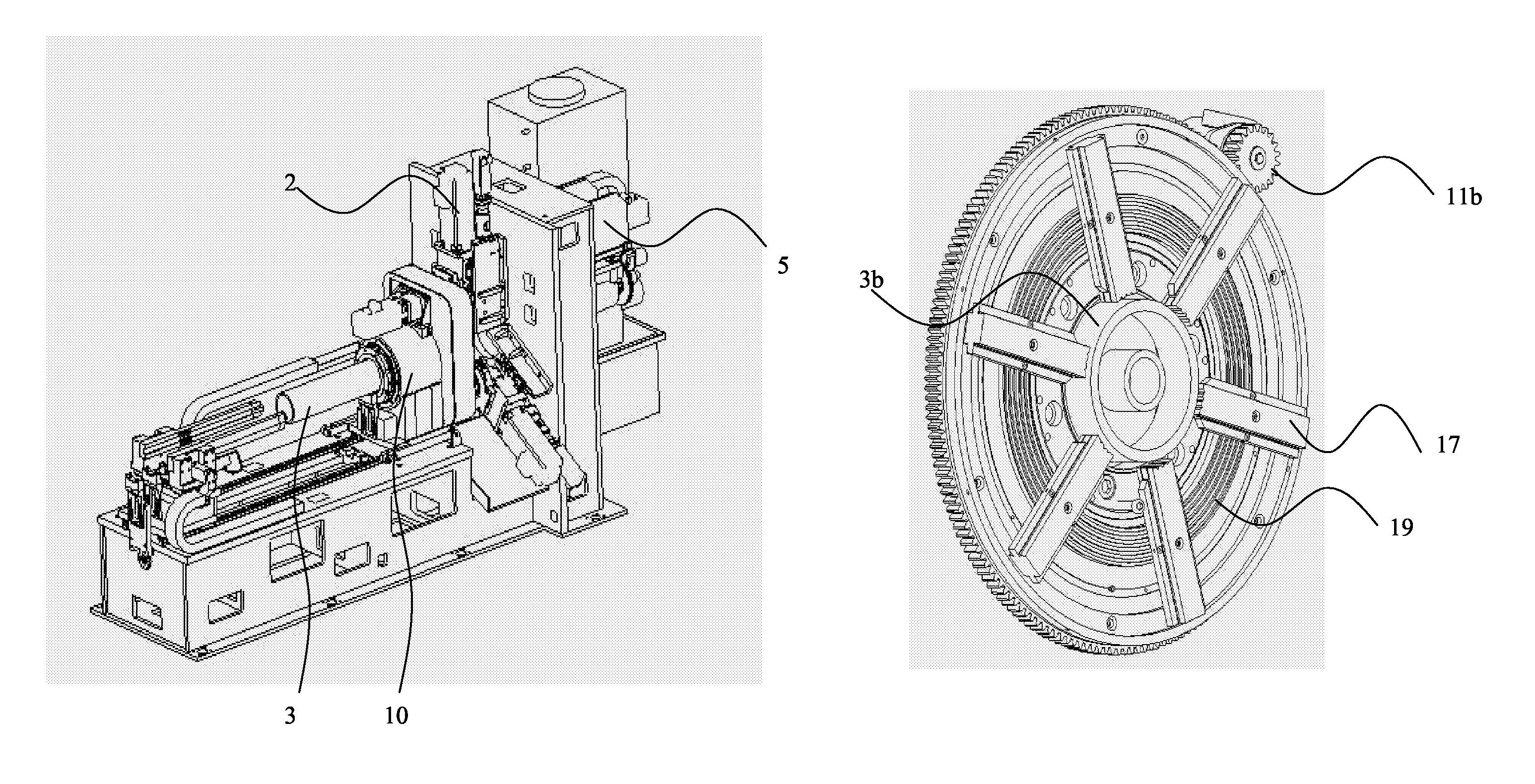

Feeding device of multi-head sawing machine for pipe

ActiveCN106112110AEasy accessImprove sawing efficiencyMetal sawing devicesMechanical engineeringEngineering

The invention discloses a feeding device of a multi-head sawing machine for a pipe. The feeding device of the multi-head sawing machine for the pipe comprises a machine frame; a feeding main shaft is rotatably mounted on the machine frame and is driven by a rotating feeding power device; a plurality of material poking gear sets are mounted on the feeding main shaft; a material poking tooth groove is circumferentially formed in each of the material poking gear sets; the positions of the material poking gear sets correspond to the positions of sawing heads on the machine frame; a feeding clearance which facilitates the entrance of a saw blade is formed in each material poking gear set; the depth of each feeding clearance is greater than the pipe diameter of the pipe; and the rotating upstream side of each material poking gear set is connected with an automatic feeding device. According to the feeding device, feeding, sawing feeding and discharging can be completed quickly, so that the sawing time is greatly shortened, and the sawing efficiency is improved.

Owner:SUZHOU KINKALTECK MACHINERY TECH

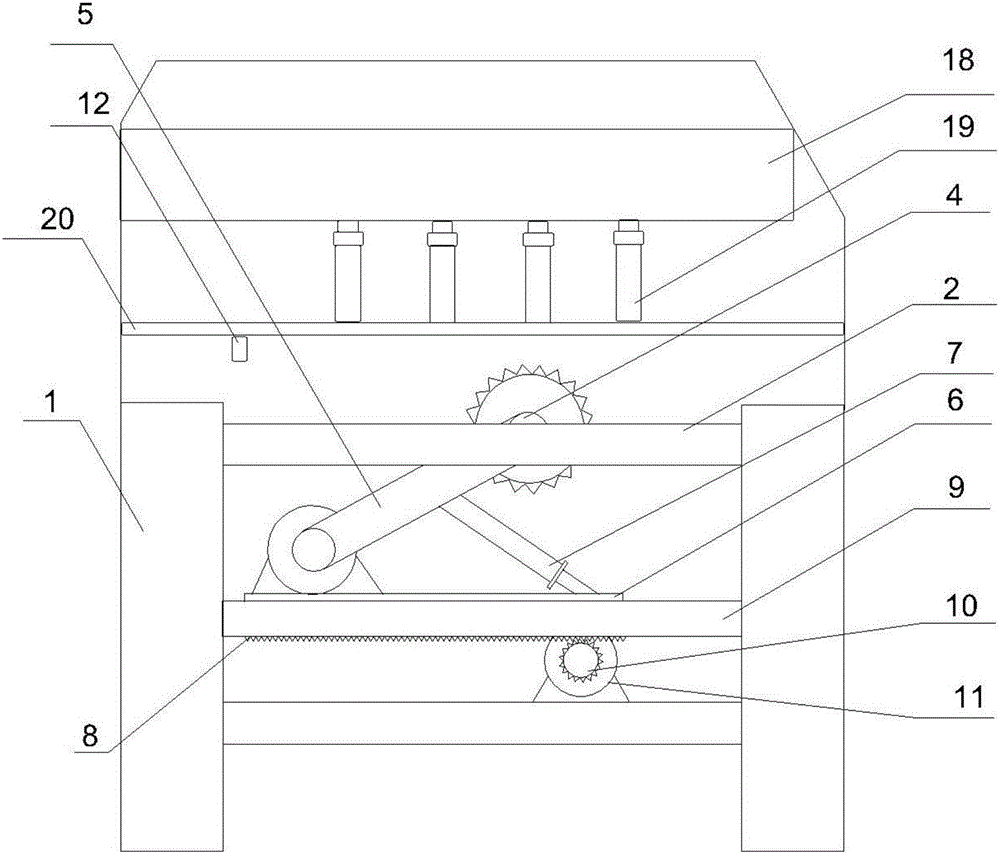

Multi-piece automatic blanking machine

ActiveCN102310227AHigh degree of automationEasy to operateMetal sawing devicesAgricultural engineeringMechanical equipment

The invention relates to the field of mechanical equipment for carrying out multi-piece sawing blanking on magnesium alloy sectional materials, in particular to a multi-piece automatic blanking machine. The multi-piece automatic blanking machine comprises a rack, a high-speed motor, a multi-station saw bit mechanism, a speed reducing motor, a main shaft, a first cam mechanism, a second cam mechanism, a multi-station metal sectional material fixture and an intermission mechanism, wherein the high-speed motor and the speed reducing motor are fixed on the rack, the multi-station saw bit mechanism is connected with the high-speed motor through a transmission belt, the multi-station saw bit mechanism comprises a multi-station saw bit shaft and at least two multi-station saw bits, the multi-station saw bits are arranged on the multi-station saw bit shaft, the main shaft is connected with the speed reducing motor through the transmission belt, the first cam mechanism is connected with the main shaft through a gear, the second cam mechanism is arranged on the main shaft and is connected with the multi-station sectional material fixture, and the intermission mechanism is arranged on the main shaft. The invention provides the multi-piece automatic blanking machine which has a simple structure, high efficiency and high precision and is convenient to operate.

Owner:嘉兴中科亚美合金技术有限责任公司

Pressing device for sawing material

InactiveCN106736747ARealize automatic arrangementAchieve compactionMetal sawing devicesWork clamping meansMechanical engineeringEngineering

The invention discloses a pressing device for a sawing material. The pressing device comprises a blocking pressing device, a left pressing device and a right pressing device, wherein the blocking pressing device, the left pressing device and the right pressing device are sequentially and parallelly mounted below fixed seats; the blocking pressing device, the left pressing device and the right pressing device comprise pressing cylinders and pressing beams; one ends of the pressing cylinders are fixed to the fixed seats; and telescopic shafts at the other ends of the pressing cylinders are connected with the pressing beams. According to the pressing device for the sawing material, a plurality of profiles can be automatically arranged and pressed, the sawing effect is guaranteed, and the sawing efficiency and cutting quality are greatly improved.

Owner:JINAN HUAXIN AUTOMATION ENG

Device for assisting gantry circular sawing machine in cutting steel plate

PendingCN107398591AExtended service lifeReduce wearMetal sawing devicesMetal sawing accessoriesCircular sawSteel plates

The invention discloses a device for assisting a gantry circular sawing machine in cutting a steel plate. The device is arranged at a saw kerf close to the front end of the steel plate and comprises a supporting base, and supporting base is connected with a supporting plate; the supporting plate is provided with a wedge mechanism capable of being wedged into a steel plate sawing gap, the tail end of the wedge mechanism is connected with a propelling mechanism, and the propelling mechanism is arranged on the supporting plate; the supporting plate is connected with a lifting mechanism, one end of the lifting mechanism is connected with the supporting plate, and the other end of the lifting mechanism is connected with the supporting base; one end of the supporting plate can ascend and descend relative to the supporting base under the action of the lifting mechanism. The device for assisting the gantry circular sawing machine in cutting the steel plate can be wedged into the saw kerf in the steel plate sawing process, the width of the saw kerf is increased, and a saw blade is prevented from being extruded by materials on side edges of the saw kerf. By means of the device, steel plate sawing can be easier, the abrasion of the surface of the saw blade is reduced, the service life of the saw blade is prolonged, and the sawing efficiency is improved.

Owner:江苏宁兴恒力智能设备有限公司

Continuous reversible precision sawing machine

ActiveCN101862860AAvoid displacementFirm and stable compression sawingMetal sawing devicesMetal sawing accessoriesCircular discMetal

The invention relates to a continuous reversible precision sawing machine, comprising a saw cutting main machine, a roller way and a pressing roller group, wherein the saw cutting main machine comprises a gantry frame and a circular disc saw, and the circular disc saw is arranged on a cross beam guide rail of the gantry frame; the roller way is laid under the gantry frame and comprises a receiving roller way, a working roller way and a finished product discharging roller way, and the working roller way can rotate forward and reversely; and the pressing roller group is arranged on the working roller way and is used for pressing a plate on the working roller way in the process of saw cutting. The sawing machine adopts a pressing mode with the pressing roller group, respectively applies dynamic pressing to the plate in the whole process of saw cutting, can realize multi-pass and multi-mode high-accuracy saw cutting and improve metal yield when in saw cutting.

Owner:BERIS ENG & RES CORP

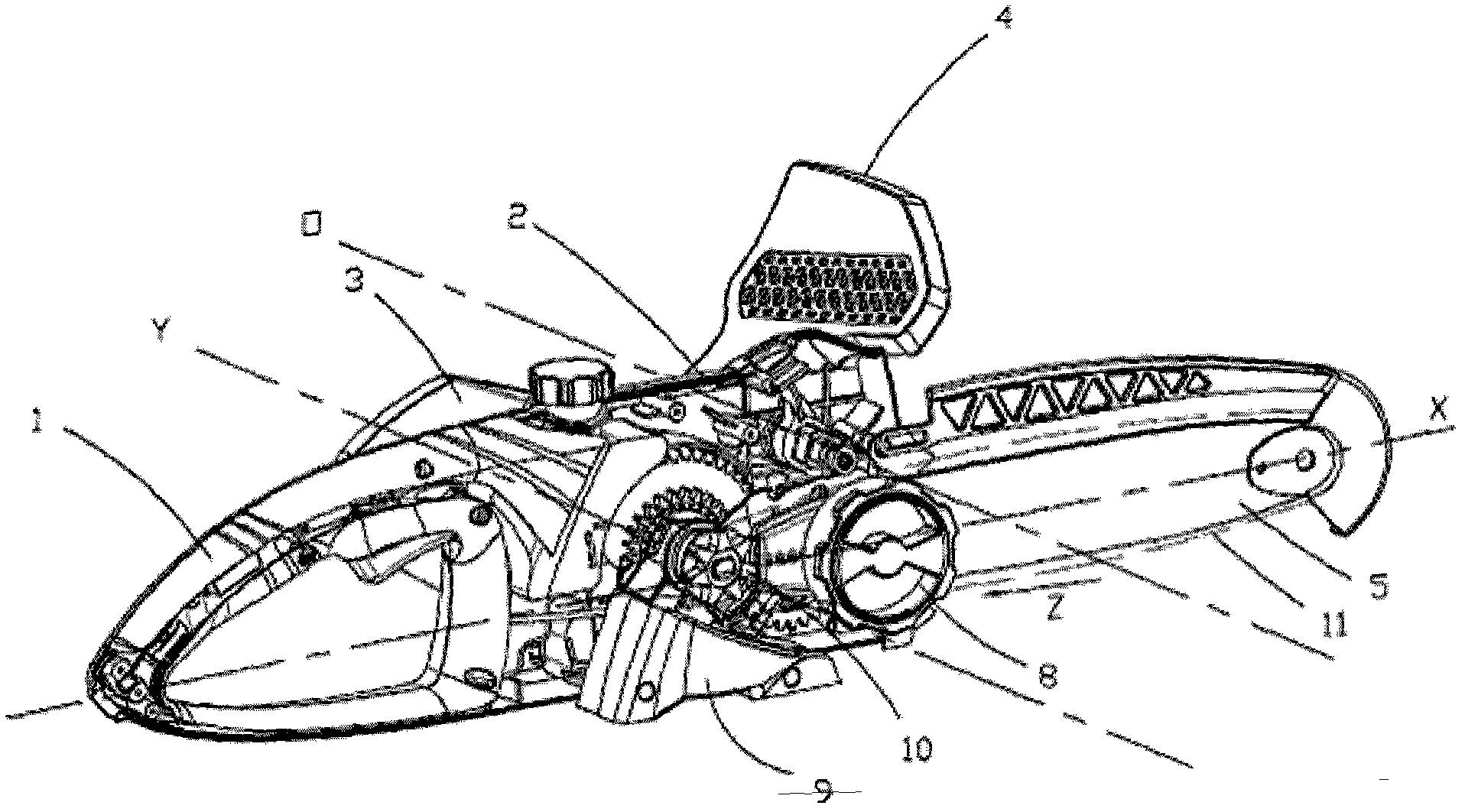

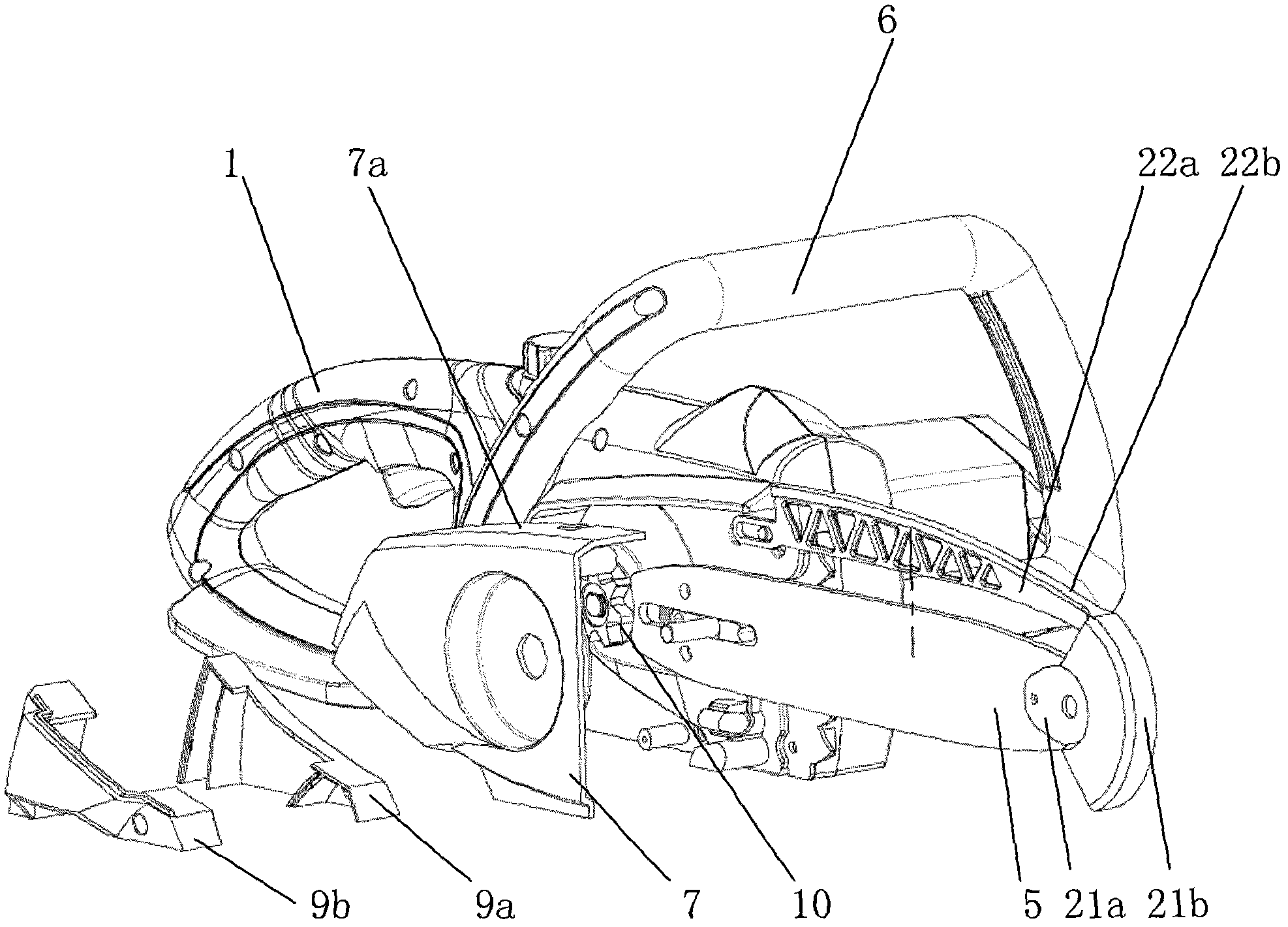

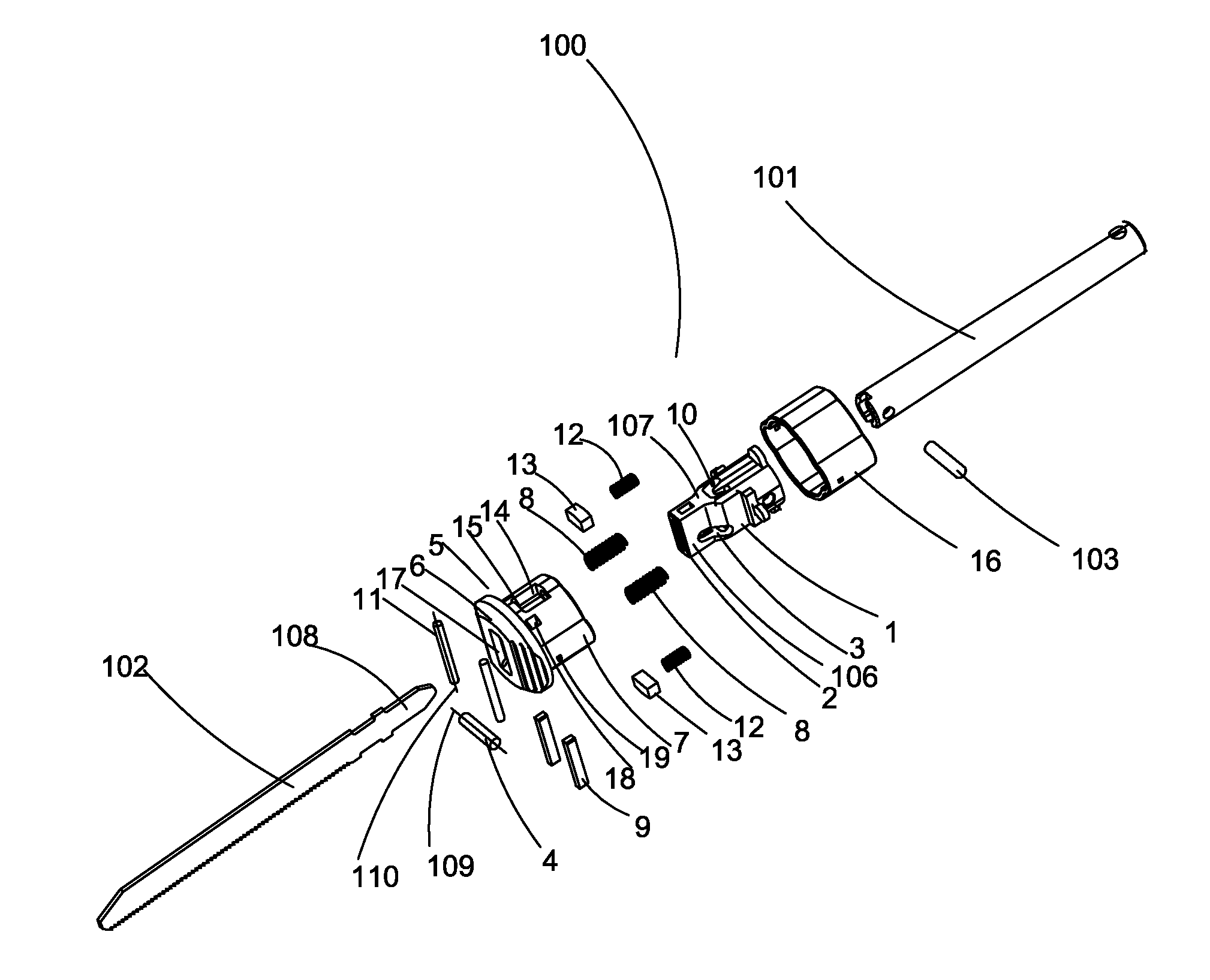

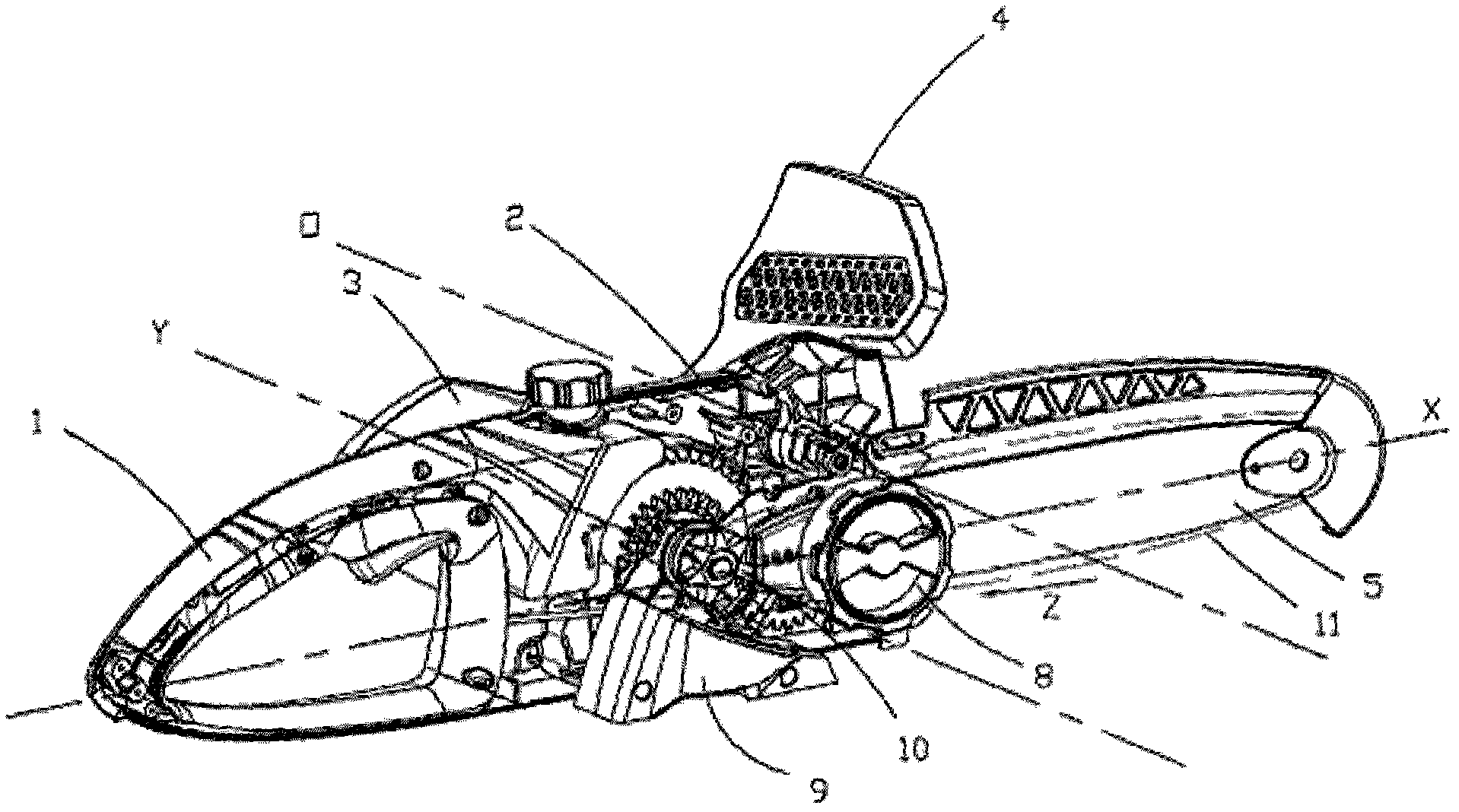

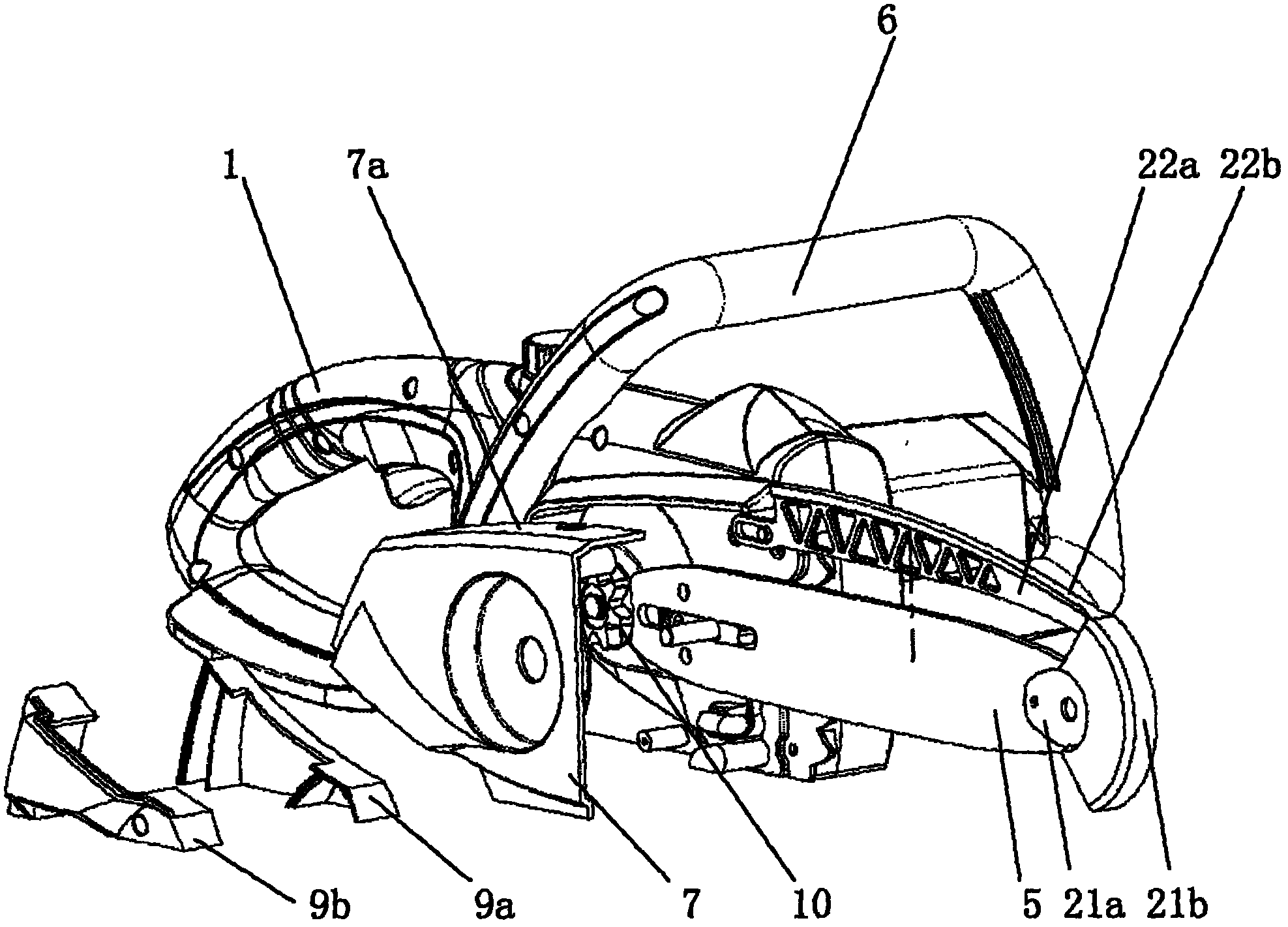

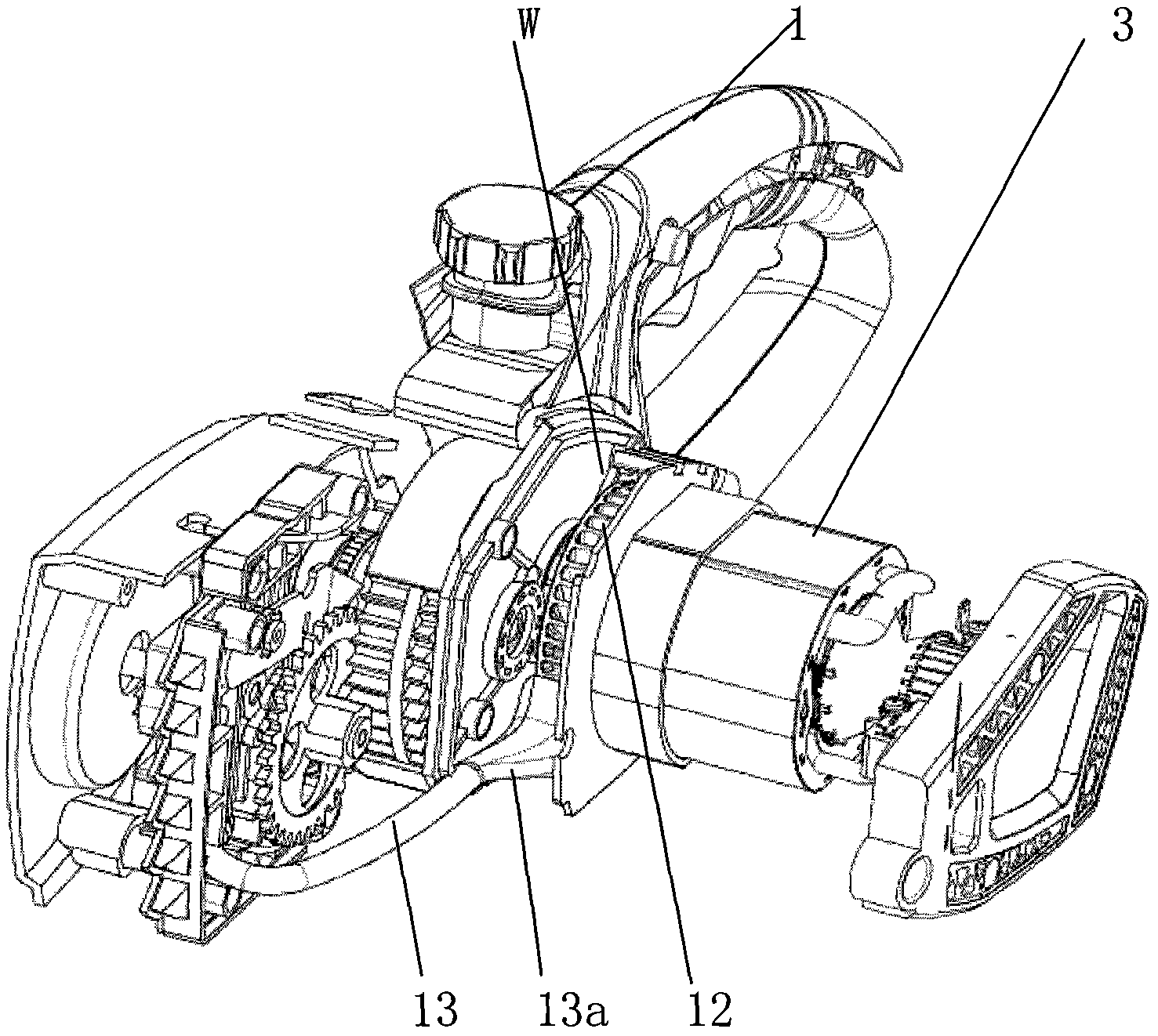

Chain saw

The invention provides a chain saw, which comprises a machine case, a motor arranged in the machine case, a chain wheel driven by the motor, a guide plate arranged on the machine case, a sawing chain arranged on the chain wheel and the guide plate, a sawing chain cover plate, and an anti-rebound shield including a holding part and a pivotal shaft part. The pivotal shaft part includes a stretching part. The anti-rebound shield has a first position and a second position enabling devices respectively to be in a brake state and a non-brake state, and is characterized in that a locking part is installed on the anti-rebound shield, the sawing chain includes a cooperation part, when the anti-rebound shield is arranged in the first position, the locking part is partially detached from the cooperation part, and when the anti-rebound part is arranged in the second position, the locking part is partially meshed with the cooperation part. The above structure prevents operators from accidentally removing the sawing chain cover plate when the devices are in the non-safety state, and effectively improves the security of the chain saw use.

Owner:CHERVON (CHINA) TRADING CO LTD

Automatic cutting method and automatic cutting system for numerical control sliding table saw

InactiveCN105922359AImprove sawing efficiencySave human effortCircular sawsNumerical controlEngineering

Owner:青岛金岭电器有限公司

Diamond circular saw web design and sawing process parameter setting method

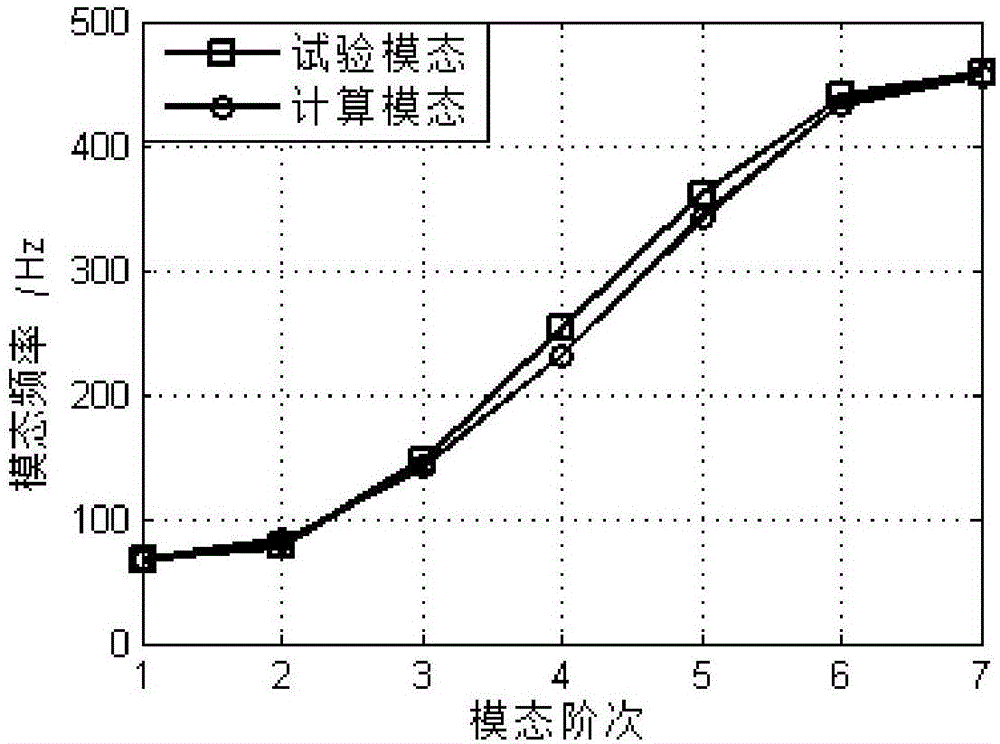

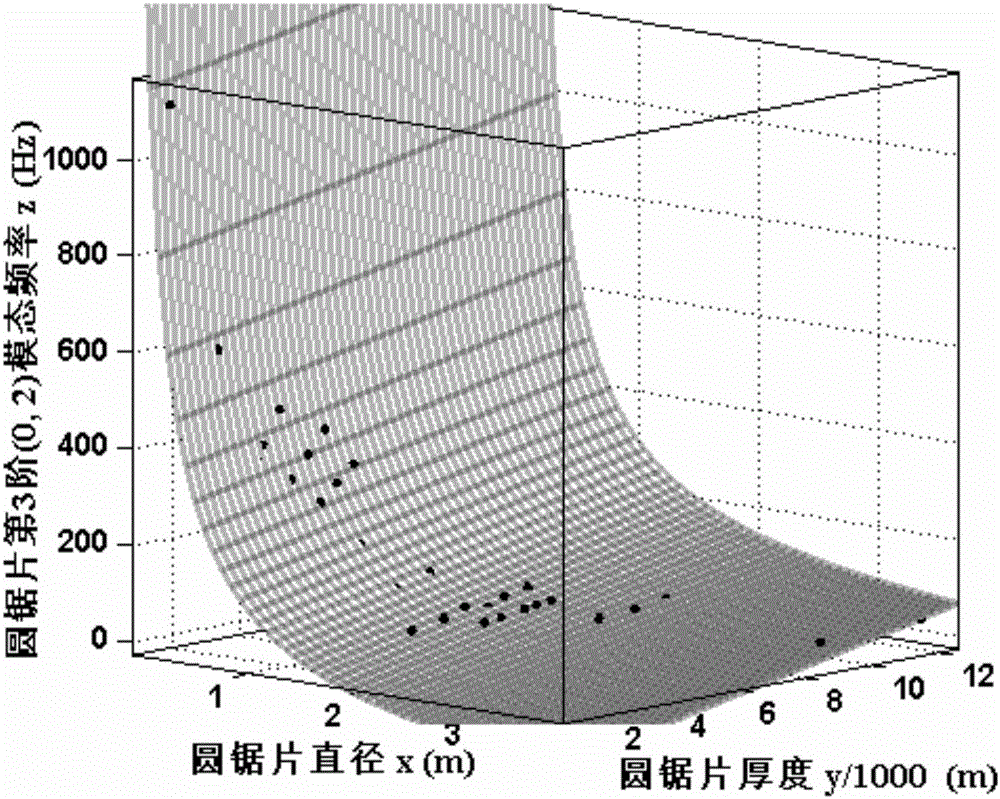

ActiveCN106777773AThe first 6 resonance frequencies are fast and accurateAccurate calculationGeometric CADDesign optimisation/simulationResonanceCircular saw

The invention relates to a diamond circular saw web design and sawing process parameter setting method. The method includes: a model experiment is used to verify the reliability of a modal simulation analysis method; different types of diamond circular saw webs are selected, and the diameters and thicknesses of the diamond circular saw webs are used as the independent variables to perform constraint modal analysis to obtain the function relationship between the first 6 order of resonance frequency of the diamond circular saw webs and the diameters and thicknesses of the diamond circular saw webs; determining the diameters, linear cutting speed and machining rotation speed of the diamond circular saw webs and the relationship between each order of resonance frequency and the diameters and thicknesses of the diamond circular saw webs according to the size and hardness of to-be-machined materials, acquiring the relationship between excitation frequency generated during machining and the rotation speed and tooth number of the diamond circular saw webs, and setting the appropriate thicknesses and tooth number of the diamond circular saw webs to build a diamond circular saw web design and sawing process parameter constraint model under the condition that the situation that resonance and working rotation speed is smaller than critical rotation speed is avoided. The method is high in universality and applicable to the design and sawing process parameter optimization of various diamond circular saw webs.

Owner:深圳市博金硬质工具有限公司

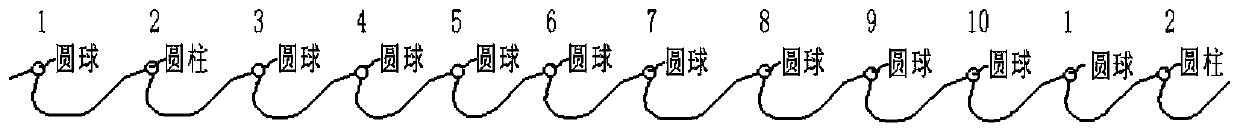

Band saw blade

The invention provides a band saw blade. The band saw blade comprises a saw blade body and saw teeth, wherein the saw teeth are arranged repeatedly according to a plurality of major cycles, and the major cycles follow the arrangement rule of a plurality of split tooth sub-cycles; each split tooth sub-cycle comprises N+1 teeth, the Nth tooth is a split tooth, and the (N+1)th tooth is a non-split tooth; among the N split teeth, the (1+3k)th tooth is a non-split tooth, and the rest are split teeth, specifically, k is a natural number, and the split sequences of every two adjacent teeth are different; the split amount of the second tooth and / or the third tooth and / or the (N-1)th tooth and / or the Nth tooth is greater than that of the rest of split teeth in each split tooth sub-cycle; and in each split tooth sub-cycle, the height of the first tooth is greater than that of the rest of split teeth, and the width of the (N+1)th tooth is greater than that of the rest of split teeth. Compared with related art, the band saw blade provided by the invention adopts a non-split tooth structure, so that the cutting force is reduced, the saw-cutting efficiency is improved and the precision of a section is improved in the process of saw-cutting materials difficult to process.

Owner:湖南泰嘉智能科技有限公司

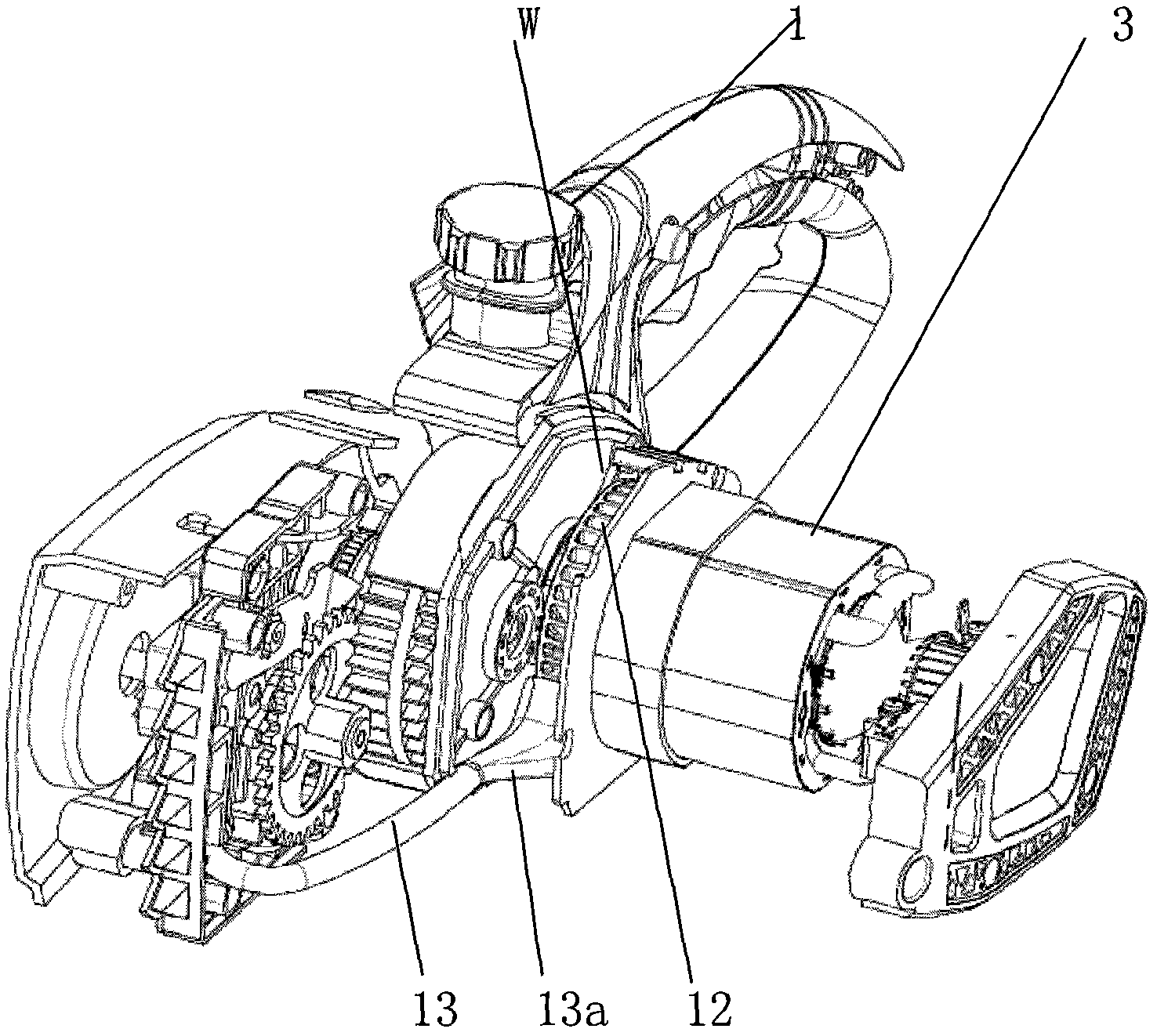

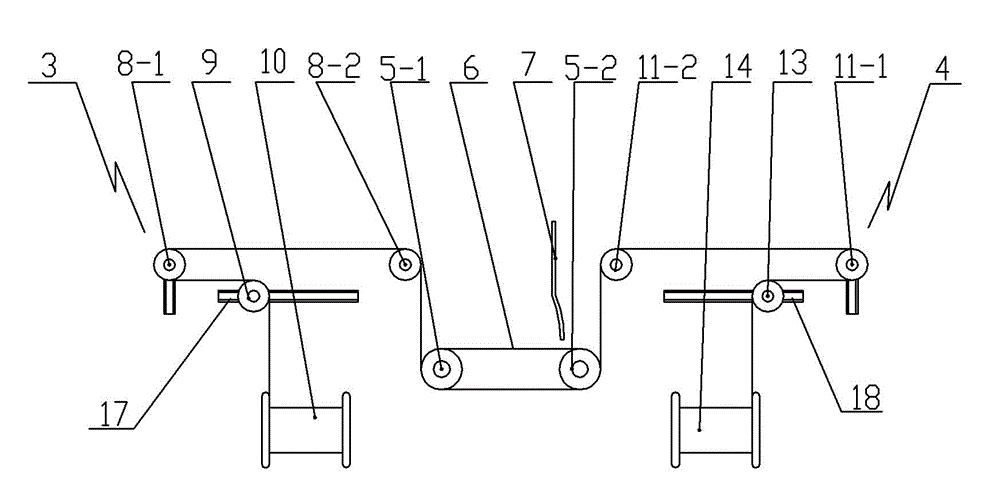

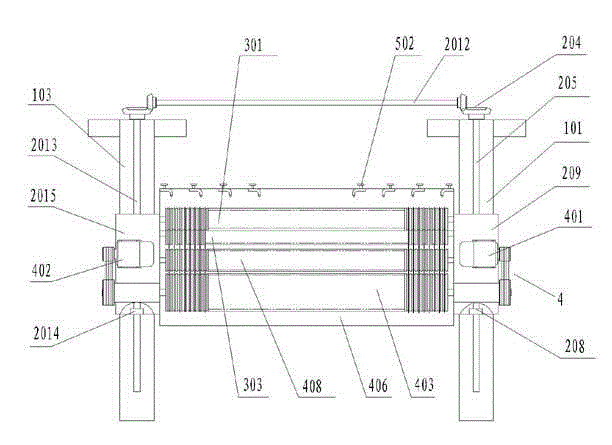

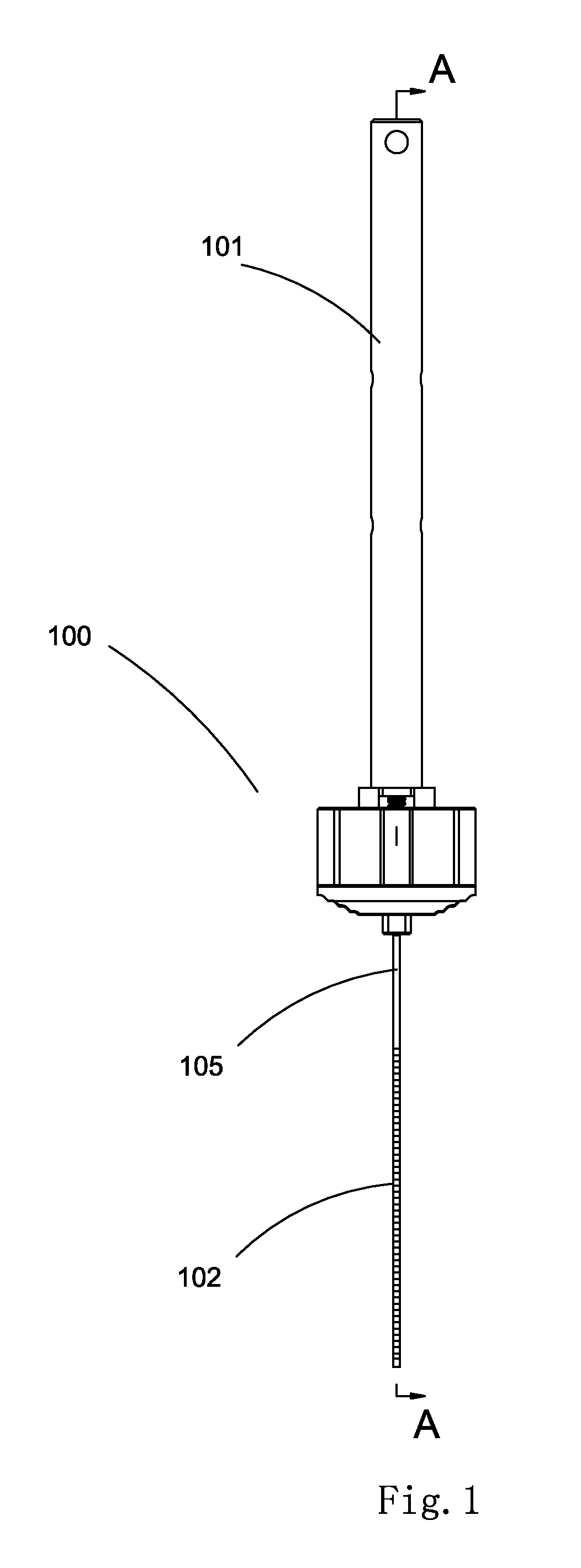

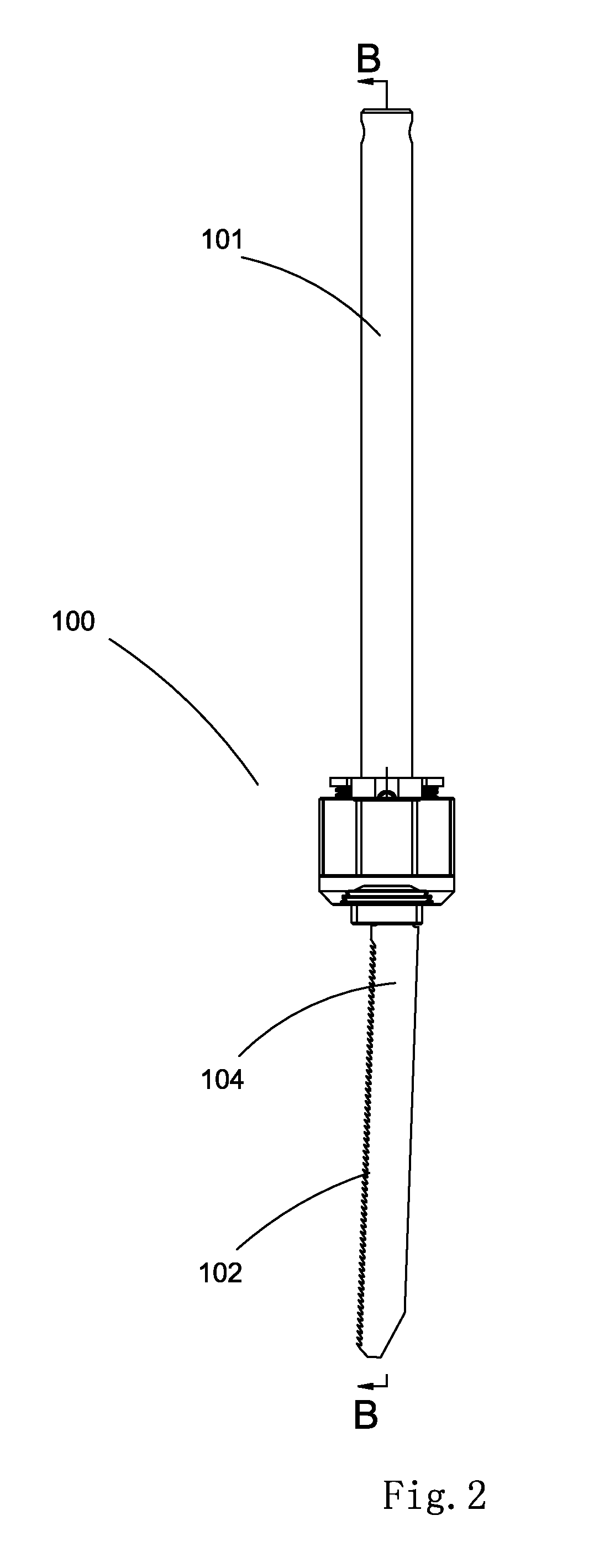

Numerically controlled diamond wire saw slicing machine

InactiveCN103600426AImprove sawing efficiencyAvoid pollutionWorking accessoriesFine working devicesDiamond wire sawEngineering

The invention provides a numerically controlled diamond wire saw slicing machine. The numerically controlled diamond wire saw slicing machine comprises a machine frame, a workpiece clamping feeding device and a reeling winding device and an unreeling winding device which are arranged on bilateral sides of lathe bed and guide rollers are arranged on bilateral sides of the machine frame. The numerically controlled diamond wire saw slicing machine is characterized in that diamond wires repeatedly are wound on the two guide rollers in an interval mode sequentially; a cooling lubricant nozzle which is corresponding to the diamond wires is arranged on the machine frame. The numerically controlled diamond wire saw slicing machine has the advantages of simplifying sawing technologies, improving the sawing efficiency, meanwhile avoiding sand pulp splash generating pollution to environment and effectively protecting the environment.

Owner:WUXI SHANGJI AUTOMATION

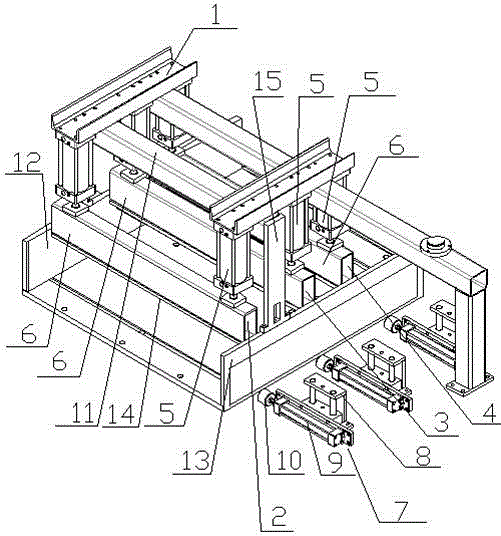

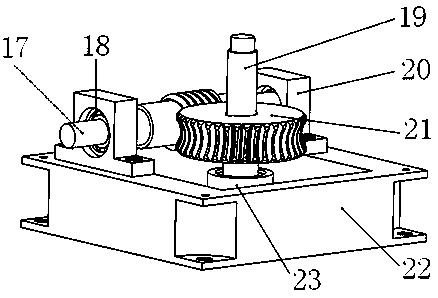

Automatic photovoltaic panel frame 45-degree sawing machine

InactiveCN109759642ARealize the adjustmentAchieve compactionMetal sawing devicesBall screwFixed frame

The invention discloses an automatic photovoltaic panel frame 45-degree sawing machine which is composed of a worktable, a motion platform, a linear guide rail, a slider, a ball screw, a slide table,a screw nut, a screw support, a motor, a rotating mechanism, a sawing mechanism, a vertical push frame, a push alignment mechanism, a fixing frame, an air cylinder, a stopping block and the like. Theautomatic photovoltaic panel frame 45-degree sawing machine has the advantages that alignment, pressing and sawing of three L-shaped photovoltaic panel frames can be achieved, and the sawing efficiency and the sawing stability are improved; the air cylinder is adopted to press a workpiece, the output force of the air cylinder is relatively large, operation is simple and convenient, and the stability of the workpiece is stable in the working process; and a worm gear and a worm are adopted for transmission, the good self-locking property is achieved, and the safety and stability of the device inthe working process are ensured.

Owner:HARBIN UNIV OF SCI & TECH

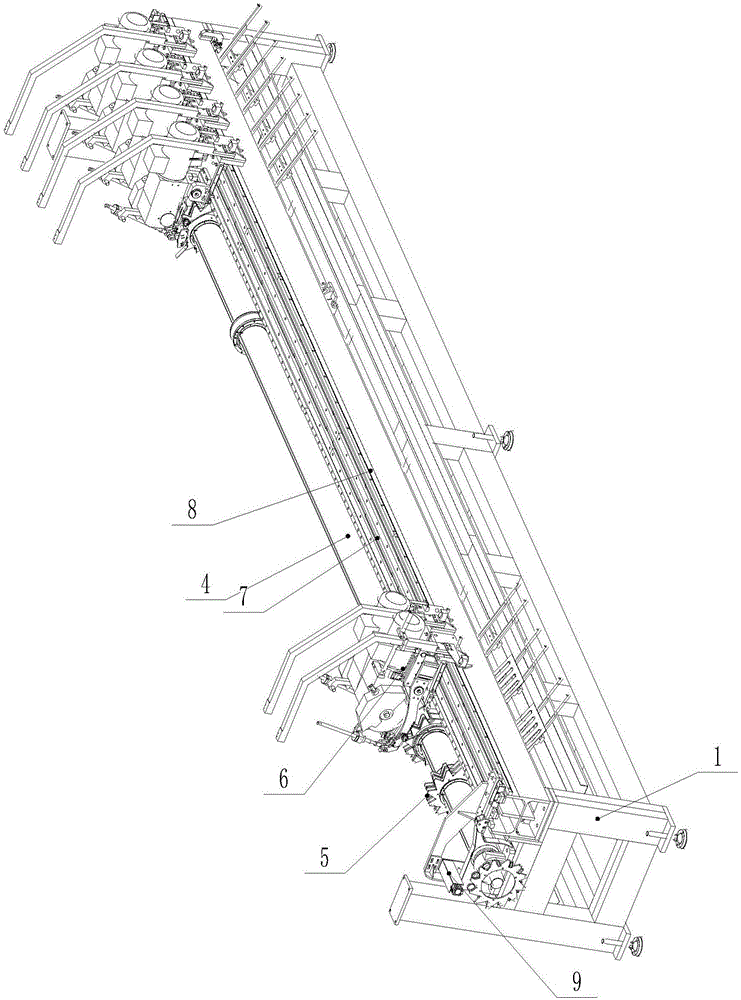

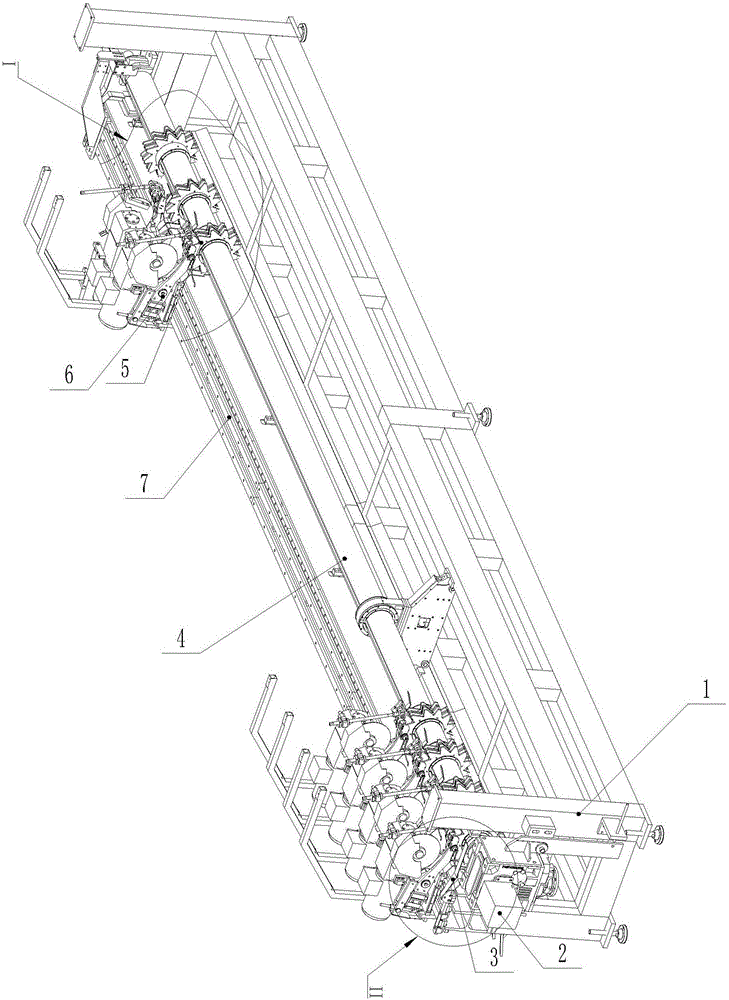

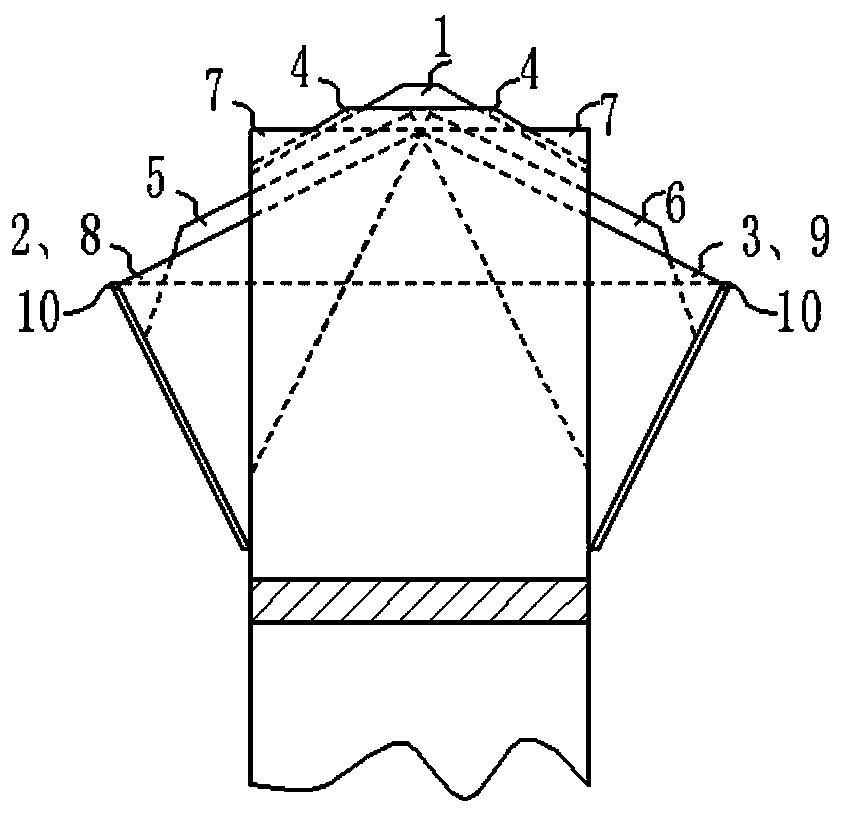

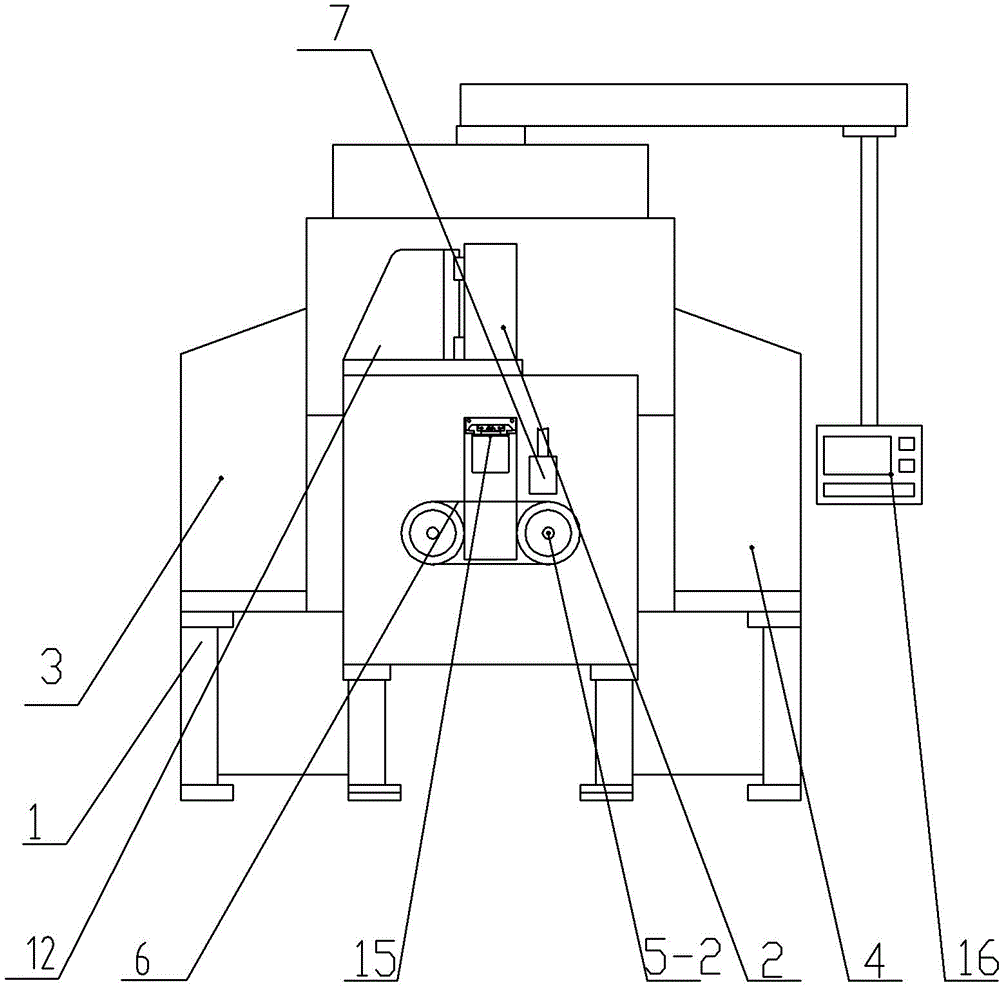

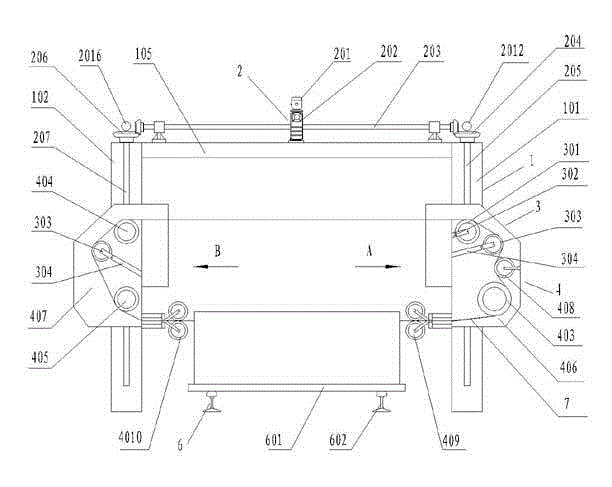

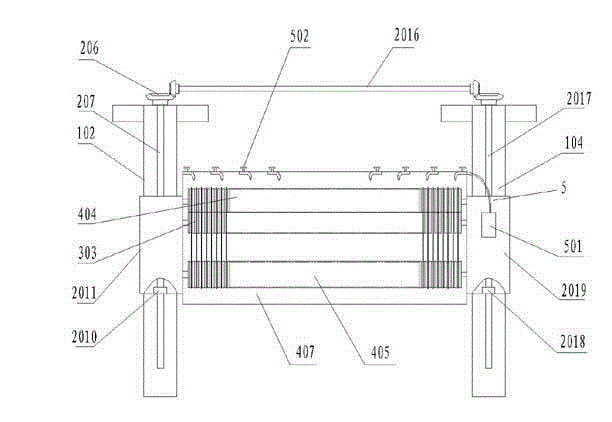

Four-column framework diamond string-bead rope gang saw

ActiveCN102941625AImprove sawing efficiencySawing surface is smoothWorking accessoriesStone-like material working toolsOn columnEngineering

The invention relates to a four-column framework diamond string-bead rope gang saw for sawing stones. The gang saw comprises a four-column framework, a lifting mechanism, a gang saw operation mechanism, a tension mechanism, a water supplying and cooling mechanism, a quarry stone vehicle and a plurality of diamond string-bead ropes, wherein the lifting mechanism is arranged on the four-column framework, the diamond string-bead ropes are supported in wheel slots of a drive wheel of the gang saw operation mechanism, a first support wheel of the gang saw operation mechanism, a second wheel of the gang saw operation mechanism and a tension wheel of the tension mechanism in a closed annular manner, and the diamond string-bead ropes are tensioned by the tension wheel to form the four-column framework diamond string-bead rope gang saw. The gang saw operation mechanism is driven by the lifting mechanism to lift on columns of the four-column framework so as to drop and lift the saw; and the diamond string-bead ropes perform one-way high-speed linear movement through the gang saw operation mechanism so as to cut and abrade granite to saw a plate. The four-column framework diamond string-bead rope gang saw provided by the invention is convenient to operate, high in sawing efficiency, good in sawing quality, few in replacement times of a saw blade, convenient to adjust, small in environment pollution and low in production cost.

Owner:荣成中磊科技发展有限公司

Clamping device for a saw blade

InactiveUS20110283858A1Enhanced efficiencyEffectively provide stable clamping of the saw bladeMetal sawing devicesMetal working apparatusEngineeringMechanical engineering

Owner:CHERVON HK LTD WANCHAI

Chain saw

InactiveCN102380662AImprove sawing efficiencyExtended service lifeMetal sawing devicesChain sawsEngineeringSprocket

The invention provides a chain saw, which comprises a machine case, a motor, a fan, a chain wheel, a guide plate, a sawing chain and an air passage, wherein the motor is arranged in the machine case, the fan is driven by the motor, the chain wheel is driven by the motor, the guide plate is arranged on the machine case, the sawing chain is arranged on the chain wheel and the guide plate, the air passage is formed in the machine case, the first end of the air passage is near the fan, and the second end of the air passage is near the sawing chain. When an air passage mechanism of the chain saw is adopted, the sawing efficiency is improved, and the service life of the sawing chain is prolonged.

Owner:CHERVON (CHINA) TRADING CO LTD

Fixed-length sawing and coding machine of aluminum bars

PendingCN109605043AImprove efficiencyImprove coding efficiencyMetal sawing devicesMetal sawing accessoriesContinuous productionMechanical engineering

The invention discloses a fixed-length sawing and coding machine of aluminum bars. The fixed-length sawing and coding machine of the aluminum bars is arranged above an aluminum bar conveying line andcomprises a machine frame, a conveying line located below the machine frame, a swing arm component arranged on the machine frame, a support arm installed on the swing arm component, a saw cutting partfixed on the support arm and a code printing assembly. The saw cutting part comprises a fixed length assembly, a pressing assembly and a saw cutting assembly arranged at the end of the fixed length assembly, the code printing assembly comprises a character code body and a power cylinder connected with the character code body, the swing arm component comprises a driving component and a rotating component, and the driving component drives the supporting arm component to turn over and lifts the saw cutting part and the code printing assembly so as to transport the aluminum bars after sawing andcode printing. According to the fixed-length sawing and coding machine of the aluminum bars, the fixed-length sawing and coding of the aluminum bars can be carried out at the same time, the cutting length is easy to adjust, and the continuous production process of multi-specification aluminum bar saw cutting and coding is realized.

Owner:FOSHAN KELI IND EQUIP

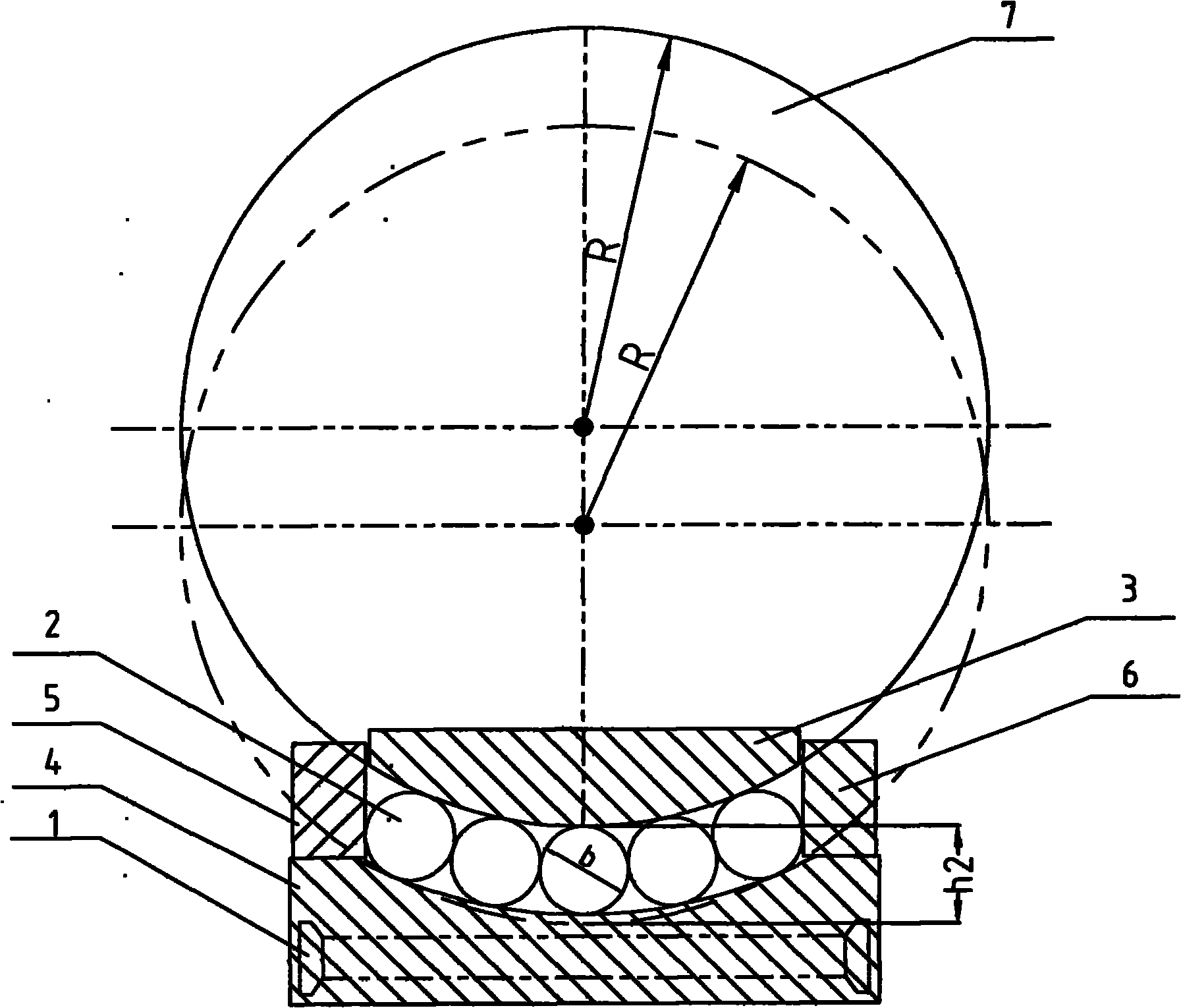

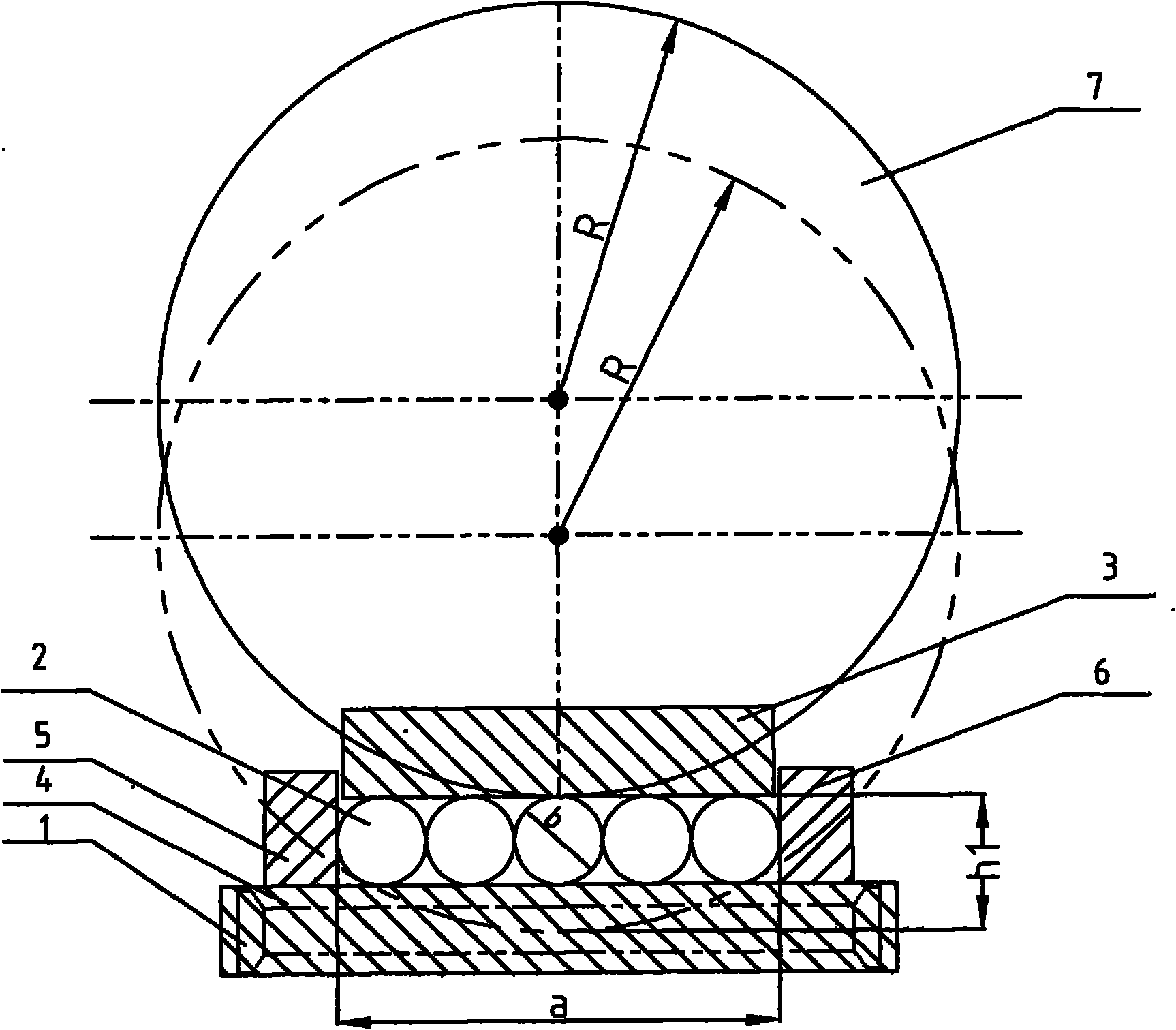

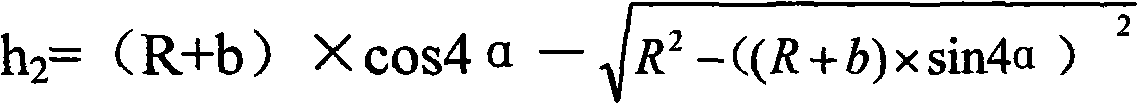

Steel pipe fixture for pipe saw mills

InactiveCN101879631AReduce the descending strokeReduce shockMetal sawing devicesMechanical engineeringSteel tube

The invention discloses a steel pipe fixture for pipe saw mills, which comprises an upper clamping plate (3), a lower clamping plate (4), a left clamping plate (5) and a right clamping plate (6). The steel pipe fixture is characterized in that: the surfaces of the upper clamping plate (3) and the lower clamping plate (4), which are contacted with steel pipes (2), are cambered, moreover, the two cambers are concentric, and the difference between the diameters of the two concentric cambers is the diameter of the clamped steel pipe (2). A saw disk can simultaneously saw each of the steel pipes in a row, the downstroke of the saw disk is shortened, the sawing time is shortened, the sawing efficiency is increased, meanwhile, from the beginning to the end of steel pipe sawing by the saw disk, the area of the row of pipes sawed by the saw disk is nearly unchanged, consequently, the load change of a sawing machine is little, the impact on the saw disk is little, tooth breaking can be reduced, and the service life of the saw disk can be prolonged.

Owner:烟台宝钢钢管有限责任公司

Large aerospace shell sawing equipment and sawing method thereof

ActiveCN109954940AImprove the range of sawing adaptationAutomatically adjust the tilt angleMetal sawing devicesMetal sawing accessoriesFeed driveEngineering

The invention discloses large aerospace shell sawing equipment and a sawing method thereof. The sawing angles for large aerospace shells are not simplex, so that a multiple-angle sawing function of asawing machine is needed. The large aerospace shell sawing equipment comprises a gantry, band saw wheels, a sawing frame, a saw band, a base, a workbench, guide chip-breaking assemblies, feeding driving assemblies, cutting direction adjusting driving assemblies, a two-axis workbench driving mechanism and a pulsation generating assembly. Each guide chip-breaking assembly comprises an oscillating guide bottom plate, an oscillating guide block, an oscillating spring, an oscillating coil and a hollow iron core, wherein the oscillating coil is wound on the hollow iron core, a suction block is arranged at the top end of the oscillating guide block, the oscillating guide block and the hollow iron core form a sliding pair, and the oscillating guide block is sleeved with the oscillating spring. Thepulsation generating assembly comprises a worm speed reducer and a pulsation generating motor. According to the large aerospace shell sawing equipment and the sawing method thereof, automatic adjusting devices enabling the sawing frame to be inclinable are designed, and the inclination angle of the sawing frame can be adjusted automatically according to sawing requirements.

Owner:HANGZHOU DIANZI UNIV

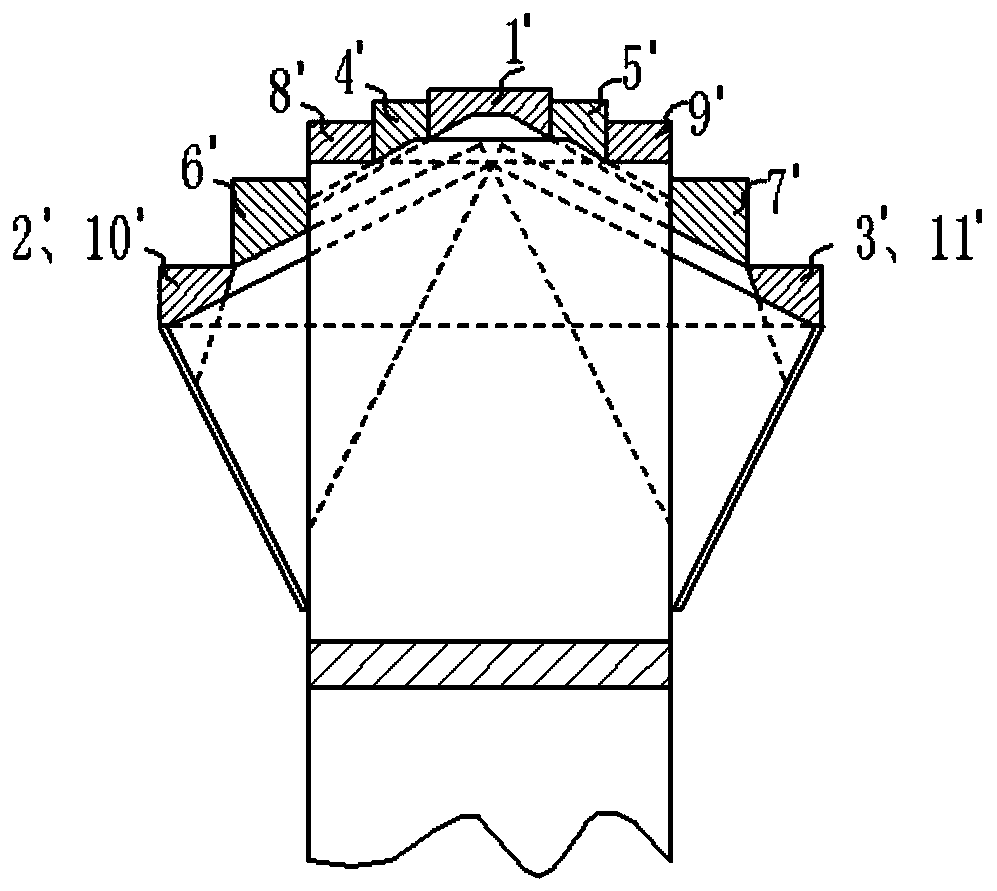

Method and device for cutting off a thick-walled pipe

InactiveUS7765901B2Easy to implementIncrease feed rateMetal sawing devicesShearing machinesThick wallEngineering

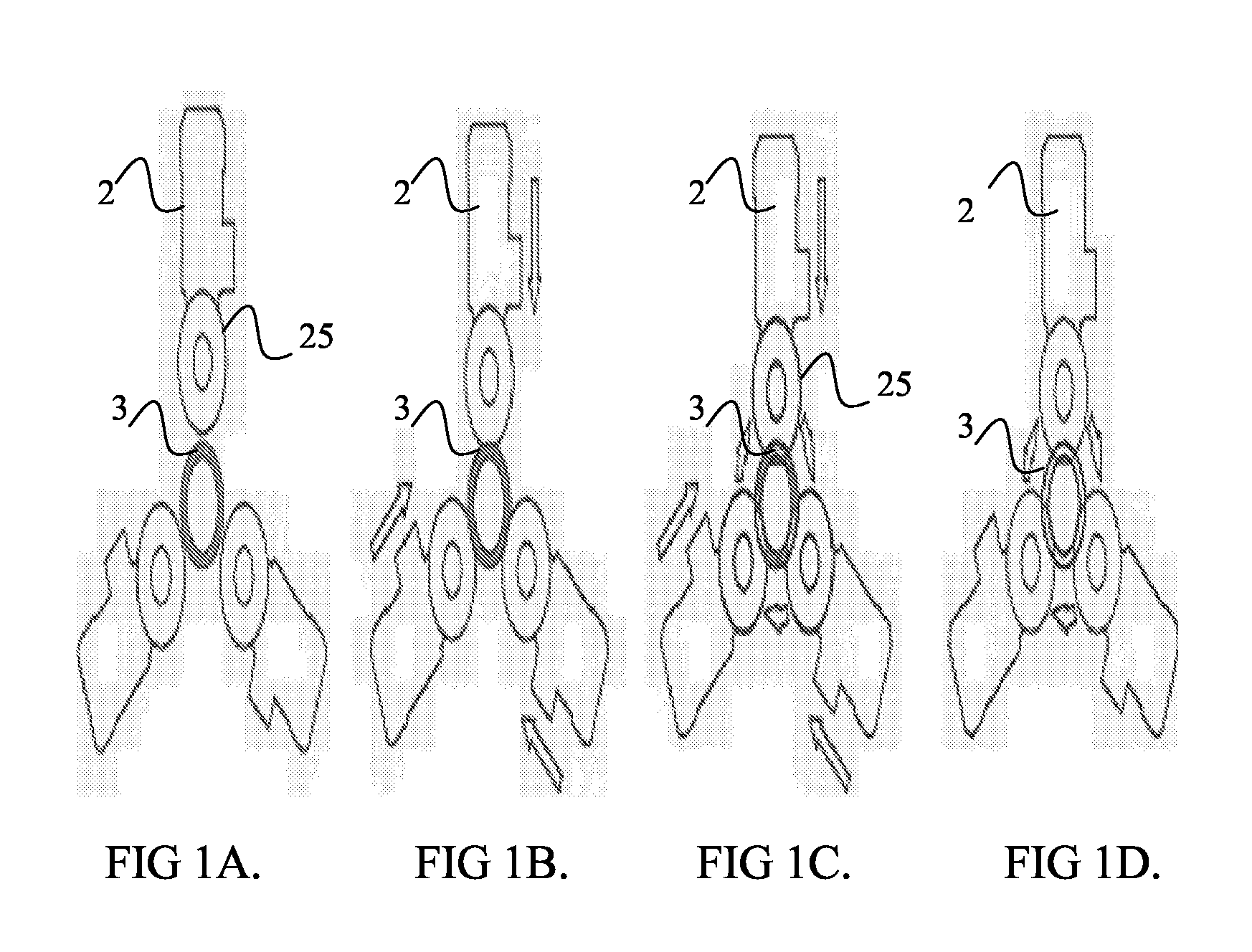

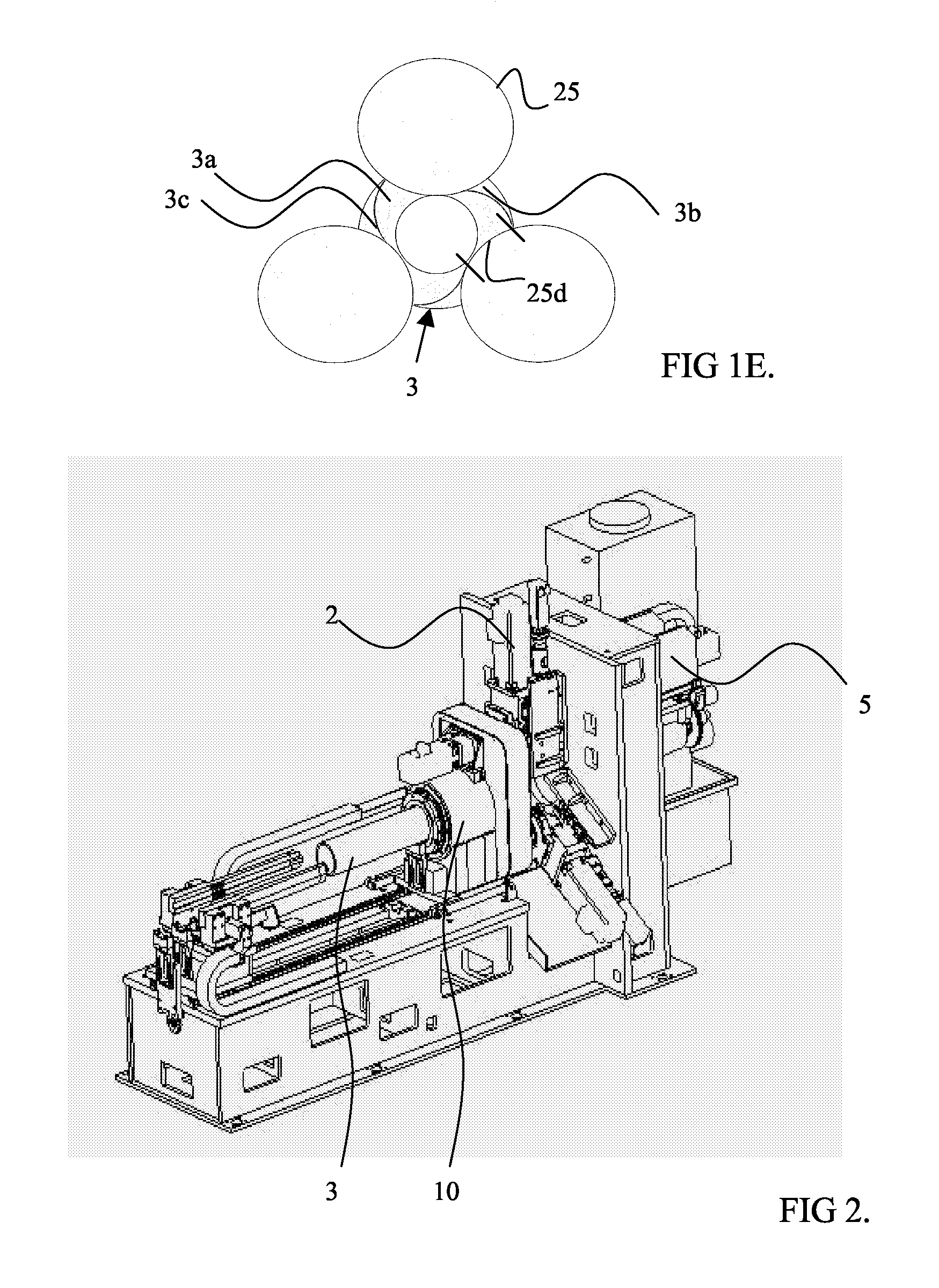

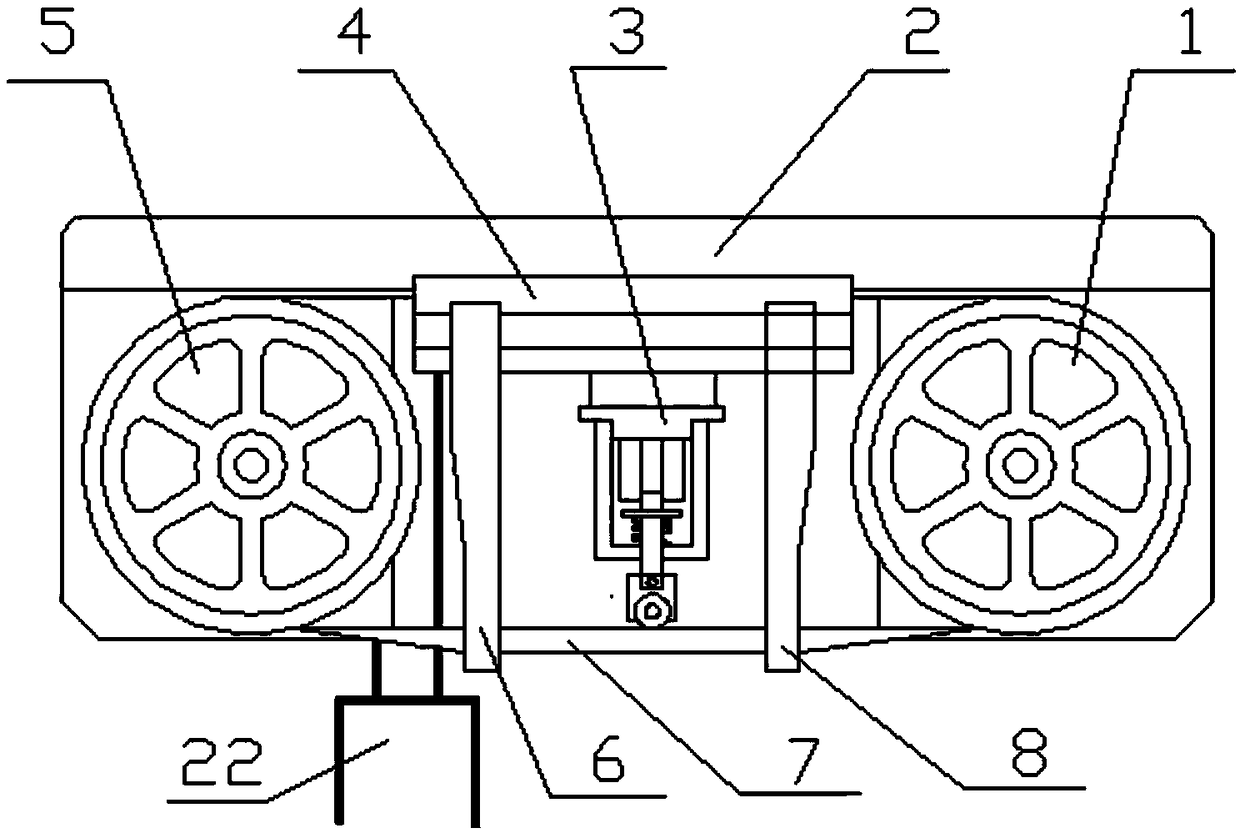

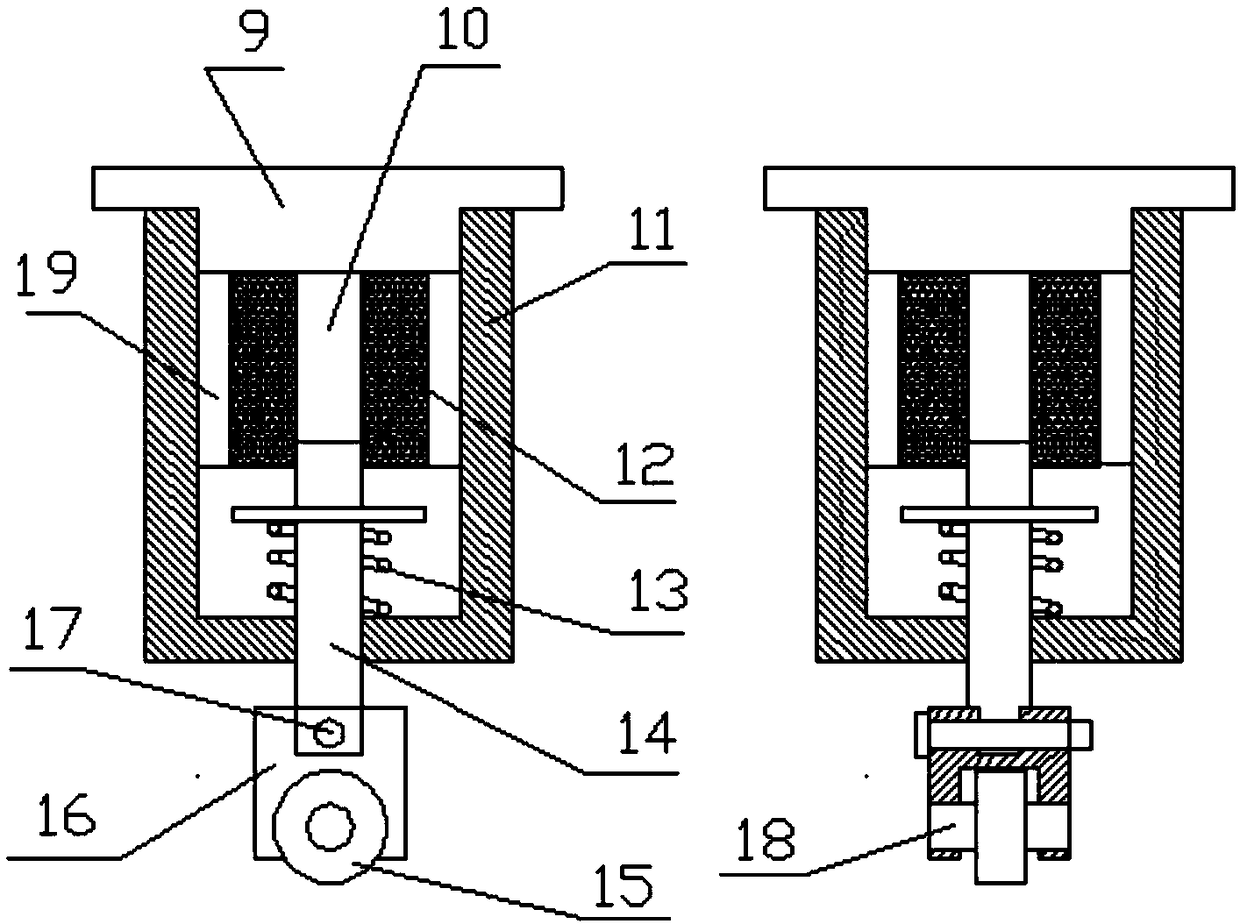

The invention relates to a method for cutting off a thick-walled pipe 3, wherein the pipe to be cut comprises an inner circumference closer to the longitudinal axis of the pipe and an outer circumference further from the longitudinal axis of the pipe. The method comprises bringing the cut-off point of the pipe to the cut-off point of a sawing unit, locking the pipe in its place by means of a fastener, sawing the pipe at the cut-off point by moving a saw 2 of the sawing unit towards the center of the pipe 3, the sawing unit comprising at least two saws. The method is characterized by moving each saw 2 of the sawing unit during the sawing radially towards the centre of the pipe until the saw blades pass through the inner surface of the pipe, and rotating the pipe during the sawing with respect to its longitudinal axis by means of a rotating device 10 connected to the fastener until the pipe is cut off, whereby, due to the rotating of the pipe, the blades 25 of the saw 2 work the pipe during a blade revolution only in one direction, which is directed from the outer circumference towards the inner circumference. Furthermore, the invention provides a saw assembly and a rotating device for implementing the method.

Owner:PLANTOOL

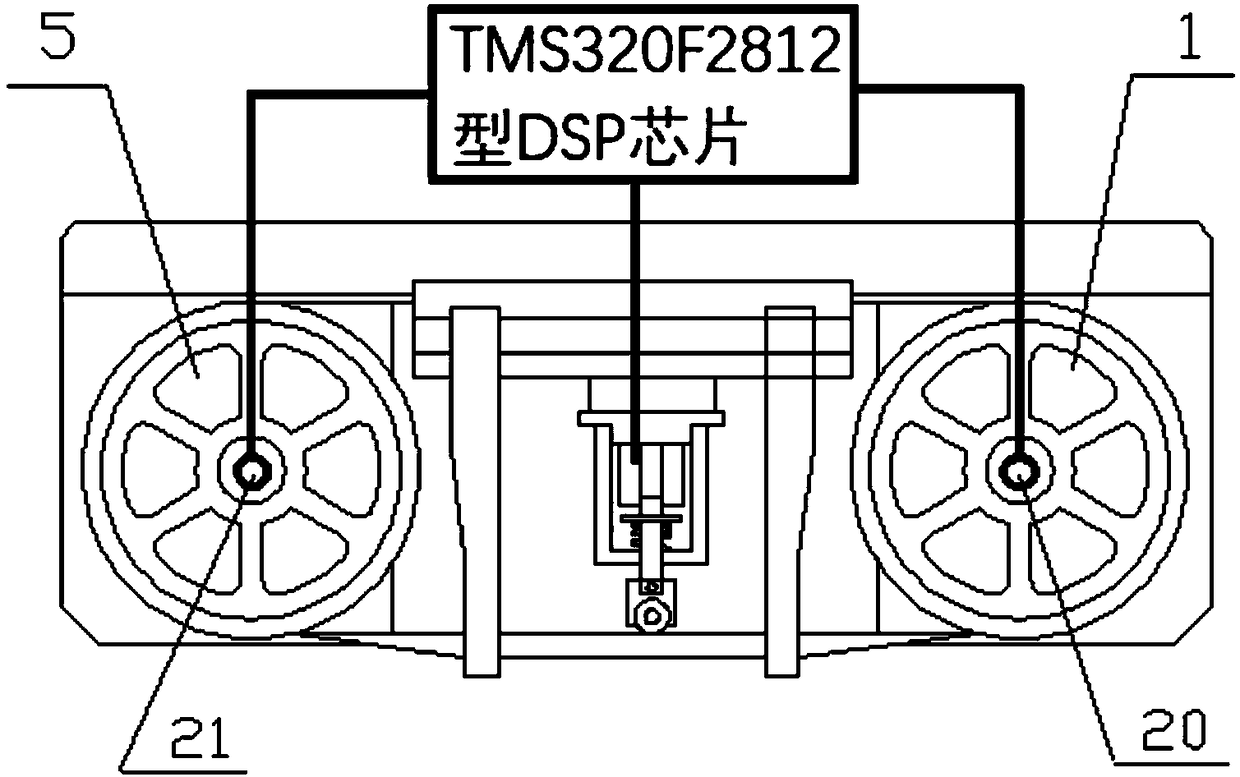

Self-adaptation controllable vibration metal cutting device and method based on super magnetostriction

PendingCN109396550ALarge strain valueHigh controllable precisionMetal sawing devicesMetal sawing accessoriesHydraulic cylinderEngineering

The invention discloses a self-adaptation controllable vibration metal cutting device and method based on super magnetostriction. A saw frame, a vibration mechanism, a saw beam, a driving belt wheel,a driven belt wheel, a saw strip, a hydraulic cylinder and a DSP chip are included. The vibration mechanism is fixed to the lower end face of the saw beam. A left guiding arm and a right guiding arm are arranged on the two sides of the vibration mechanism correspondingly. The base is arranged at the opening position in the upper end of the shell. The lower end face of the base is connected with anamplitude changing rod through a super magnetostriction material. The amplitude changing rod penetrates through the bottom face of the shell and is connected with a bearing frame. The outer side faceof the super magnetostriction material is sequentially sleeved with an exciting coil and a permanent magnet. The driven belt wheel and the driving belt wheel are provided with a rotation speed sensorand a torque sensor correspondingly. The rotation speed sensor and the torque sensor are connected with the DSP chip. The DSP chip is connected with the vibration mechanism through a PLC. Through thesimple structure design, saw strip vibration cutting can be achieved, saw strip tooth tips can more easily cut into the materials, and cuttings can be more easily discharged.

Owner:LISHUI UNIV

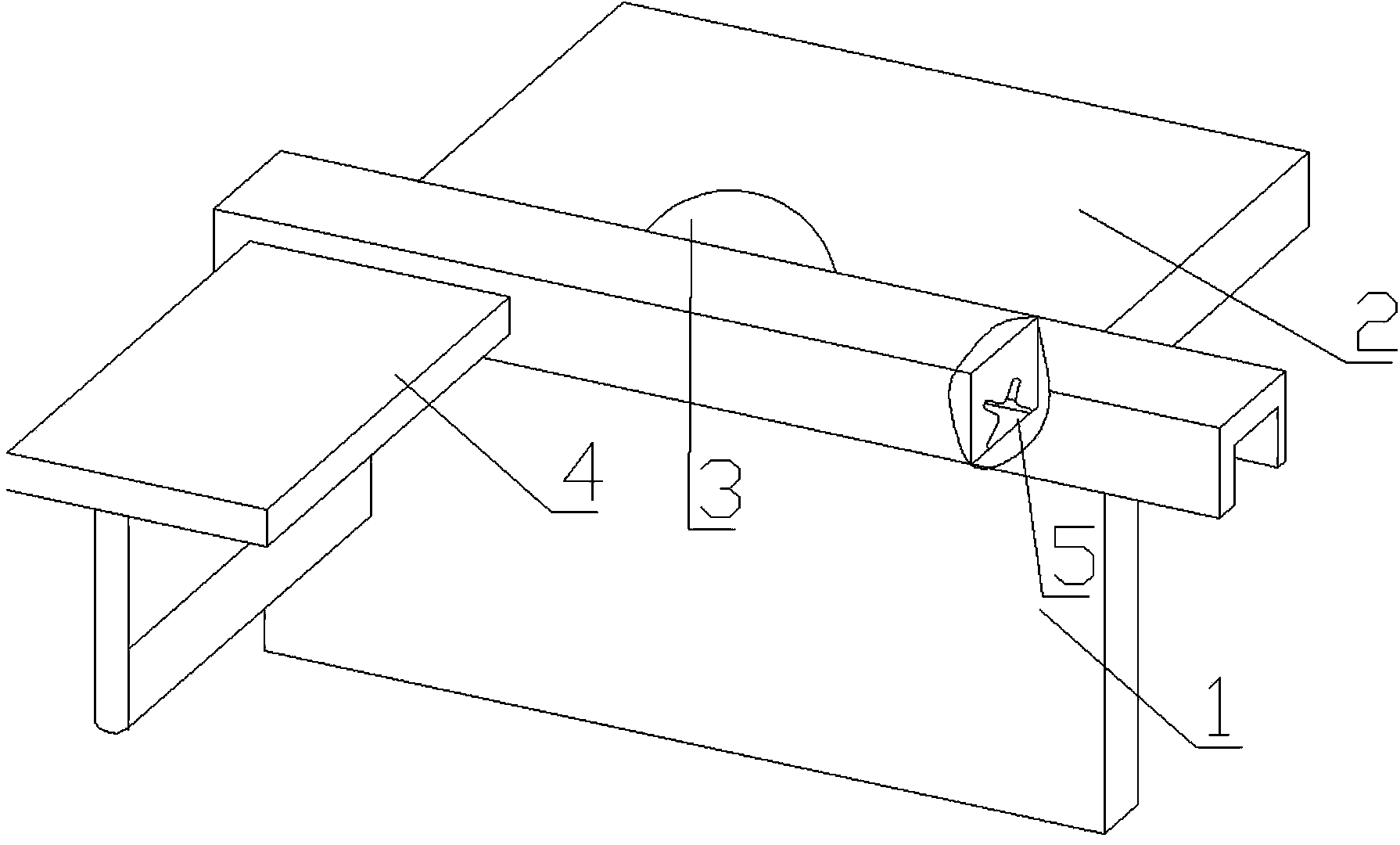

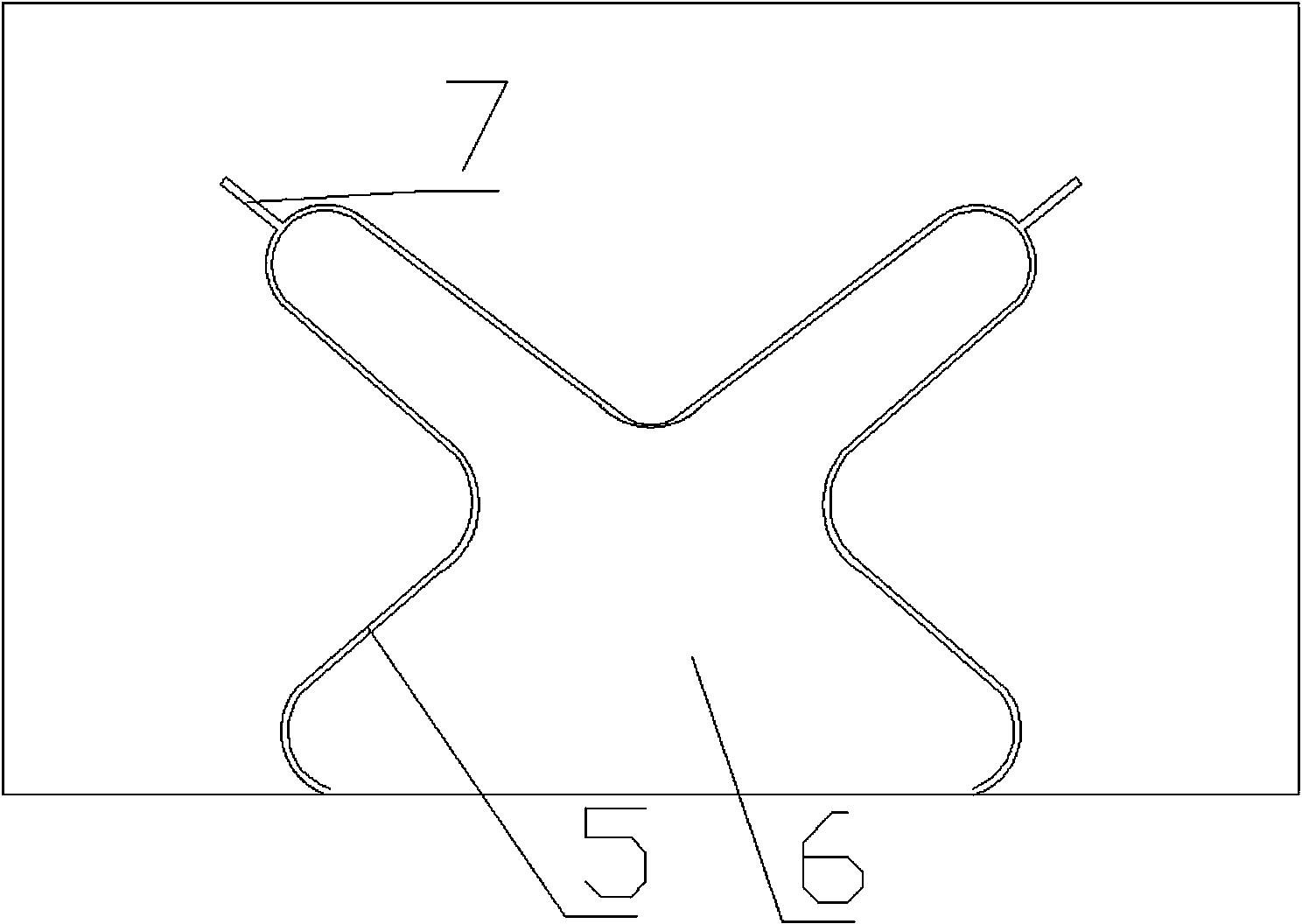

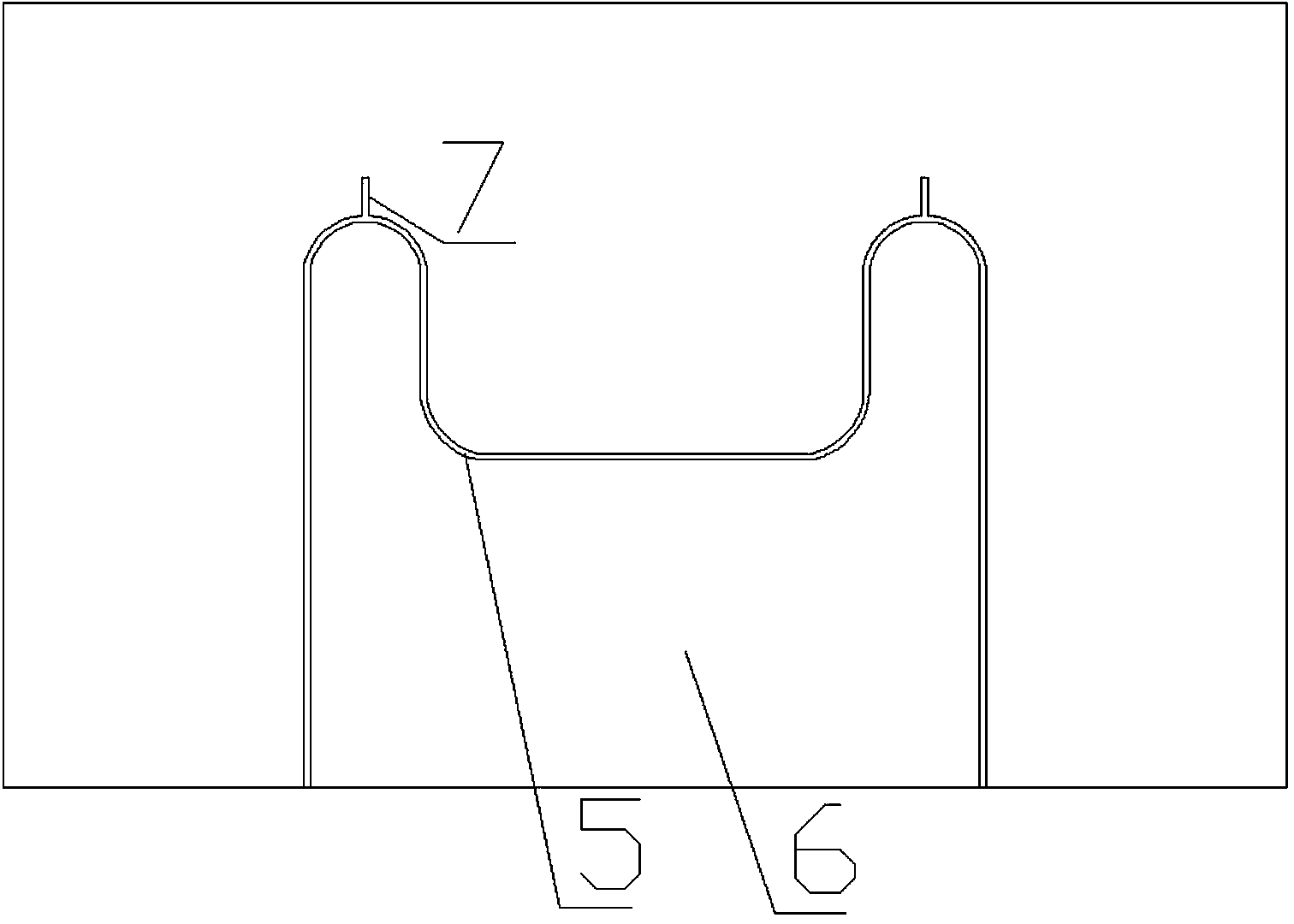

High-stability sliding table saw

InactiveCN103878828AImprove sawing efficiencyExtended service lifeCircular sawsEngineeringMechanical engineering

The invention discloses a high-stability sliding table saw which is characterized by comprising a machine frame (1) of the sliding table saw. A working table top (2) and a movable table top (4) are arranged on the machine frame (1), a saw web (3) is arranged on the working table top (2), the movable table top (4) slides on the machine frame (1) through a sliding groove (5) and a guide rail (6), and the cross section of the sliding groove (5) and the cross section of the guide rail (6) are in X shapes or I shapes. According to the sliding table saw, the cross section of the sliding groove and the cross section of the guide rail are in the X shapes or the I shapes, two protruding end faces of the guide rail are matched with the sliding groove, when the sliding table saw is used, even if the guide rail is abraded, gaps between the end faces and the sliding groove are enlarged, but when the sliding groove is matched with the guide rail in a positioned mode, the distance between the two protruding end faces is constant, and the good fixing effect can still be achieved. Compared with the prior art, the high-stability sliding table saw is simple in structure, the service life of the guide rail can be greatly prolonged, the stability of the guide rail can be greatly improved, and the saw cutting efficiency of the high-stability sliding table saw is improved.

Owner:HUZHOU CITY NANXUN HENGLI WOODEN PROD FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com