Wood floor stacking machine and floor cutting production line

A palletizer and wooden floor technology, which is applied in the field of wooden floor palletizers and panel cutting production lines, can solve the problems of low handling efficiency, heavy wooden floor texture, and low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

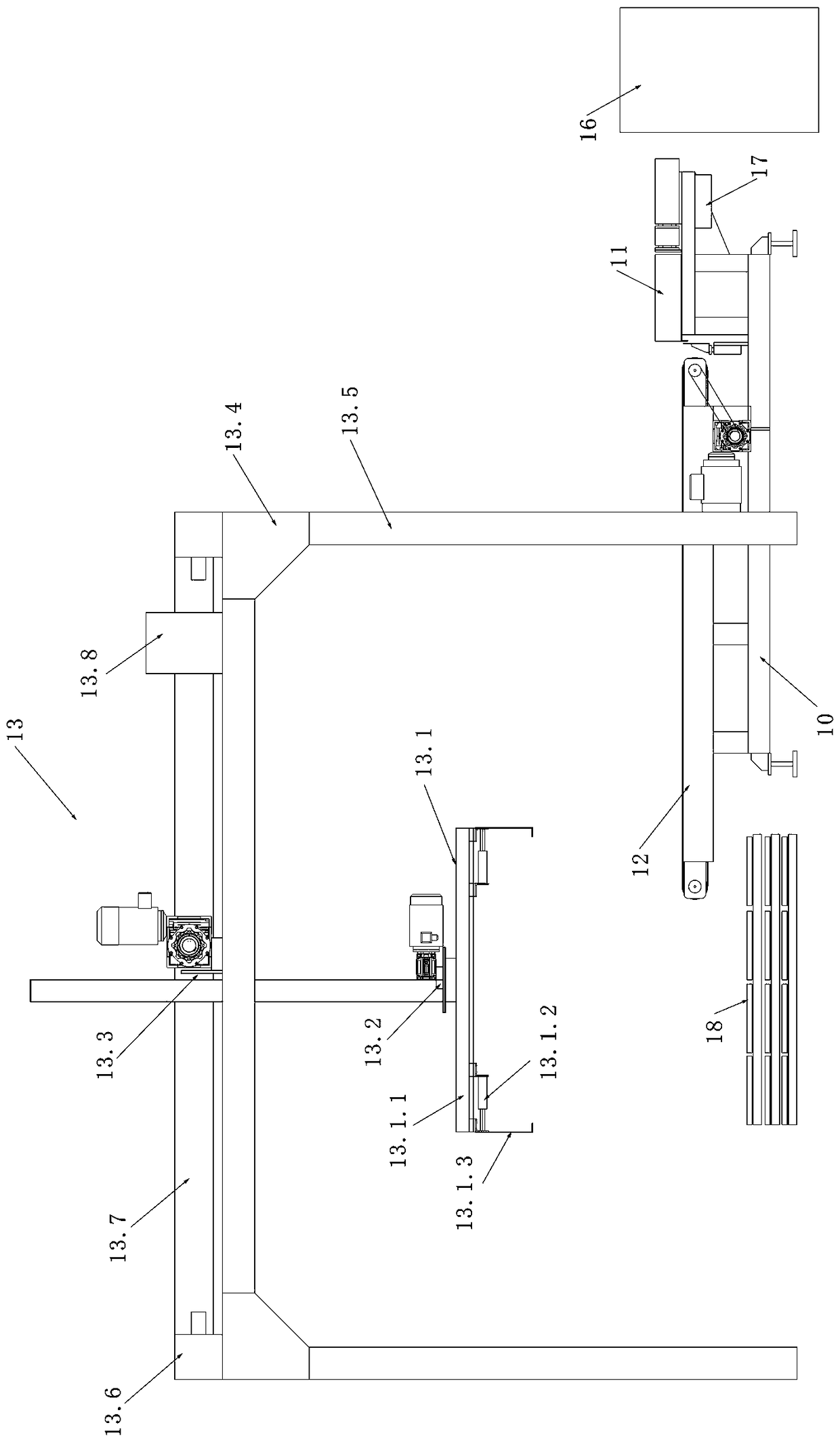

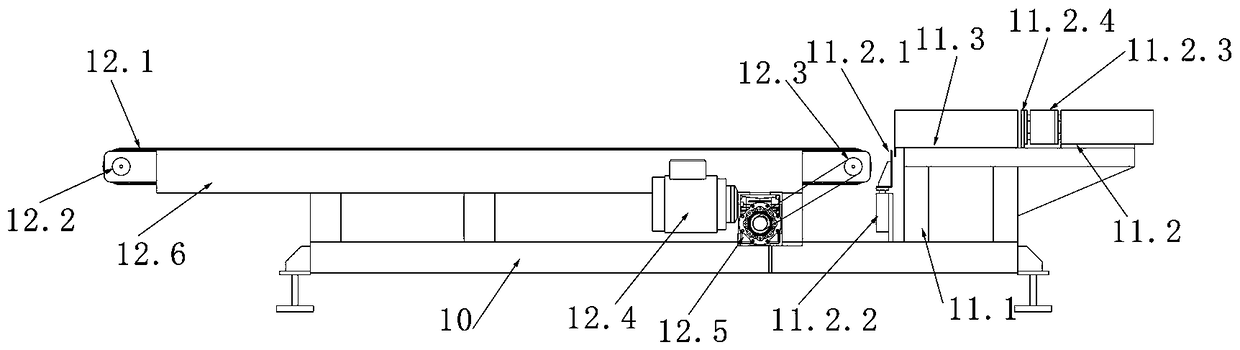

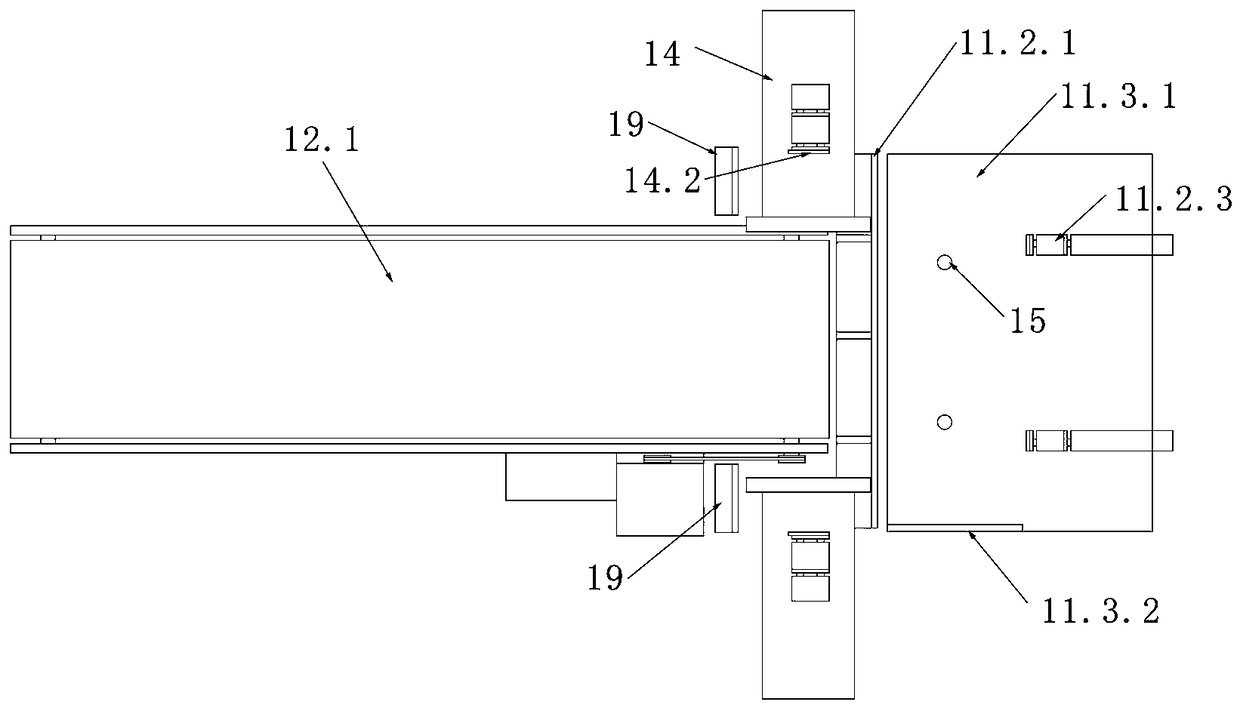

[0056] As shown in 1-16, the wooden floor palletizer includes a base 10, a receiving board mechanism 11, a board feeding mechanism 12, and a palletizing mechanism 13. The base 10 is equipped with a board feeding mechanism 12 and a receiving board mechanism. 11. The front end of the plate feeding mechanism 12 is the conveying end, and the rear end is the output end. The receiving plate mechanism 11 is located in front of the sending end of the plate feeding mechanism 12, and the stacking mechanism 13 is located above the output end of the plate feeding mechanism 12. The receiving plate mechanism 11 includes The receiving platform 11.1, the first alignment device 11.2, and the front receiving platform 11.3. The receiving platform 11.1 is equipped with a first alignment device 11.2 and a front receiving platform 11.3. The first alignment device 11.2 includes a first alignment baffle 11.2. 1. The first alignment baffle lifting device 11.2.2, the alignment push plate A pushing device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com