Numerically controlled diamond wire saw slicing machine

A diamond wire and slicing machine technology, which is applied to work accessories, fine working devices, stone processing equipment, etc., can solve the problems of complex processes, low sawing efficiency of wire saw slicing machines, and mortar splashing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

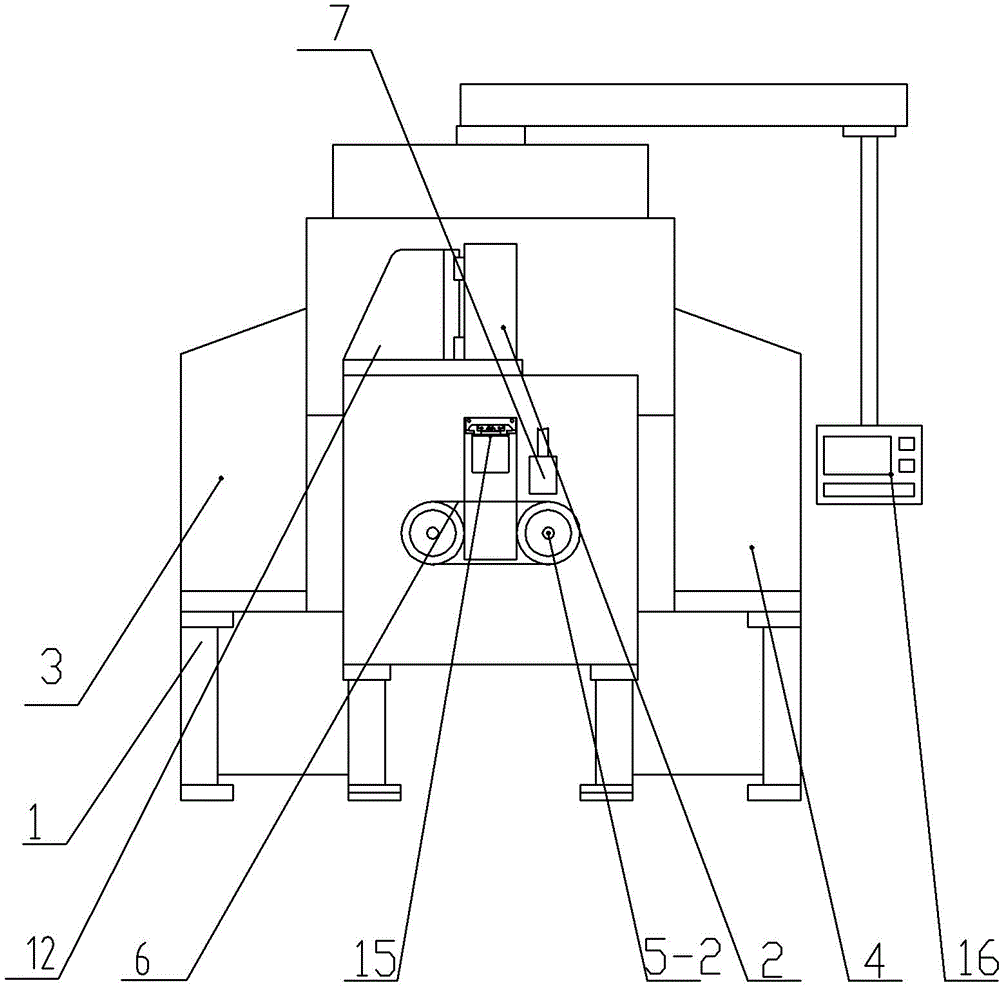

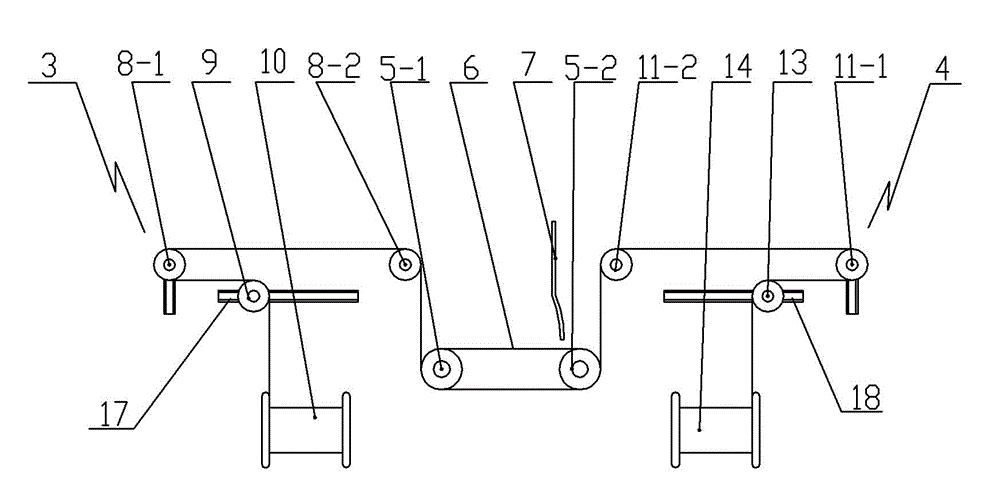

[0009] See figure 1 , figure 2 , a diamond wire saw slicing machine according to the present invention, which includes a frame 1, a workpiece clamping and feeding device 2 arranged on the upper end of the frame, and a wire take-up and winding device 3 arranged on both sides of the bed, a wire winding device In the device 4, guide rollers 5-1 and 5-2 are arranged on both sides of the frame 1, and the diamond wire 6 is wound on the two guide rollers 5-1 and 5-2 successively multiple times while keeping the distance between them. The frame 1 A cooling lubricant nozzle 7 is provided corresponding to the diamond wire 6 on the upper side, and the workpiece clamping and feeding device 2 is fixed on the support 12 of the feeding mechanism.

[0010] The take-up winding device 3 includes the fixed wire pulleys 8-1, 8-2, the wire take-up sliding wire pulley 9 and the wire take-up reel 10, and the pay-off winding device 4 includes the fixed wire pulleys 11-1, 11-1, 11-2. Paying-off sli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com