Self-adaptation controllable vibration metal cutting device and method based on super magnetostriction

A giant magnetostrictive and metal cutting technology, which is applied in the attachments of sawing machines, metal sawing equipment, sawing machine devices, etc. It is difficult to ensure the accuracy of the vibration mechanism and other problems, so as to improve the cooling effect, improve the sawing efficiency, and increase the output power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

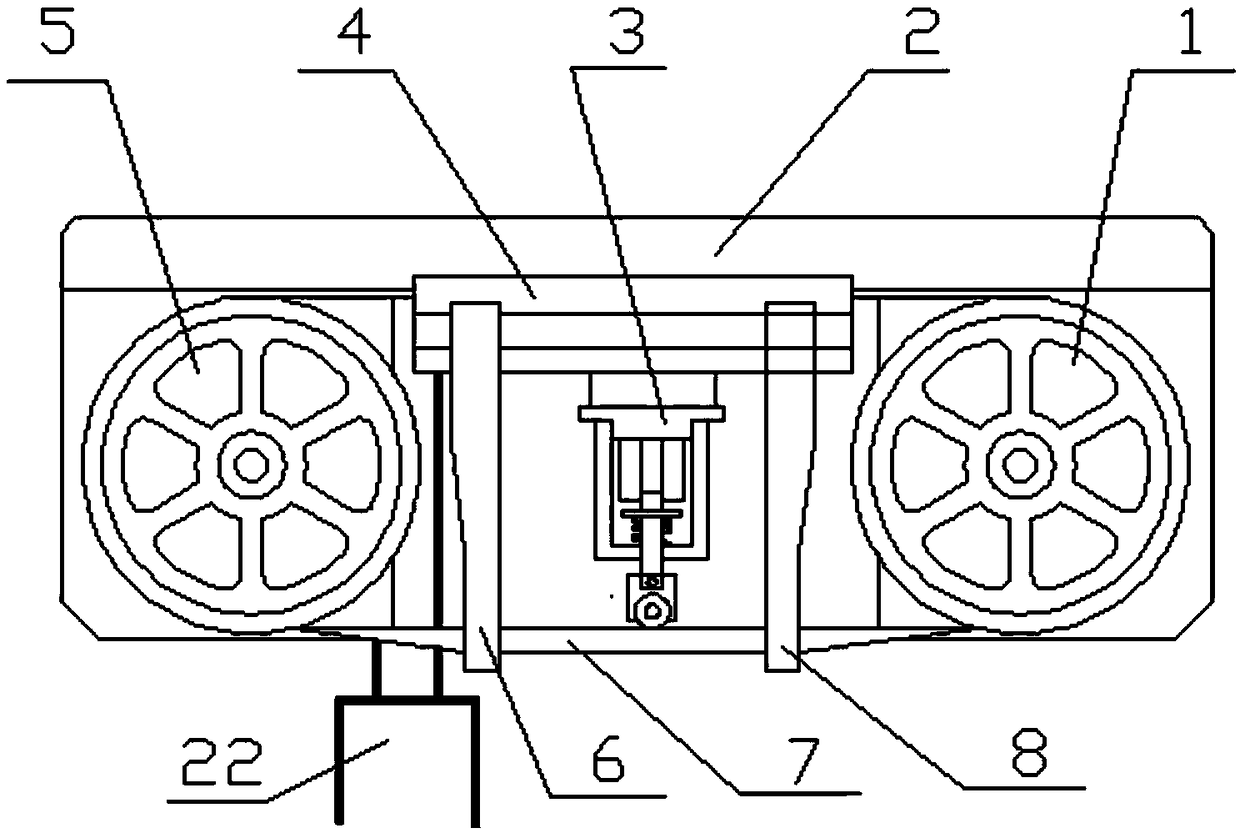

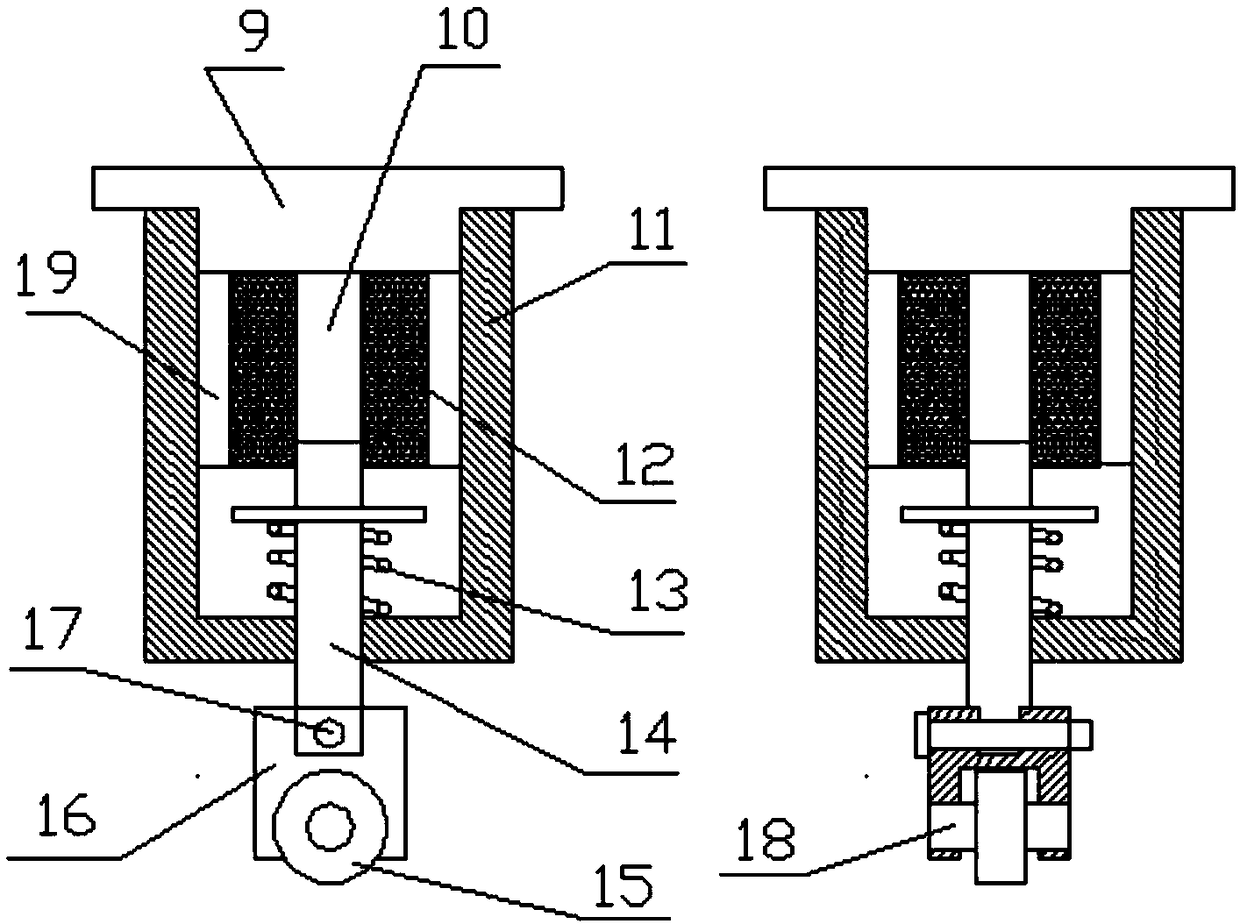

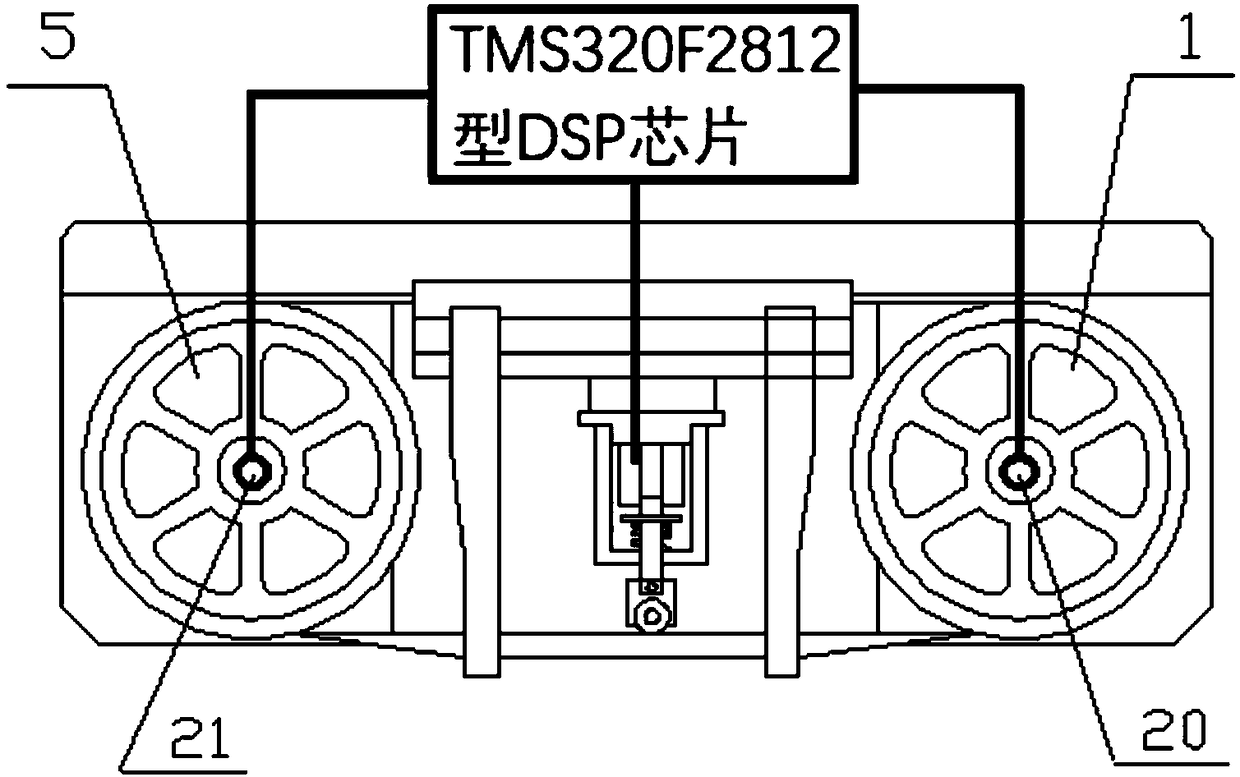

[0032] Such as figure 1 As shown, a driving pulley 1 and a driven pulley 5 are installed on both sides of the saw frame 2 respectively, and a conveyor belt is set on the driving pulley 1 and the driven pulley 5, and a saw blade 7 is installed on the outside of the conveyor belt. A vibration mechanism 3 and a saw beam 4 are installed between the moving pulleys 5, the saw beam 4 is fixed on the saw frame 2, the upper end of the vibration mechanism 3 is fixed on the middle part of the lower end surface of the saw beam 4, and the lower end of the vibration mechanism 3 is connected to the saw blade 7 located below. The back is in rolling contact; the two sides of the vibrating mechanism 3 are respectively provided with a left guide arm 6 and a right guide arm 8, and the upper ends of the left and right guide arms 6, 8 are respectively fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com