High-temperature giant electrostrictive strain ceramic material and preparation method thereof

An electro-strain, ceramic material technology, used in ceramic molding machines, manufacturing tools, etc., can solve the problems of low operating temperature, limited Curie temperature, deterioration of piezoelectric performance, etc., and achieve large strain values, small hysteresis, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

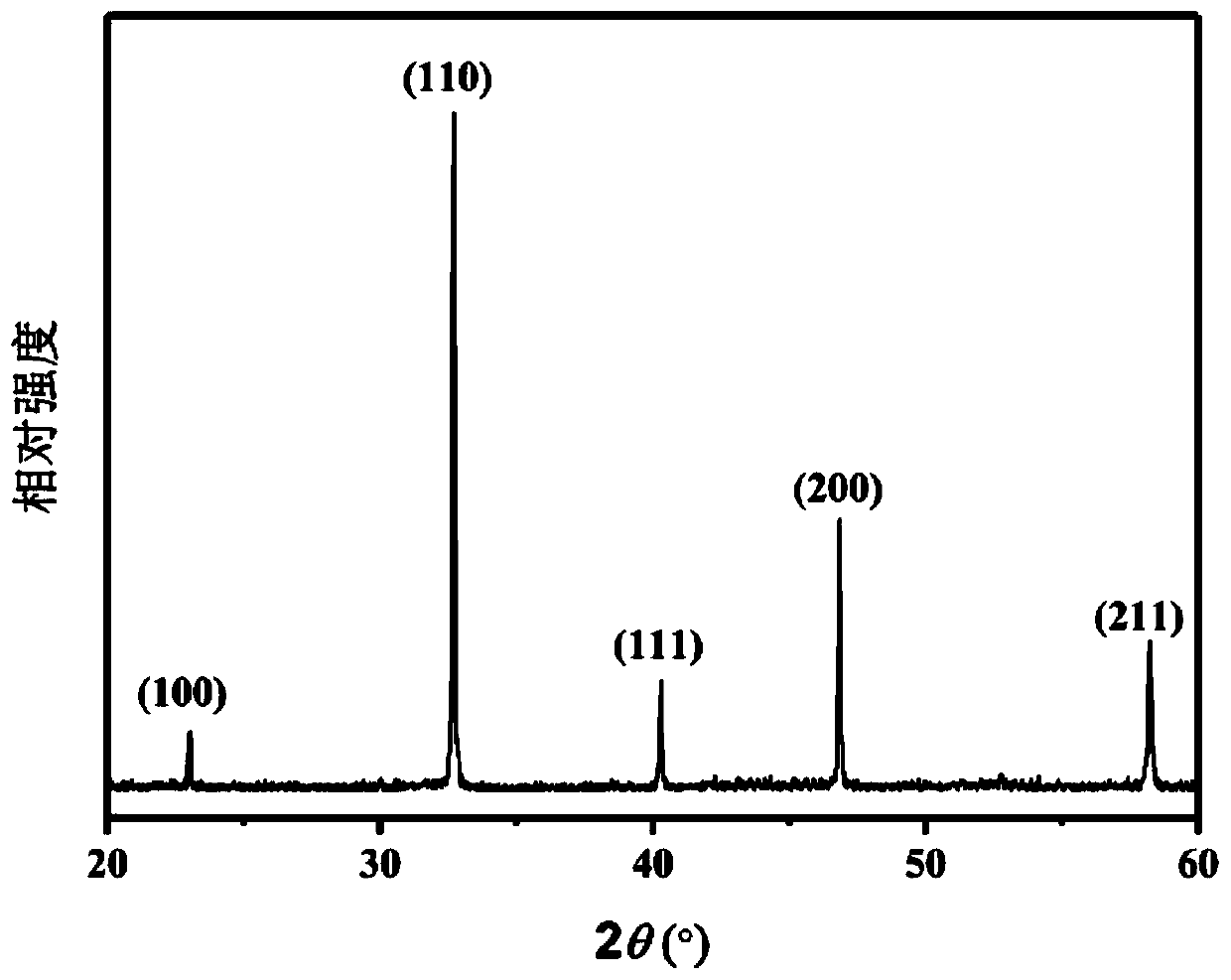

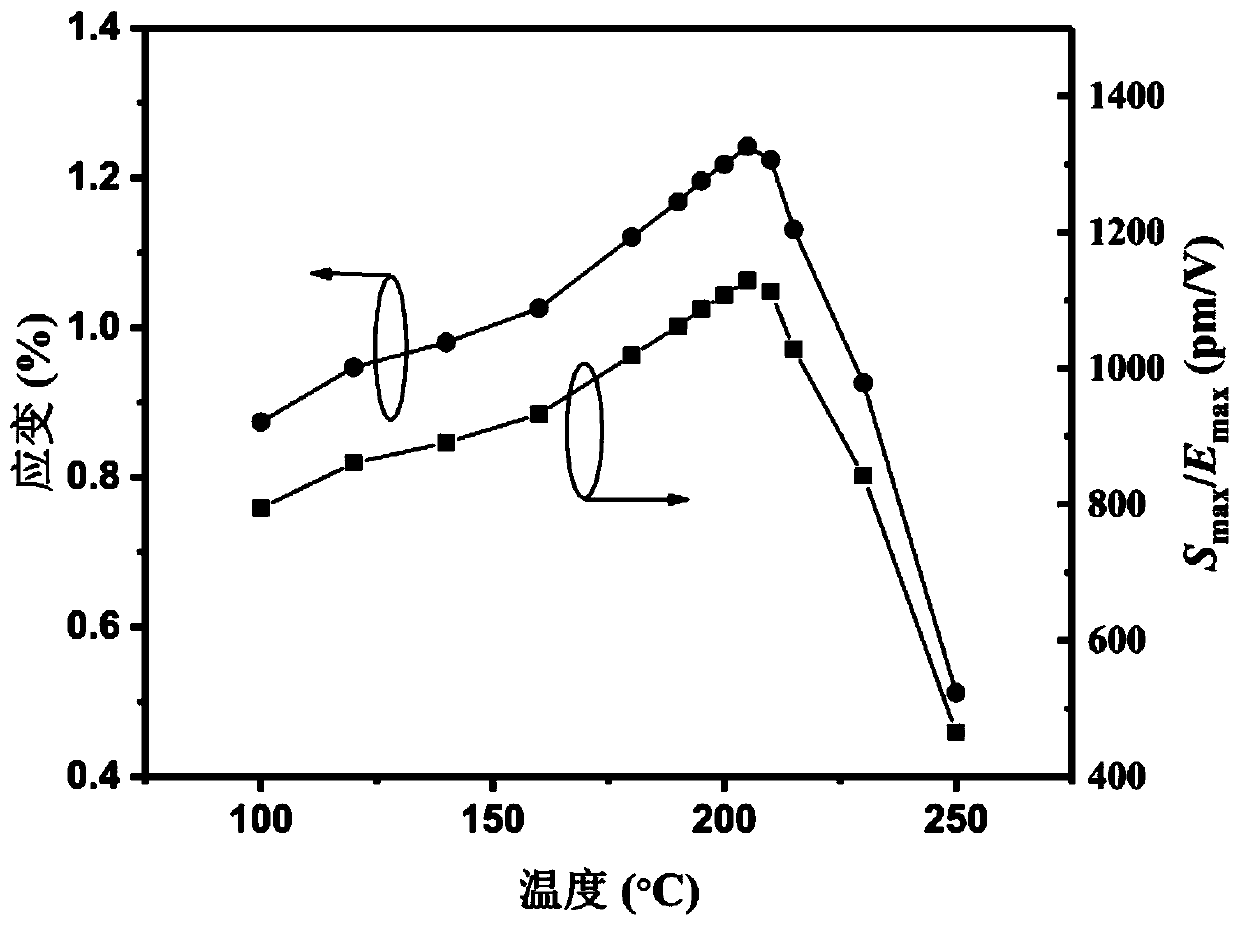

[0018] According to 0.95Bi 0.5 Na 0.5 TiO 3 -0.05Bi 0.1 Na 0.7 NbO 3 The chemical composition of bismuth oxide, sodium carbonate, titanium dioxide (rutile phase) and niobium oxide and other raw materials are weighed, and the ceramics are sintered by the traditional solid-state reaction method.

[0019] According to Bi 0.5 Na 0.5 TiO 3 (BNT) and Bi 0.1 Na 0.7 NbO 3 (BNN) ratio, weigh the above raw materials, add a suitable amount of alcohol, and carry out planetary ball milling for 4 hours; then dry the slurry, sieve and pre-calcine at 850°C for 2 hours; the obtained BNT and BNN The calcined powder is mixed and ball-milled for 4 hours according to the ratio of 0.95BNT-0.05BNN, dried and sieved, then added with an appropriate amount of polyvinyl alcohol aqueous solution (PVA), ground and granulated, and formed by dry pressing. Finally, debinding the green body at 600°C for 2 hours, and then sintering at 1080°C for 2 hours to obtain the ceramic material with the desire...

Embodiment 2

[0022] According to 0.925Bi 0.5 Na 0.5 TiO 3 -0.075Bi 0.1 Na 0.7 NbO 3 The chemical composition of bismuth oxide, sodium carbonate, titanium dioxide (rutile phase) and niobium oxide and other raw materials are weighed, and the ceramics are sintered by the traditional solid-state reaction method.

[0023] According to Bi 0.5 Na 0.5 TiO 3 (BNT) and Bi 0.1 Na 0.7 NbO 3 (BNN) ratio, weigh the above raw materials, add a suitable amount of alcohol, and carry out planetary ball milling for 4 hours; then dry the slurry, sieve and pre-calcine at 850°C for 2 hours; the obtained BNT and BNN The calcined powder was mixed and ball-milled for 4 hours according to the ratio of 0.925BNT-0.075BNN. After drying and sieving, an appropriate amount of polyvinyl alcohol aqueous solution (PVA) was added, ground and granulated, and formed by dry pressing. Finally, debinding the green body at 600°C for 2 hours, and then sintering at 1080°C for 2 hours to obtain the ceramic material with the...

Embodiment 3

[0026] According to 0.9Bi 0.5 Na 0.5 TiO 3 -0.1Bi 0.1 Na 0.7 NbO 3 The chemical composition of bismuth oxide, sodium carbonate, titanium dioxide (rutile phase) and niobium oxide and other raw materials are weighed, and the ceramics are sintered by the traditional solid-state reaction method.

[0027] According to Bi 0.5 Na 0.5 TiO 3 (BNT) and Bi 0.1 Na 0.7 NbO 3(BNN) ratio, weigh the above raw materials, add a suitable amount of alcohol, and carry out planetary ball milling for 4 hours; then dry the slurry, sieve and pre-calcine at 850°C for 2 hours; the obtained BNT and BNN The calcined powder is then mixed and ball milled for 4 hours according to the ratio of 0.9BNT-0.1BNN, dried and sieved, then added with an appropriate amount of polyvinyl alcohol aqueous solution (PVA), ground and granulated, and formed by dry pressing. Finally, debinding the green body at 600°C for 2 hours, and then sintering at 1080°C for 2 hours to obtain the ceramic material with the desire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com