Blast hole inner multi-point energy-gathered micro perforation type blasting method and installation structure thereof

A technology of installation structure and blast hole, which is applied in blasting, blasting barrels, weapon accessories, etc., can solve the problems of inconspicuous single consumption effect of explosives, small direct contact area, and increased blasting cost, etc., and achieves simple and easy implementation method, Easy to accept, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

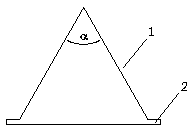

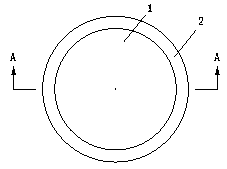

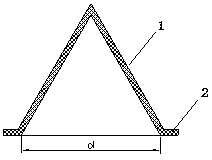

[0071] In a quarry, the stone is quarried by the medium and deep hole step blasting method. The rock is medium-hard sandstone. The diameter of the blasthole 3 is 115mm, the depth of the blasthole is 8m, and the filling is 3m. Charge 6 adopts No. 2 rock emulsion explosive with a specification of Φ70mm-2000g. Three rows of blastholes are arranged in one blasting, and the holes are arranged in a plum blossom pattern. The layout plan of the blastholes is as follows Figure 4 shown. The cone apex angle α of the energy gathering cover is taken as 60°, and the diameter of the bottom circle refers to the formula Select, actually take d = 40mm, and take 5mm for the blank holder width. The plan view of the energy-gathering hole of the energy-gathering cover is as follows: Figure 5 shown. A shaped charge pack of explosives is placed in a shaped cover, and the shaped cover is finally arranged in a folded manner in the blast hole. The structure diagram of the shaped charge in the bla...

Embodiment 2

[0073] A shaped charge pack of explosives is placed in a shaped cover, and the shaped cover is finally arranged in a reciprocating manner in the blast hole. The structure diagram of the shaped charge in the blast hole is shown in Figure 8 shown. All the other conditions are the same as in Example 1.

Embodiment 3

[0075]In the vertical middle and deep hole blasting, because the bottom rock is in a state of bidirectional or multidirectional stress, and the chassis resistance line is relatively large, the root ridges are often left at the bottom of the blasthole after blasting, and the root ridges need secondary drilling and blasting treatment or mechanical treatment. The cost of blasting is increased, which affects the construction progress. In conventional blasting, the position of the charge center is often lowered by increasing the super-depth, so as to overcome the resistance at the bottom of the step and reduce the root remaining. This approach increases the amount of drilling and charge, thereby greatly increasing the cost of blasting, and cannot completely eliminate the root ridge phenomenon. Combined application of the present invention, the enhanced micro-perforation blasting method can be used at the bottom of the blasthole, and the common micro-perforation blasting method can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com