Intelligent sawing band sawing machine

A band sawing machine and sawing technology, which is applied in the direction of sawing machine, metal sawing equipment, measuring/indicating equipment, etc., can solve the problems of large changes in sawing power, sawing efficiency and low service life of saw blades, and achieve the goal of improving service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

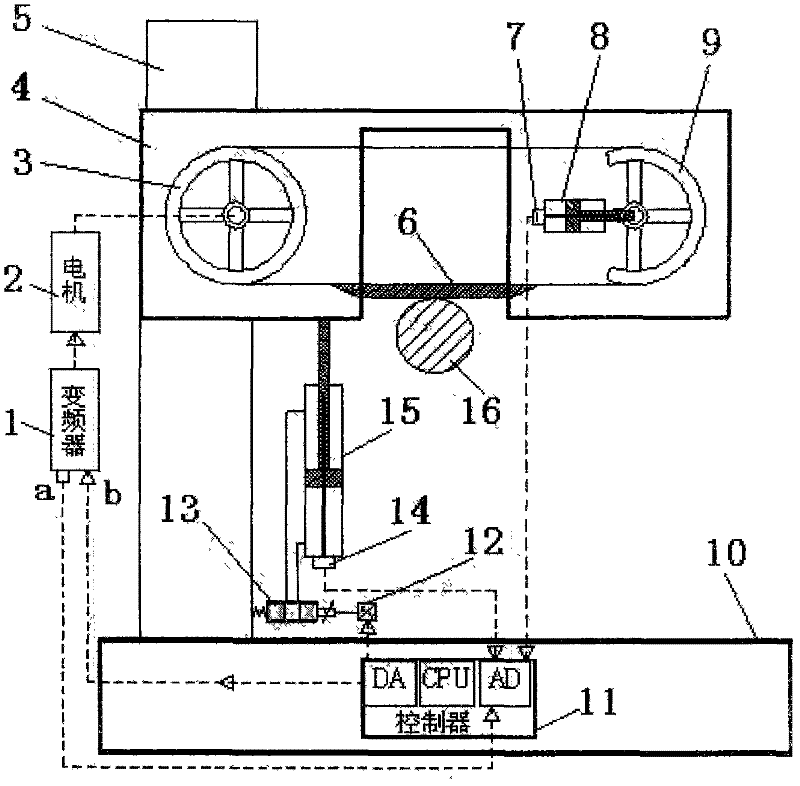

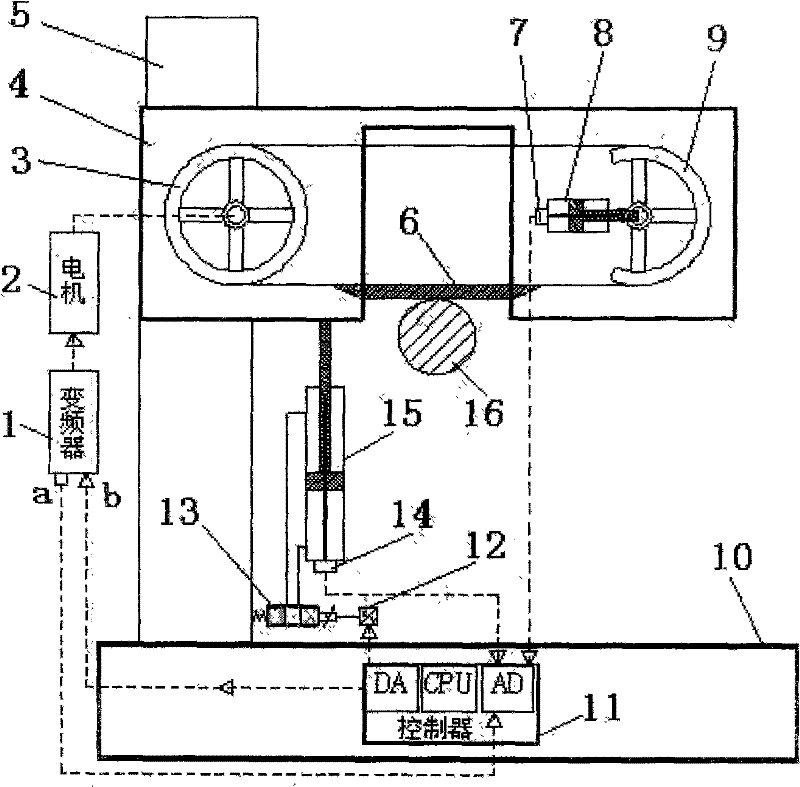

[0008] Notes on drawings: 1-saw disc variable frequency drive, 2-main drive motor, 3-active saw disc, 4-saw frame, 5-column, 6-saw blade, 7-saw blade tensioning hydraulic cylinder pressure sensor, 8-saw blade Tension hydraulic cylinder, 9-driven saw disc, 10-bed, 11-machine controller, 12-drive amplifier circuit board, 13-three-position four-way electro-hydraulic proportional valve, 14-saw frame feed hydraulic cylinder displacement Sensor, 15-saw frame feeding hydraulic cylinder, 16-workpiece.

[0009] Such as figure 1 As shown, an intelligent sawing band sawing machine includes a bed 10, a cantilever saw frame 4 installed on the bed 10, a lifting saw frame feeding hydraulic cylinder 15, a saw blade 6, a main drive motor 2, and an active saw disc 3. Driven saw disc 9, saw blade tensioning hydraulic cylinder 8, saw disc variable frequency drive 1, complete machine controller 11, said complete machine controller 11 includes central processing unit CPU, analog-to-digital AD conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com