Patents

Literature

65results about How to "Realize automatic arrangement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

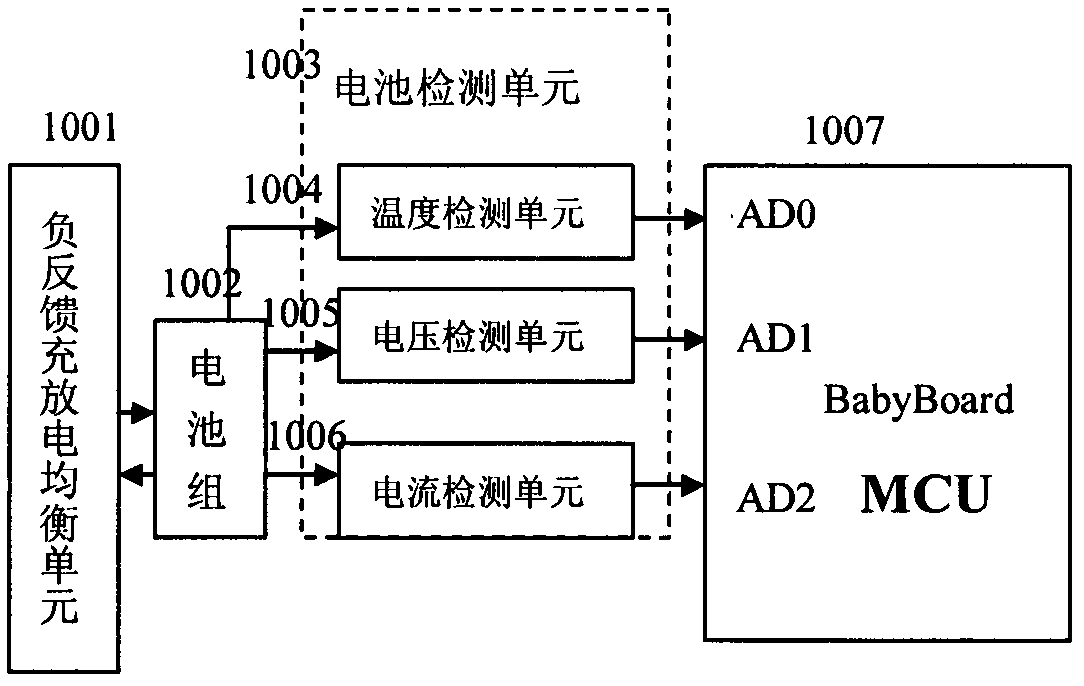

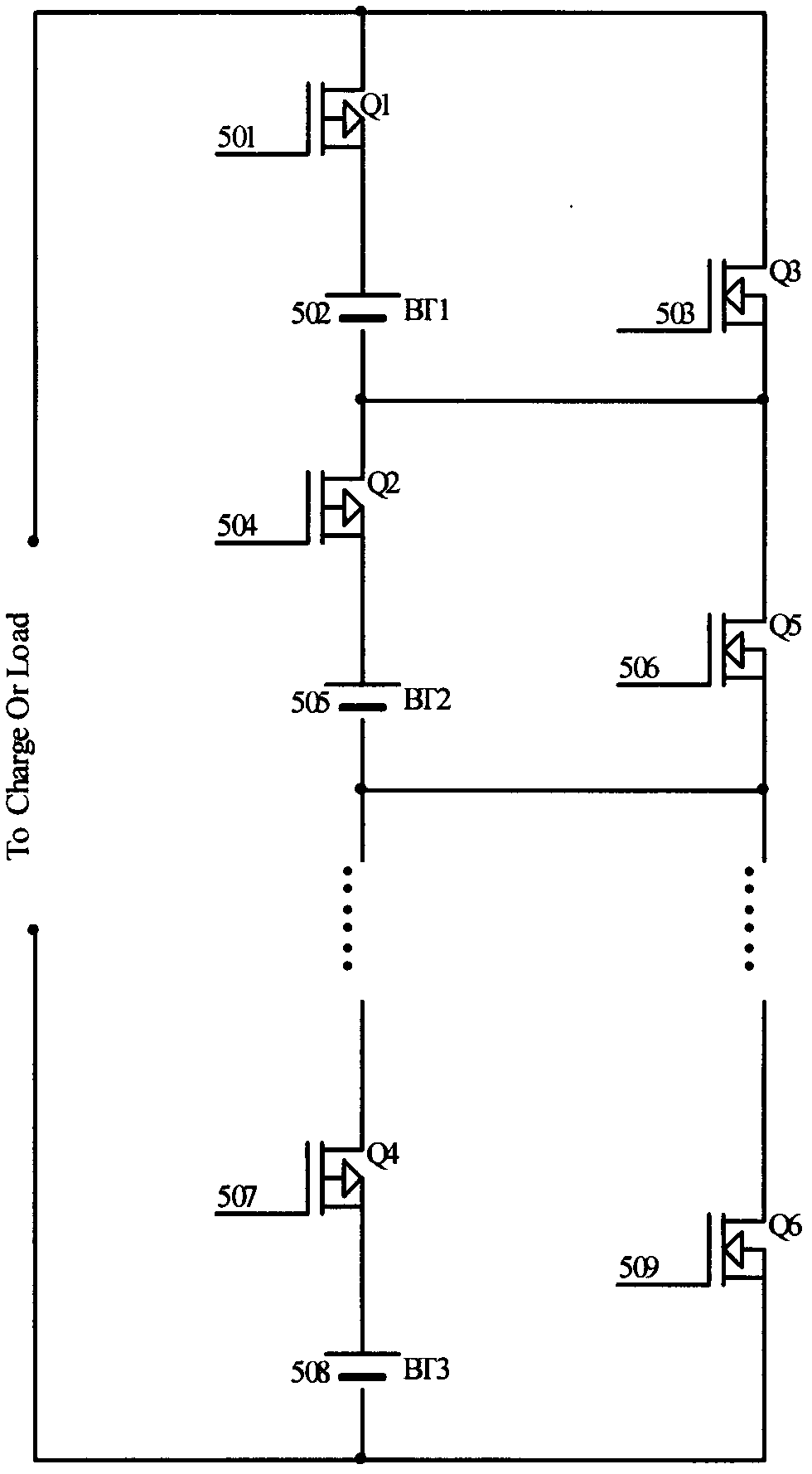

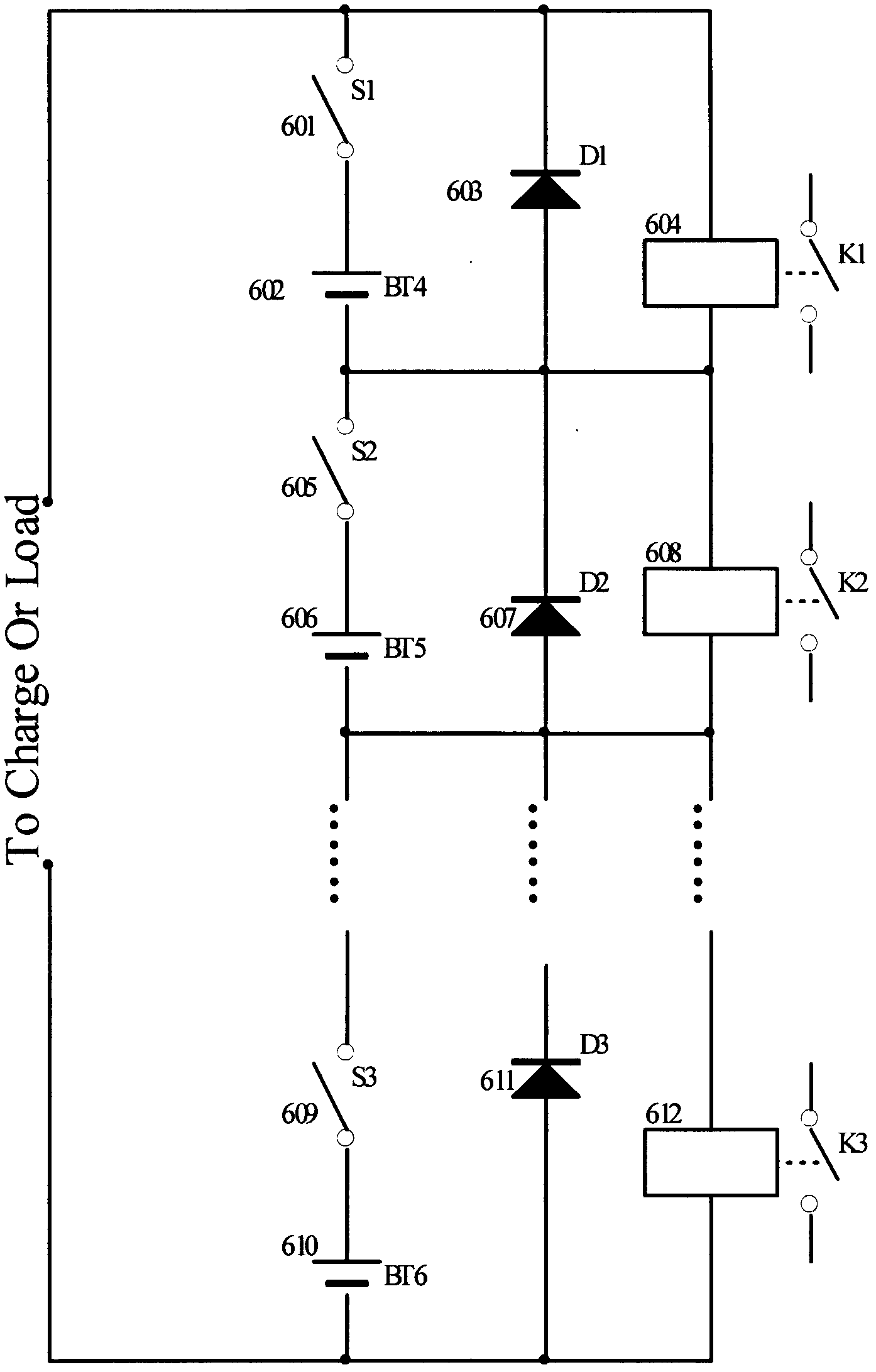

Lithium ion battery management system

InactiveCN102306943AUniform lossImprove protectionBatteries circuit arrangementsElectric powerCapacitanceControl manner

The invention discloses a lithium ion battery management system and a control method thereof, and comprises battery charge and discharge management scheduling, battery information communication and battery life assessment. Adding a battery cell in series or withdrawing the battery cell in a controlled manner is realized by utilizing a switch circuit. Data transmission between series battery cells is realized by utilizing hardware and software forwarding circuits. In a rated charge and discharge condition, through carrying out charge and discharge tests on a lithium ion battery repeatedly, recording charge and discharge times, and voltage curve and battery internal resistance of each charge and discharge operation, constructing a four-dimensional data table, and determining equivalent cycle times and present full charge capacity of the battery by utilizing an interpolation method, an equivalent cycle life of a battery pack is determined. According to the invention, energy transduction devices like an inductance capacitor are not needed, characteristics of batteries in a same battery pack tend to be consistent, a service life of the battery pack is prolonged, overpressure resistant requirements of each component are mitigated, a basic basis of estimating battery full charge capacity and accurate estimation of a battery life is established, and possibility of large scale interchangeability application is provided.

Owner:HEBEI JIANTOU NEW ENERGY CO LTD

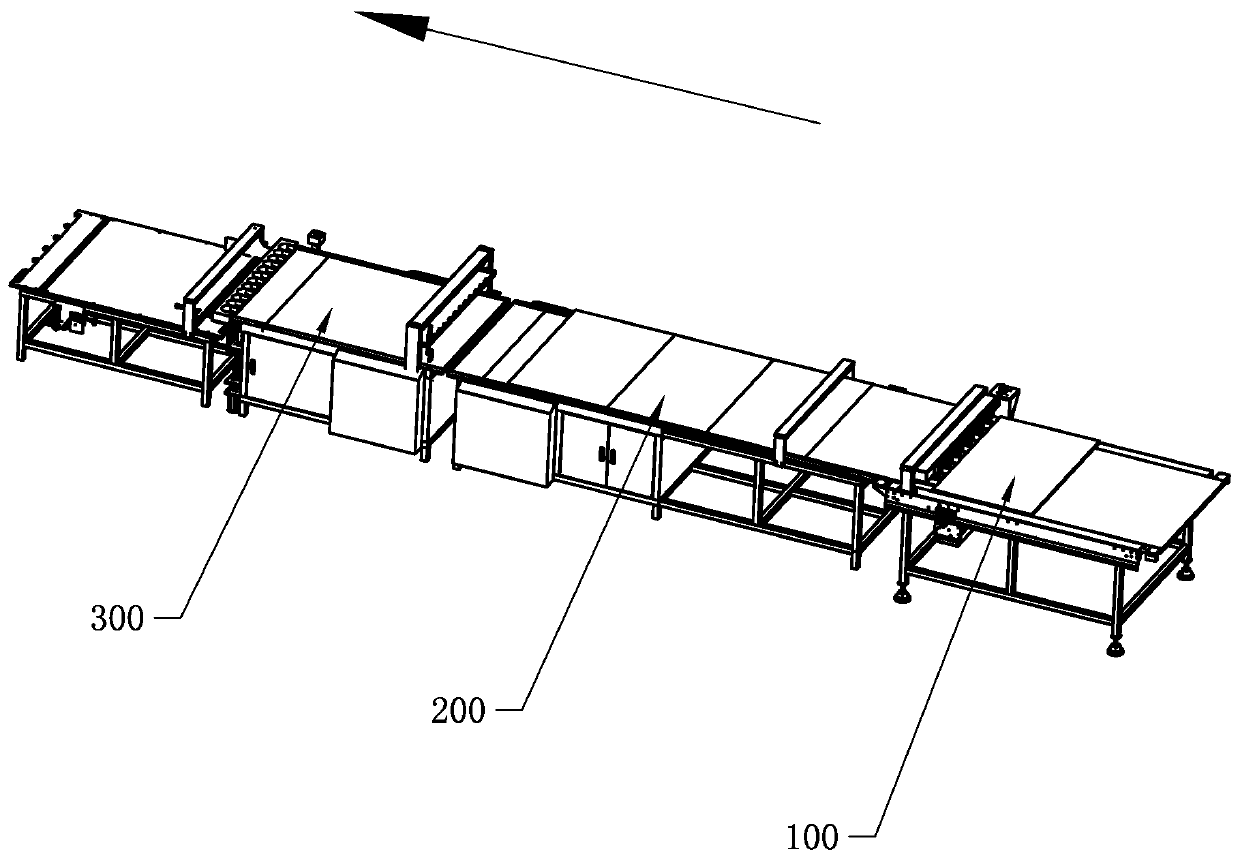

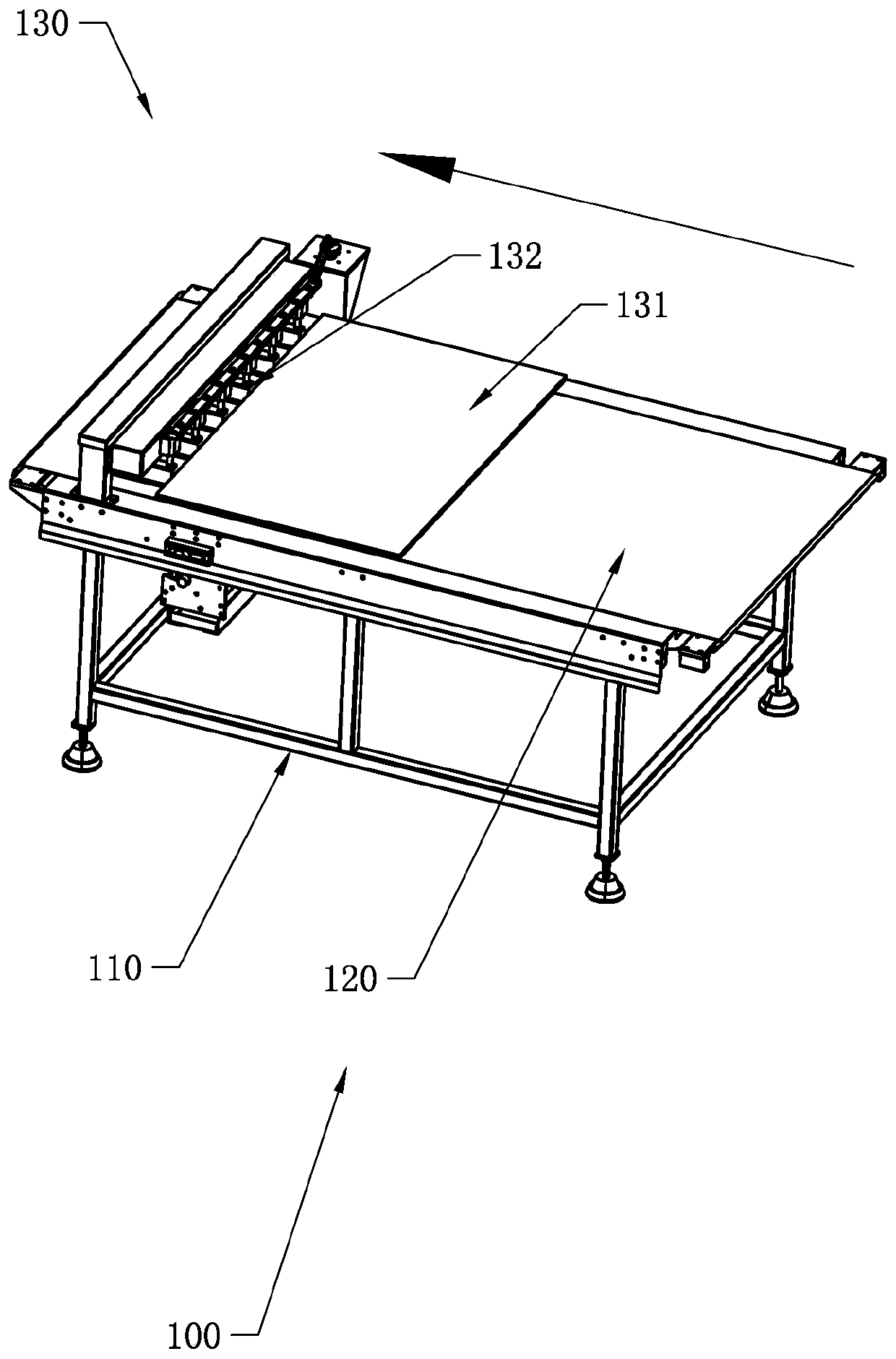

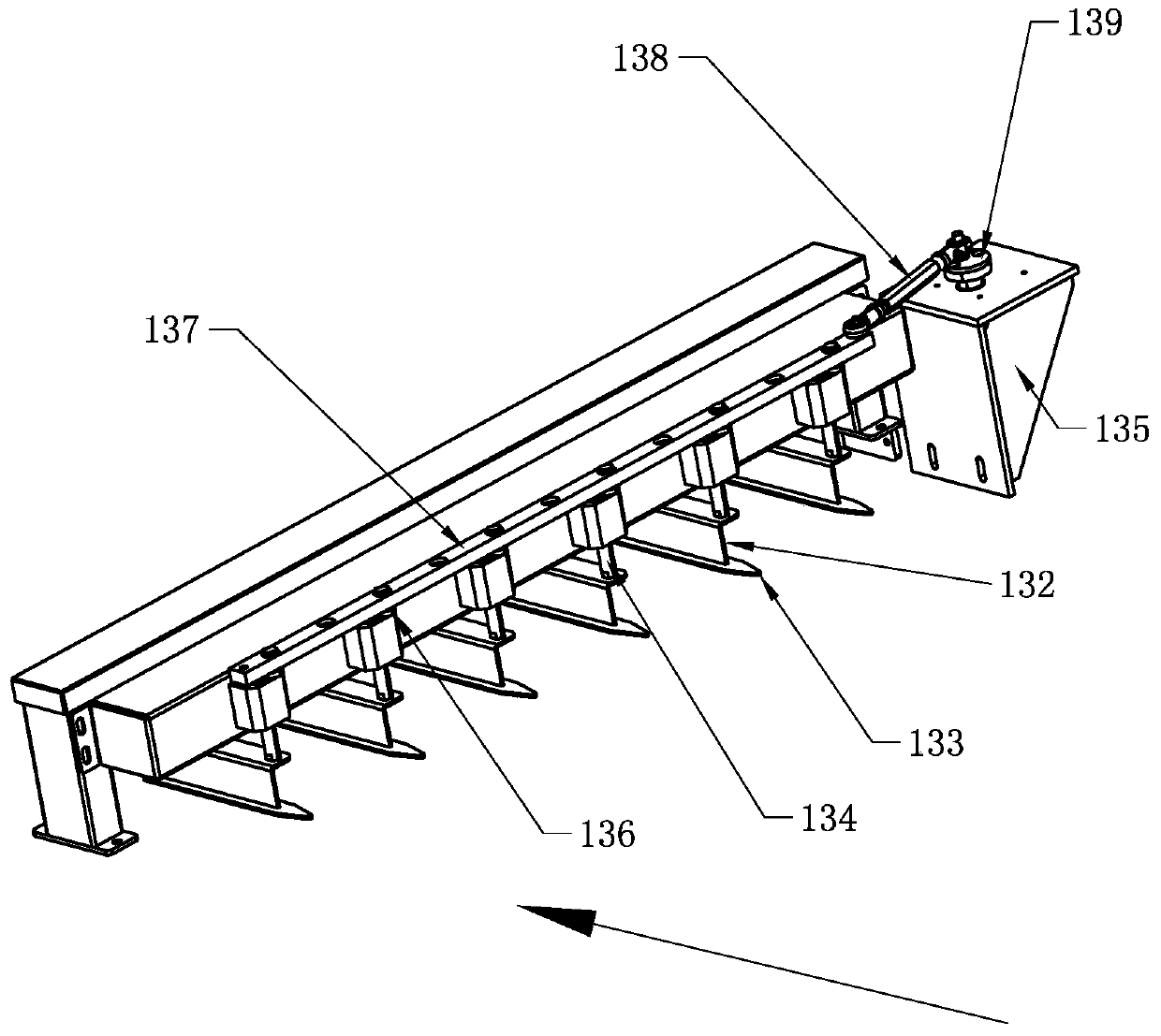

Wood tray manufacture method

InactiveCN101417452AThe nailing position is uniform and beautifulImprove the stabilityWood working apparatusProduction lineUltimate tensile strength

The invention relates to a manufacturing method of wood trays, including the following steps of: forming front components of wood trays; turning over the front components of the wood trays; forming back components of the wood trays at back sides of the front components of the wood trays to produce the wood trays; postprocessing procedures; lining up and stacking the wood trays into a block; and exporting and carrying the whole block of wood trays stacked well into a warehouse. Compared with the prior art, the invention has the advantages that only 4 to 6 operators are needed in the whole production line, which equals the production efficiency of 20 operators with manual operation; the amount of labor can be saved by 70 percent and the production efficiency can be increased by more than 5 times; the labor intensity of workers can be reduced; the wood trays are lined up in order and can be staggered positively and negatively to save space; and single-deck trays can save space by more than 40 percent, site and space can be saved, and all processing equipment can be installed on the production line.

Owner:吴继荣

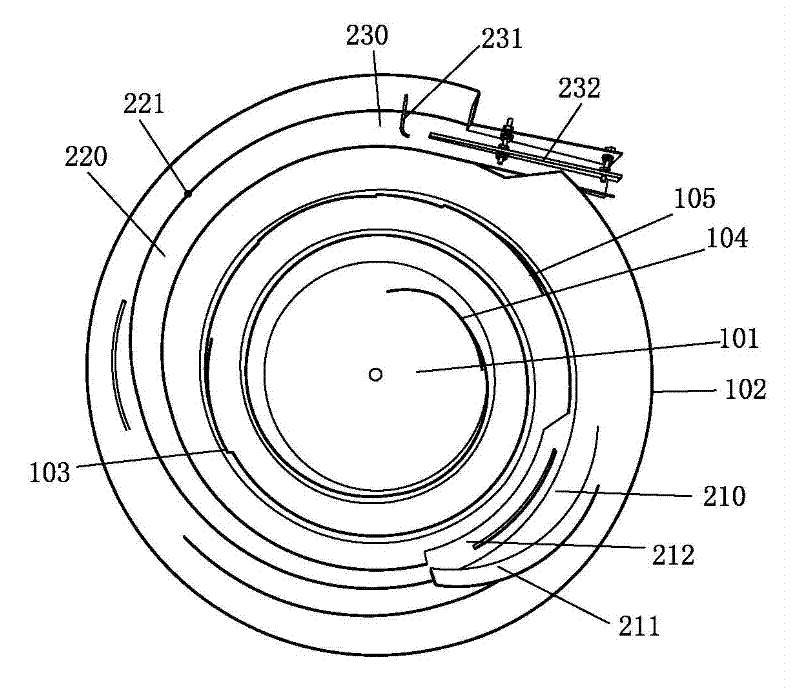

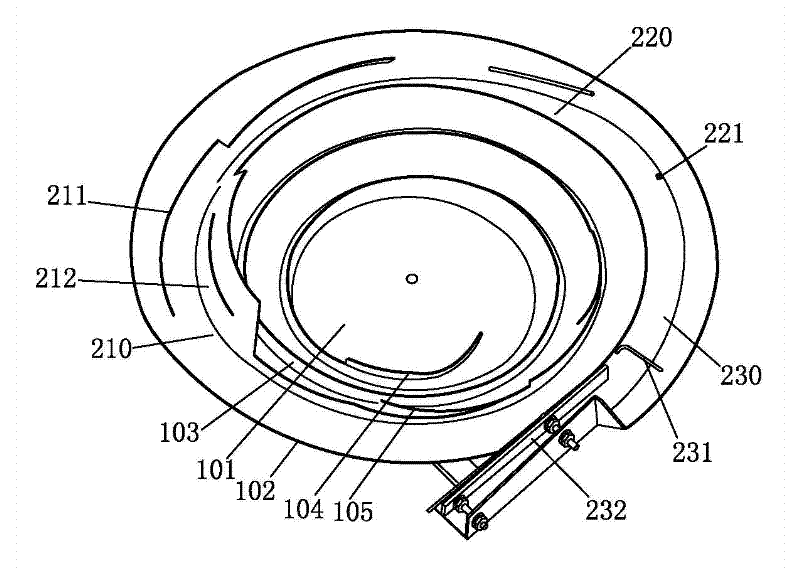

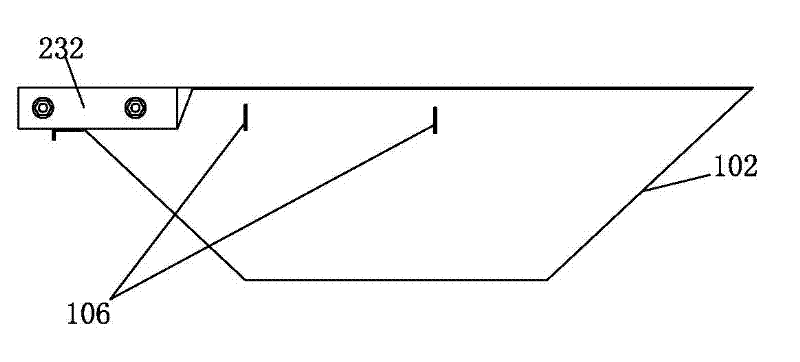

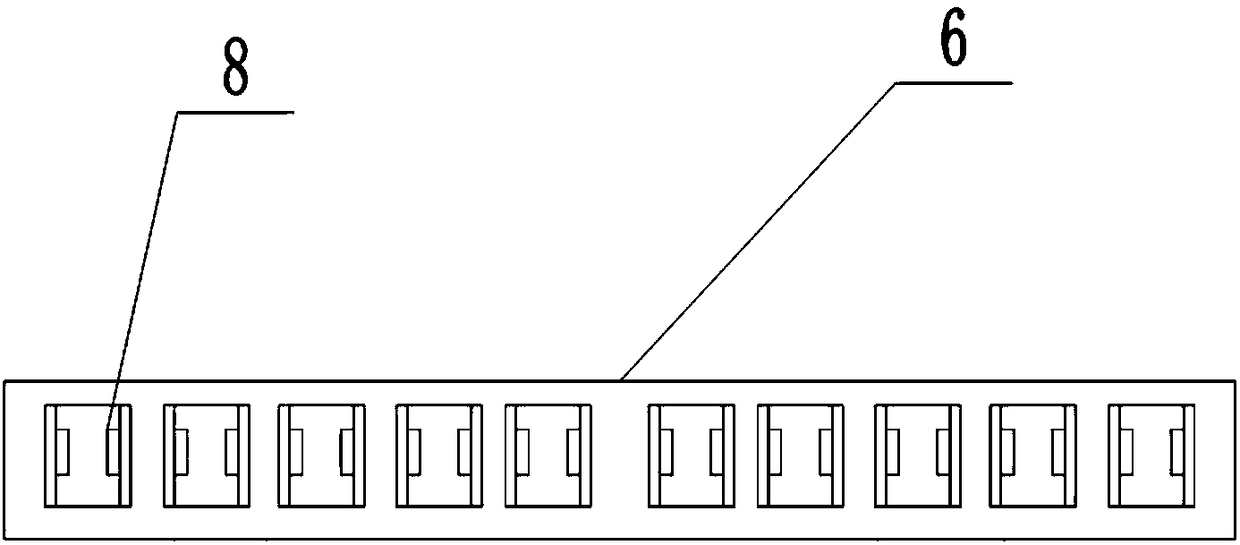

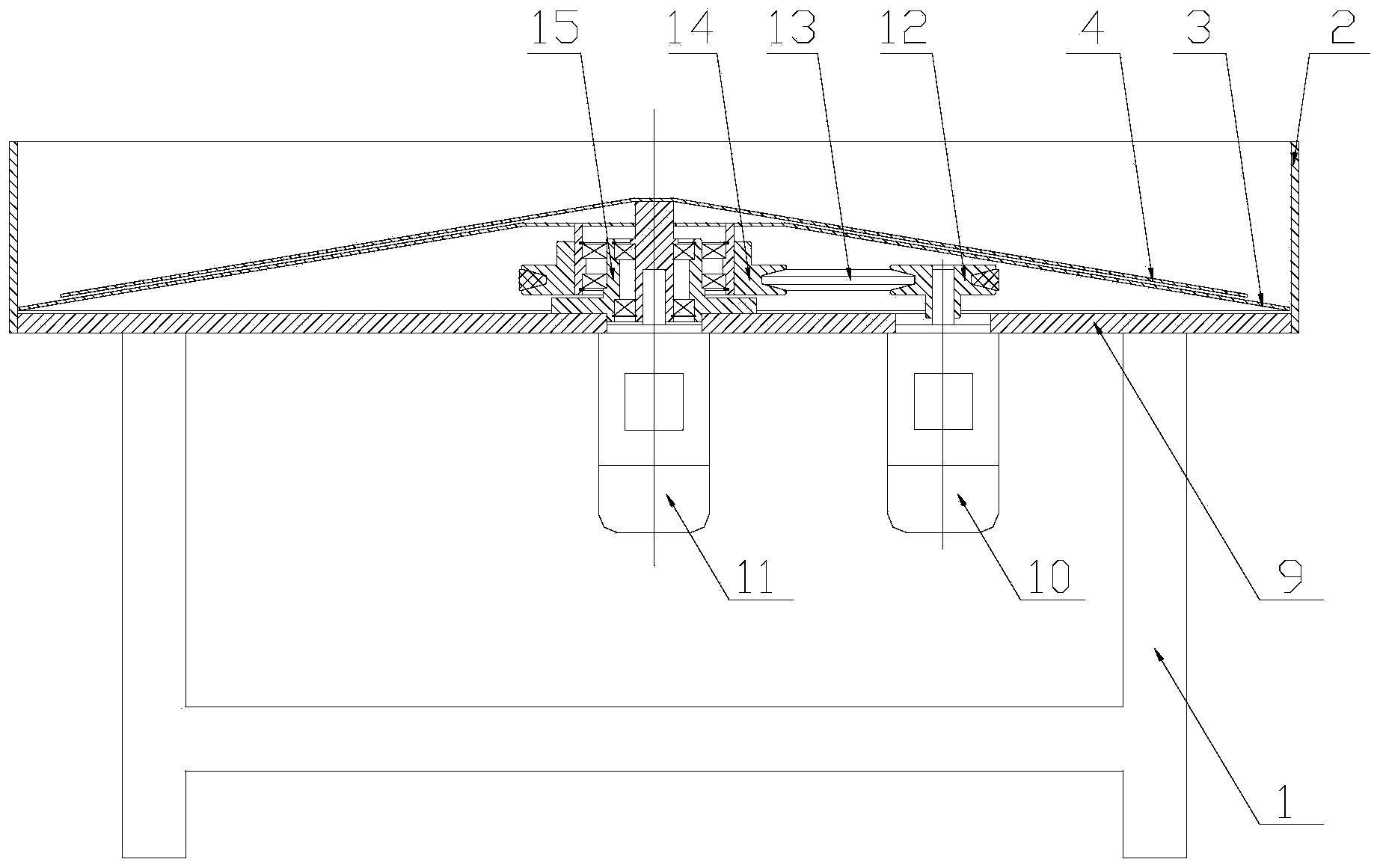

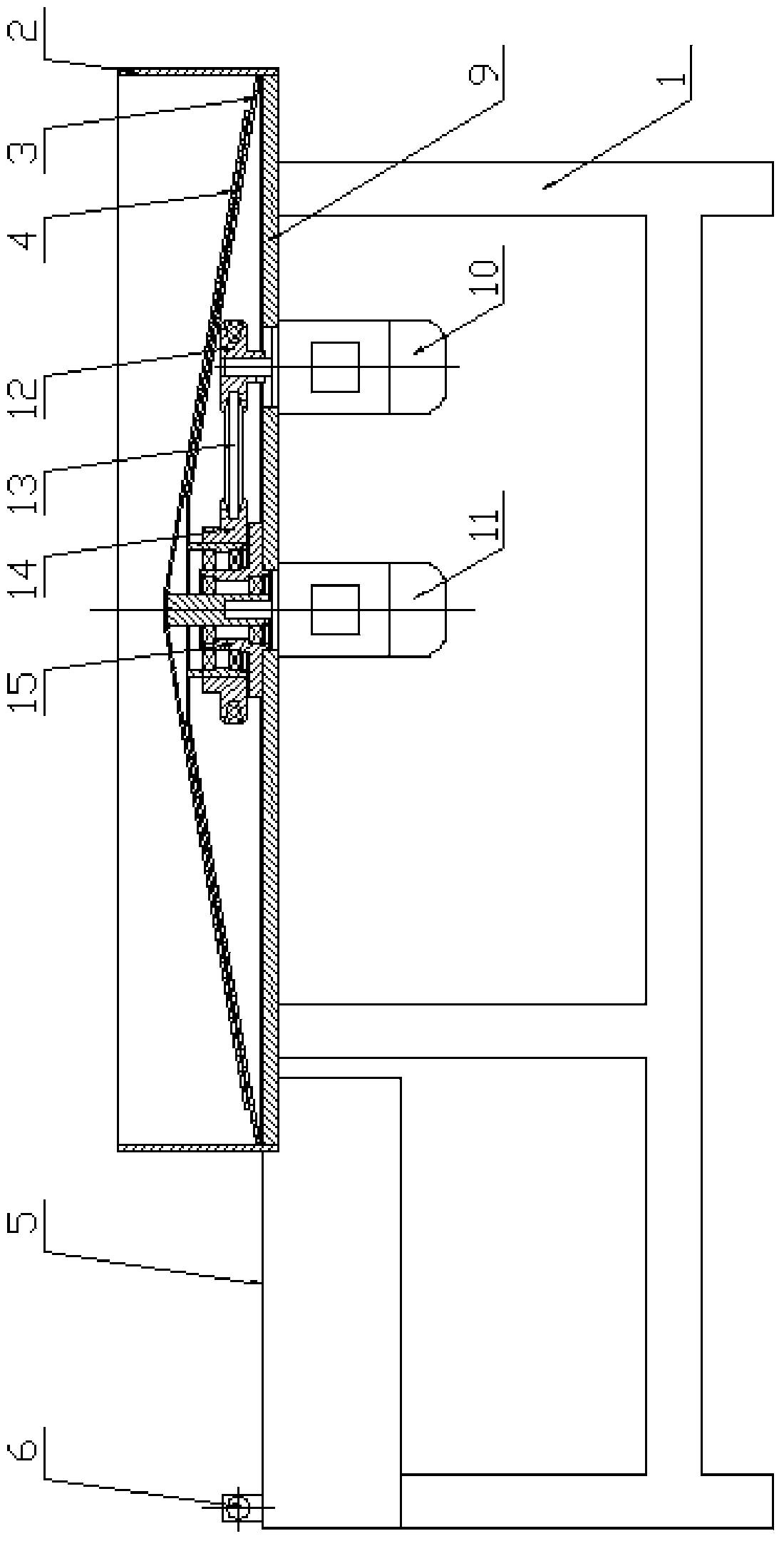

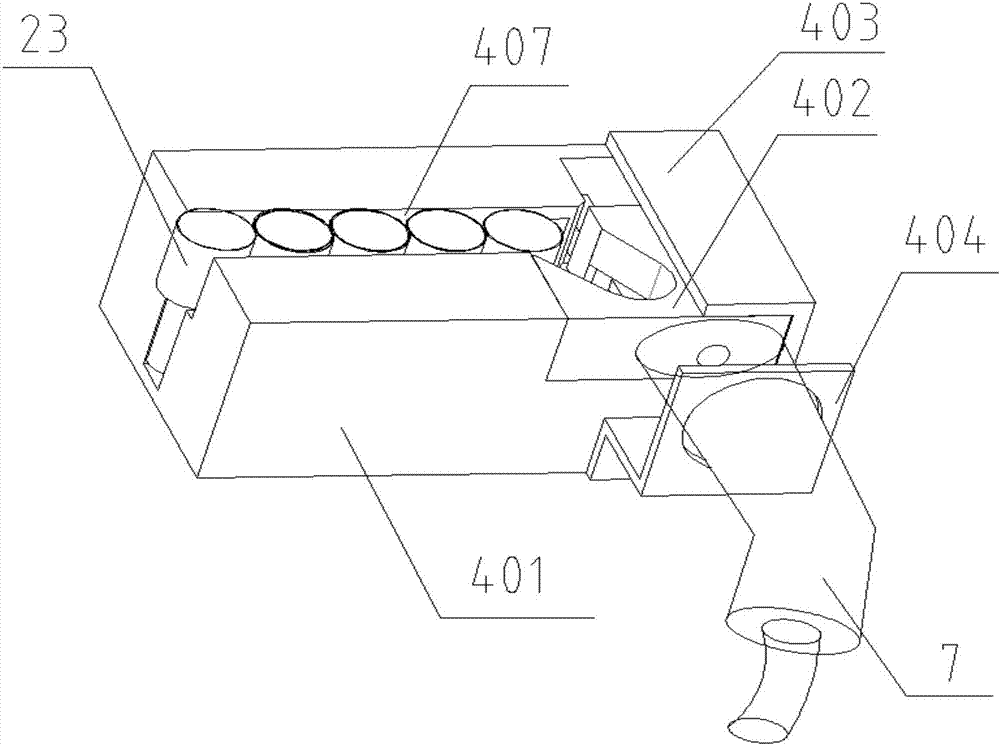

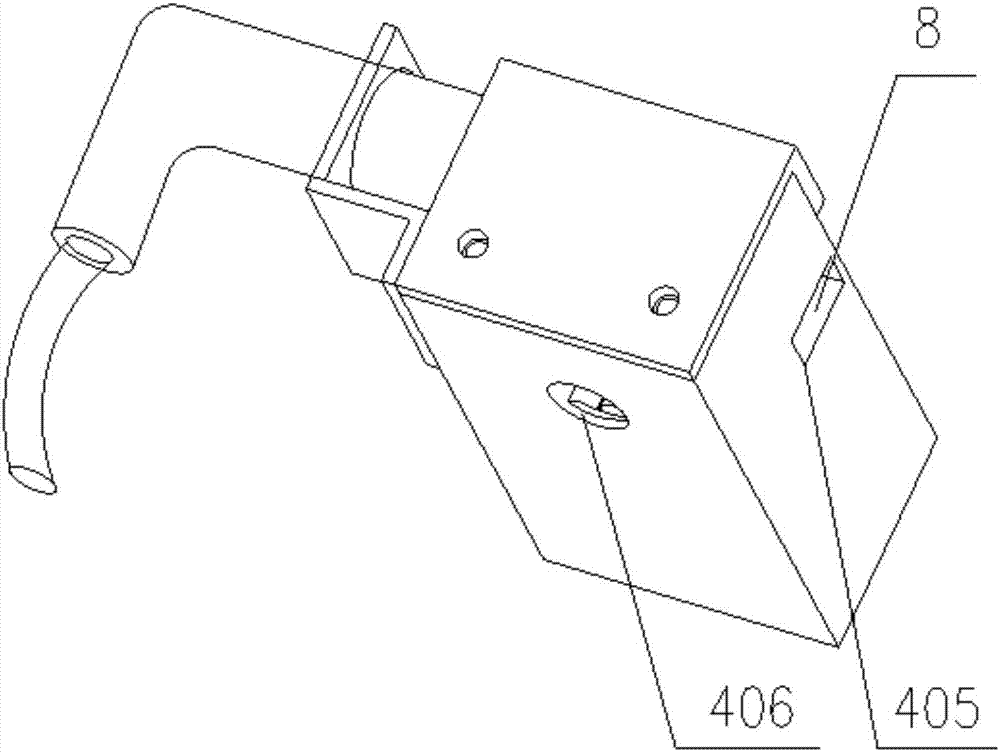

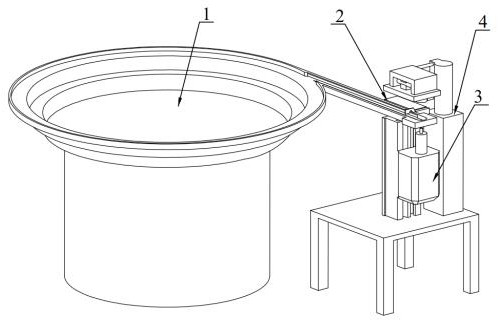

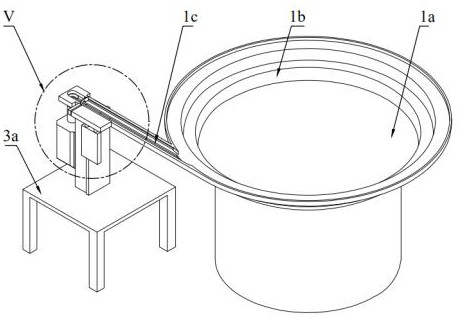

A feeding tray of an automatic feeding device

InactiveCN102259751AReasonable structural designRealize automatic arrangementJigging conveyorsConveyor partsEngineeringMechanical engineering

The invention relates to a feeding tray of an automatic feeding device, which includes a tray surface and a side wall surrounding the tray surface. A spirally rising feeding track is arranged on the inner side of the side wall, and the feeding end of the feeding track is located at a lower part of the tray surface. A monolithic track is extended from the discharge end of the track, and the monolithic track spirals up along the side wall, and the monolithic track includes at least a turning section, a sorting section and a sorting section. It has the advantages of reducing a large number of manual operations, improving work efficiency and reducing production costs.

Owner:GUANGDONG GALANZ GRP CO LTD

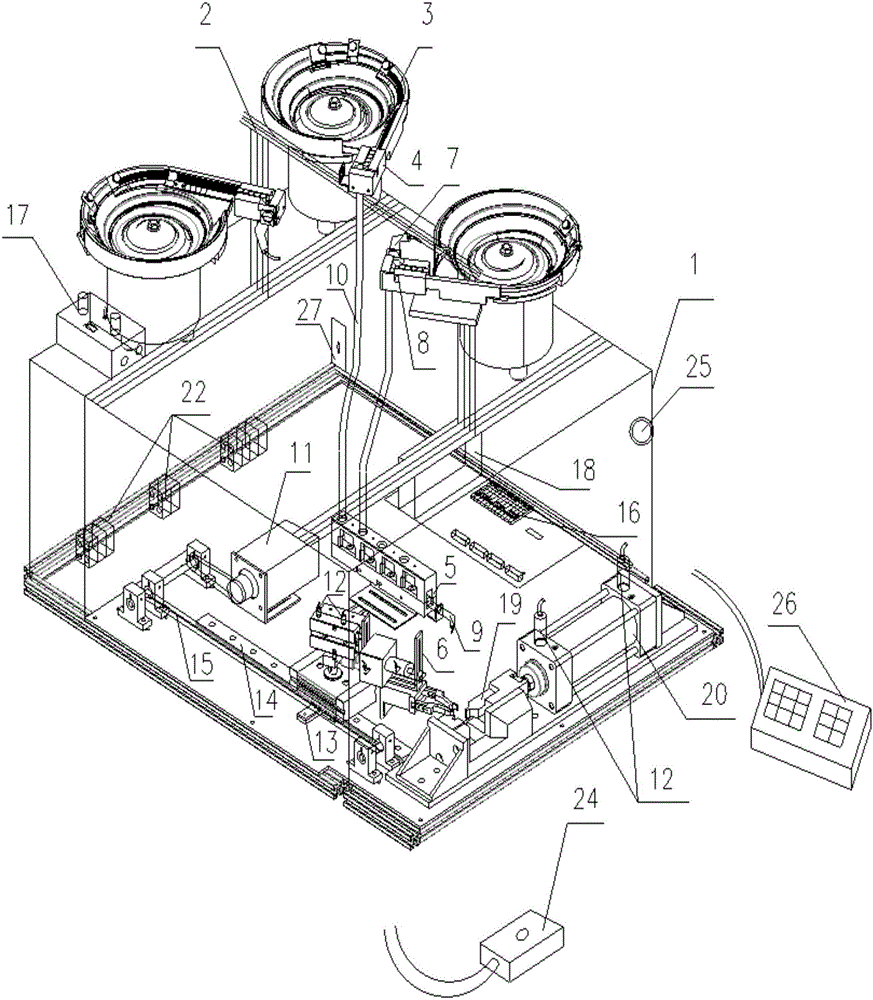

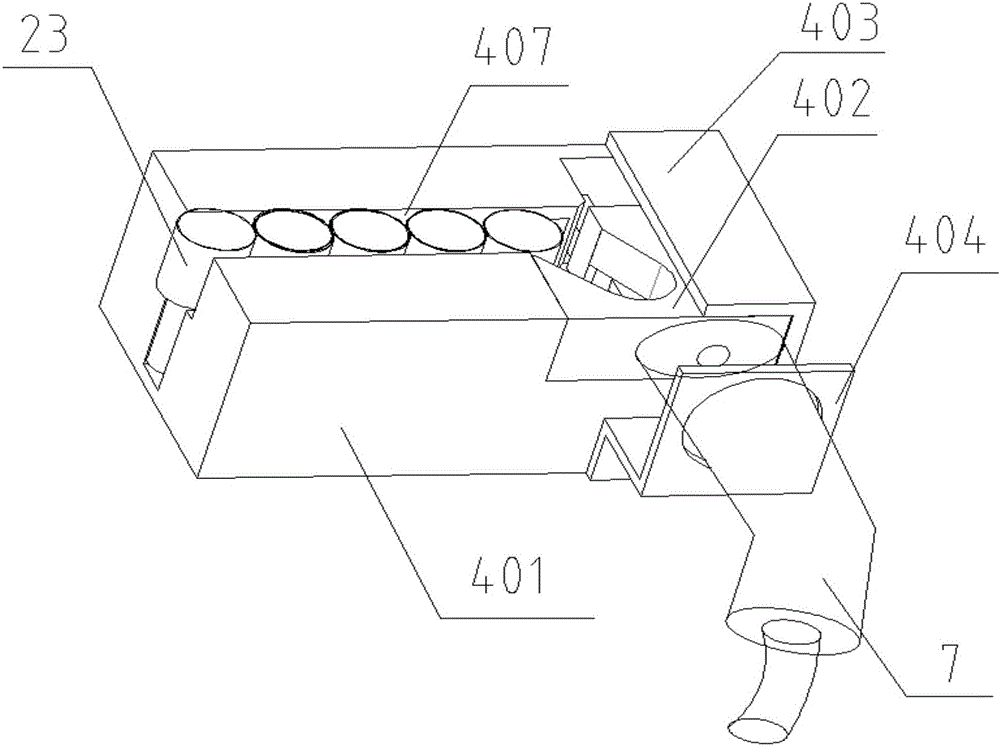

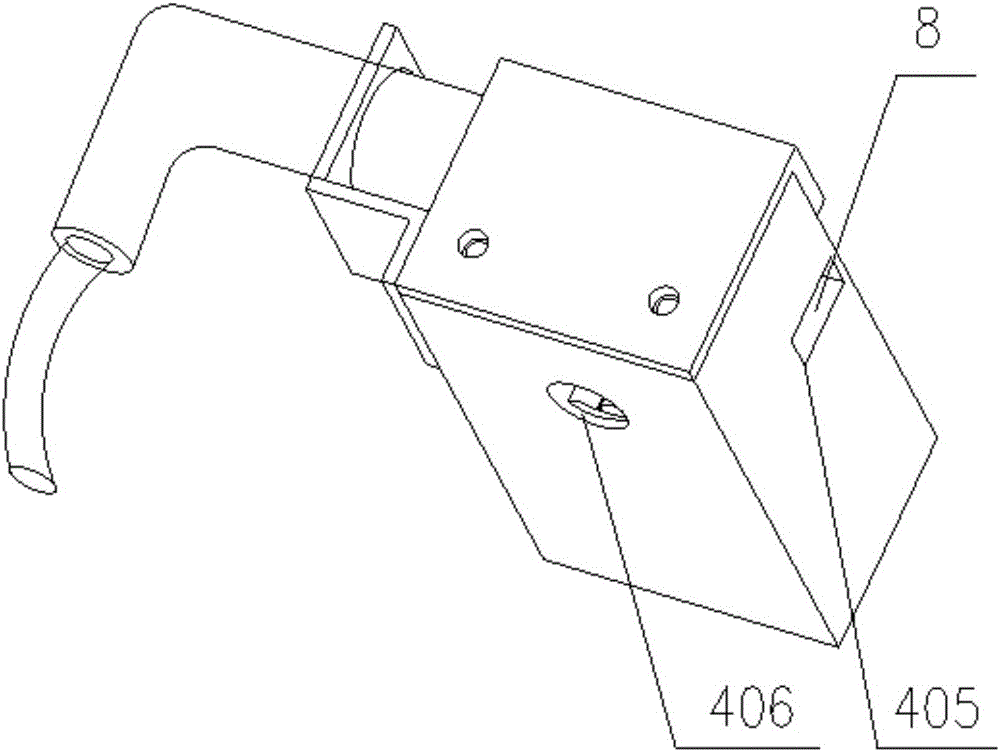

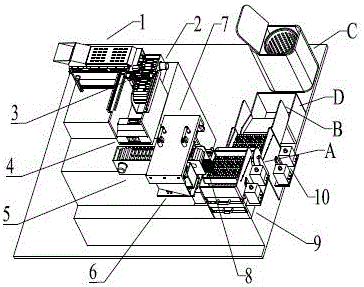

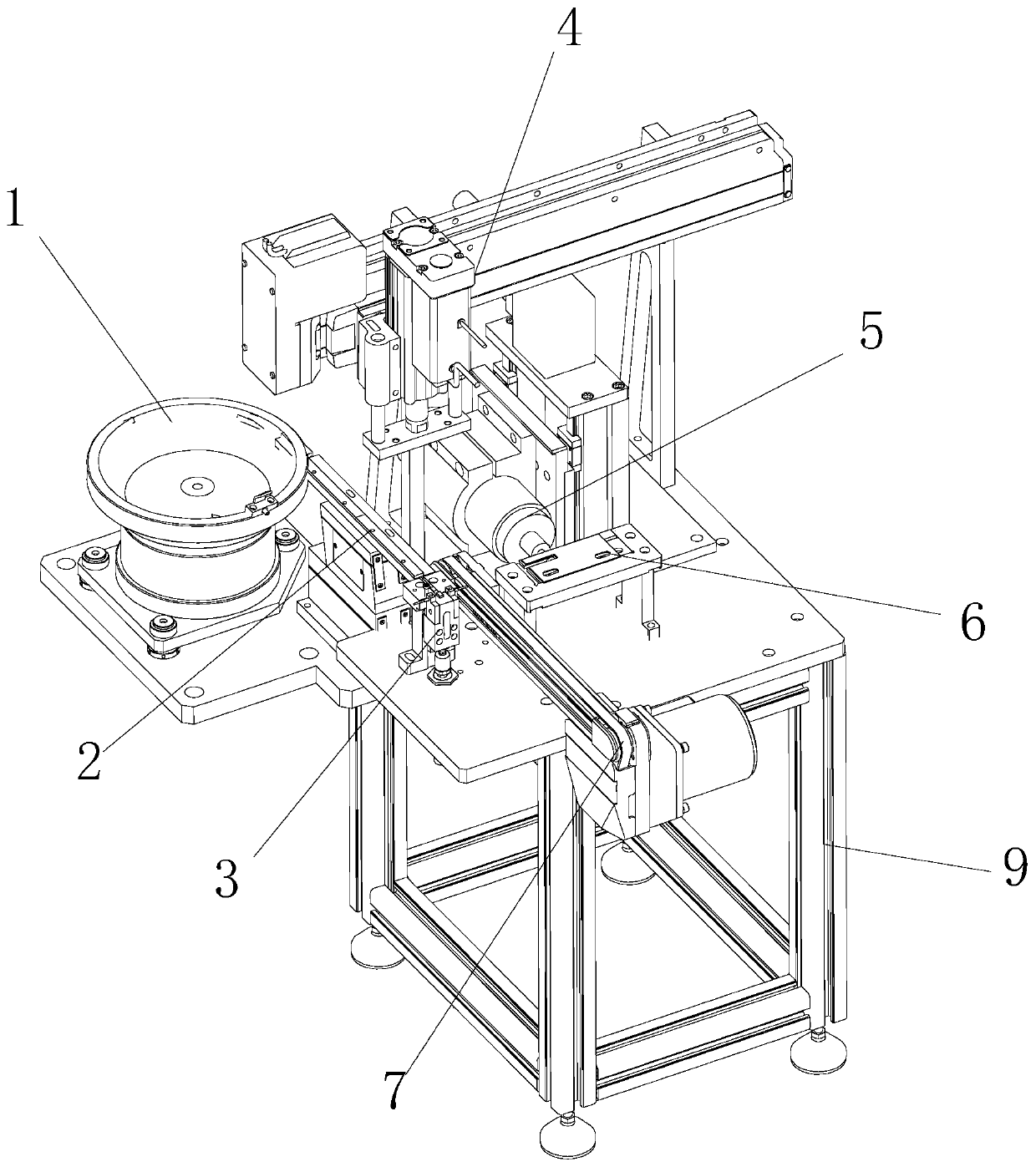

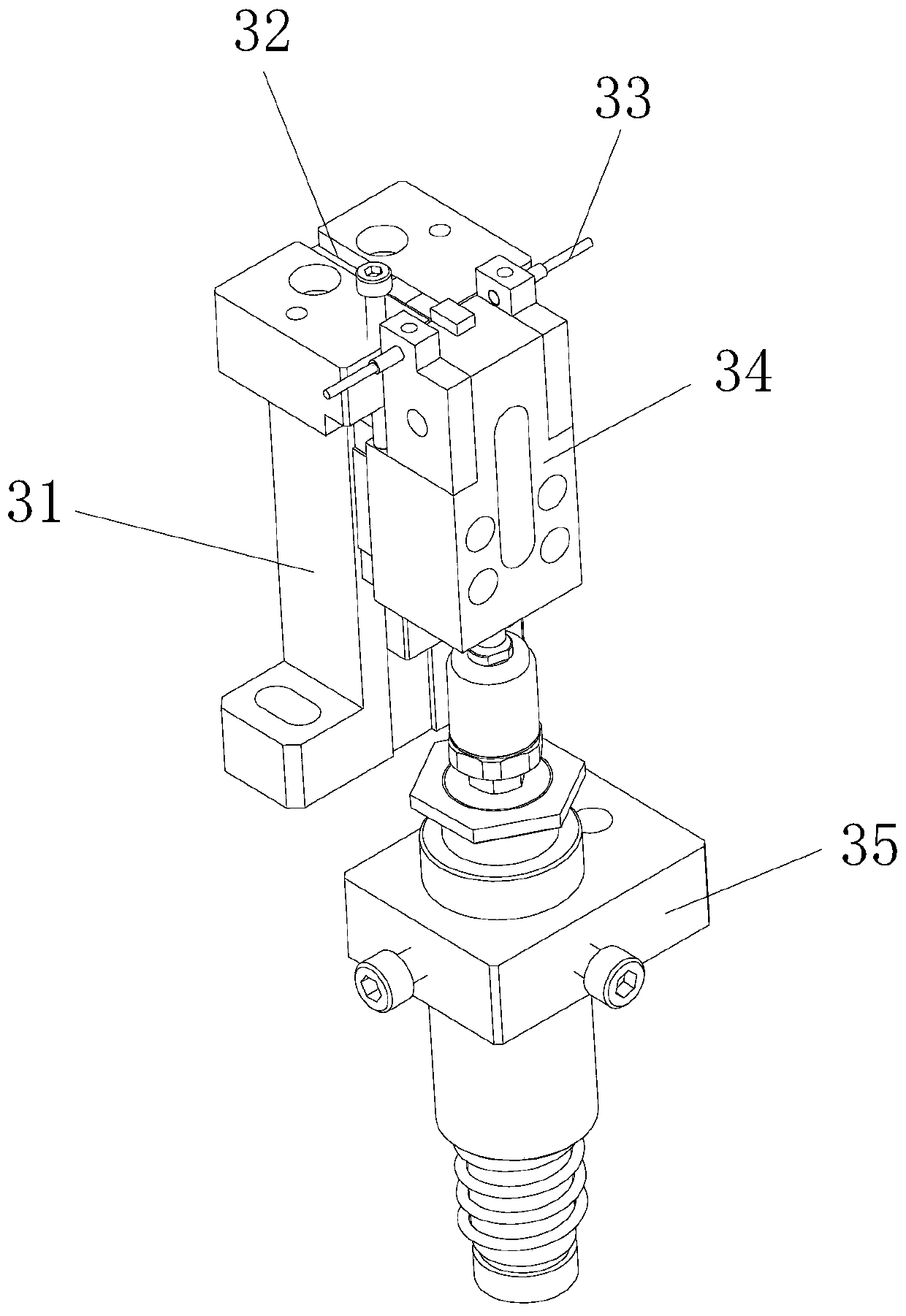

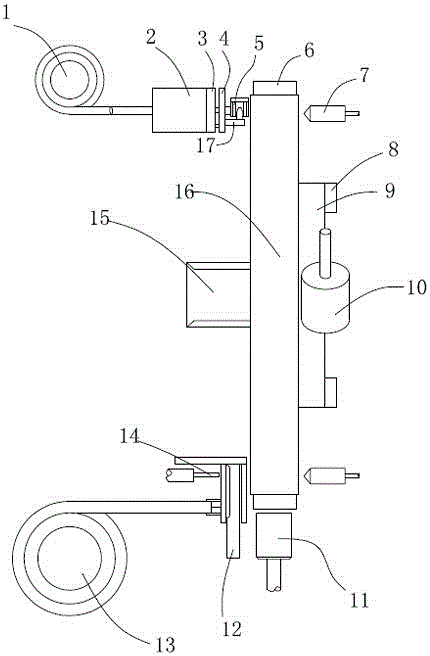

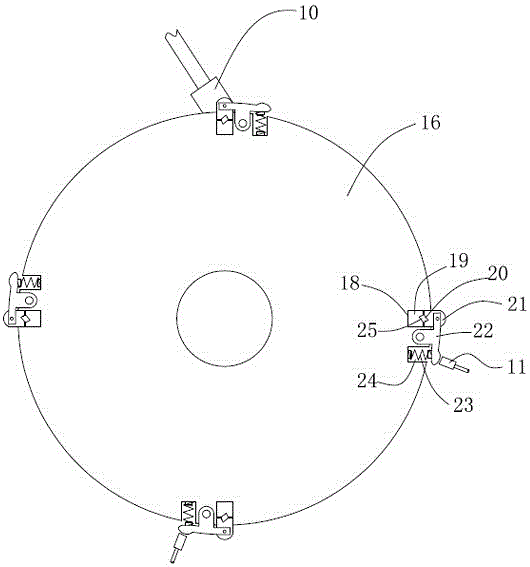

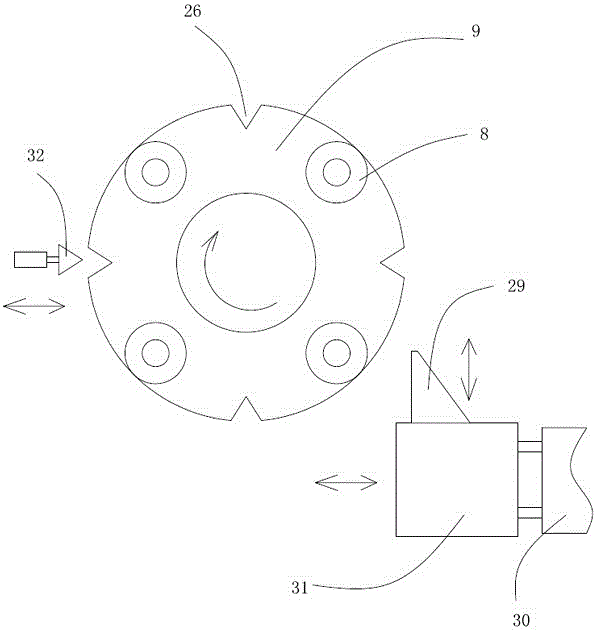

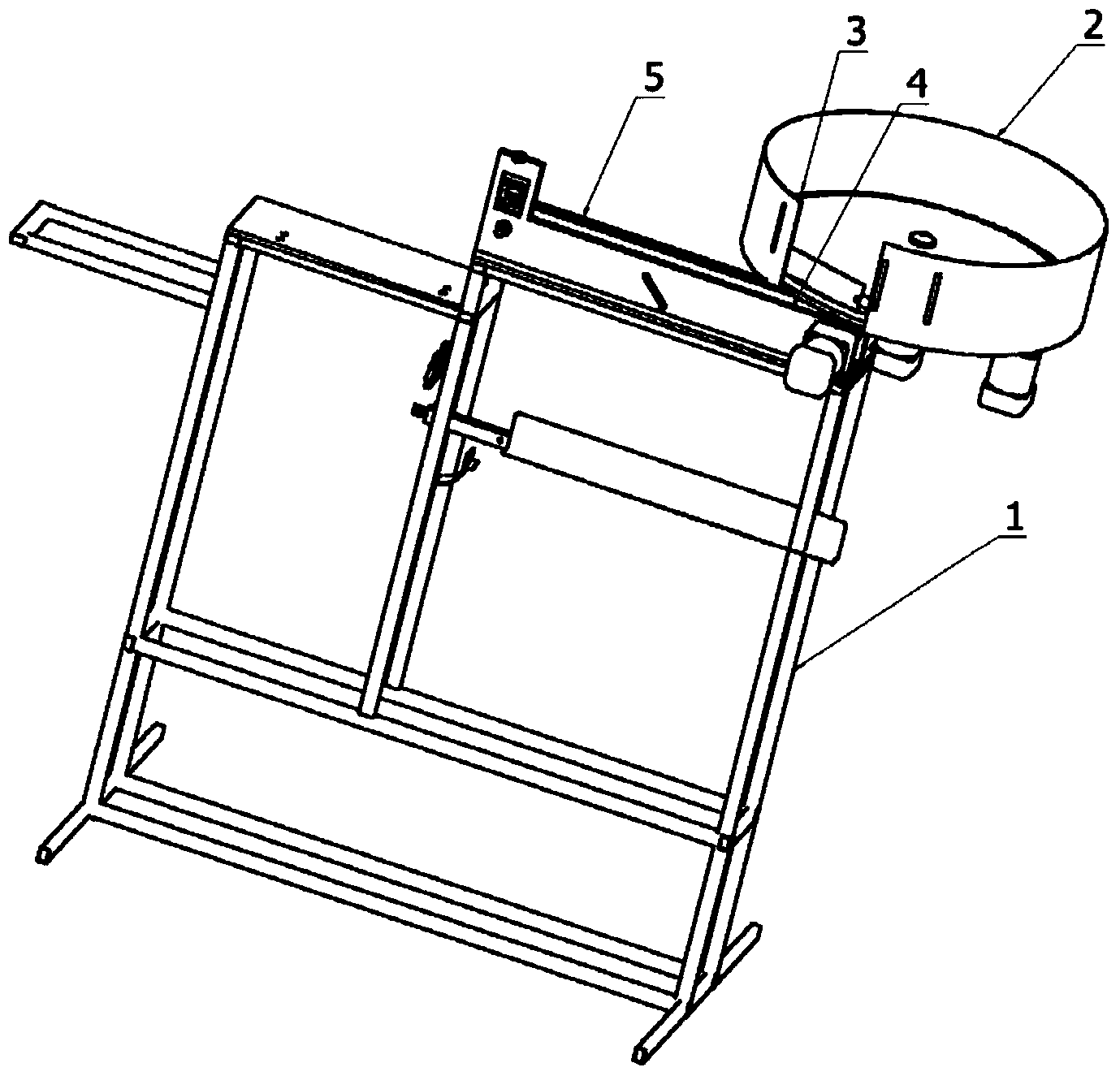

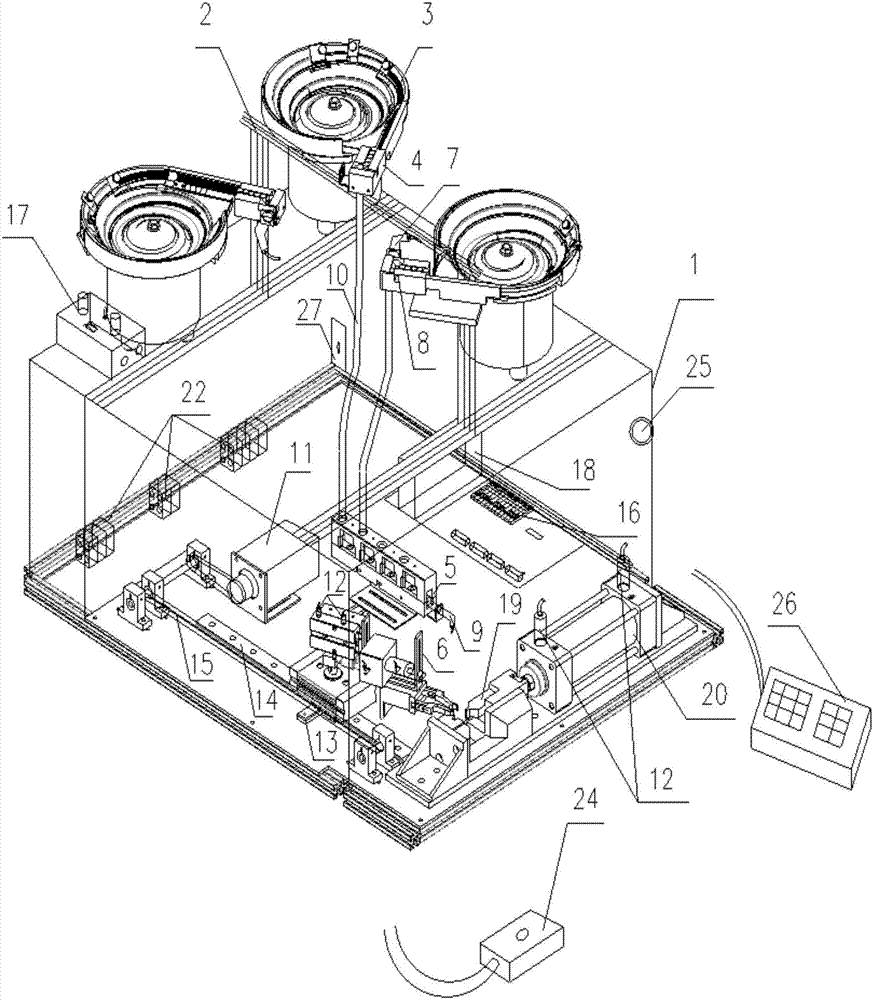

Four-color bulk terminal crimping machine

ActiveCN105703195ARealize automatic arrangementAccurate grippingLine/current collector detailsMicrocontrollerVibration control

The invention belongs to the technical field of an electrical device, relates to a novel terminal crimping machine, in particular to a four-color bulk terminal crimping machine. The main body structure of the four-color bulk terminal crimping machine comprises a protective cover, a support, vibration discs, escapement devices, a centering device, a manipulator, escapement air cylinders, escapement sensors, a dropping air cylinder, a transmission pipe, a motor, a solenoid valve, a pulley, a guide rail, a synchronous belt, a singlechip microcomputer, a vibration disc controller, a power supply transformer, mechanical pincers, a mechanical pincers air cylinder, a dropping sensor, a relay, terminals, a terminal machine controller, a power supply, an air source, a control stepping plate, a wire and a pipe line. With the arrangement of escapement devices and the centering device which are in correspondence to the four vibration discs and the control of the singlechip microcomputer, the plurality of terminals are simultaneously and automatically pressed; the novel terminal crimping machine has the advantages of simple structure, reliable principle, low preparation cost, high crimping efficiency, high crimping quality rate and application environment friendliness.

Owner:QINGDAO SPELSBERG ELECTRICAL ENG TECH CO LTD

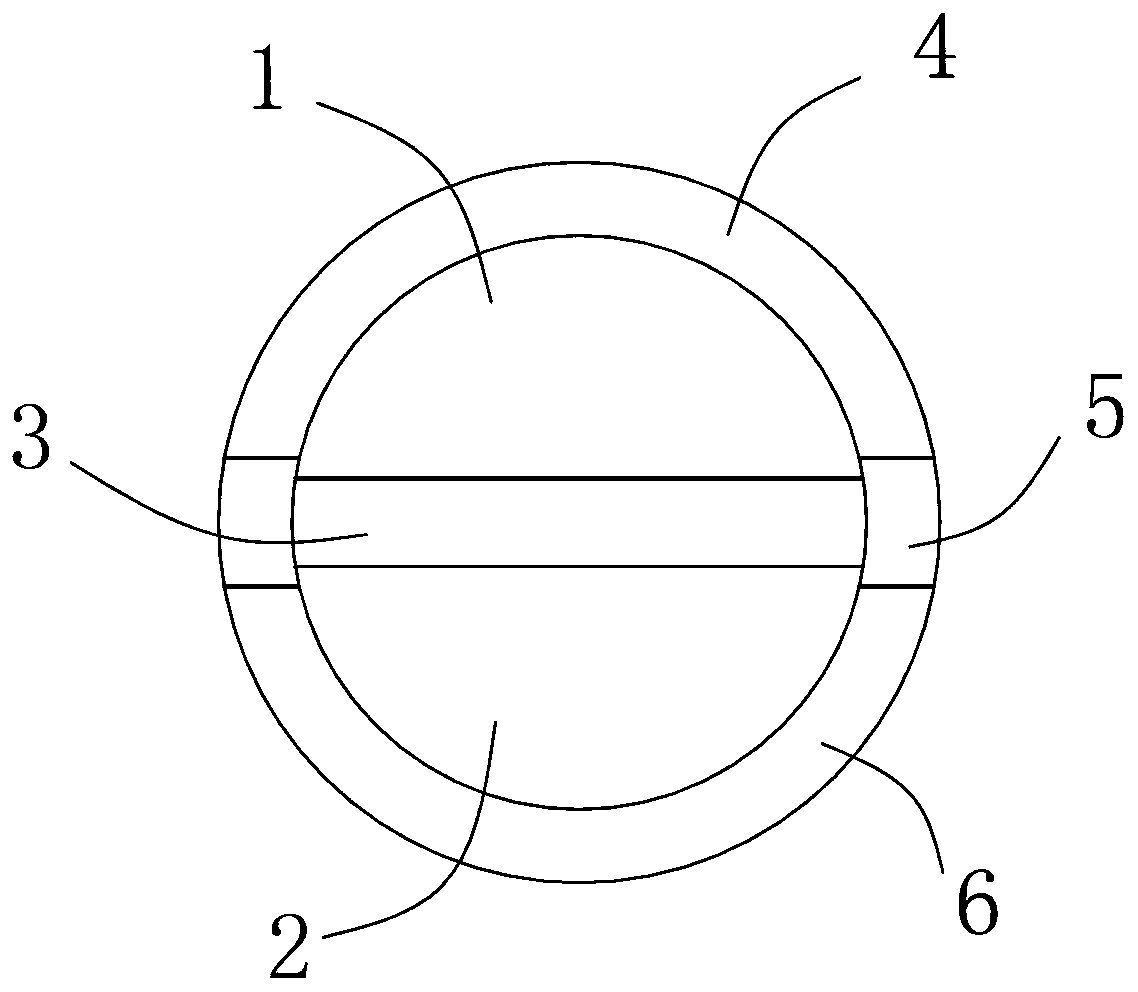

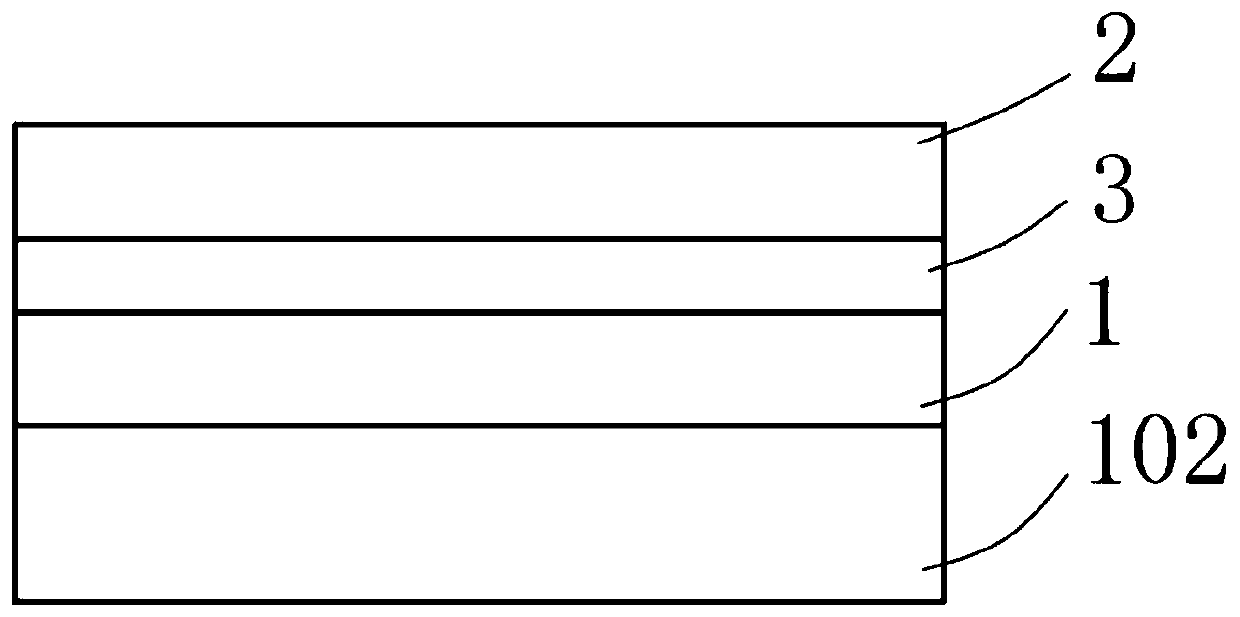

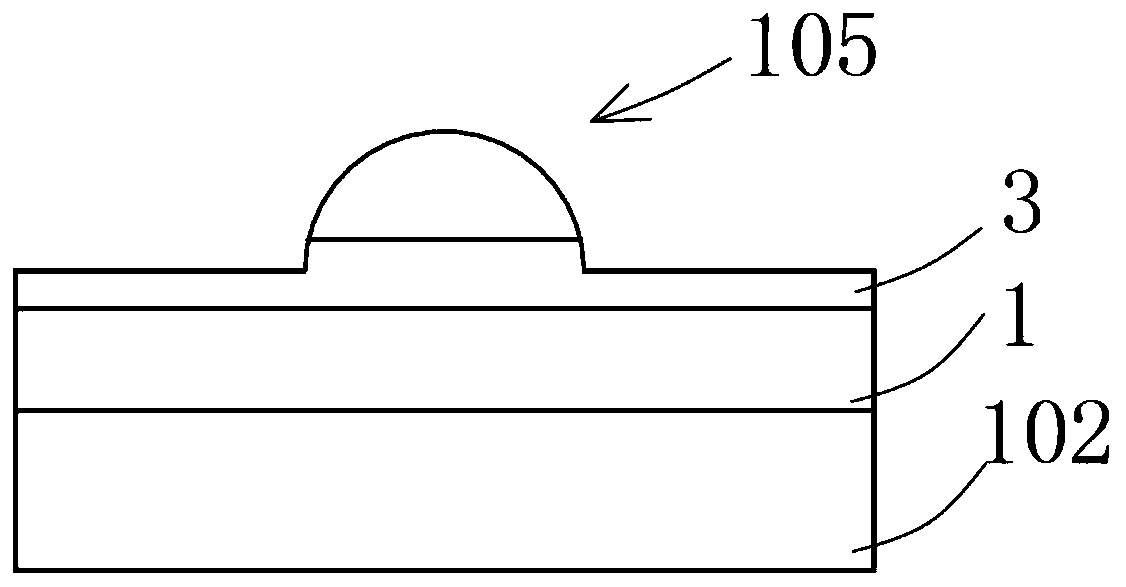

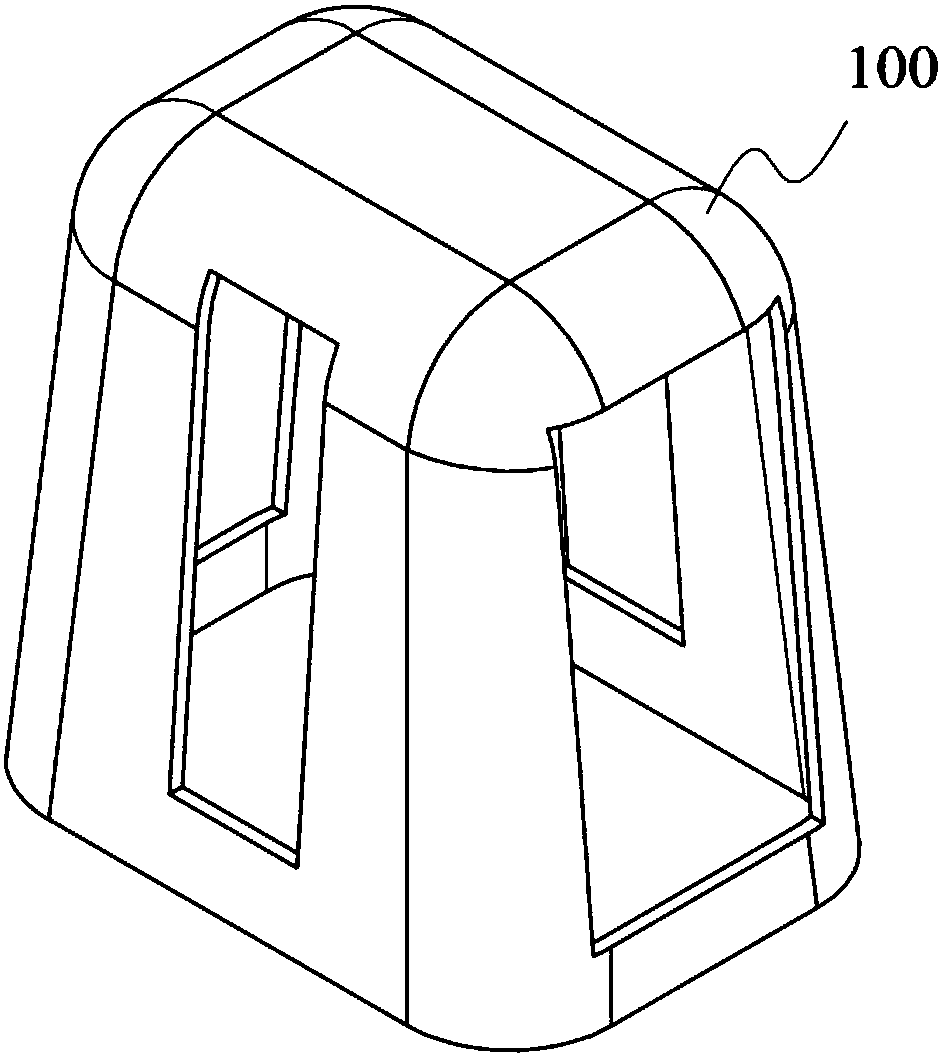

Spherical vertical micro LED and manufacturing method thereof, display panel and transfer method thereof

PendingCN111540815AAccurateImprove yieldSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The invention provides a spherical vertical micro LED and a manufacturing method thereof, a display panel and a transfer method thereof. The spherical vertical micro LED comprises a first semiconductor layer, a second semiconductor layer, a light-emitting layer, a first electrode, an insulating layer and a second electrode, the light-emitting layer is arranged between the first semiconductor layerand the second semiconductor layer; the first electrode covers at least part of the surface of the first semiconductor layer, the second electrode covers at least part of the surface of the second semiconductor layer, and the insulating layer covers the light-emitting layer or covers the light-emitting layer and part of the surfaces of the first semiconductor layer and the second semiconductor layer. The first semiconductor layer, the second semiconductor layer and the light-emitting layer form a sphere structure. The first electrode, the insulating layer and the second electrode form a spherical structure covering the outer layer, so that the spherical vertical micro LED is formed, the micro LED is prevented from being clamped outside the loading trap in the transfer process, the micro LED is conveniently and accurately aligned with the loading trap in the transfer process, and the transfer yield and the production efficiency can be effectively improved.

Owner:CHONGQING KONKA PHOTOELECTRIC TECH RES INST CO LTD

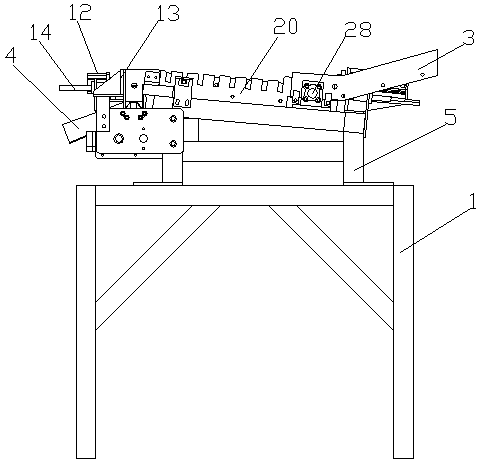

Bearing bush automatic collector

ActiveCN107777342ARealize automatic arrangementPromotion of automated processing and productionConveyorsConveyor partsElectric machineryEngineering

The invention discloses a bearing bush automatic collector which comprises a machine frame, a material plate, a feed groove and a discharge groove. A support is arranged between the material plate andthe machine frame. The support adjusts the inclination degree of the material plate through adjusting feet. Bearing bushes can not roll down when pushed from low place to high place. The bearing bushes fall to the position above a groove of the material plate from the feed groove at low place and are then pushed into the groove one by one, then the whole row of bearing buses are pushed to a nextgroove by a push plate, the bearing bushes are automatically arrayed till being finally pushed to an inclined groove, a lead screw driven by a motor is arranged below the inclined groove, a push blockon the lead screw pushes the bearing bushes towards the discharge groove to flow from the discharge groove to the next section. In order to prevent the bearing buses from being scattered at the inclined groove, baffles with adjustable distance are arranged outside the inclined groove so as to adapt to the bearing bushes with different diameters. The automatic feeding and discharging of the orderly-arrayed bearing bushes in the transition process is realized, design is simple, and wide popularization value is achieved.

Owner:ZHENJIANG N E T DIAMOND

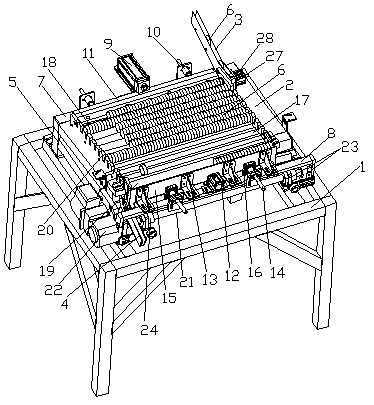

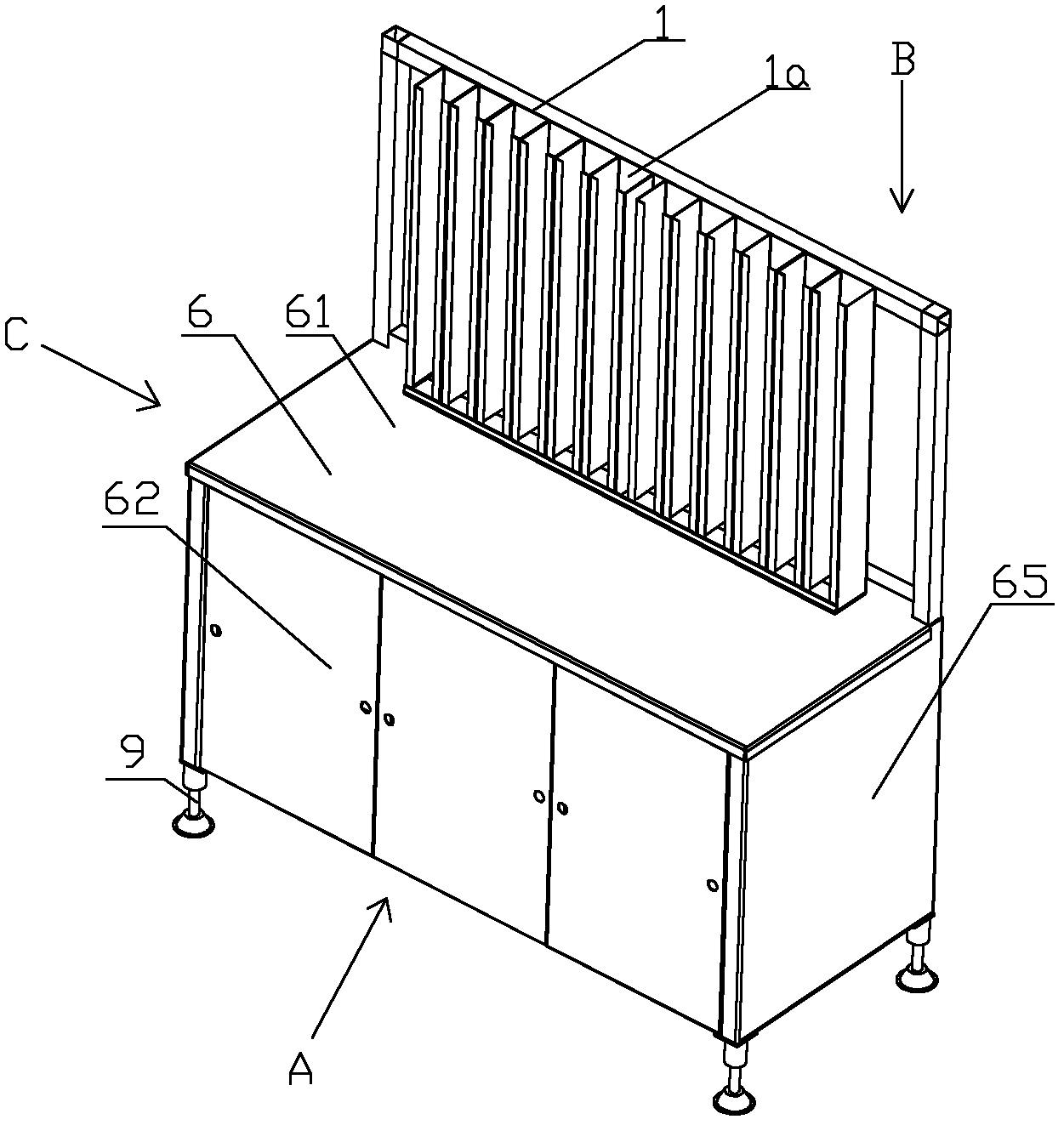

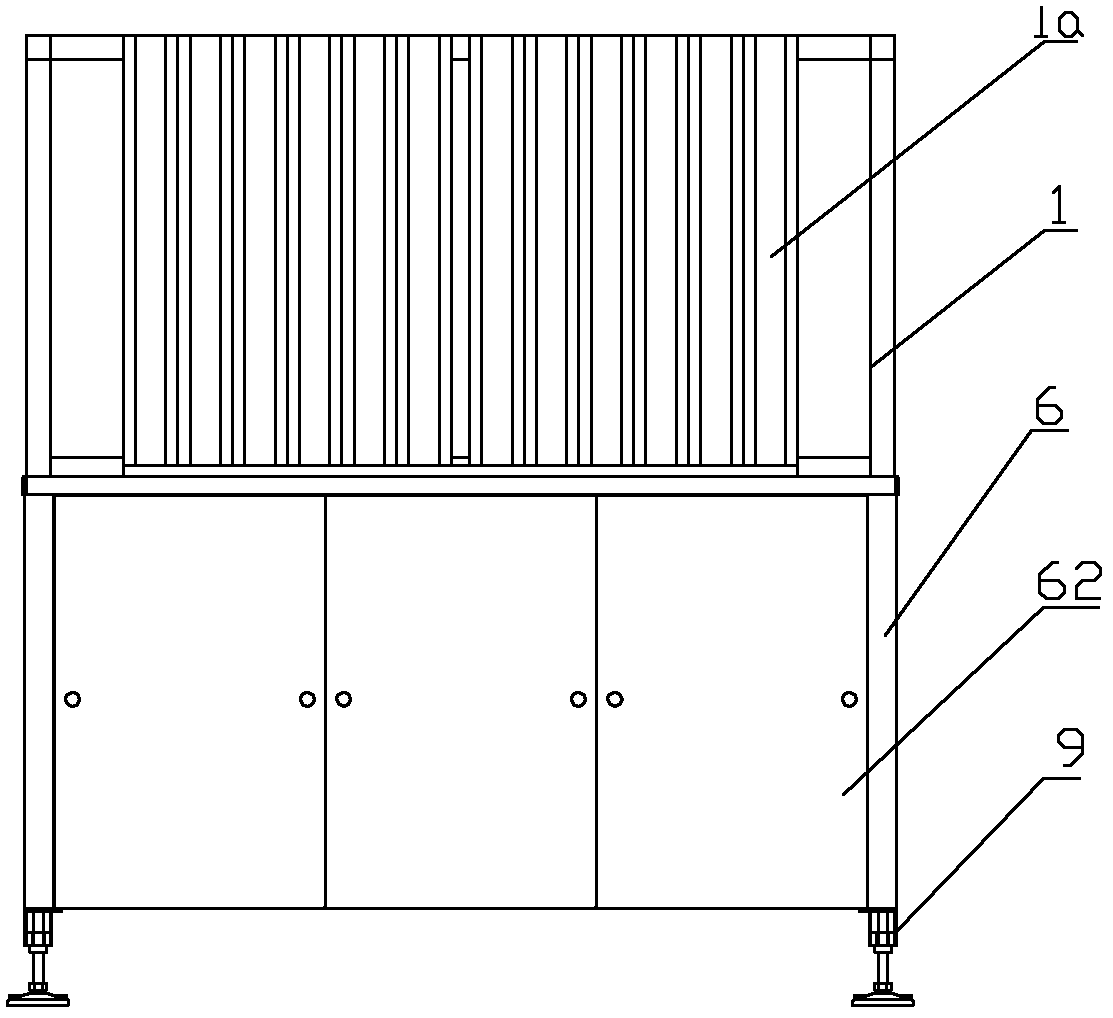

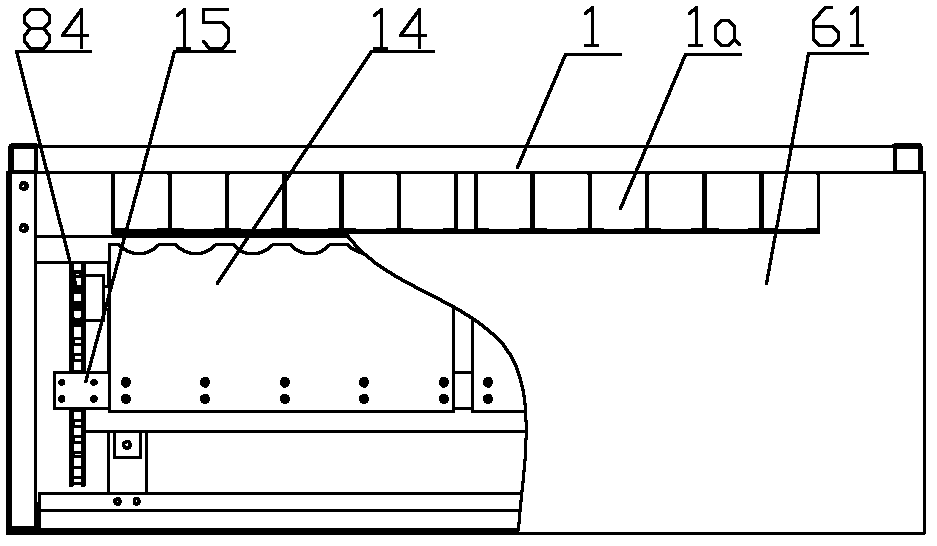

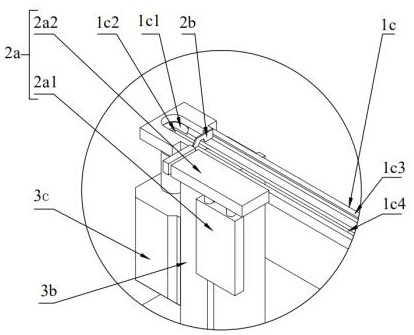

Pressing device for sawing material

InactiveCN106736747ARealize automatic arrangementAchieve compactionMetal sawing devicesWork clamping meansMechanical engineeringEngineering

The invention discloses a pressing device for a sawing material. The pressing device comprises a blocking pressing device, a left pressing device and a right pressing device, wherein the blocking pressing device, the left pressing device and the right pressing device are sequentially and parallelly mounted below fixed seats; the blocking pressing device, the left pressing device and the right pressing device comprise pressing cylinders and pressing beams; one ends of the pressing cylinders are fixed to the fixed seats; and telescopic shafts at the other ends of the pressing cylinders are connected with the pressing beams. According to the pressing device for the sawing material, a plurality of profiles can be automatically arranged and pressed, the sawing effect is guaranteed, and the sawing efficiency and cutting quality are greatly improved.

Owner:JINAN HUAXIN AUTOMATION ENG

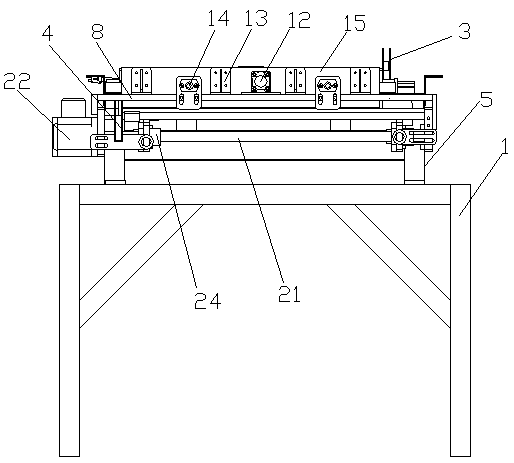

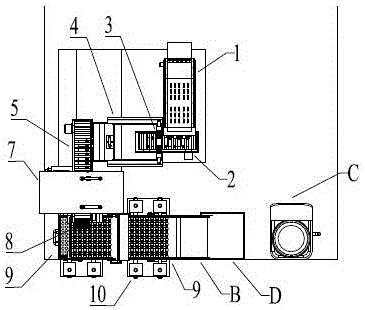

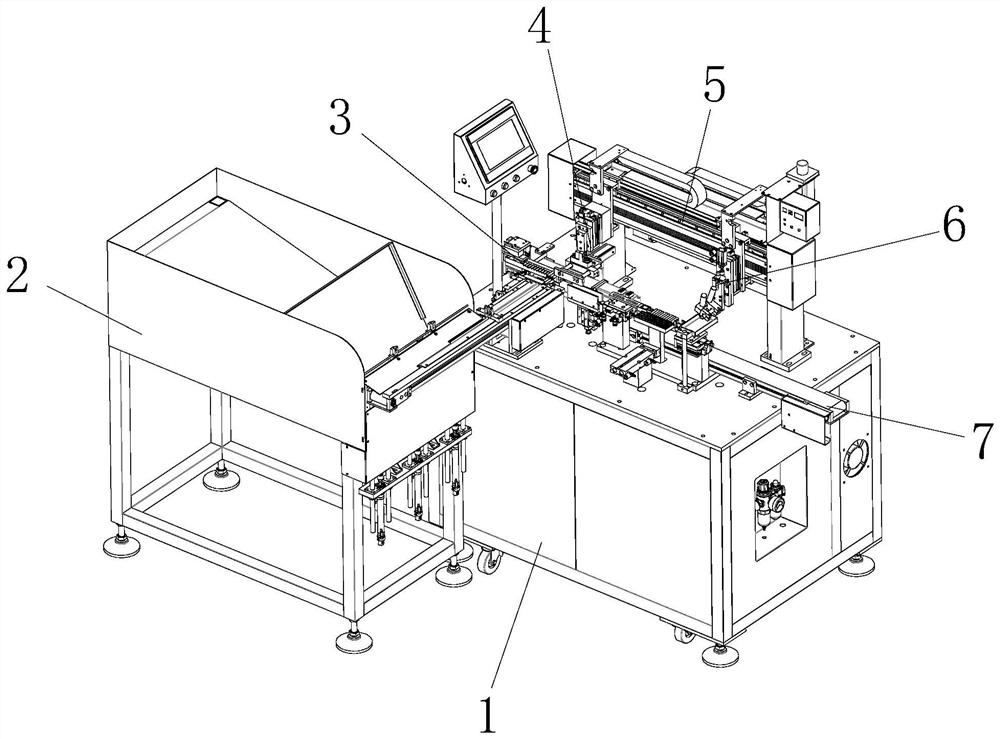

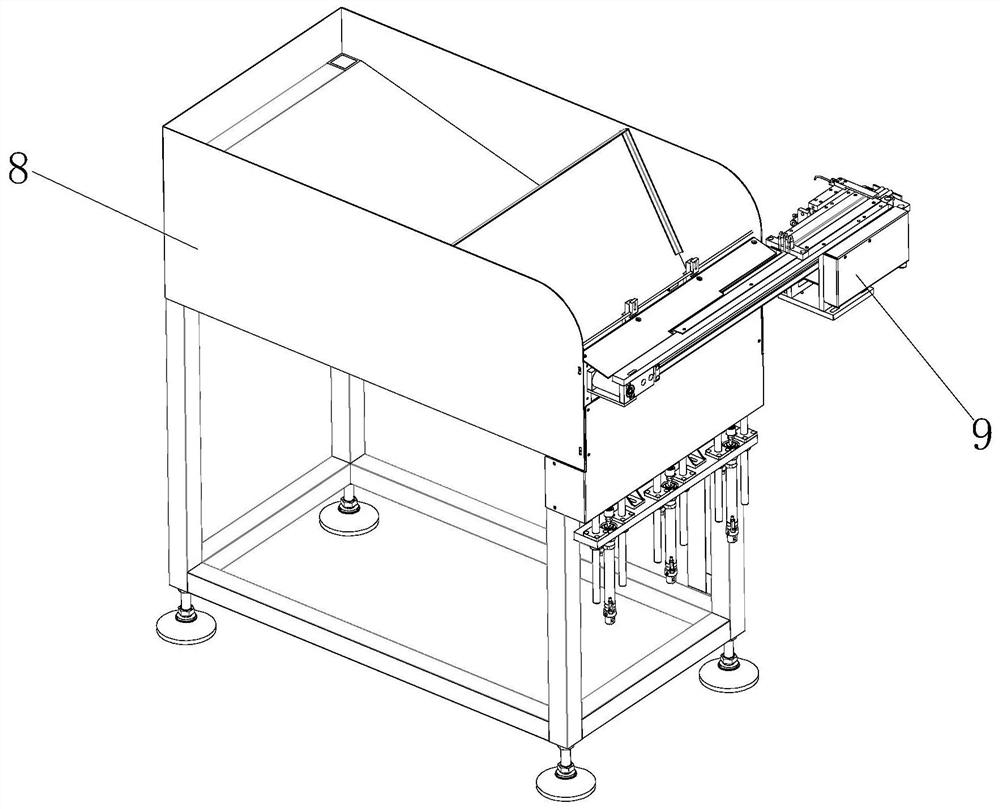

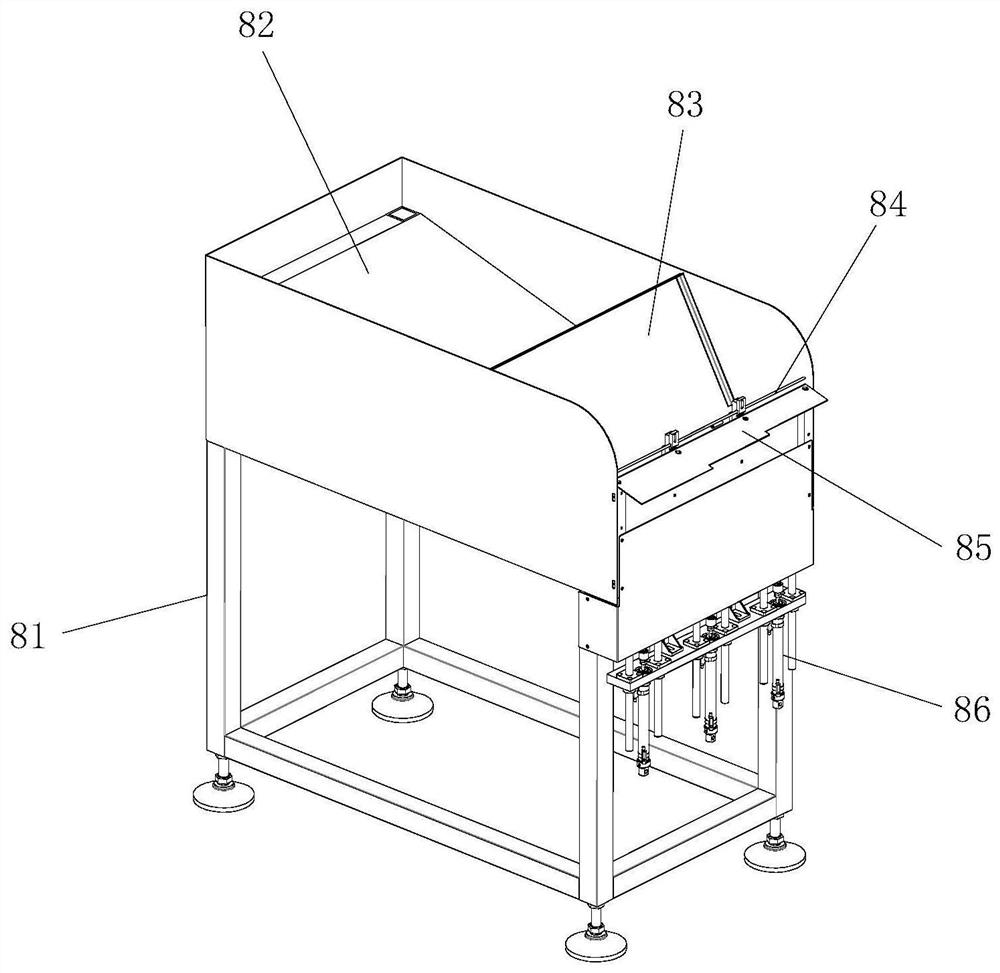

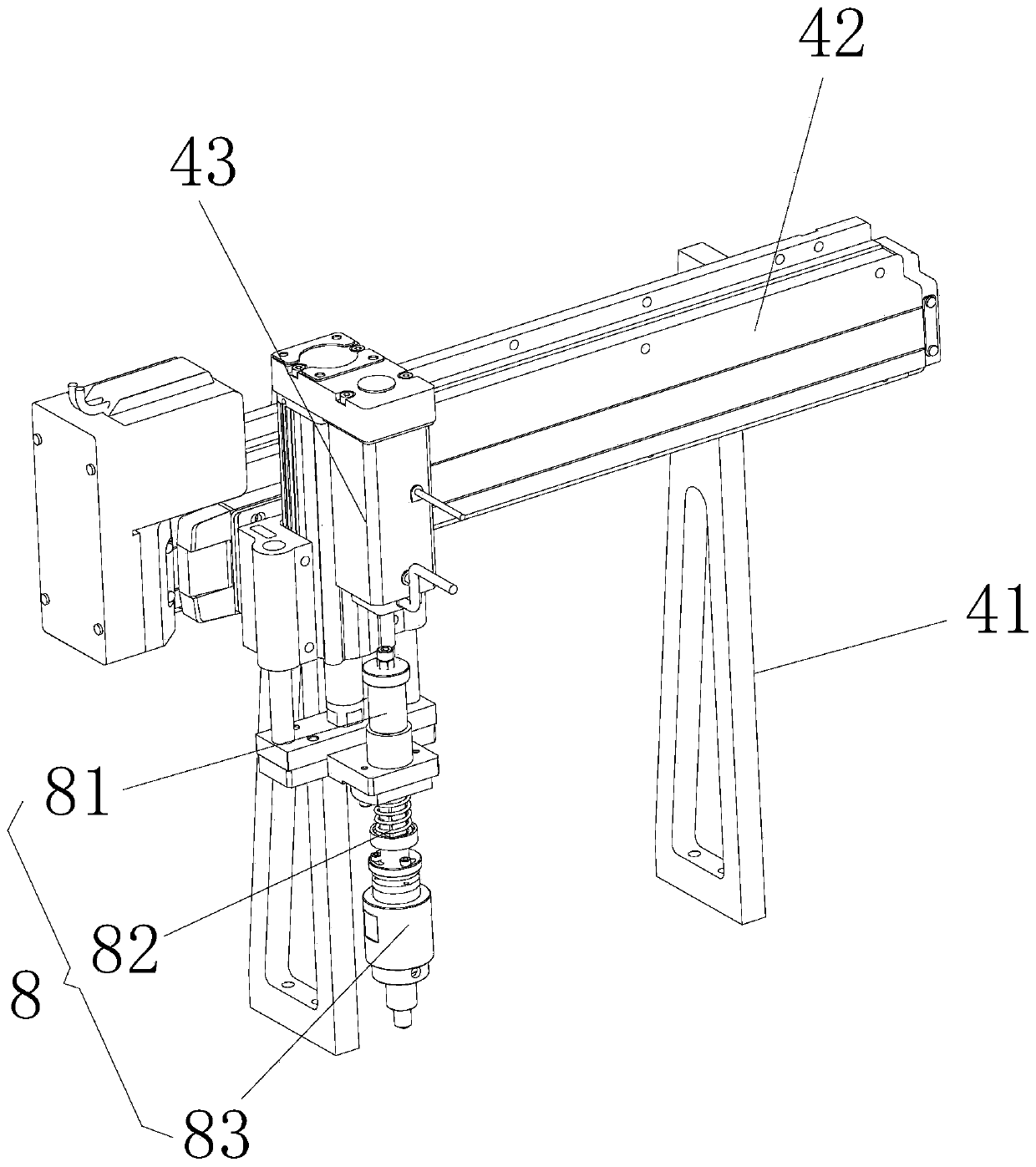

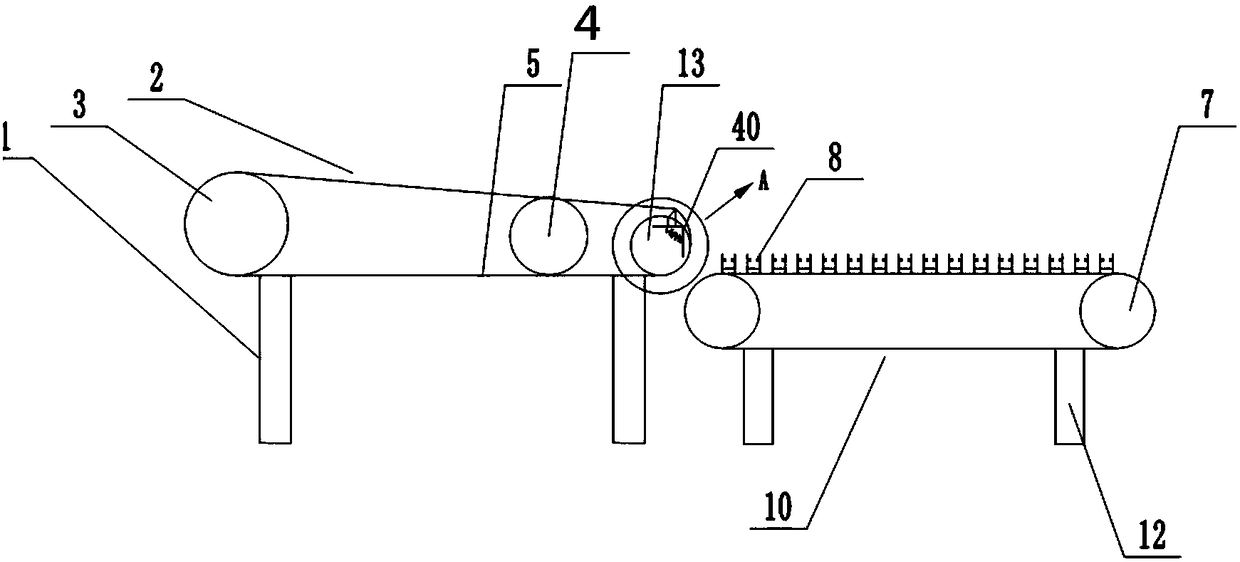

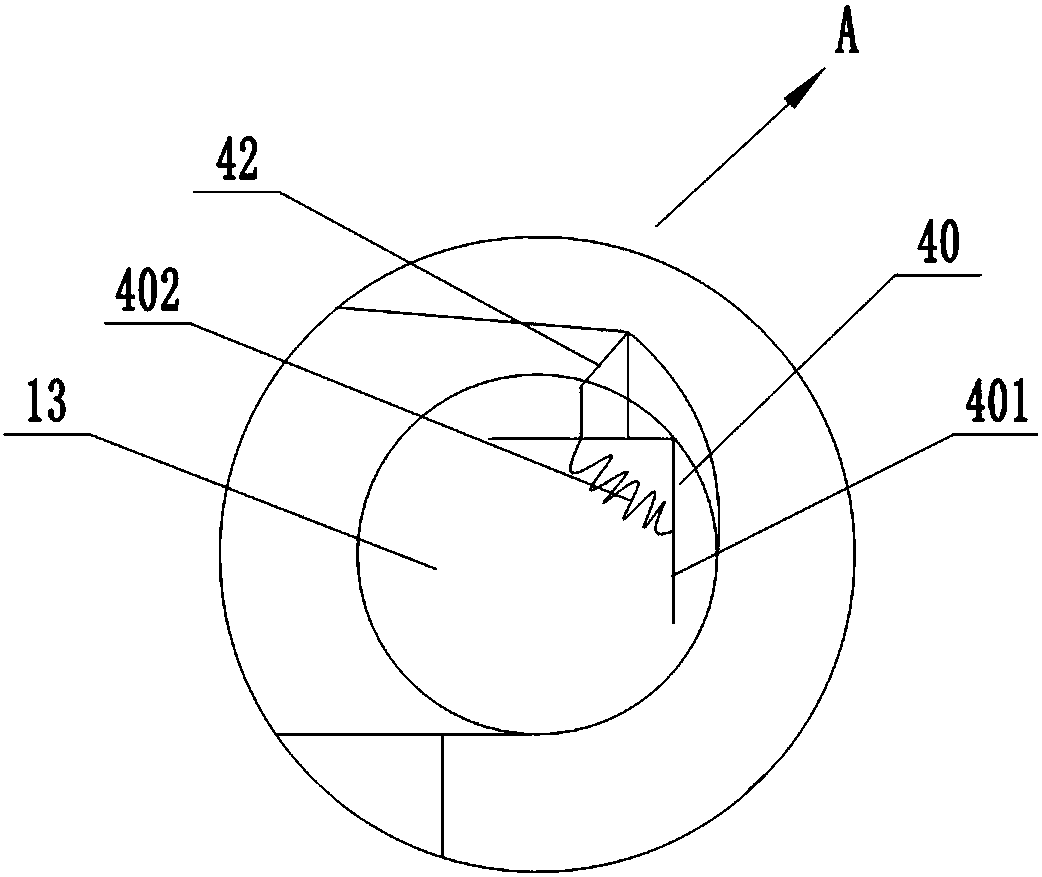

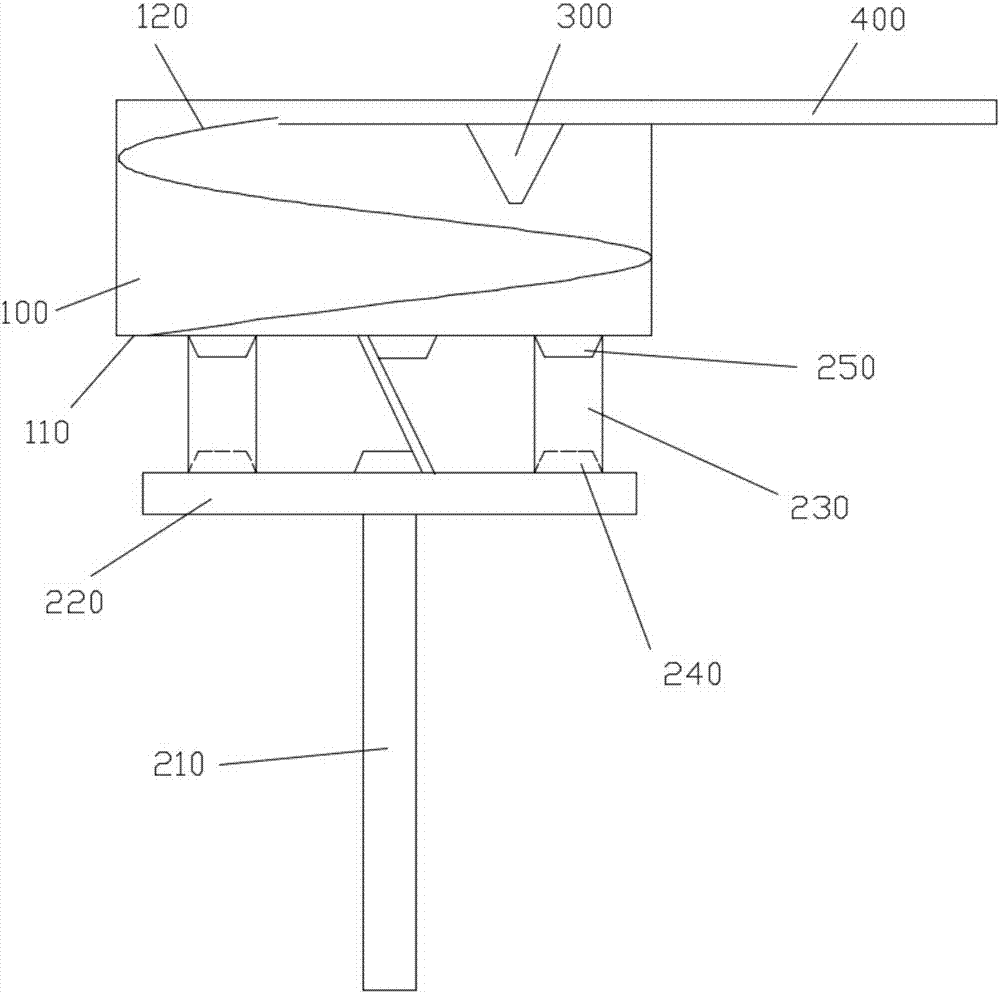

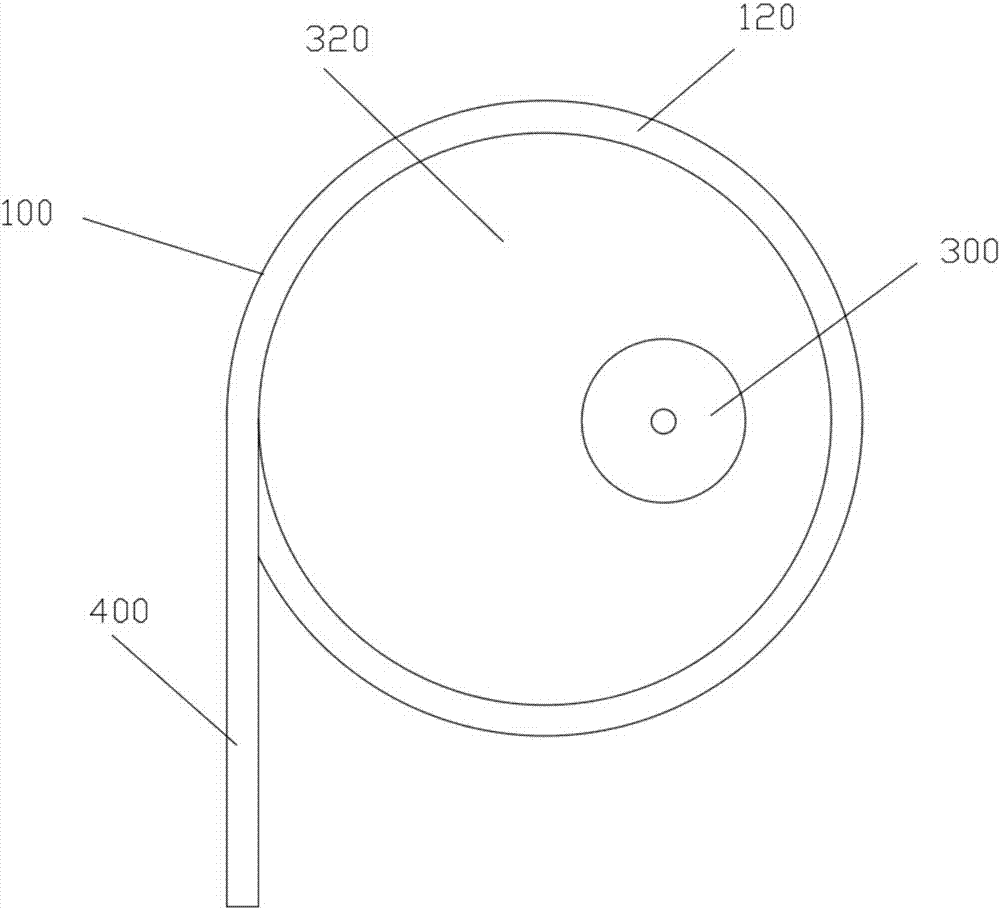

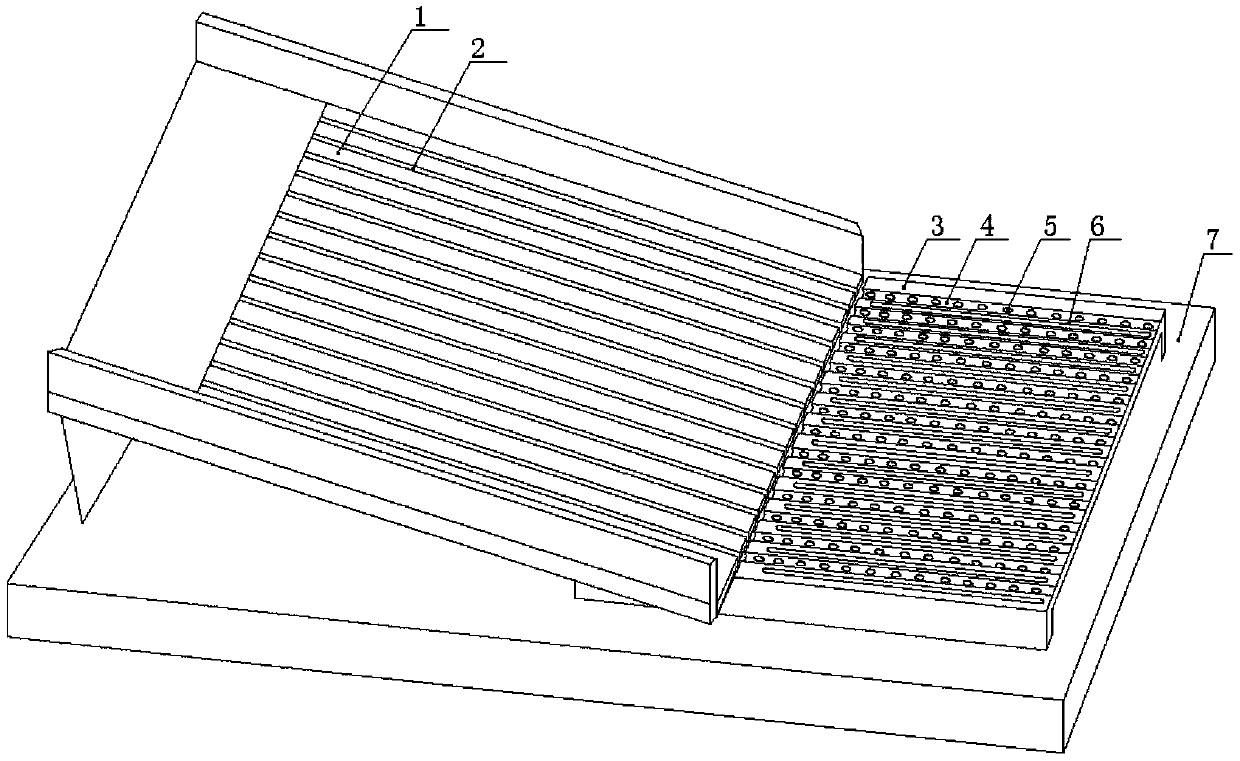

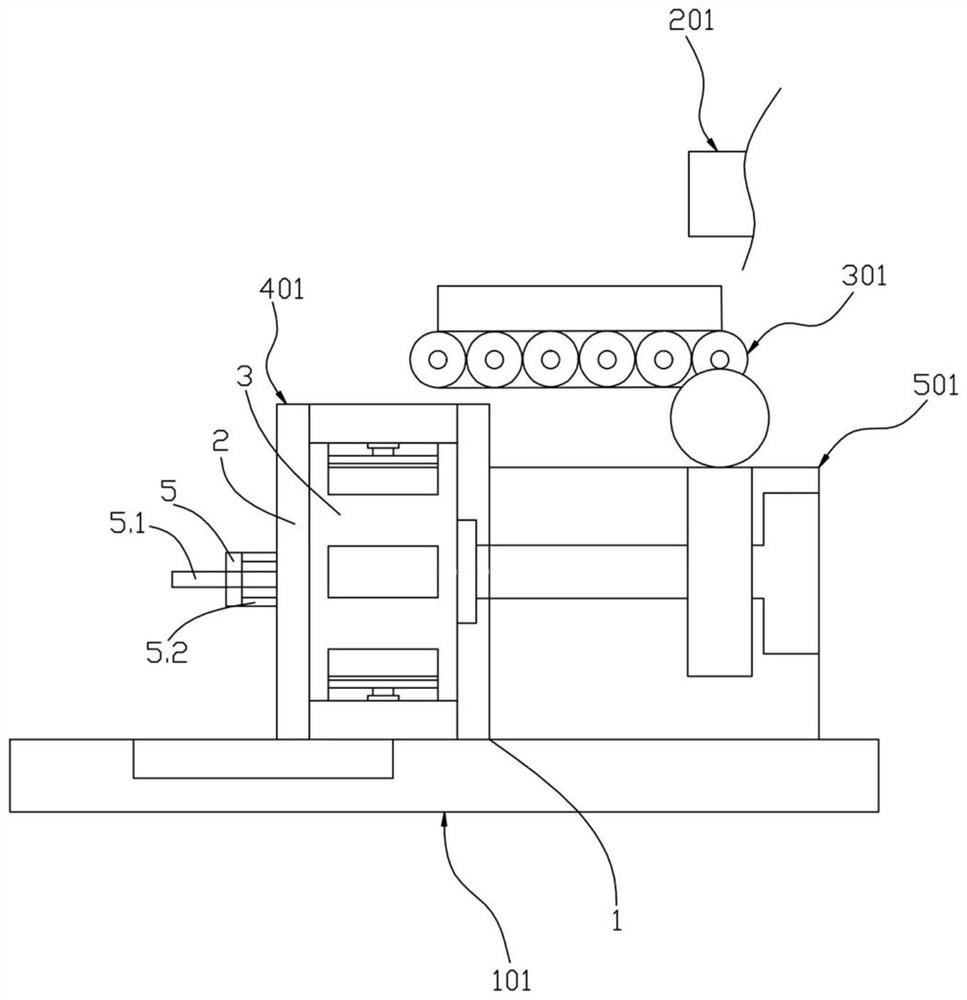

Full-automatic damage-free corn stigma harvesting machine

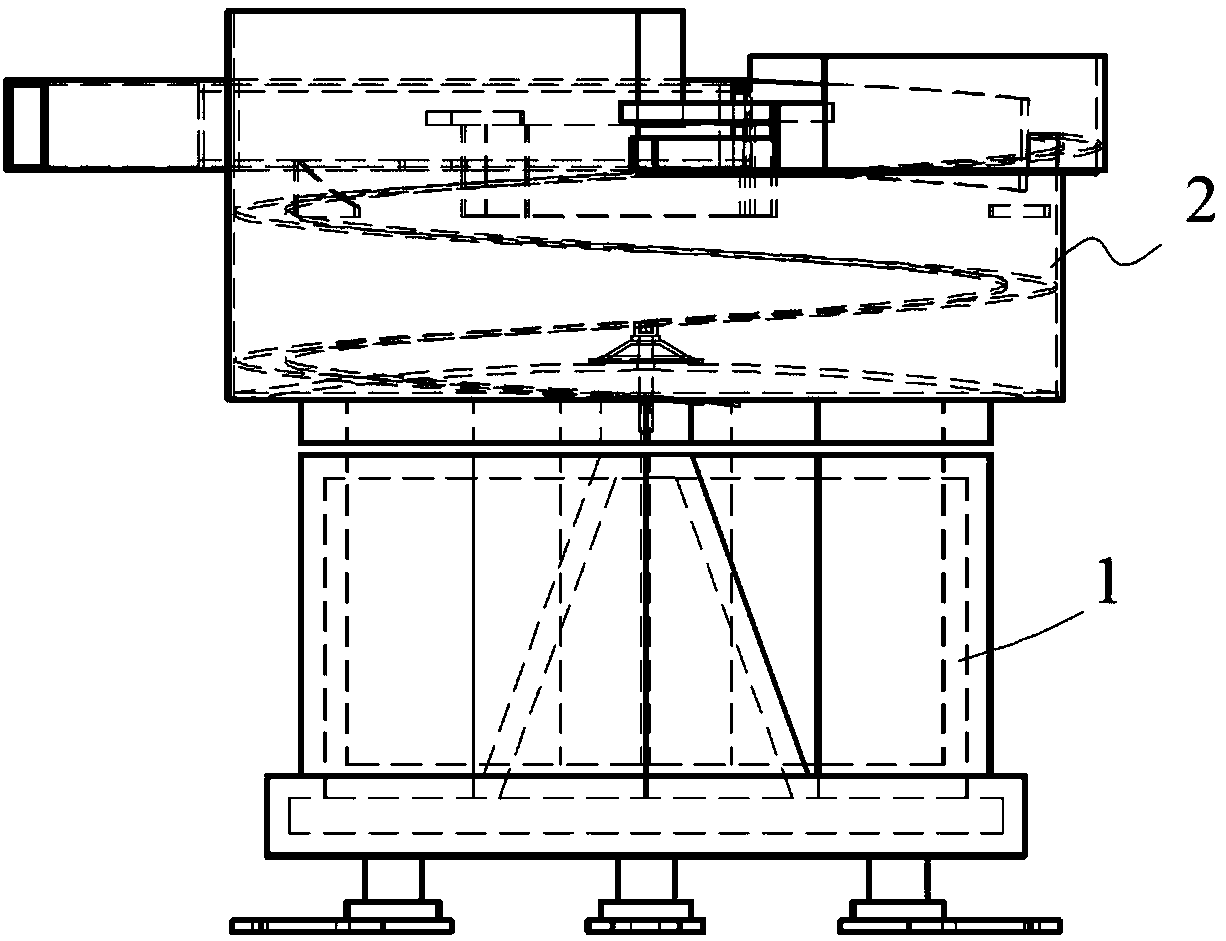

ActiveCN106576615AFully automated processingIncrease productionHarvestersThreshersEngineeringAutomatic processing

The invention discloses a full-automatic damage-free corn stigma harvesting machine. The full-automatic damage-free corn stigma harvesting machine comprises a corn arranging device (1), a corn conveying device (2), a clamping and delivery device (3), a clamping and delivery device rack (4), a kernel removing and conveying device (5), a cob kernel tipping bucket (6), a corn cob kernel removing device (7), a connecting net (8), a separating device (9), a corn stigma collecting device (10), a turnover device (A) and a corn peel separating device (B). The full-automatic damage-free corn stigma harvesting machine achieves full-automatic processing of corns, saves labor, can complete classified collection through cooperation of all the components, and can also complete automatic collection of corn stigmas, thereby greatly improving the yield of the corn stigmas and ensuring the quality of the corn stigmas. The corn stigma collecting device can well collect the corn stigmas, the collection requirements of the corn stigmas are met, the yield of the corn stigmas is improved, integrity of the corn stigmas can be ensured, and various requirements for the corn stigmas can be met.

Owner:YANGXIN JINFENG ECOLOGICAL FIBER CO LTD

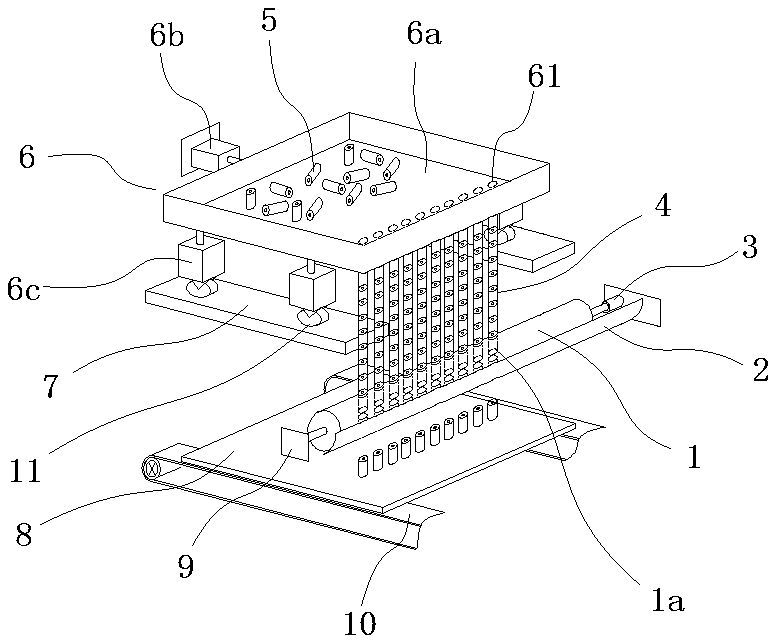

Columnar magnet arranging device and method

The invention discloses a columnar magnet arranging device and method. The columnar magnet arranging device comprises a shaking sorting table, a rotary shaft and a conveying plate. Multiple guide holes are formed in one side of the bottom of the shaking sorting table. Guide pipes correspondingly communicating with the guide holes are arranged on the lower portions of the guide holes. The rotary shaft is horizontally arranged between the shaking sorting table and the conveying plate. Column holes corresponding to outlets in the bottoms of the guide pipes are formed in the outer surface of the rotary shaft. The columnar magnet arranging device and method aim at achieving automatic and orderly arrangement.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

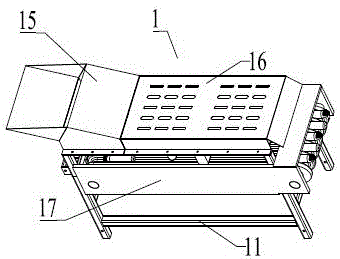

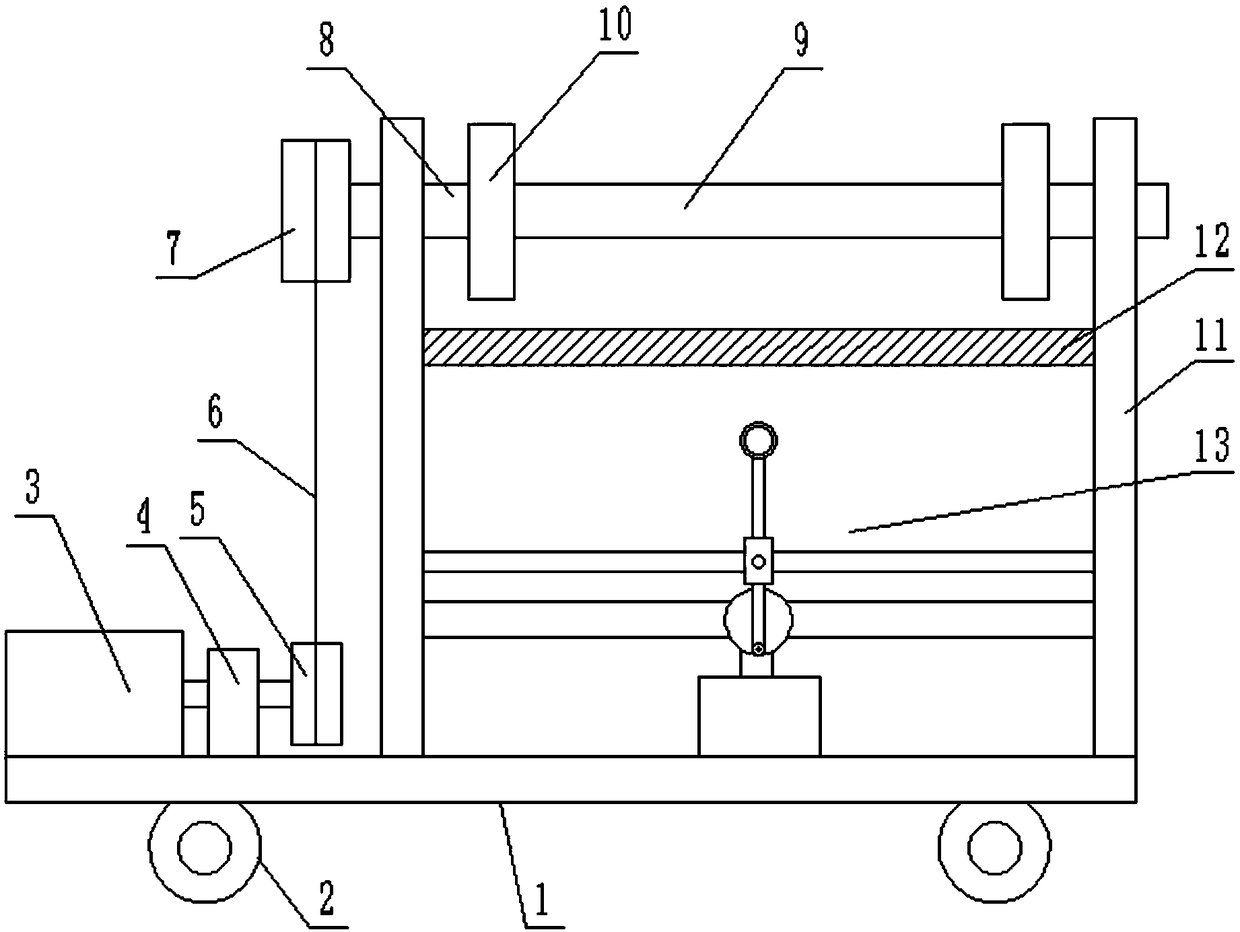

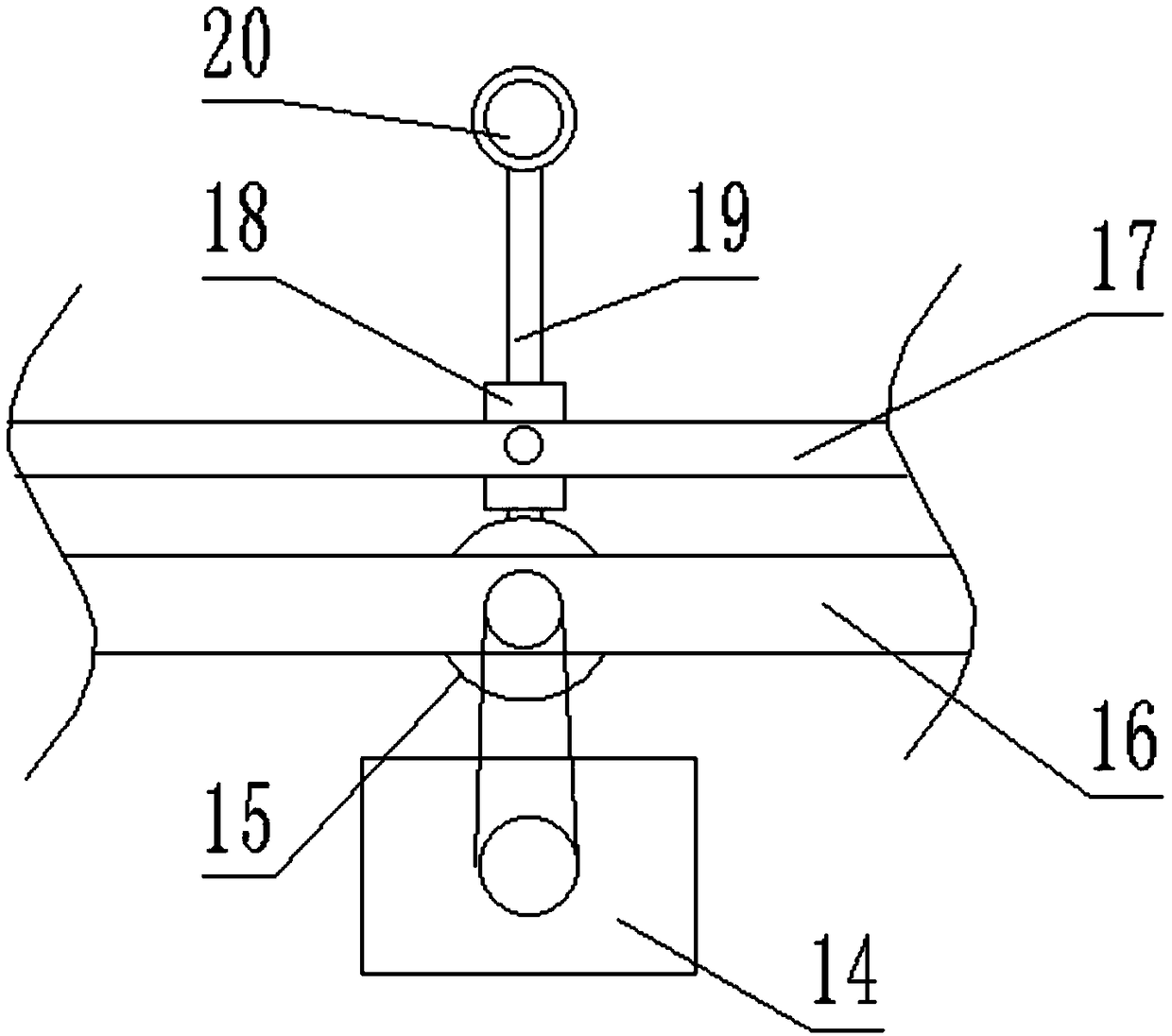

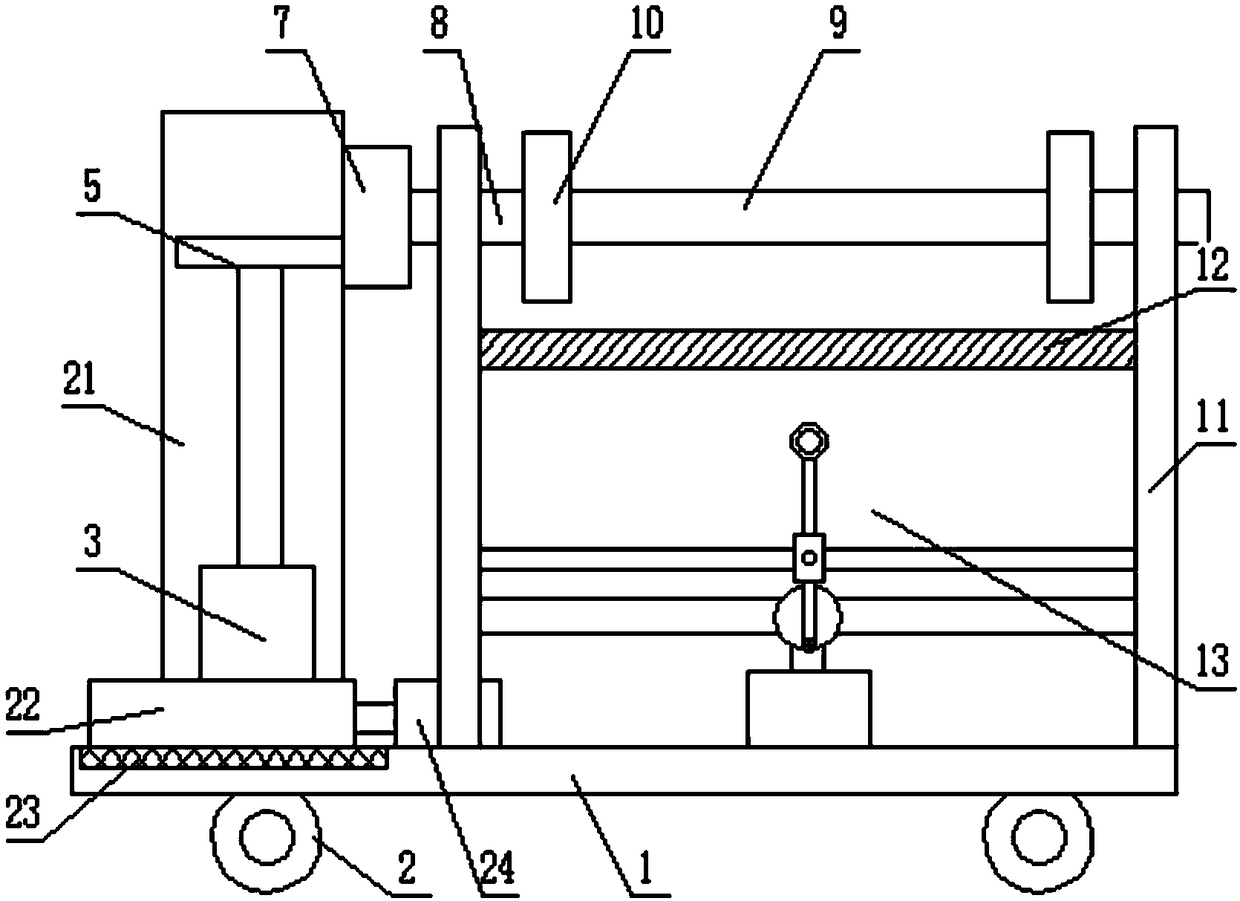

Automatic sorting machine for bread slices

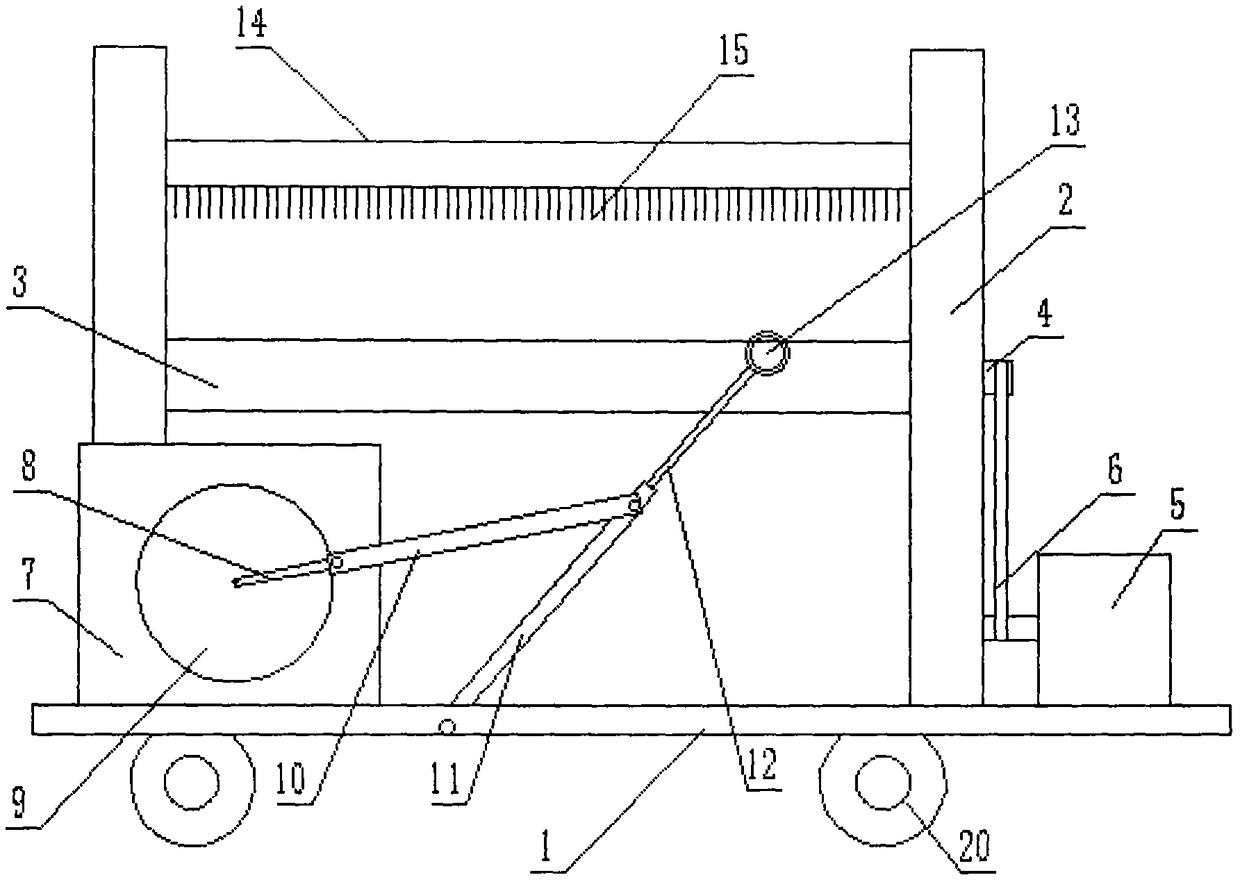

ActiveCN102293226ARealize automatic arrangementAvoid human contactDough processingElectric machineryStructural engineering

The invention discloses an automatic bread slice arranging machine, which comprises a blanking hopper, a cutting device and a feeding device, wherein the cutting device is arranged below the blanking hopper; the feeding device comprises a motor of which the free end in transmission connection with an eccentric wheel, a rocking handle component of which one end is in transmission connection with an eccentric shaft of the eccentric wheel through a connecting rod pin component and the other end is in transmission connection with a transverse rotating shaft, a right chain wheel component which isin transmission connection with the right end of the rotating shaft, a left chain wheel component which is in transmission connection with the left end of the rotating shaft, and a feeding plate component which is arranged below the cutting device and of which the left and right ends are in transmission connection with the left chain wheel component and the right chain wheel component respectively along the vertical direction. The automatic bread slice arranging machine has high production efficiency, is clean and sanitary and meets the using requirements of the conventional bread processing industry.

Owner:广州浩胜食品机械有限公司

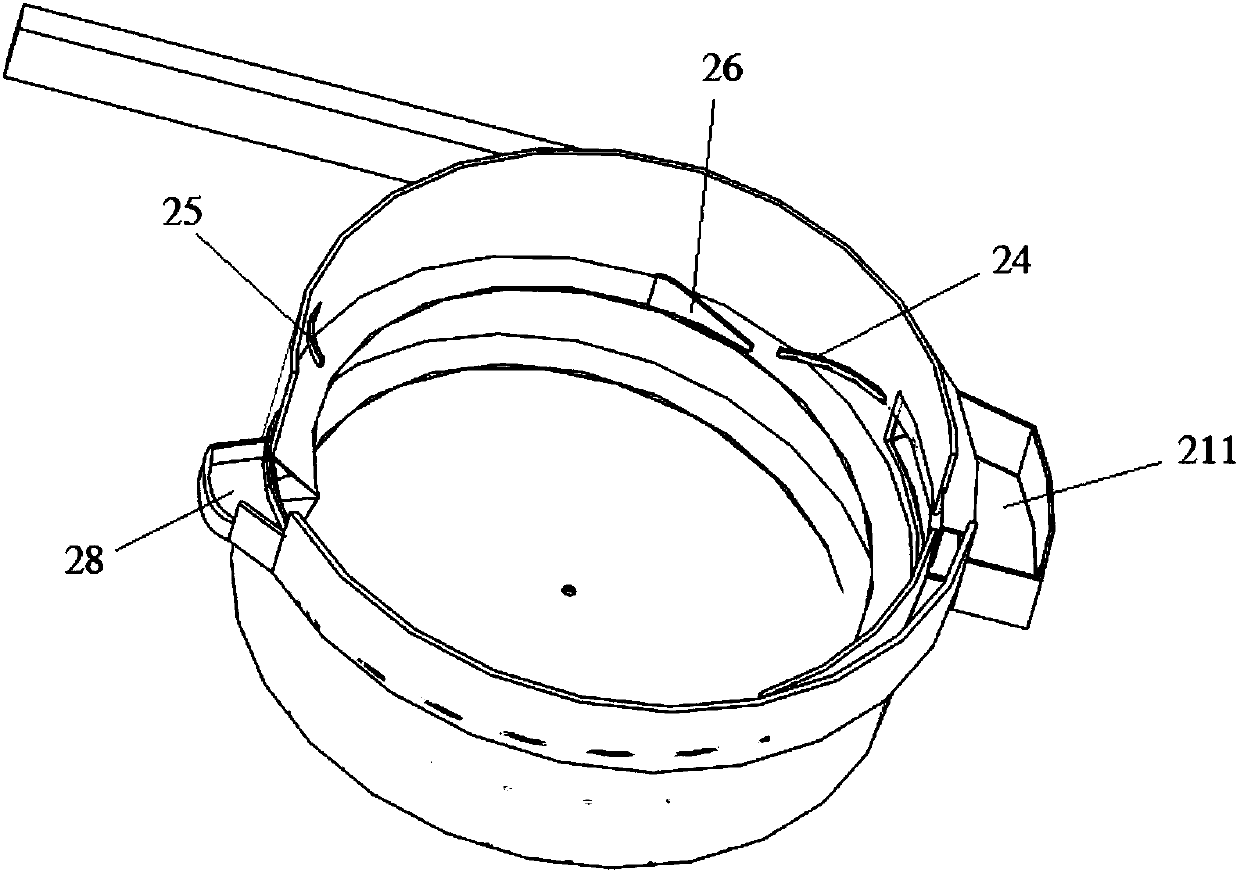

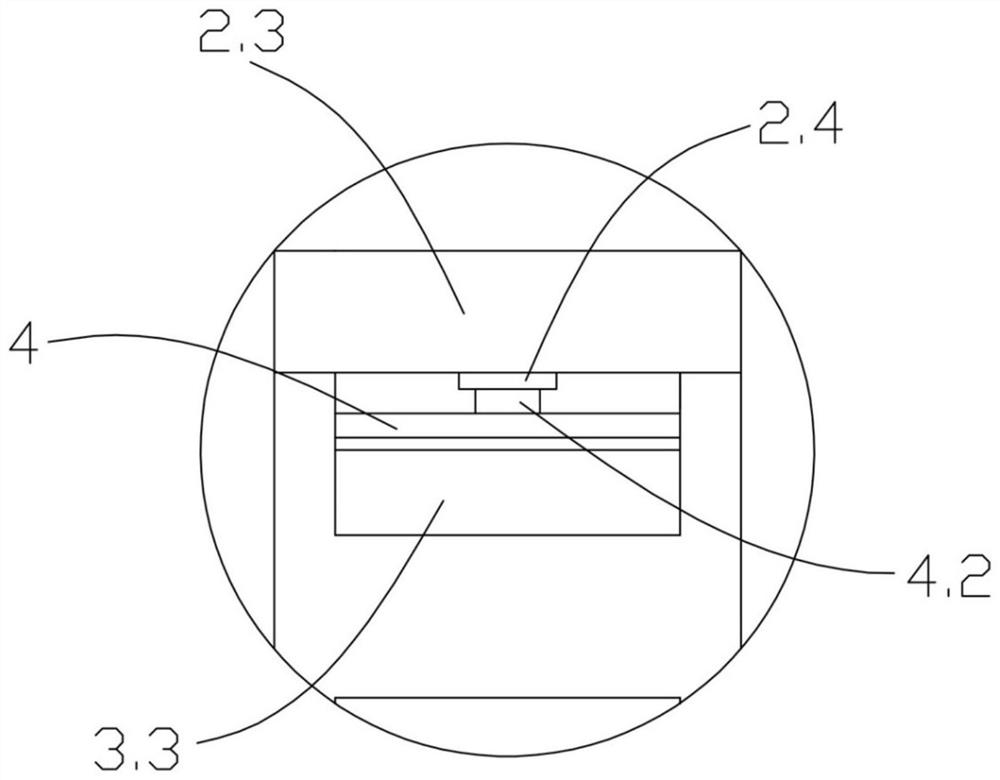

Toothbrush cover automatic arrangement device

ActiveCN107840123ARealize automatic arrangementImplement automatic installationJigging conveyorsConveyor partsProduction rateEngineering

The invention discloses a toothbrush cover automatic arrangement device. The toothbrush cover automatic arrangement device comprises a vibration motor (1), and a vibration disc (2) connected to the vibration motor (1); the vibration disc (2) comprises a cylinder (21), and a rotating disc (22) formed on a spiral rail of the cylinder (21); the rotating disc (22) is provided with a first stop bar (23), a second stop bar (24), an overturning stopper (26) and a third stop bar (25) arranged in a toothbrush cover advancement direction in sequence; the first stop bar (23), the second stop bar (24) andthe third stop bar (25) extend above the rotating disc (22), and form passing height limiting space with the spiral rail of the rotating disc (22); the overturning stopper (26) is perpendicularly fixed on the edge of the rail of the rotating disc (22); and the height of the top edge of the overturning stopper (26) is gradually increased in the toothbrush cover advancement direction. The toothbrush cover automatic arrangement device can realize automatic arrangement of toothbrush covers, is convenient to realize automatic installation of the toothbrush covers, reduces the cost, and improves the productivity.

Owner:BERNER PLASTIC PROD SUZHOU CO LTD

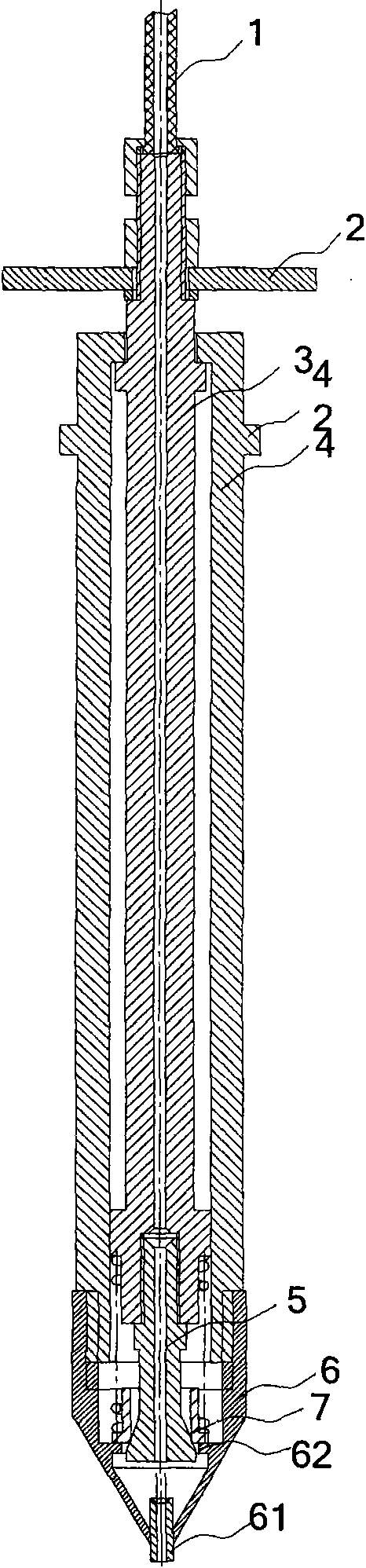

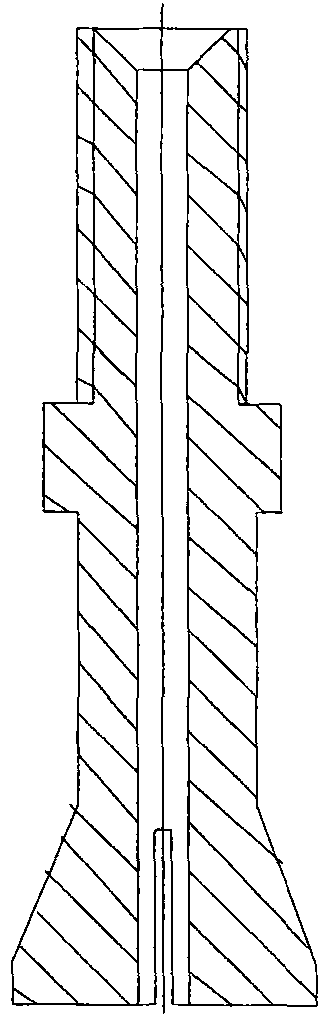

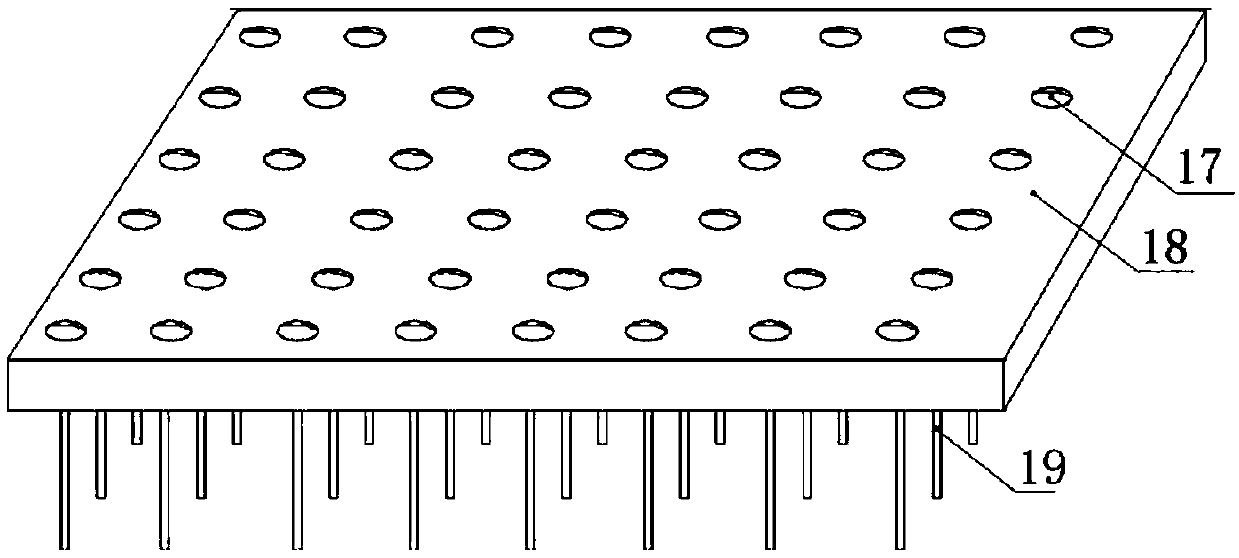

Ceramic column grid array packaging and column planting device

ActiveCN102024714ARealize automatic arrangementImprove work efficiencySemiconductor/solid-state device manufacturingEngineeringFeeding tube

The invention relates to a ceramic column grid array packaging and column planting device. The invention is characterized in that the device comprises a feeding tube, a stock bin, a sheath, a valve and a cap, wherein the feeding tube, the stock bin and the valve are sequentially connected, the tube cavities are opposite along axial direction, the stock bin and the valve are respectively sheathed in the sheath and the cap, the cap is provided with a discharge hole, and the discharge hole is opposite to the tube cavity of the valve. A welding column is arranged in the tube cavity of the column planting device by virtue of the feeding tube, the column planting device is vertically placed on the case of the tube to be welded when planting the column, and the stock bin drives the valve to movealong axial direction in the sheath, thus controlling the delivery of the welding column by utilizing the open and close of the tube cavity of the valve to realize automatic welding column planting. By utilizing the invention, the problems that manual column planting wastes time and labor and the accuracy is low are solved, and the work efficiency and the column planting accuracy are greatly improved.

Owner:BEIJING MXTRONICS CORP +1

Multi-line material bonding machine device and implementation method thereof

ActiveCN113734769AImprove product qualityFast bondingLiquid surface applicatorsFinal product manufactureStructural engineeringManufacturing engineering

The invention discloses a multi-line material bonding machine device. The multi-line material bonding machine device comprises a rack, a mechanical arm is connected to the upper portion of the rack, the output end of the mechanical arm is connected with a material clamping mechanism and a material bonding mechanism, the material clamping mechanism is located on one side of the material bonding mechanism, a discharging mechanism corresponding to the material bonding mechanism and an arranging mechanism corresponding to the material clamping mechanism are arranged above the rack, and a feeding mechanism corresponding to the arranging mechanism is arranged on one side of the rack. The invention further discloses an implementation method of the multi-line material bonding machine device. According to the multi-line material bonding machine device and the implementation method, automatic arrangement of materials and integration after arrangement are realized; the mechanical arm drives the material clamping mechanism to act to realize automatic carrying of materials, and the mechanical arm drives a gluing head to act to cooperate with a material seat lifting module to realize automatic gluing and bonding of the materials; and the multi-line material bonding machine device has the characteristics of being high in quality of bonded products, high in bonding speed, high in bonding precision, stable in productivity and capable of saving labor cost.

Owner:华创天成(东阳市)电子有限公司

Automatic double-row type lead acid battery pole group arranging process

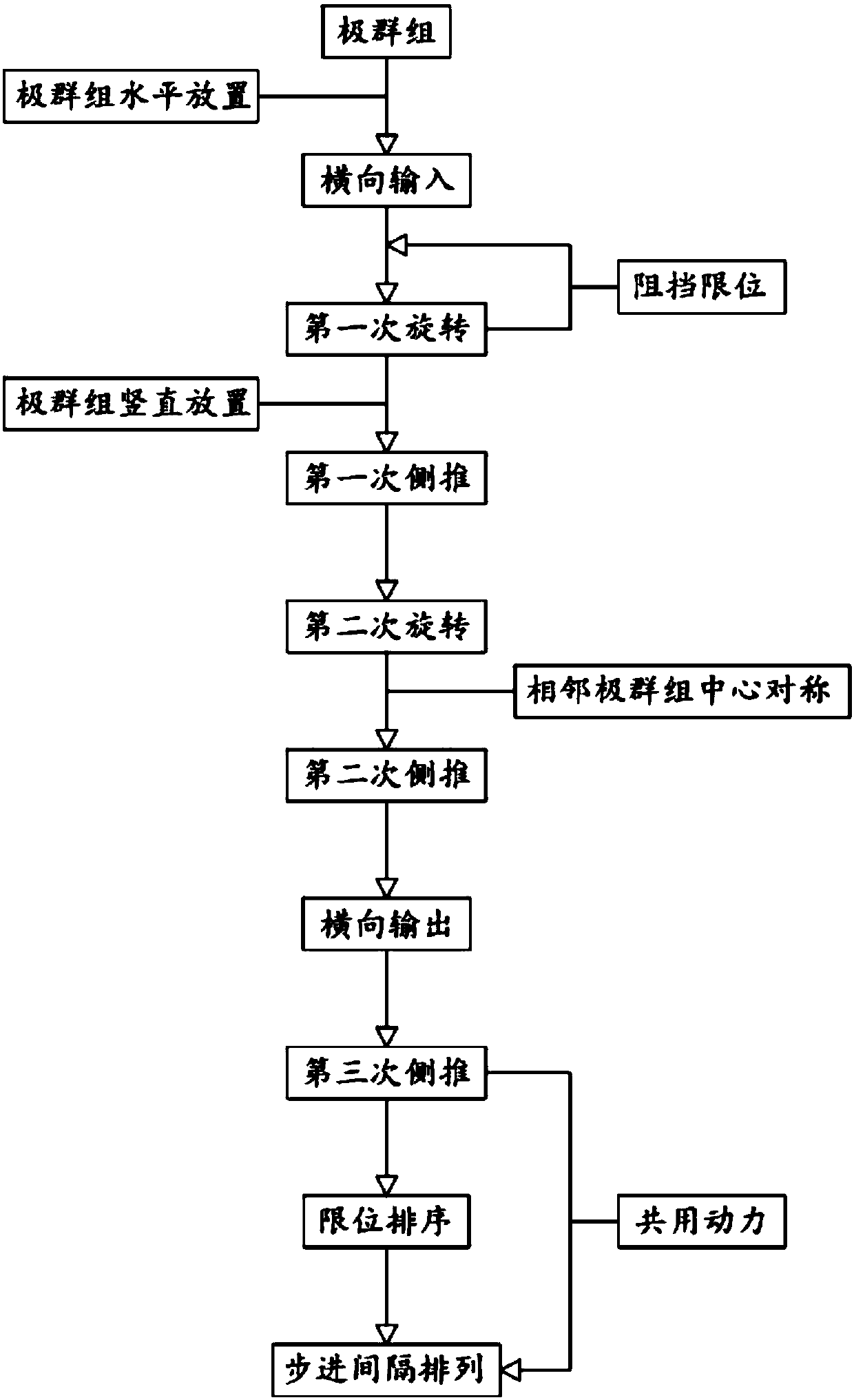

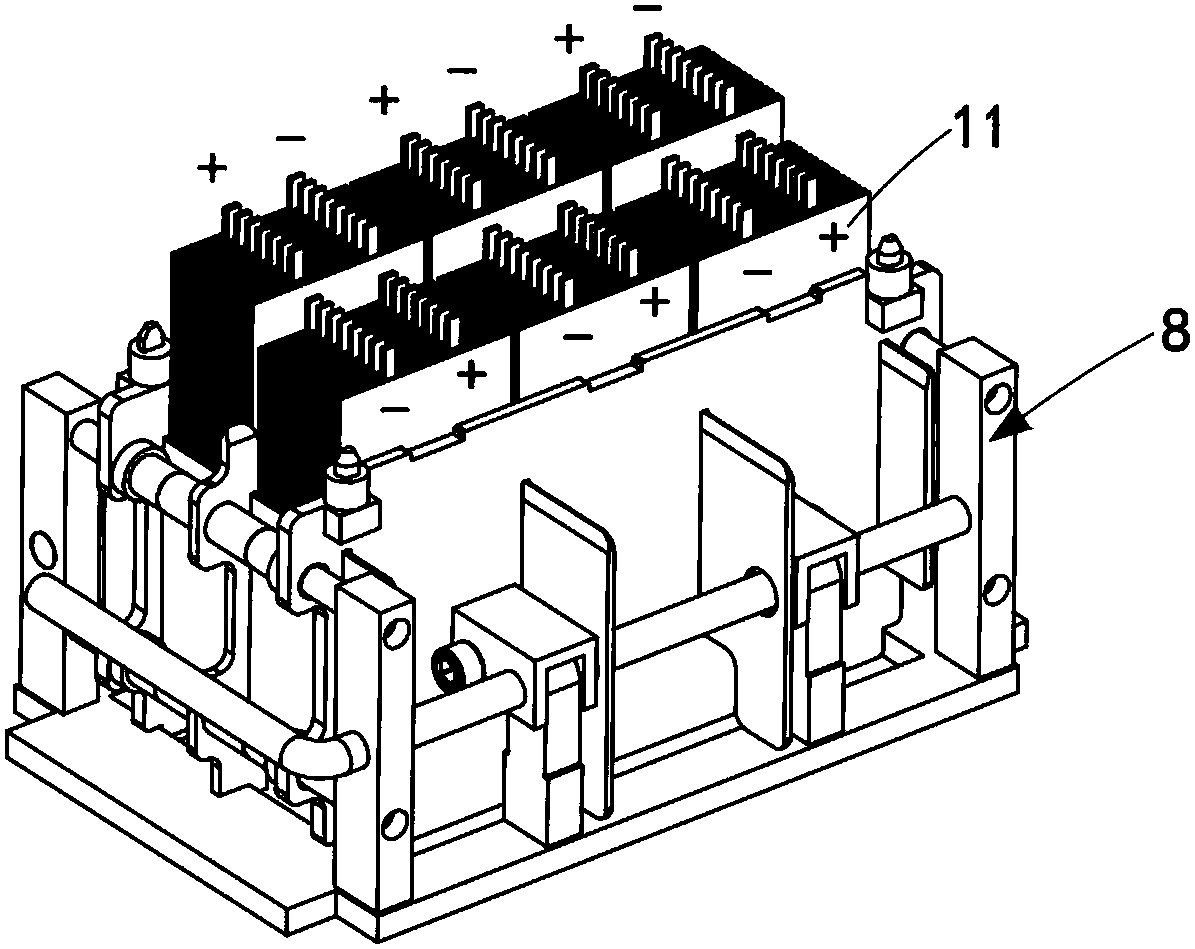

ActiveCN107768740ARealize automatic arrangementImprove work efficiencyFinal product manufactureLead-acid accumulators constructionDouble rowElectrical and Electronics engineering

The invention provides an automatic double-row type lead acid battery pole group arranging process and aims to solve the technical problem of automatic arrangement of double-row type lead acid batterypole groups. The process comprises a first rotation procedure and a second rotation procedure, namely a horizontally conveyed pole group unit is rotated into being arranged vertically, secondly the vertically arranged pole group unit is rotated for a second time, then centers of front and back adjacent pole group units are arranged symmetrically, two adjacent pole group units are pulled and limited in a third lateral push procedure, and the pushed pole group units are pushed into a battery in a stepping procedure, and thus automatic arrangement of pole groups for forming a group of double-rowtype lead acid batteries is achieved. By adopting the process, manual operation is substituted by mechanical operation, the working efficiency is improved, and the arrangement failure rate is reduced.

Owner:临泉鹏成机电技术有限公司

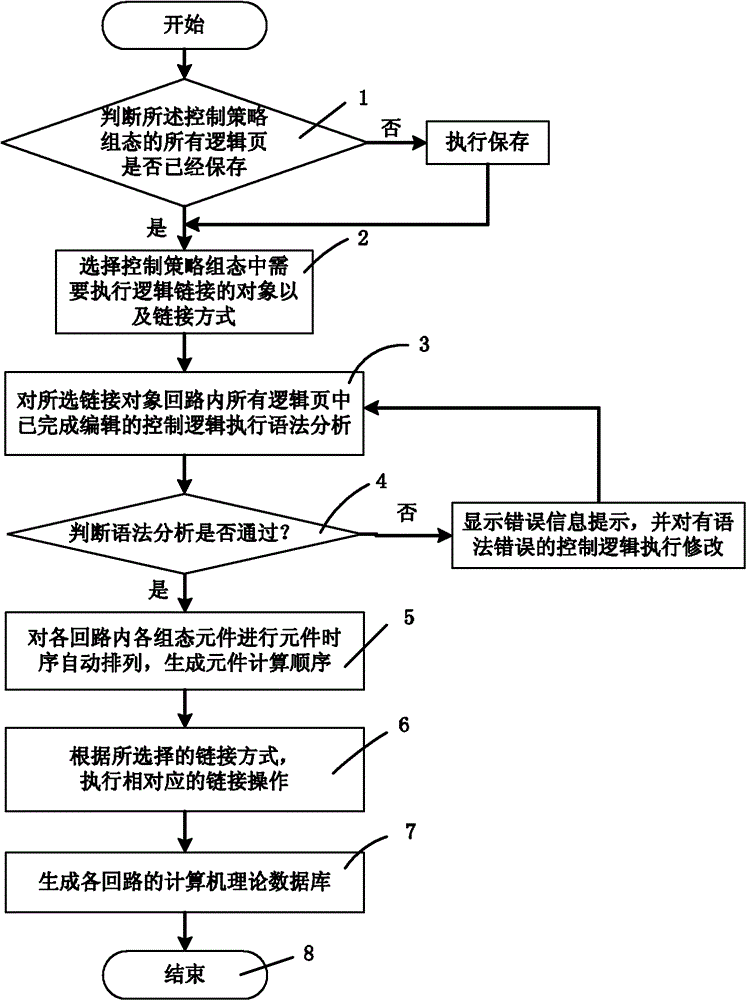

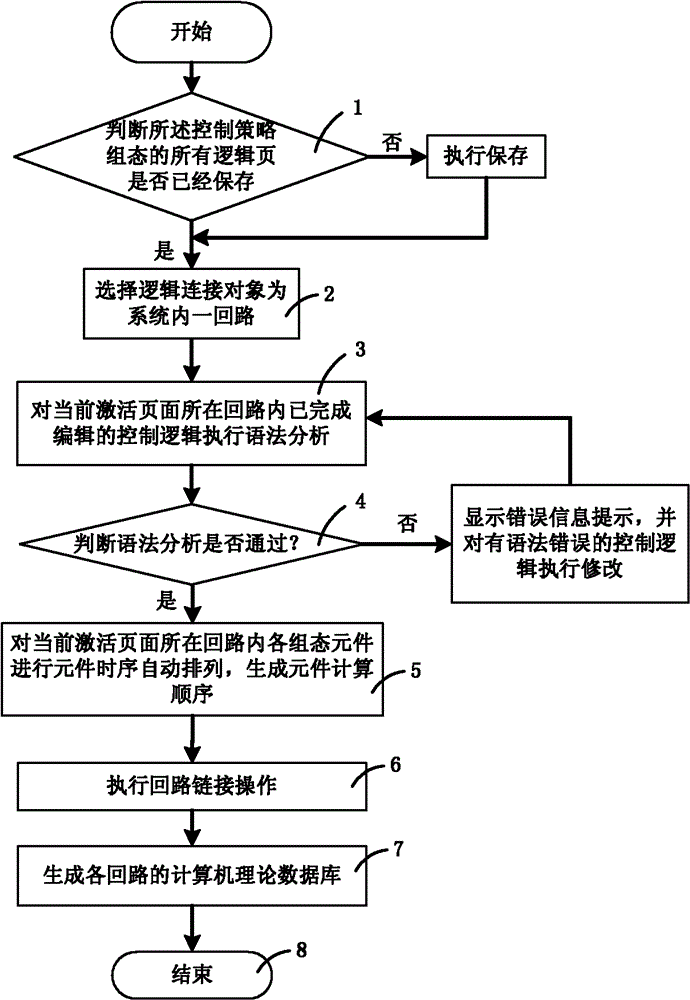

The Method of Component Timing Automatic Arrangement and Logical Linking Method of Control Strategy Configuration

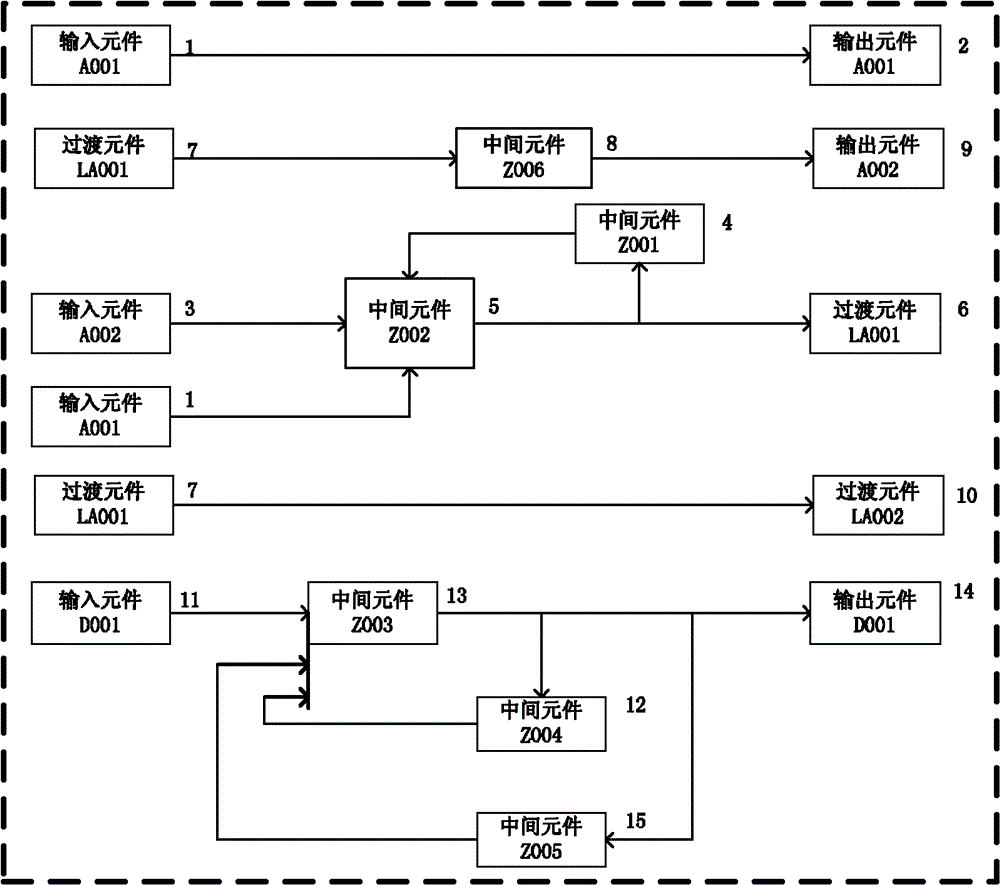

ActiveCN103135975BIncrease flexibilityRealize automatic arrangementSpecific program execution arrangementsSorting problemComputer science

The invention provides an element sequence automatic arrangement method of a control strategy configuration. The method is achieved based on a following topological sorting rule: firstly, a priority level of an input side element is superior to a priority level of an output side element; secondly, two elements which are inputted by each other are compared with the number of elements without sorting of input sides of two elements, and elements with less number are firstly sorted; thirdly, input elements or transitional elements just conduct once sorting in the same return circuit, the input elements or the transitional elements are arranged on the input side, and the input elements and the transitional elements have the same subscript numbers and properties; fourthly, the transitional elements with the same subscript numbers and properties repeatedly occur in the same return circuit, and if some transitional elements are arranged on the output side, the transitional elements which are arranged on the output side are taken out to firstly conduct sorting. The invention further provides a logic link method of the control strategy configuration. The logic link method of the control strategy configuration comprises a return circuit link and a system link. The element sequence automatic arrangement method of the control strategy configuration and the logic link method thereof achieve automatic arrangement of element sequences, not only improve efficiency of industrial control configuration, but also solve unscientific sorting problem of a round-robin algorithm, and strongly guarantee stability and safety of an industrial control process.

Owner:IAP FUJIAN TECH CO LTD

Equipment suitable for automatic grinding of magnetic materials, and implementation method thereof

PendingCN110802473ARealize automatic arrangementRealize feedingGrinding drivesGrinding feed controlStructural engineeringMaterial distribution

The invention discloses equipment suitable for automatic grinding of magnetic materials. The equipment suitable for automatic grinding of the magnetic materials comprises a rack, wherein a workpiece arrangement vibration disc is connected with the upper portion of the rack, a material distribution mechanism is arranged on one side of the workpiece arrangement vibration disc, a grabbing and transferring assembly is arranged on one side of a linear vibration feeding rail, a sucker assembly is connected to the grabbing and transferring assembly, a grinding wheel adjusting assembly is arranged below the grabbing and transferring assembly, a grinding positioning platform is arranged at one end of the grinding wheel adjusting assembly, and one end of the grinding positioning platform is providedwith a grinding finished product conveying belt. The invention also discloses an implementation method of the equipment suitable for the automatic grinding of the magnetic materials. Workpieces are arranged through the workpiece arrangement vibration disc and are loaded through the linear vibration feeding rail, so that the automatic arrangement and the loading of the workpieces are realized; andwhen an in-place detection sensor detects whether the workpieces are in place or not, an electromagnet push rod drives a jacking piece to separate the workpieces, and automatic separation of the workpieces is realized.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

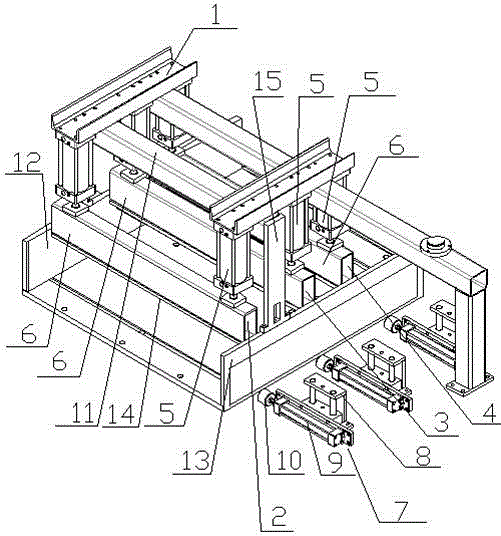

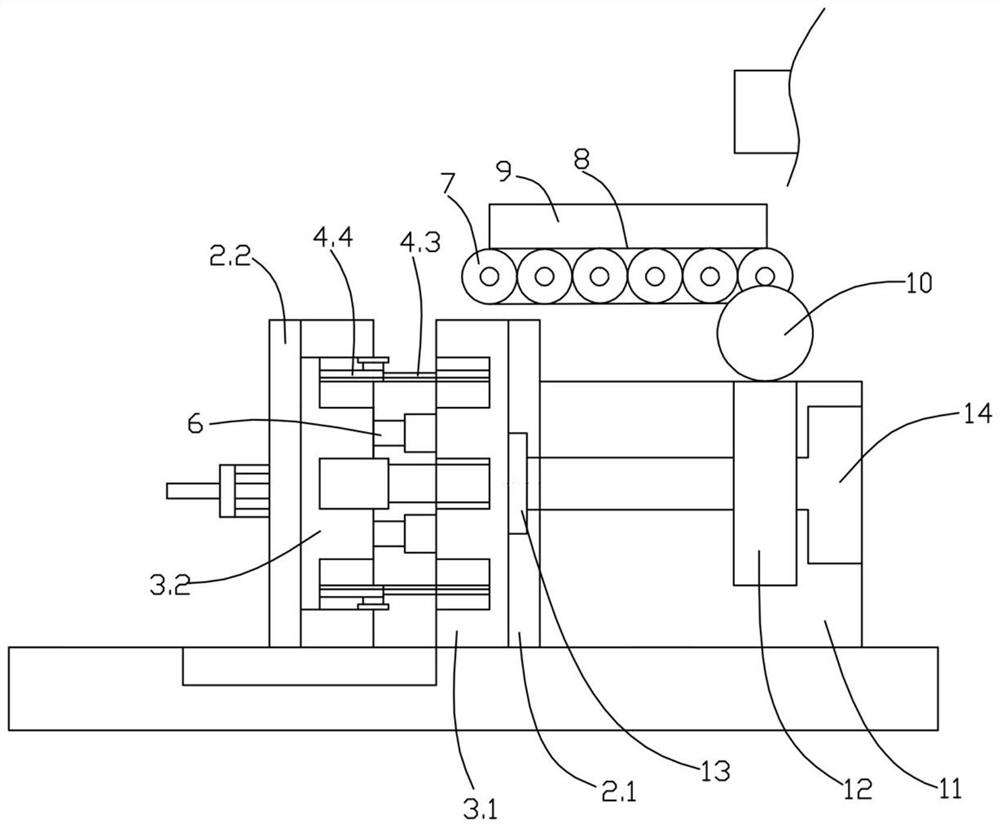

Automatic arranging device of single-shot press

InactiveCN102837955ARealize automatic arrangementAvoid damageEdge grinding machinesConveyor partsEngineeringSingle shot

The invention discloses an automatic arranging device of a single-shot press. The automatic arranging device comprises a magnetic core outlet platform device, a magnetic core level overturning device, a conveyor belt device, a magnetic core positive surface burr removing device, a magnetic core vertical overturning device, a magnetic core negative surface burr removing device, a plate pushing plate and a product arranging platform. According to the automatic arranging device provided by the invention, the pressed magnetic core is overturned and subjected to burr removing twice, and then conveyed to the product arranging area through the conveyor belt, and the magnetic cores can be automatically arranged on the product arranging platform by being pushed via the plate pushing device; during actual production, automatic arrangement can be reasonably achieved according to the requirement of a follow-up sintering process, and the burr on the surface of the pressed magnetic core can be universally removed, thus, the damage on the product due to manual operation can be avoided, and the percent of pass of products can be improved.

Owner:天通(六安)新材料有限公司

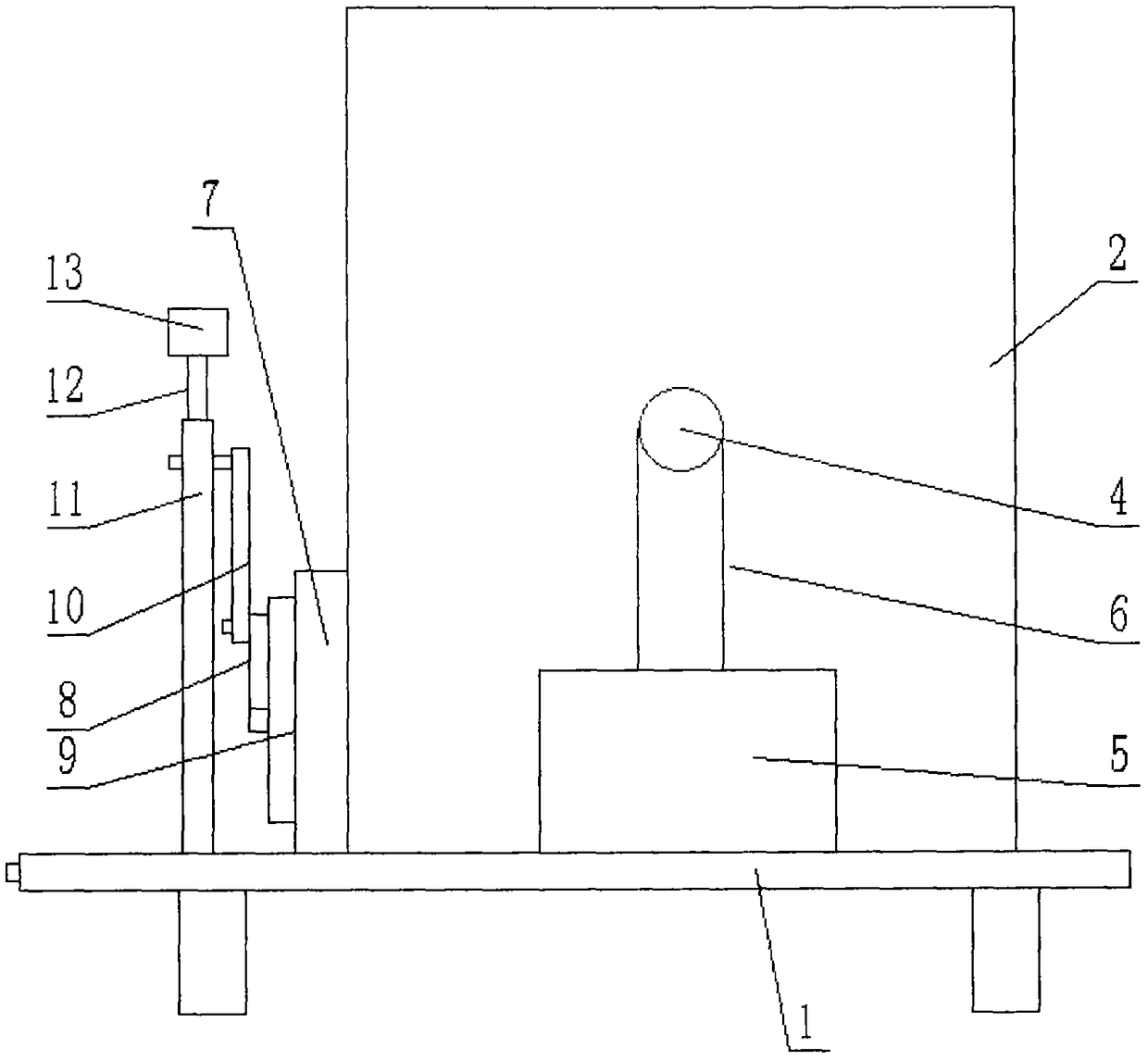

Automatic conveying and arrangement device of brake pads

The invention belongs to the technical field of automobile spare parts, and particularly discloses an automatic conveying and arrangement device of brake pads. The automatic conveying and arrangementdevice comprises a conveying table and an arrangement table. The conveying table is composed of a driving wheel, a driven wheel, a supporting wheel and a conveying belt A. The arrangement table is composed of transmission wheels and a conveying belt B wrapping the transmission wheels. The arrangement table is close to the supporting wheel on the conveying table. An elastic part and a sliding blockcapable of sliding up and down are arranged in the supporting wheel, and the sliding block is located on the upper portion of the elastic part and partially stretches out of the supporting wheel. Locating devices are arranged on the conveying belt B and are each composed of two longitudinal plates, a base and clamp blocks. The device solves the problems that in the prior art, the conveying efficiency of the brake pads before machining is low and the manual cost is large, and the device capable of achieving automatic conveying and arrangement of the brake pads is provided.

Owner:CHONGQING JIANAN IND & TRADE

Full-automatic carbon brush assembling equipment

ActiveCN105826792ARealize automatic arrangementFully automatedRotary current collectorContact member assembly/disassemblyVertical planeEngineering

The invention relates to full-automatic carbon brush assembling equipment, and overcomes the defect that assembling of an existing carbon brush adopts manual assembling, grinding and repairing treatment needs to be performed on a carbon block in an early stage, and a process is increased. The full-automatic carbon brush assembling equipment includes a station rotating disc, a carbon block automatic feed mechanism, a carbon block automatic grinding and repairing mechanism, a spring automatic feeding assembling mechanism and a carbon brush automatic discharge mechanism, wherein the station rotating disc is vertically arranged and rotates in a vertical plane, the carbon block automatic feed mechanism includes a carbon block vibration arrangement cylinder and a carbon automatic transfer device, and the spring automatic feeding assembling mechanism includes a spring vibration arrangement cylinder and a spring grip. The carbon block automatic feed mechanism can realize automatic arrangement of carbon blocks and can automatically clamp the carbon blocks onto the station rotating disc, the spring automatic feeding assembling mechanism realizes automatic arrangement of springs and automatically assemblies the springs to end parts of the carbon blocks through the spring grip, in a rotating process of the station rotating disc, automatic grinding and repairing are realized by the carbon block automatic grinding and repairing mechanism, processes are reduced, the whole process realizes automation, and the efficiency is improved.

Owner:丽水市长新电器制造有限公司

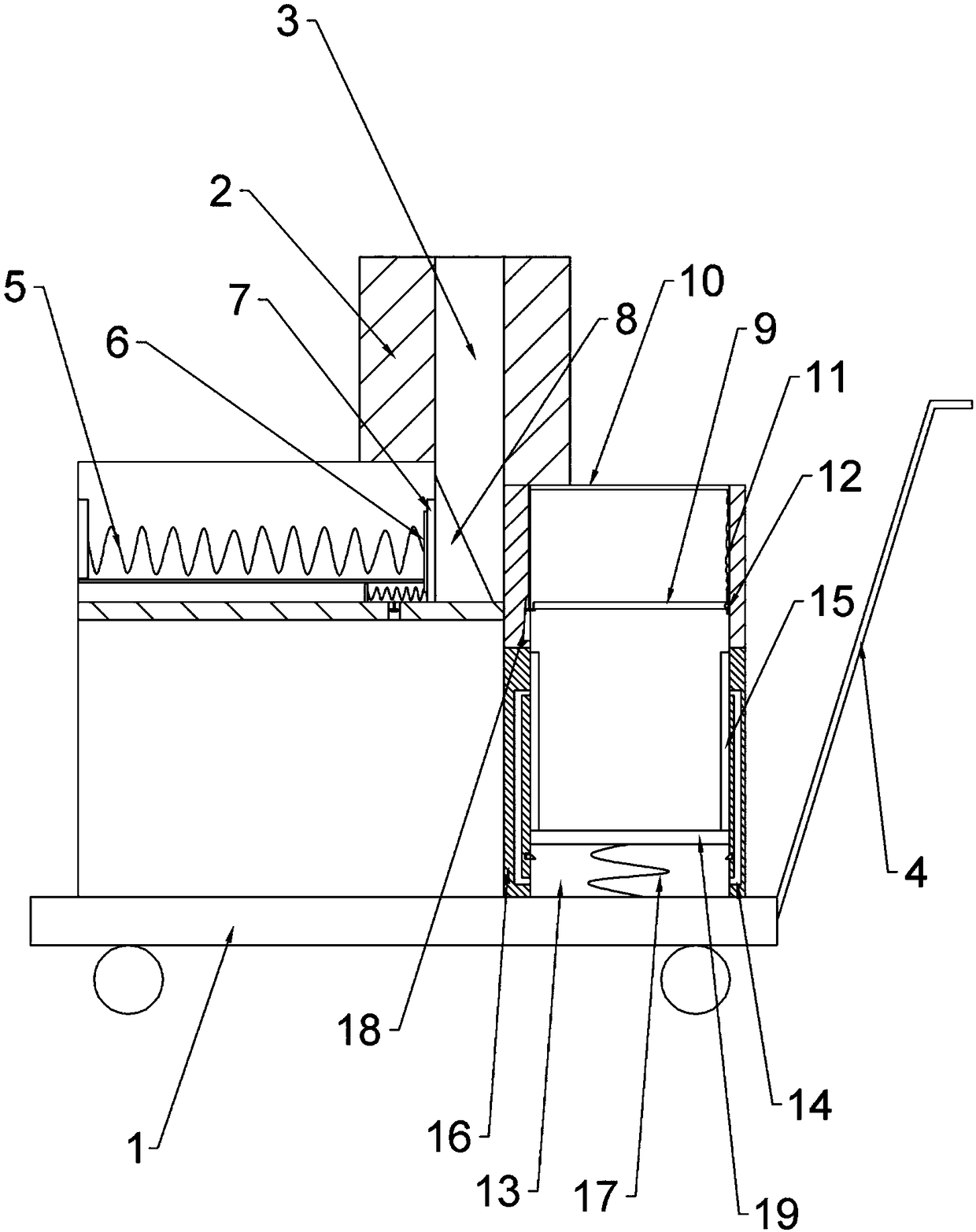

Component transport device

ActiveCN108482459AEasy to fixRealize automatic arrangementHand carts with multiple axesHand cart accessoriesMotor vehicle partEngineering

The invention belongs to the field of machining devices, and particularly discloses a component transport device which comprises a vehicle. A fixing tank is arranged at the upper end of the vehicle, an arranging structure is detachably connected with the upper side of the fixing tank and comprises a dropping portion, an oblique block, a first pressure spring and a push plate, a vertical dropping groove is formed in the middle of the dropping portion, and the fixing tank is positioned on the lower side of an arranging cavity and is communicated with the arranging cavity. The component transportdevice has the advantage that automobile components can be automatically arranged by the aid of the component transport device and can be automatically fixed by the aid of the component transport device.

Owner:宁波鑫神泽汽车零部件有限公司

Feeding device of egg tart cooking machine

PendingCN110447670ARealize continuous baking productionImprove production efficiencyCharging/discharging ovensEngineeringTransfer mechanism

The invention discloses a feeding device of an egg tart cooking machine, which includes a third frame body, the third frame body is provided with an intermittent transfer mechanism, and the intermittent transfer mechanism is used to make the egg tarts move in batches. The intermittent transfer mechanism includes a third conveyor belt and a fourth conveyor belt arranged along an egg tart conveyingdirection, the third conveyor belt is higher than a fourth conveyor belt, and the intermittent transfer mechanism further includes a transfer assembly for transferring the egg tarts from the third conveyor belt to the fourth conveyor belt. The transfer assembly is disposed between the third conveyor belt and the fourth conveyor belt. The transfer assembly includes a receiving cavity that receivesthe tart from up and down, a support plate that intermittently closes the bottom of the receiving cavity, a carrier board disposed below the support plate for placing egg tarts, a third power component for driving the carrier board to move up and down, and a side pushing plate for pushing the egg tarts from the carrier board to the fourth conveyor belt. The feeding device of the egg tart cooking machine of the present invention can output the egg tarts in a set quantity, is convenient for packaging, and does not affect the use of the egg tart cooking machine.

Owner:WUYI UNIV

Automatic arranging device for hoses

InactiveCN104340659ARealize automatic arrangementAvoid manual contactConveyor partsElectric machineryEngineering

The invention provides an automatic arranging device for hoses. The automatic arranging device comprises a frame, a lower turntable, an upper turntable, a protective ring and a power device, wherein the lower turntable is rotatably arranged on the frame; coaxial with the lower turntable, the upper turntable is rotatably arranged on the frame and positioned on the upper surface of the lower turntable; the diameter of the upper turntable is smaller than that of the lower turntable; the protective ring is arranged in the circumferential direction of the lower turntable in an encircled manner; a hose outlet is formed in the side wall of the protective ring; the power device comprises a lower turntable motor and an upper turntable motor which have reverse rotation directions; the lower turntable motor is connected with the lower turntable; the upper turntable motor is connected with the upper turntable. The automatic arranging device for the hoses, provided by the invention, has the advantages as follows: the lower turntable motor and the upper turntable motor rotate in reverse directions to drive the lower turntable and the upper turntable to rotate respectively; under the rotations of the lower turntable and the upper turntable, the hose rotates together with the lower turntable along the inner wall of the protective ring due to a centrifugal effect and is finally sent out from the hose outlet; compared with the prior art, the automatic arranging device has the advantages that the labor is saved, the hoses are automatically arranged, the working efficiency is increased, manual contact of the hoses is avoided and sanitary requirements are satisfied.

Owner:南通市通州区三槐机械制造有限公司

A four-color bulk terminal crimping machine

ActiveCN105703195BRealize automatic arrangementAccurate grippingLine/current collector detailsMicrocontrollerVibration control

Owner:QINGDAO SPELSBERG ELECTRICAL ENG TECH CO LTD

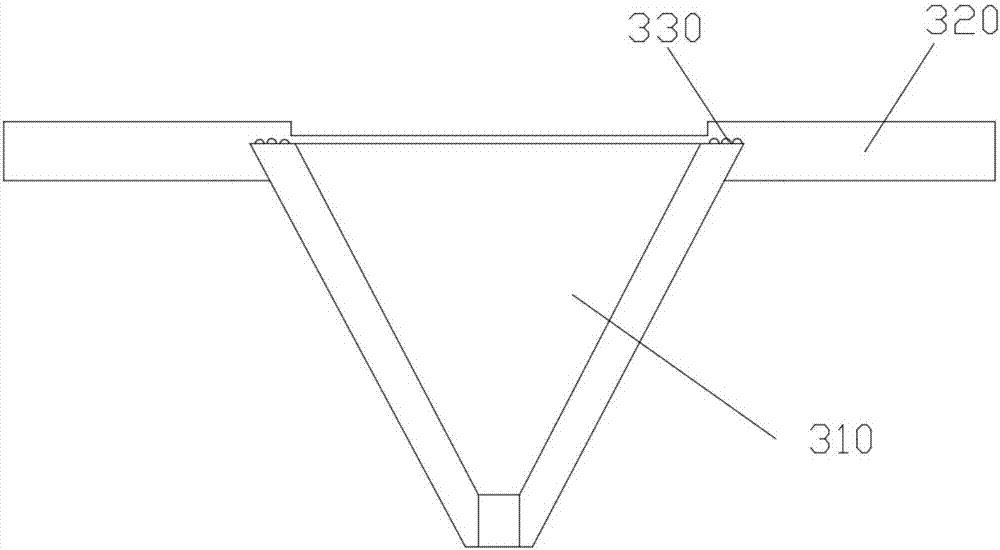

Feeding mechanism of universal joints

PendingCN107973069ARealize automatic arrangementReduce workloadConveyor partsRotary conveyorsUniversal jointEngineering

The invention discloses a feeding mechanism of universal joints. The feeding mechanism comprises a barrel body, a rotating plate, a rotating assembly, a funnel assembly and a feeding groove; the feeding groove is located at the top of the barrel body, and the top of the barrel body is provided with an opening connected with the feeding groove in a matched mode; the rotating plate is located at thebottom of the barrel body and is rotatably connected with the barrel body; the rotating assembly is located below the rotating plate, and the rotating assembly and the rotating plate rotate synchronously; and the funnel assembly faces the barrel body and is rotatably connected with the barrel body. Compared with the prior art, through rotating of the rotating plate, raw materials move towards theedge of the barrel body under action of centrifugal force, so that the raw materials simultaneously enter a conveying groove under action of the centrifugal force, automatic arranging and automatic feeding of the raw materials are achieved, meanwhile, the raw materials can only enter the barrel body only through the funnel assembly, so that the raw materials are only required to be poured throughthe funnel assembly and can be automatically sorted while passing the funnel assembly, therefore, the raw materials are not required to be sorted, and the workload of operators is reduced.

Owner:PINGHU PINYAO MACHINERY AUTOMATION CO LTD

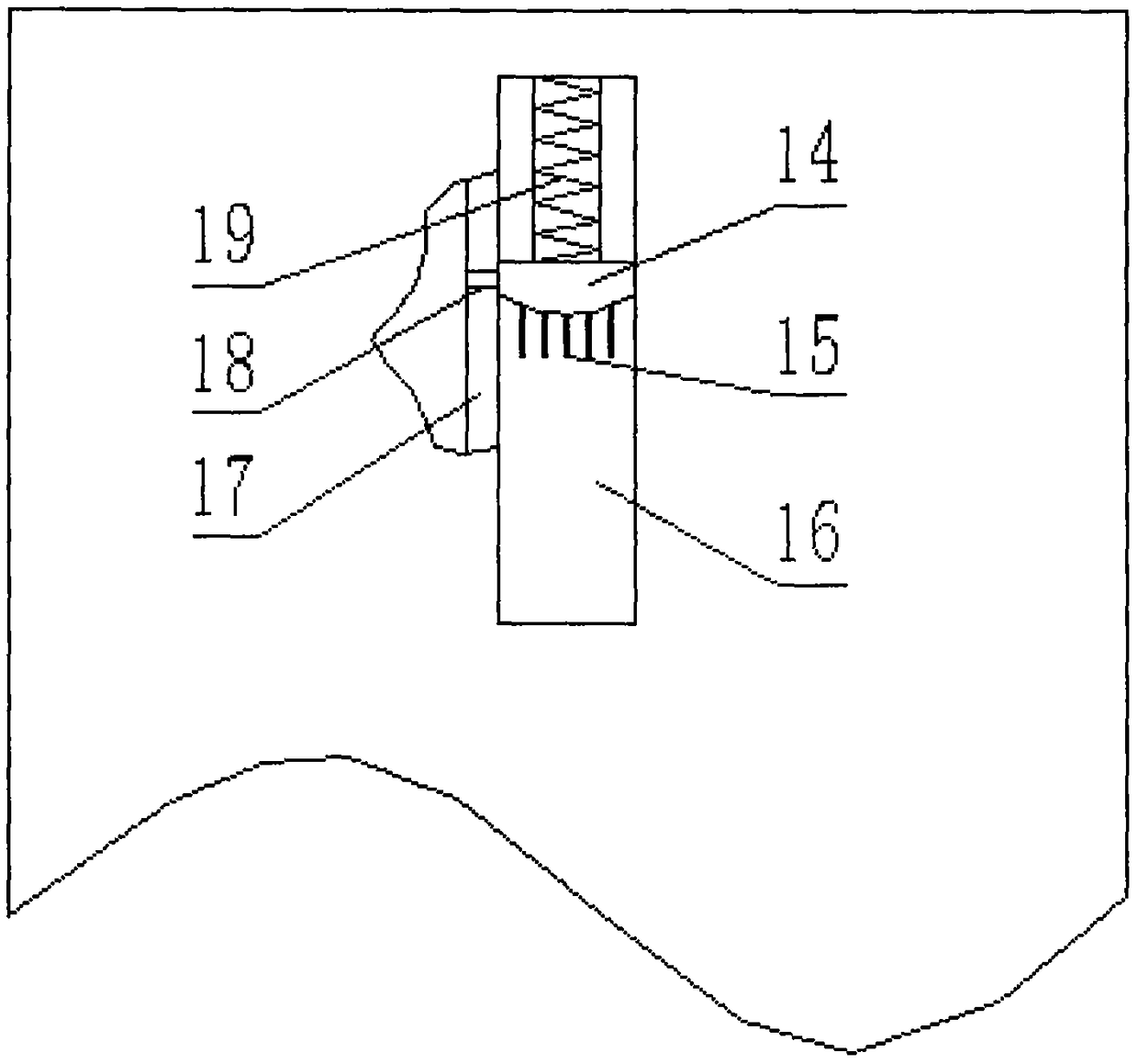

Self-arrangement cable winding and unwinding device for mechanical and electrical installation

InactiveCN108861829AIngenious structureAvoid entanglementFilament handlingVehicle frameClamp connection

The invention discloses a self-arrangement cable winding and unwinding device for mechanical and electrical installation. The device comprises a car frame, a bracket, a two-way motor and a winding andunwinding roller, wherein the bracket is located above the car frame, the bracket is composed of two vertical plates arranged in parallel and perpendicular to the car frame, the two ends of the winding and unwinding roller are provided with rotating shafts in clamped connection with the winding and unwinding roller respectively, the rotating shafts are inserted in the bracket and rotationally connected with the bracket, and a guider is arranged under the winding and unwinding roller; the guider comprises an adjusting motor, a first transverse rod and a second transverse rod, the adjusting motor is fixed on the plane of the car frame, and the first transverse rod and the second transverse rod are located above the adjusting motor and arranged in sequence. The self-arrangement cable windingand unwinding device for the mechanical and electrical installation has the advantages that the structure of the guider is ingenious, during the winding and unwinding work, a rotating rod performs reciprocating swing in a certain angle, so that cables can move back and forth on the winding and unwinding roller during winding, it is avoided that the cables centrally wind on a same place to cause twining, thereby achieving the automatic arrangement of the cables during winding so as to provide convenience for being taken and used later, equipment required by the guider is simple and easy to obtain, and the operation is convenient.

Owner:黄惠珍

Water and electricity mounting barrier-free cable winder for building construction

The invention discloses a water and electricity mounting barrier-free cable winder for building construction. The water and electricity mounting barrier-free cable winder comprises a vehicle frame, asupporting frame fixed to the vehicle frame and a winding roller; and a barrier-free winding and unwinding device is further arranged on the vehicle frame and comprises a low-speed motor fixed to thevehicle frame and located on the front side of the supporting frame, and a swing rod rotationally mounted on the vehicle frame, an output shaft of the low-speed motor is located on the front side faceof the low-speed motor, a rotating disc is mounted on the output shaft, a direct-connection rotating rod fixedly connected with the rotating disc and perpendicular to the output shaft of the low-speed motor is mounted at the center of the front side face of the rotating disc, and a hinging rod rotationally connected with the direct-connection rotating rod is arranged at the front end of the direct-connection rotating rod. According to the water and electricity mounting barrier-free cable winder, by arranging the barrier-free winding and unwinding device on the vehicle frame, cables can be uniformly and orderly wound on the winding roller when wound and unwound, thus the situation that the cables are wound at the same place in a centralized mode is avoided, automatic arrangement of the cables during winding is achieved, unwinding for taking and using is convenient, and the water and electricity mounting barrier-free cable winder is simple in driving mode, easy and convenient to operate, convenient to maintain and suitable for being used and popularized.

Owner:JIANGSU SUZHONG CONSTR GROUP

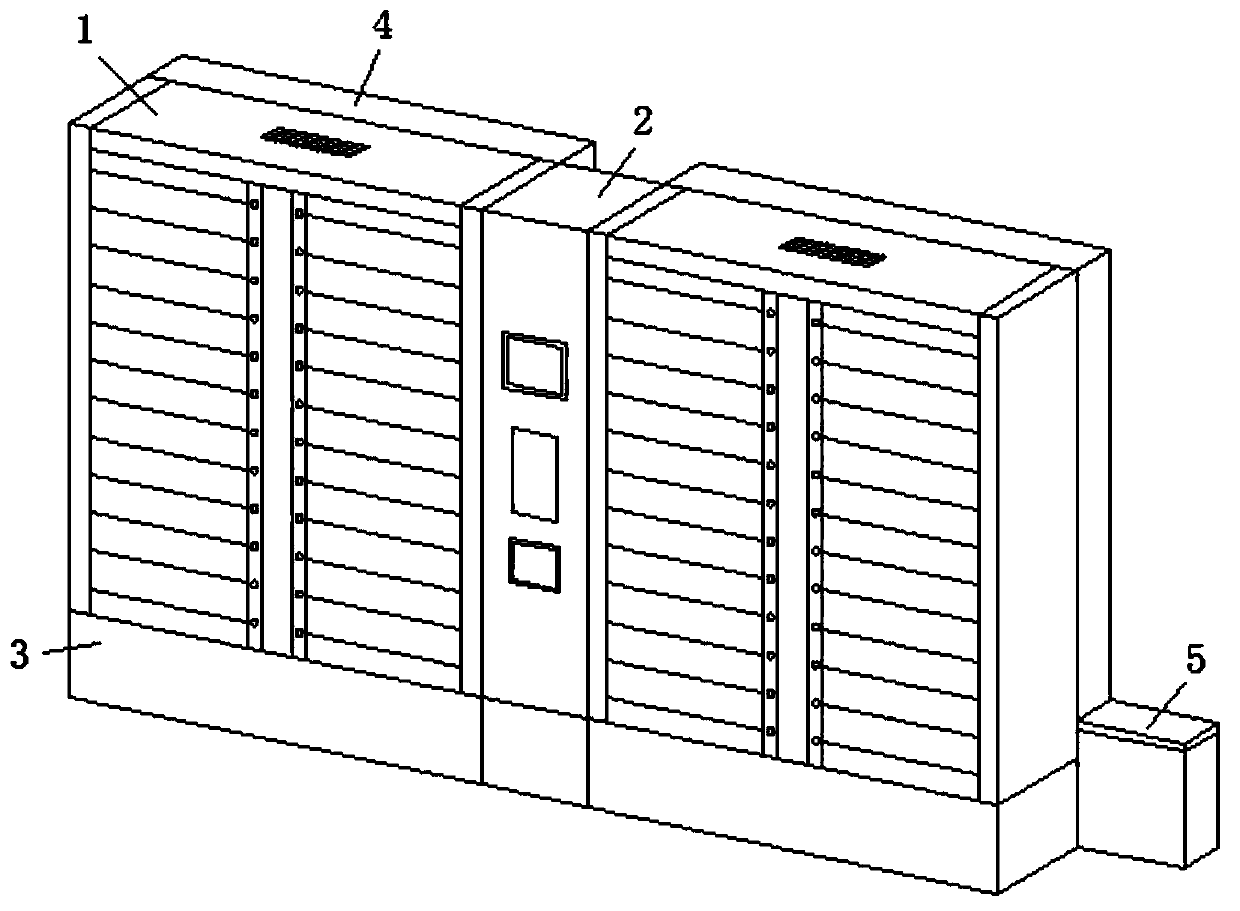

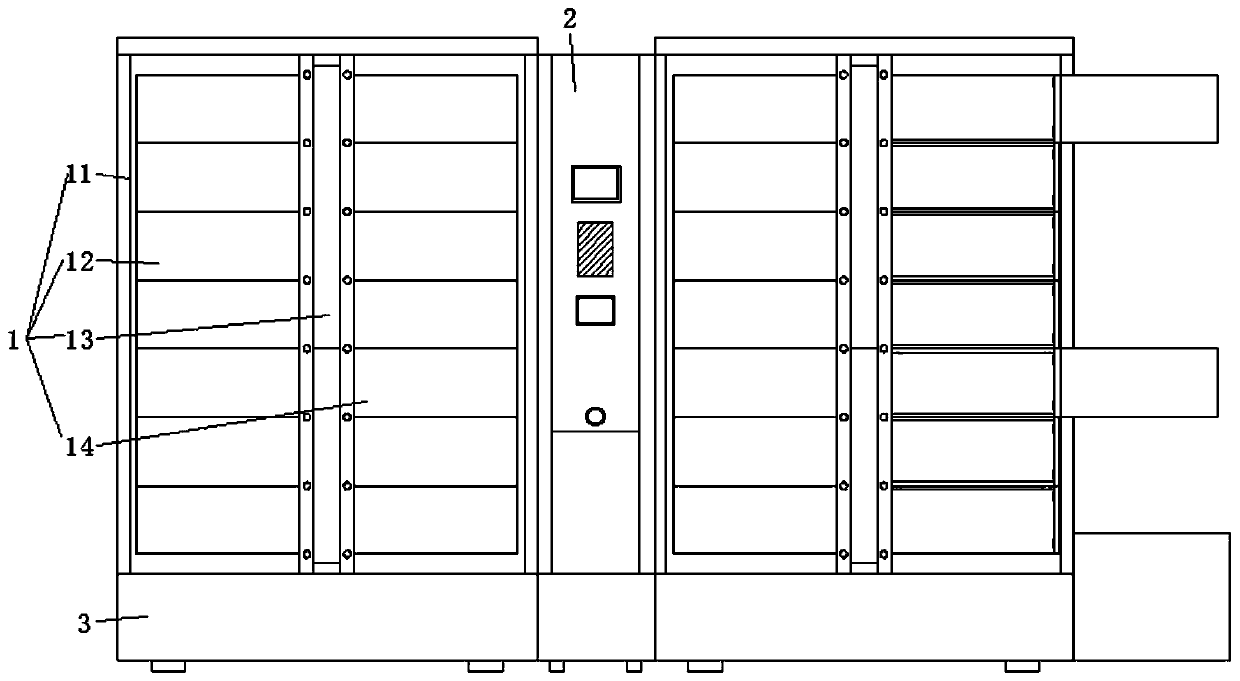

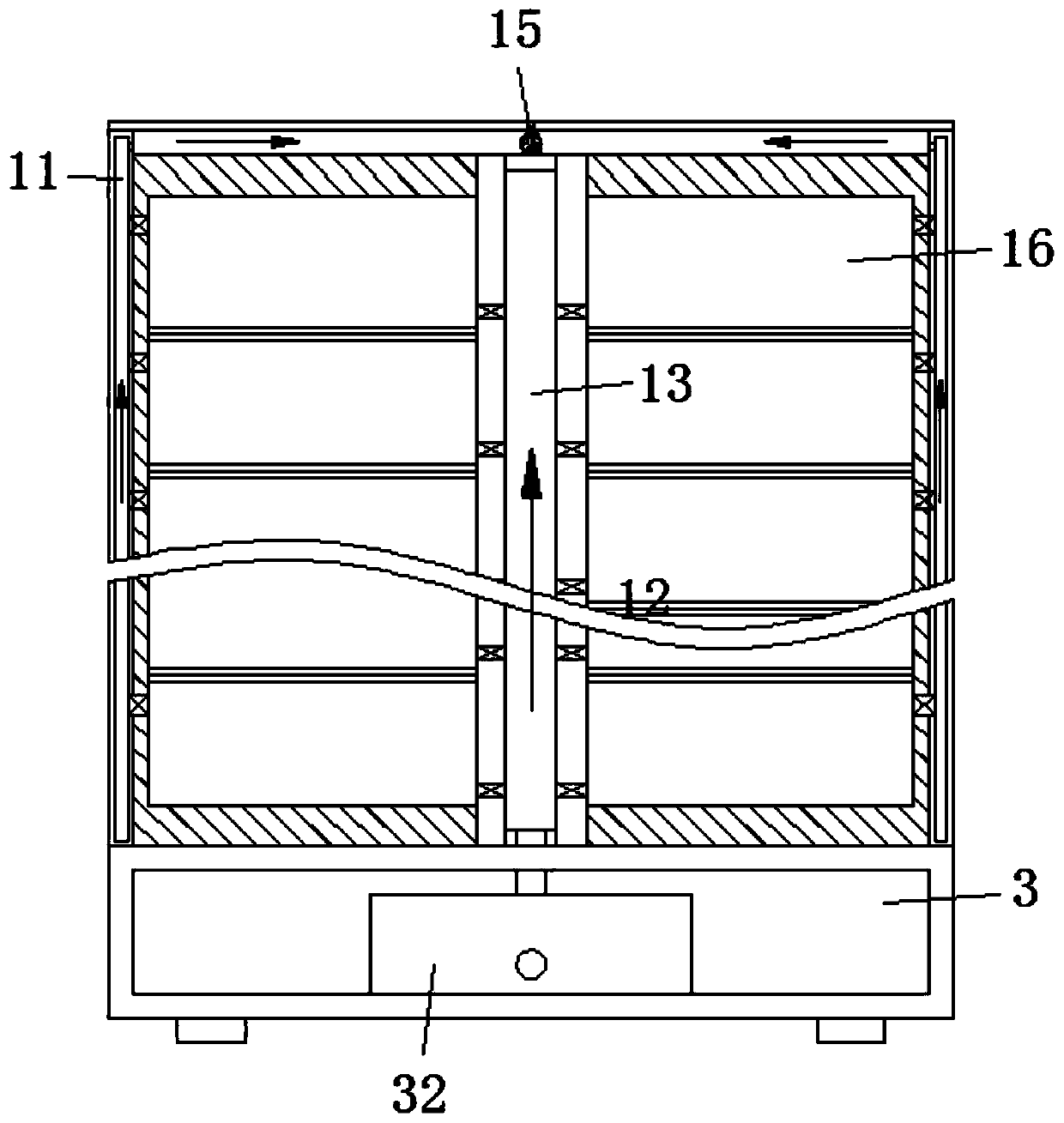

Automatic medicine storage cabinet

PendingCN111012073AMeet different needsEasy to operateChestsDressing tablesPharmacy medicineDrug Storage

The invention belongs to the technical field of medical medicine storage, and discloses an automatic medicine storage cabinet which comprises at least one unit cabinet body used for storing medicine,multiple storage cavities are formed in each unit cabinet body, and a medicine inlet and a medicine outlet are formed in the two sides of each storage cavity; the medicine inlets are located in the back faces of the unit cabinet bodies and provided with sealing assemblies in a matched mode. The medicine outlets are located in the front faces of the unit cabinet bodies and provided with automatic cabinet doors in a matched mode, and an arrangement assembly is further arranged in each storage cavity. A control cabinet is used for realizing automatic control of the unit cabinet bodies; a base ismounted at the bottoms of the unit cabinet bodies and the control cabinet, and a conveying device is mounted in the base; a medicine feeding device is connected to one end of the base; a distributingdevice is mounted at the top of the base and positioned on the back surface of the unit cabinet body; in conclusion, full-automatic medicine feeding and discharging are achieved, different requirements for medicine changing and supplementing of workers and medicine taking of patients are met, operation is easy, remote monitoring is achieved, and use is safe.

Owner:北京通达思睿科技有限公司

Full-automatic cross-flow fan blade shaft hole angle adjusting all-in-one machine

PendingCN112172020ARealize automatic arrangementSame directionDomestic articlesControl systemControl engineering

The invention relates to the field of cross-flow fan blade machining equipment, in particular to a full-automatic cross-flow fan blade shaft hole angle adjusting all-in-one machine which comprises a control system, a feeding device, a pushing device, a lifting steering device and a clamping positioning device. The feeding device is used for arranging and conveying shaft sleeve assemblies; the pushing device is used for sequentially pushing the shaft sleeve assemblies on the feeding device into the lifting steering device; the lifting steering device is used for pushing the shaft sleeve assemblies into the clamping positioning device; the clamping positioning device is used for grabbing the shaft sleeve assemblies and adjusting the angles of shaft holes in the shaft sleeve assemblies; and the control system is used for controlling the feeding device, the pushing device, the lifting steering device and the clamping positioning device to operate in a linkage fit mode. The device is simplein structure and convenient to operate, the shaft hole in each shaft sleeve assembly is adjusted to be opposite to the vacancy between blades through integrated control, and in the whole process, thelabor of workers is greatly reduced, the production efficiency is improved, and the cost is saved.

Owner:四川朗迪塑胶电器有限公司

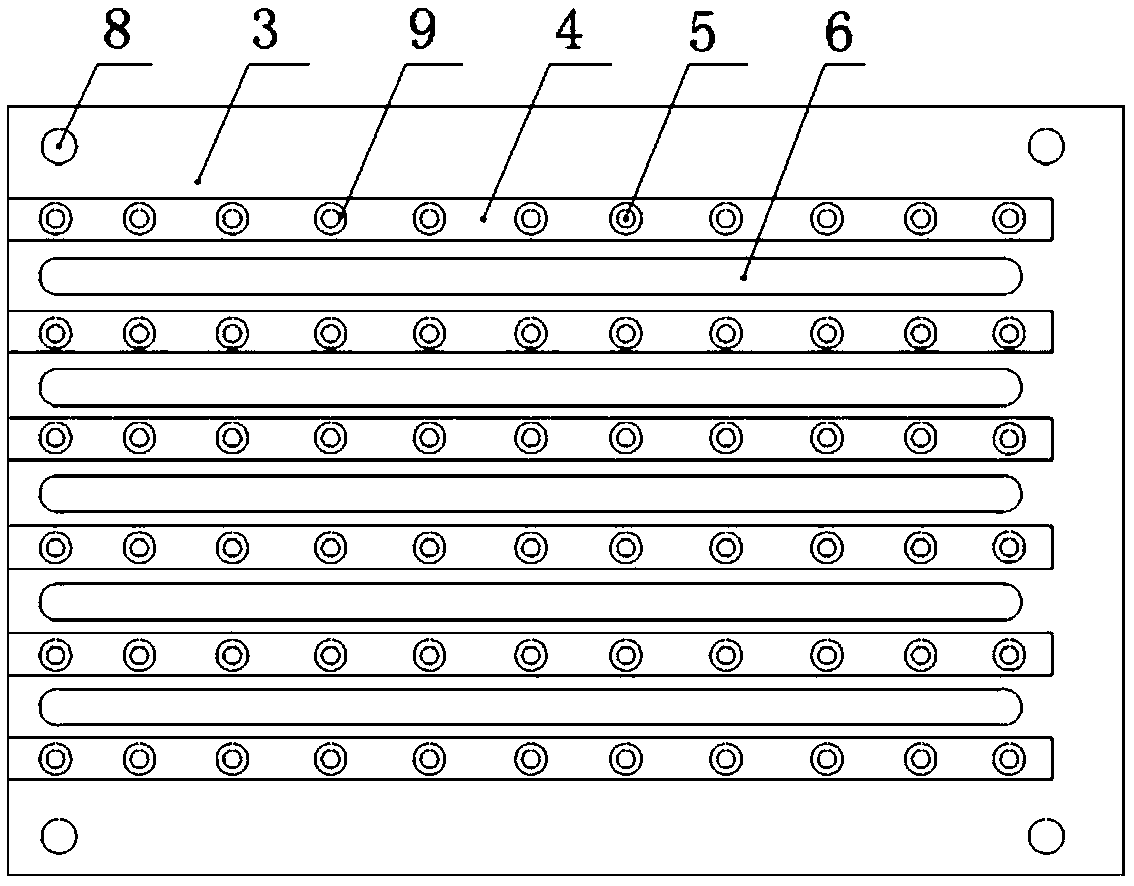

Wire arrangement device

ActiveCN109616435ARealize automatic arrangementImprove efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesDiode

The invention relates to the technical field of diode processing, in particular to a wire arrangement device. The wire arrangement device comprises an obliquely-arranged feeding plate, wherein the feeding plate is connected with a driving mechanism for driving the feeding plate to vibrate, a plurality of feeding channels are arranged on the feeding plate, a material receiving mechanism for arranging pins is detachably arranged at the lower end of the feeding plate, a wiring mechanism has a multilayer structure, and each layer is respectively provided with a wire arrangement structure for collecting and rearranging the redundant pins. According to the scheme of the invention, the problem that the pins that are not successfully arranged need to be manually collected for wire re-arrangement,and troublesome operations and low efficiency are caused in the prior art can be solved.

Owner:ANHUI LONGXINWEI TECH CO LTD

An automatic arrangement mechanism for firecracker outer cylinder

ActiveCN110906803BPrevent fallingEliminate height differenceFireworksEngineeringMechanical engineering

The invention relates to an automatic arrangement mechanism for fireworks outer tubes, which includes a frame on which a paper winding machine is installed, and also includes: a transmission mechanism installed on the frame, a sorting mechanism, a transmission mechanism, and the sorting mechanism includes: a corner The device has an outer disk and an inner disk, the outer disk is installed on the frame, the inner disk is installed in the outer disk and can rotate relative to the outer disk, the outer disk and the inner disk respectively include the fixed end of the outer disk, the movable end of the outer disk, the fixed end of the inner disk, the movable end of the inner disk, and the fixed end of the inner disk is fixed In the fixed end of the outer disk, the movable end of the inner disk is fixed in the movable end of the outer disk. The upper and lower ends of the outer disk are provided with a blanking port, and the inner disk is provided with a number of blanking grooves; the end cover has a first-level cover and a second-level cover; positioning The board is installed on the movable end of the outer disk through the positioning rod. The technical scheme can automatically complete the process of arranging the outer cylinders by mechanization, and can solve the problems of low efficiency, high labor intensity, large number of workers and high production cost.

Owner:上栗县诚信烟花有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com