A feeding tray of an automatic feeding device

An automatic material feeding and tray technology, applied in the direction of vibrating conveyors, conveyors, conveyor objects, etc., can solve the problems of uneven concentricity, increased cost, loose shafts, etc., to achieve reduced production costs, reasonable structural design, The effect of reducing manual operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention will be described in further detail below in conjunction with the accompanying drawings.

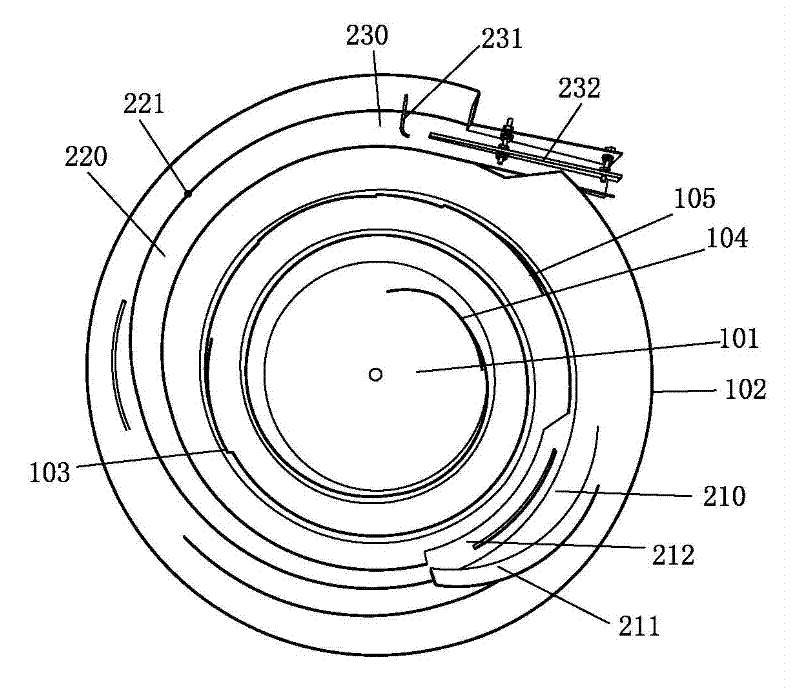

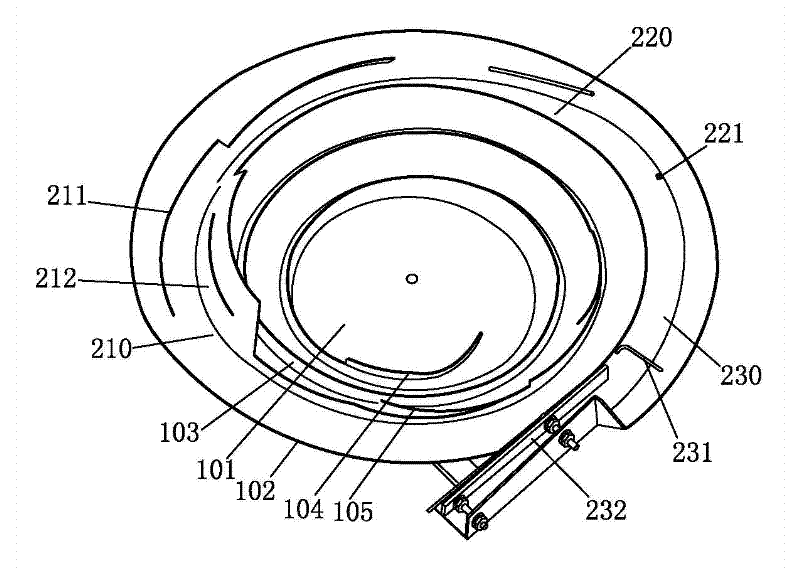

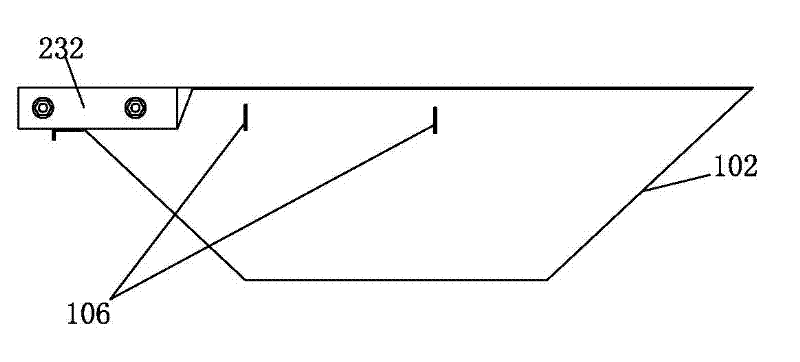

[0016] Such as figure 1 and figure 2 As shown, a material tray of an automatic feeding device includes a tray surface 101 and a side wall 102 surrounding the tray surface. There is a feeding track 103 spirally rising along the side wall 102, and the feeding end of the feeding track 103 is located at the lower part of the disk surface 101; , the end of the monolithic rail 200 protrudes from the side wall 102, and the discharge end of the loading rail 103 is connected to the feeding end of the monolithic rail 200. The monolithic rail 200 includes a turning section 210, a sorting section 220 and a sorting section 230.

[0017] The feed end of described feeding track 103 is provided with arc-shaped guide bar 104, and the front end of arc-shaped guide bar 104 is low and wide, and accessories are easily introduced in it, and the rear end of arc-shaped guide bar 104 is h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com