Automatic arranging device of single-shot press

An automatic arranging and pressing technology, applied in conveyor objects, transportation and packaging, machine tools suitable for grinding workpiece edges, etc., can solve problems such as inability to deburr, increase defective products, waste time, etc., to avoid product damage , the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

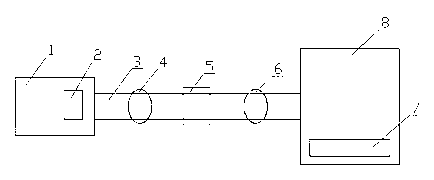

[0009] Such as figure 1 As shown, an automatic arrangement device for a single-shot press, including a magnetic core exit platform device (1), a magnetic core horizontal turning device (2), a conveyor belt device (3), a magnetic core front deburring device (4), a magnetic core Vertical overturning device (5), deburring device on the reverse side of the magnetic core (6), push plate device (7) and product arrangement platform (8), the magnetic core exit platform device (1) is connected with the magnetic core horizontal overturning device (2), The magnetic core exit platform device (1) is connected with the conveyor belt device (3) through the guide rail, and the magnetic core is transferred to the conveyor belt device (3), and the conveyor belt device (3) is transmitted and connected with the product arrangement platform (8) through the guide rail, and demagnetized The core front burr device (4), magnetic core vertical turning device (5), demagnetizing core back burring device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com