Full-automatic cross-flow fan blade shaft hole angle adjusting all-in-one machine

A technology of cross-flow fan blades and angle adjustment, which is applied to household components, home appliances, other household appliances, etc., can solve the problems of low efficiency, high production cost of cross-flow fan blades, and large labor consumption, and achieves convenient operation and reduces labor. Labor, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

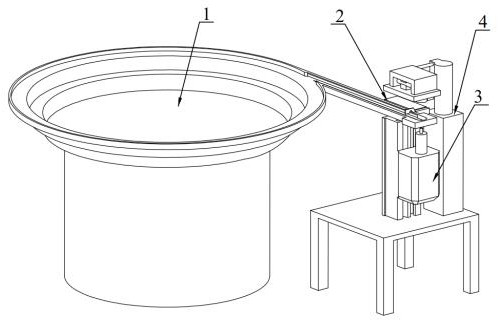

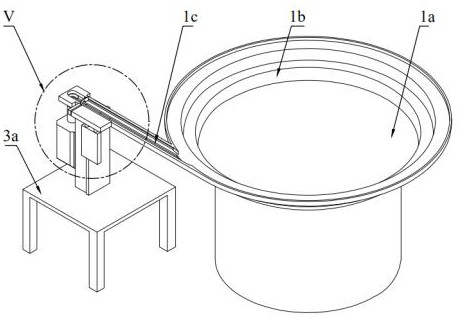

[0032] Such as Figure 1-5 As shown, a full-automatic all-in-one machine for adjusting the shaft hole angle of cross-flow fan blades, pour the shaft sleeve assembly 5 into the feeding device, adjust the operation program of the control system, press the start switch, and the feeding device 1 will put the shaft sleeve assembly 5 are sequentially arranged and transported to the discharge port, and the pushing device pushes the shaft sleeve assembly 5 at the position of the feed device discharge port into the lifting and steering device 3 in turn, and the lifting and steering device 3 moves vertically to push the shaft sleeve assembly 5 into In the clamping and positioning device 4, the clamping and positioning device 4 adjusts the angle of the shaft hole 51 of the shaft sleeve assembly 5 and then docks with the cross-flow fan blade in the injection mold. The control system controls the feeding device 1, the pushing device 2, and the lifting and steering device 3 Cooperating with...

Embodiment 2

[0037] Such as Figure 1-5 As shown, the fully automatic cross-flow fan shaft hole angle adjustment integrated machine of this embodiment has the same structure as that of Embodiment 1, the difference is that: the support 31 is also provided with a lifting mechanism 3b, and the first servo motor 3c Set on the lifting mechanism 3b.

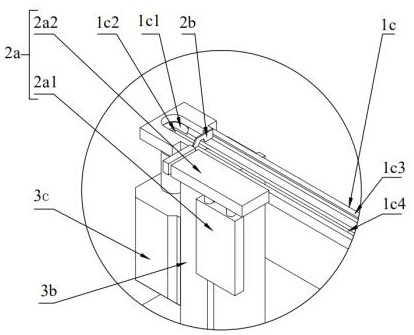

[0038] The fully automatic all-in-one machine for adjusting the shaft hole angle of cross-flow fan blades in this embodiment preferably adopts a photoelectric sensor 5 arranged on one side of the claw, so that when the lifting mechanism 3b drives the rotating rod 3c1 on the first servo motor 3c to pass through The through hole 22 at the tail end of the conveying guide rail 1c generates a control signal when the shaft sleeve assembly 5 is pushed up to cut off the photoelectric sensor signal in the claw, so that the first servo motor 3c starts to rotate, and the shaft sleeve assembly 5 is connected to the shaft sleeve assembly 5 under the action of g...

Embodiment 3

[0040] Such as Figure 1-5 As shown, the fully automatic cross-flow air blade shaft hole angle adjustment integrated machine of this embodiment has the same structure as that of Embodiment 2, the difference is that it also includes a pushing device 2, and the pushing device 2 is arranged on the conveying guide rail 1c- On the side, the pushing device 2 includes a first driving cylinder 2a and a blocking block 2b, and the first driving cylinder 2a includes a first telescopic cylinder 2a1 and a second telescopic cylinder 2a2 arranged on the first telescopic cylinder 2a1, The blocking block 2b is detachably connected to the telescopic rod of the second telescopic cylinder 2a2, the first telescopic cylinder 2a1 drives the second telescopic cylinder 2a2 to move in a direction perpendicular to the conveying guide rail 1c, and the second telescopic cylinder 2a2 drives The blocking block 2b moves along the conveying direction of the conveying guide rail 1c, and pushes the single sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com