Water and electricity mounting barrier-free cable winder for building construction

A barrier-free technology for building construction, applied in the field of building construction equipment, can solve the problems of inconvenient operation, complex structure of the guide device, uneven winding of cables, etc., and achieve the effect of easy maintenance, easy operation, and convenient unwinding and taking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

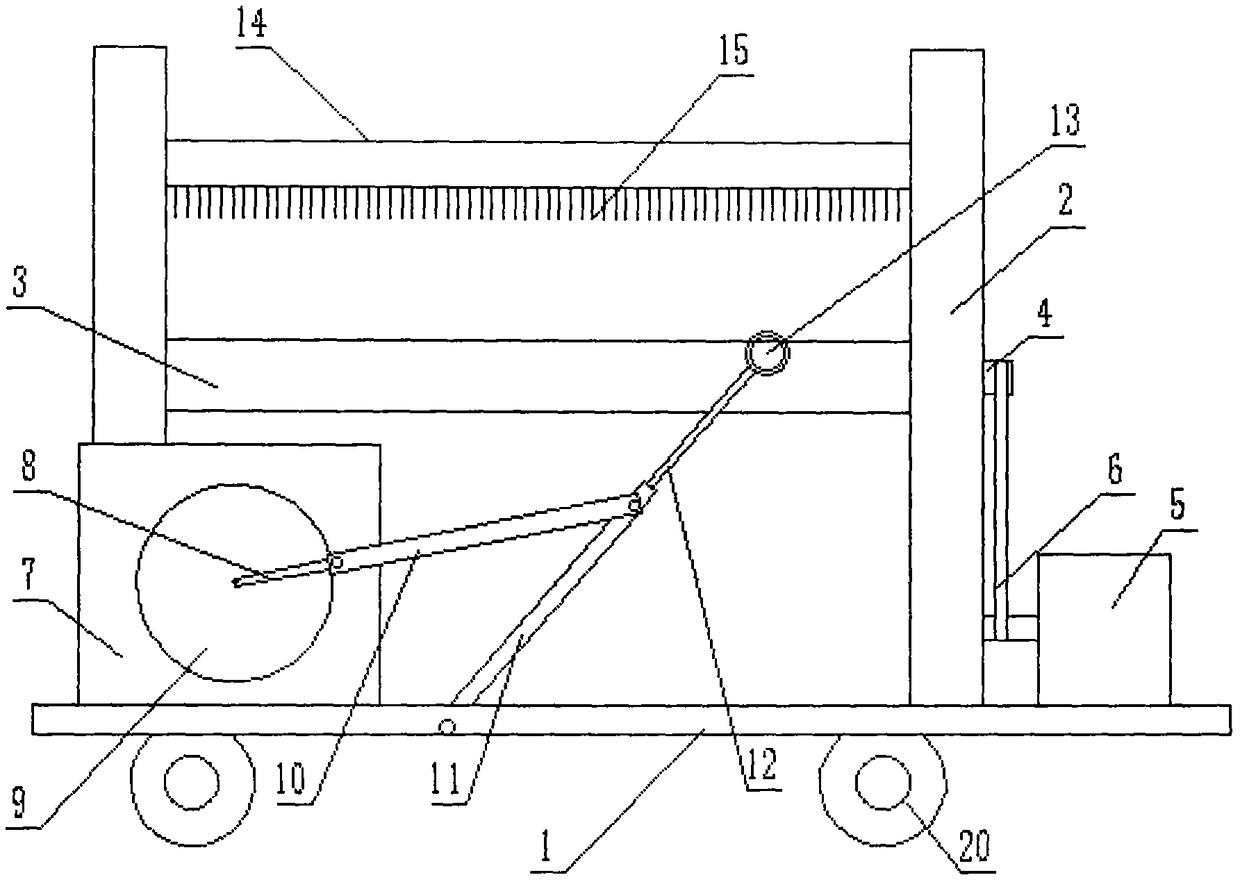

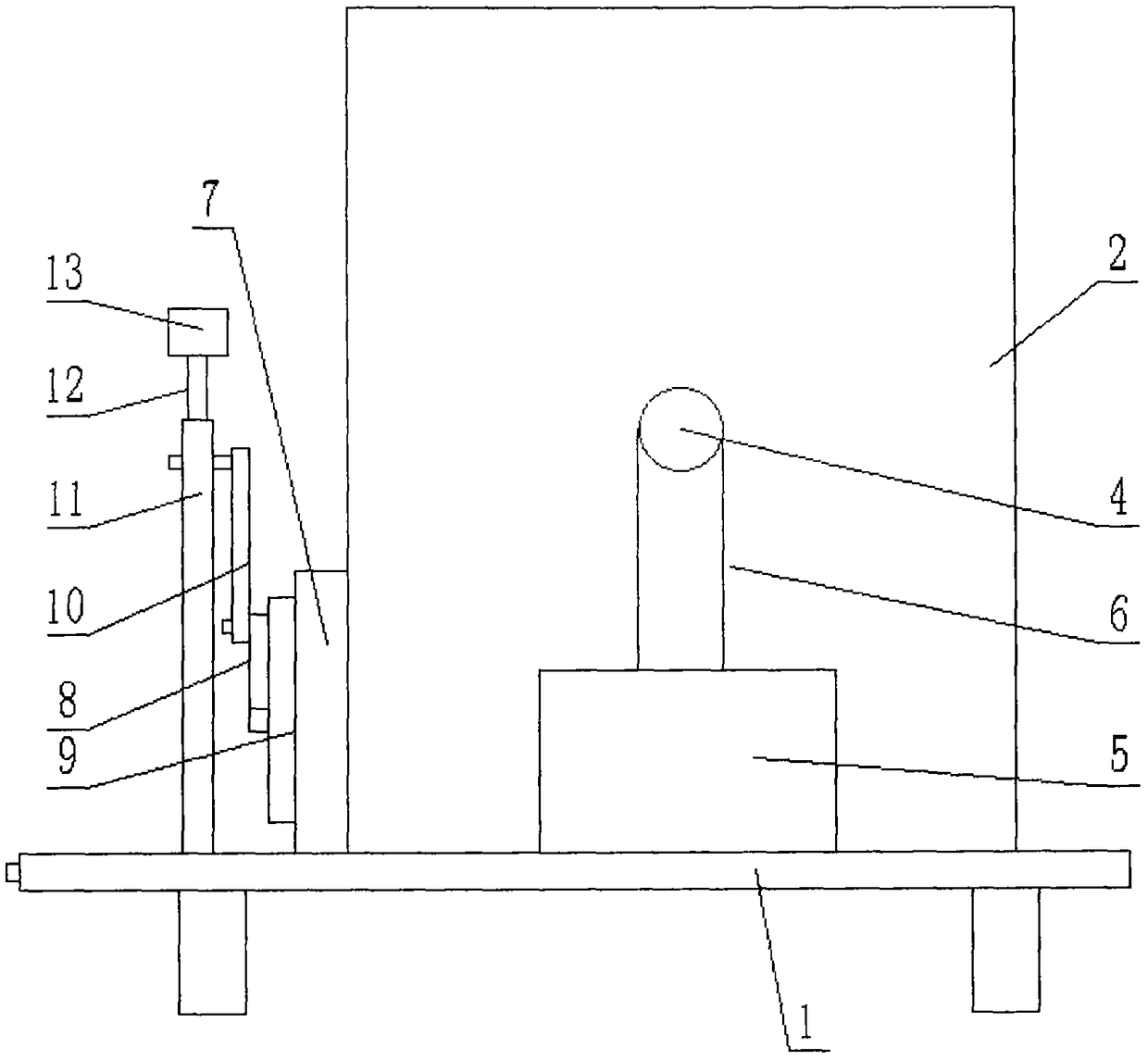

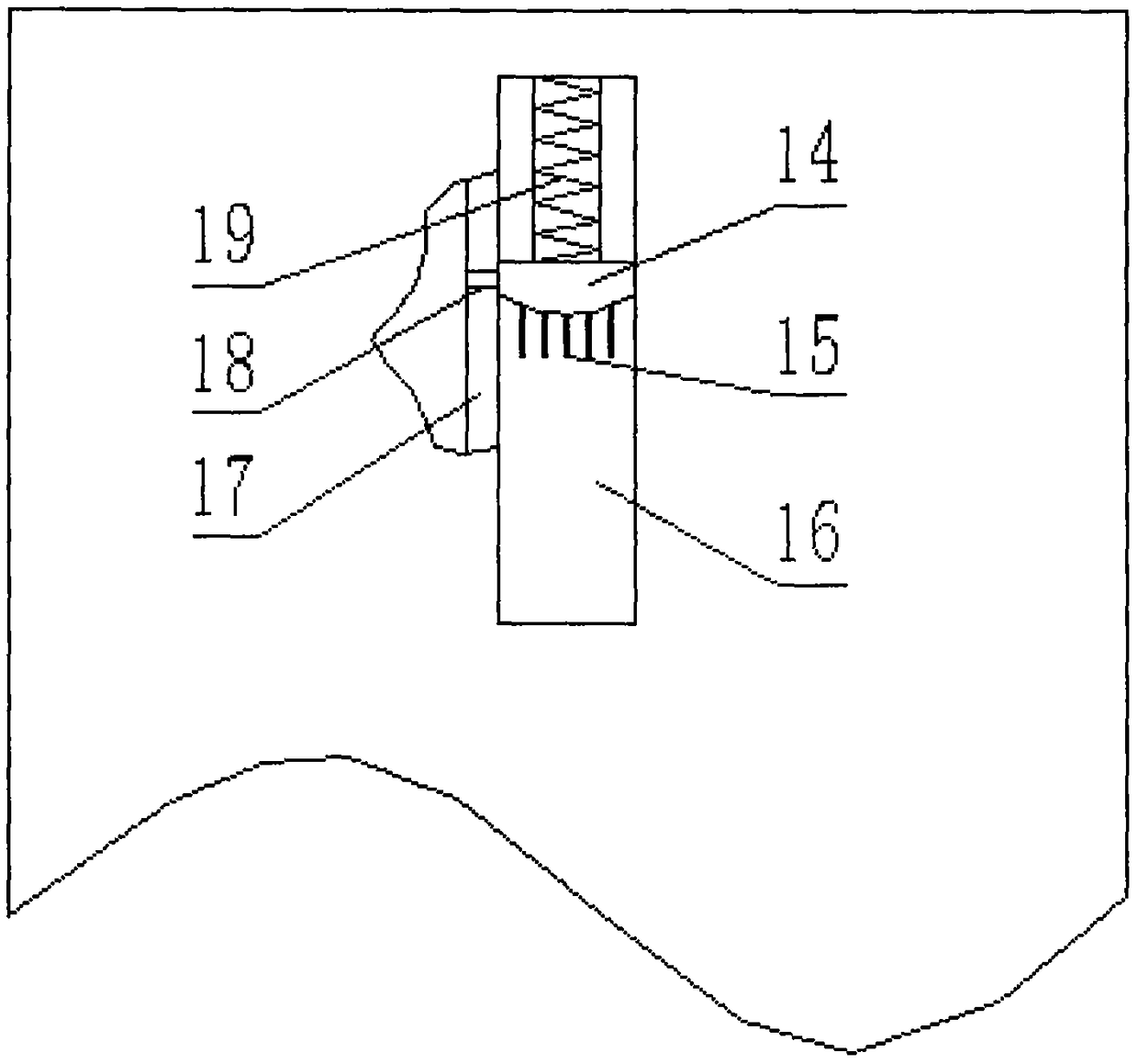

[0018] see Figure 1-3 , a barrier-free cable retractor for water and electricity installation in building construction, including a vehicle frame 1, a support frame 2 fixed on the vehicle frame 1 and a winding roller 3, and the support frame 2 is vertically fixed on the vehicle frame 1 and parallel to each other arranged on both sides of the length direction of the frame 1 composed of square plates, the winding roller 3 is located in the center of the height direction between the two square plates, on both sides of the winding roller 3 is provided with a support The rotating shaft 4 in the frame 2 and connected to it in rotation, one of the rotating shafts 4 stretches out from the outside of the support frame 2, and a drive motor 5 is also provided on the vehicle frame 1, and the output shaft of the drive motor 5 is connected to the support frame 2 The outer rotating shaft 4 is connected by a transmission belt 6; when the cable is unwound, the driving motor 5 drives the windi...

Embodiment 2

[0022] The difference with Embodiment 1 is that there are two lifting rods 14 located on the upper and lower sides of the winding roller 3 and arranged symmetrically. Clear effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com