Wire arrangement device

A wire arrangement and wire structure technology, applied in the field of diode processing, can solve problems such as low efficiency and troublesome operation, and achieve the effects of convenient operation, good effect, and avoiding pin drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is further described in detail through specific implementation methods:

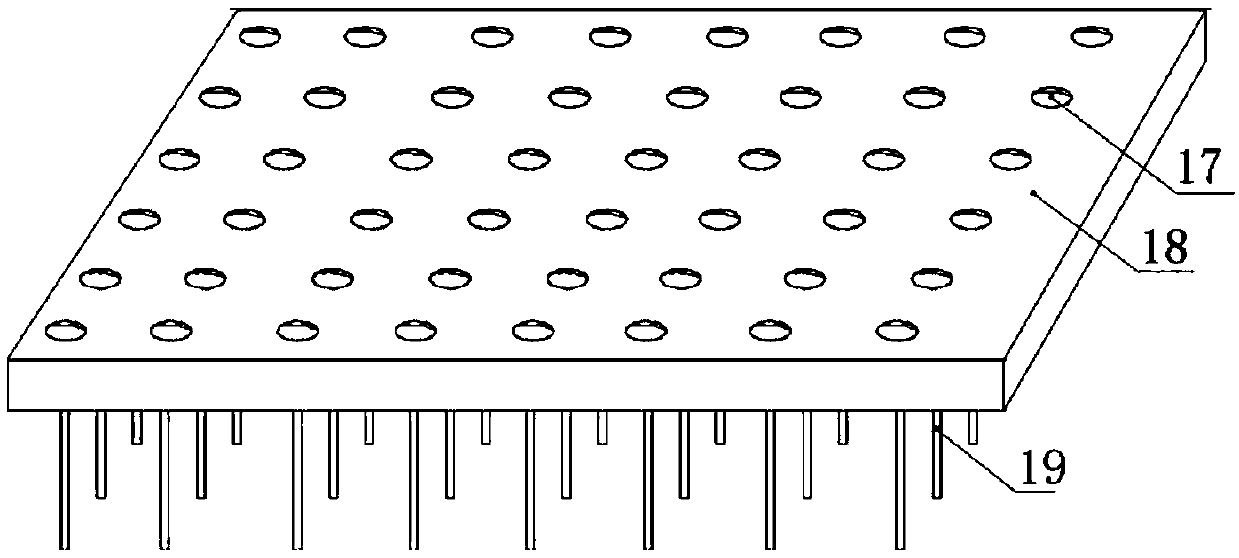

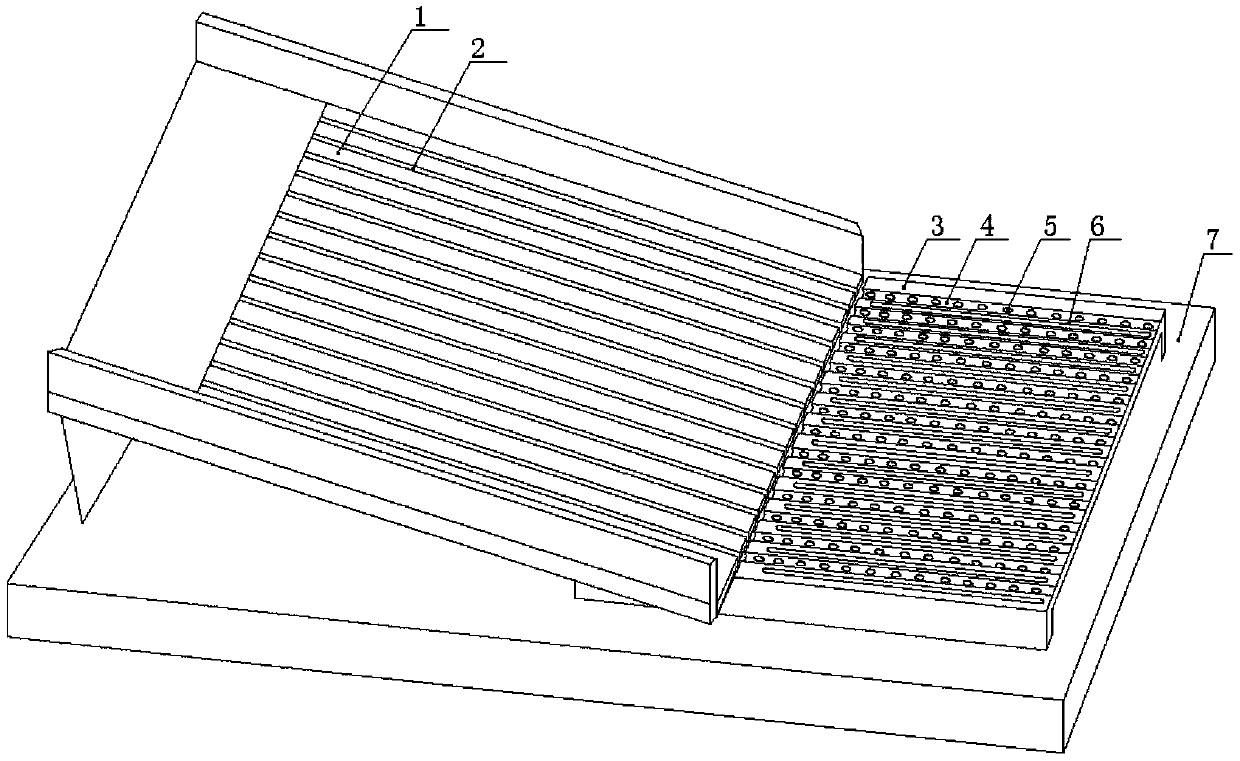

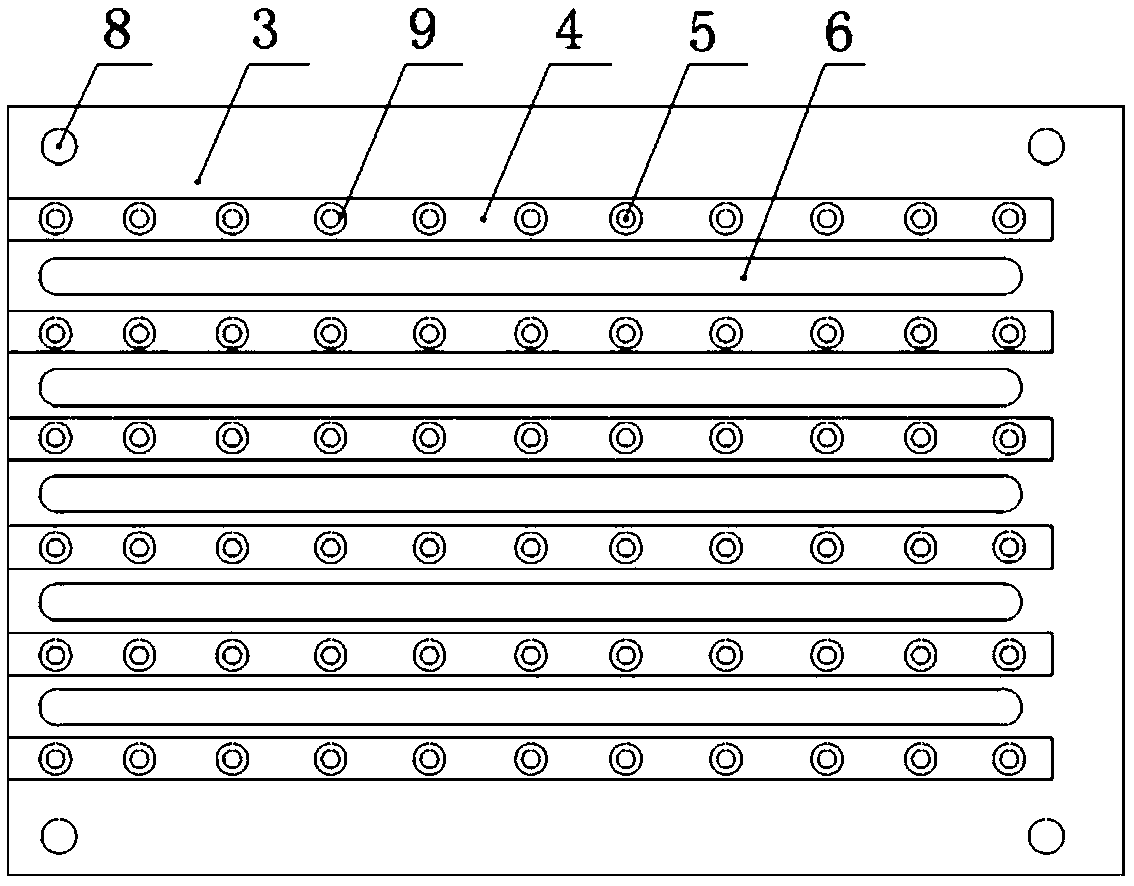

[0025] The reference signs in the drawings of the description include: feeding plate 1, feeding channel 2, first receiving plate 3, receiving trough 4, socket 5, leaking hole 6, frame 7, connecting hole 8, air bag 9, Connecting rod 10, second material receiving plate 11, conduit 12, piston 13, piston rod 14, air chamber 15, handle 16, cable hole 17, cable plate 18, pin 19.

[0026] Such as figure 2 As shown, a cable arrangement device of the present invention includes a frame 7, on which a feeding plate 1 is obliquely installed, and the feeding plate 1 is connected with a driving mechanism for driving its vibration. In this embodiment, the driving mechanism adopts Shanghai Zhichuan Company NETTER vibrator. The feeding plate 1 is provided with several feeding passages 2 for conveying the pins 19, the feeding passages 2 are arranged along the length direction of the feeding board 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com