Patents

Literature

42results about How to "Achieve permutation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

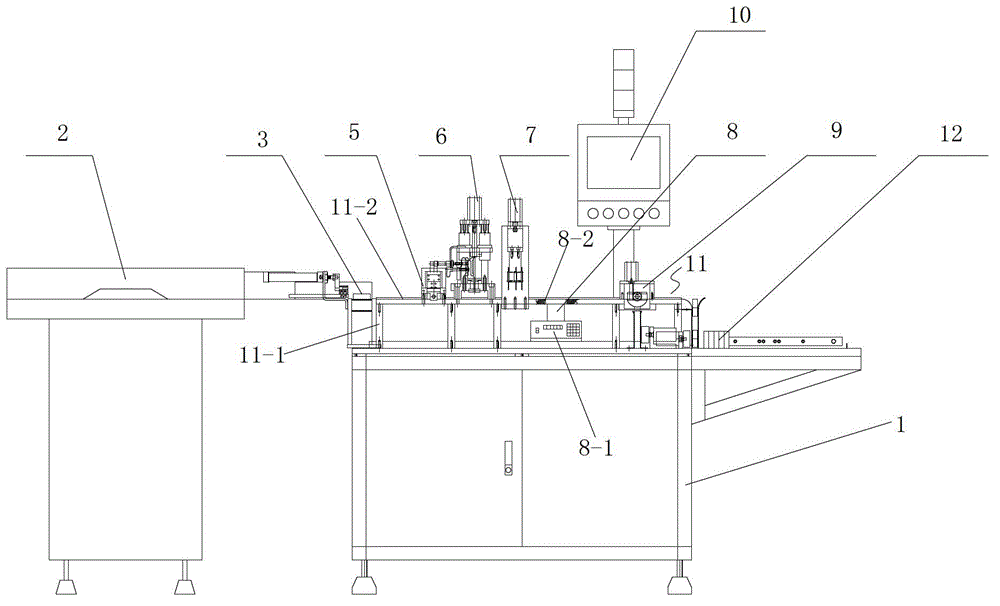

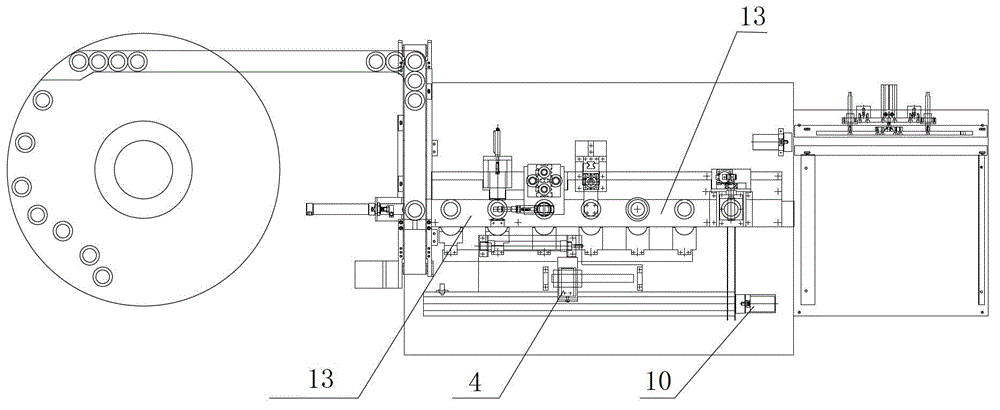

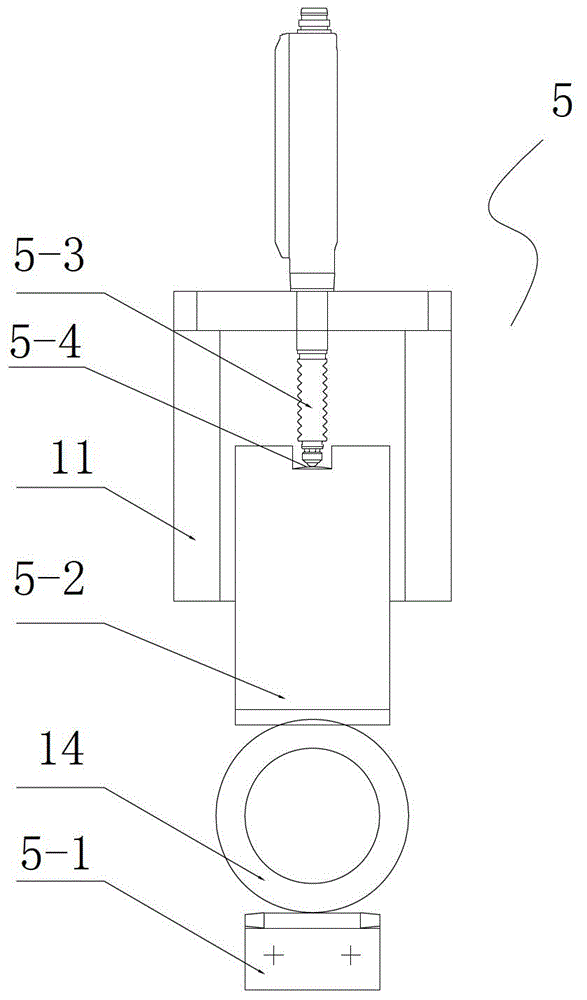

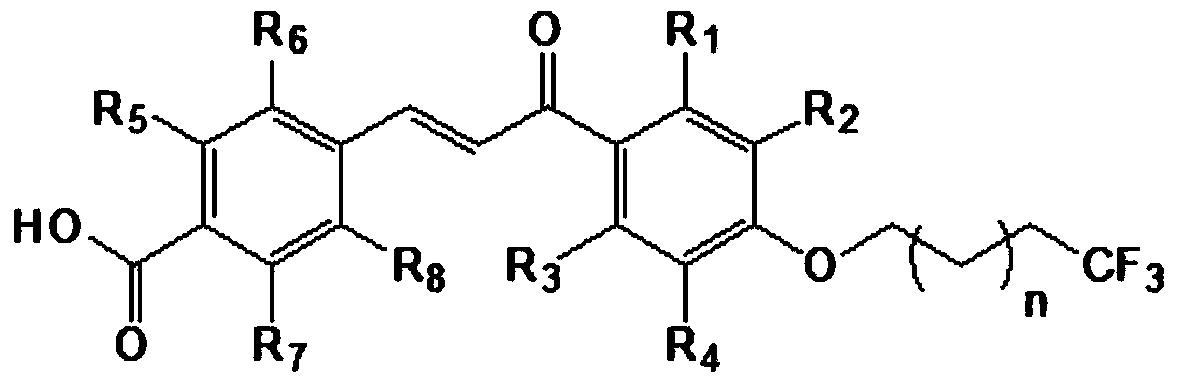

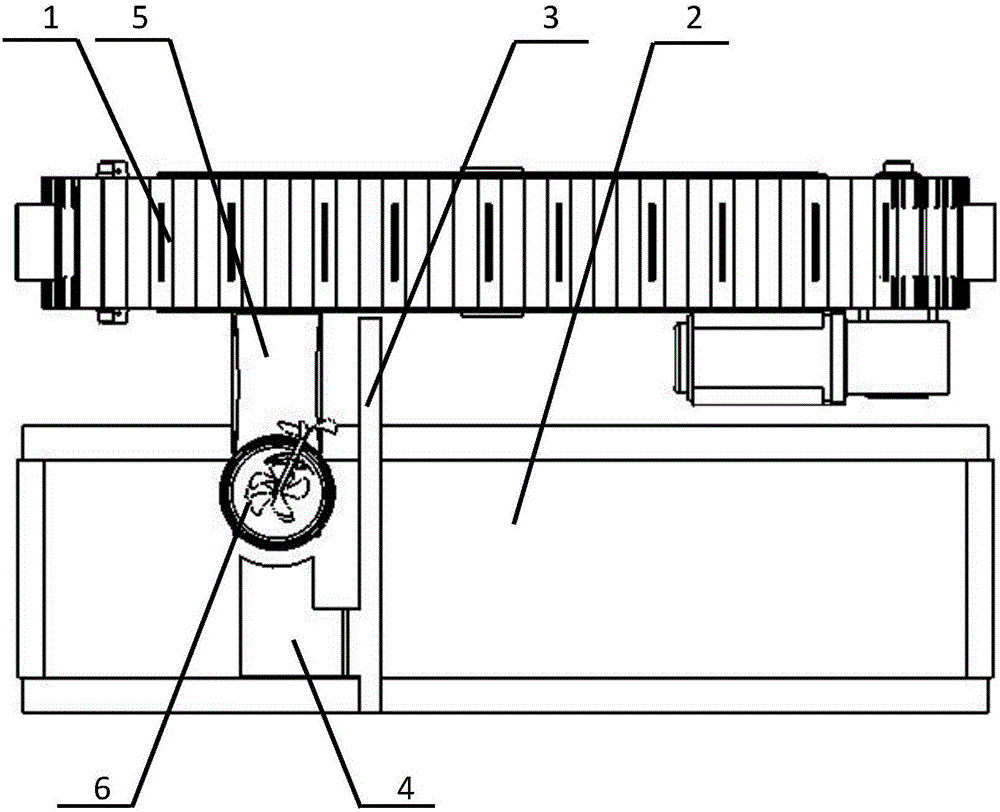

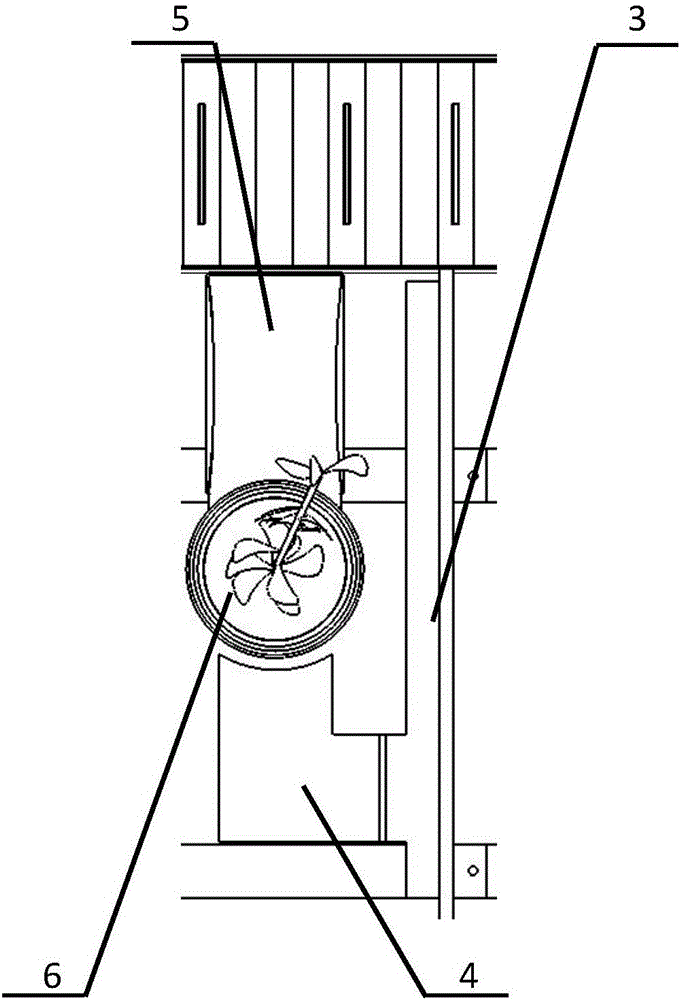

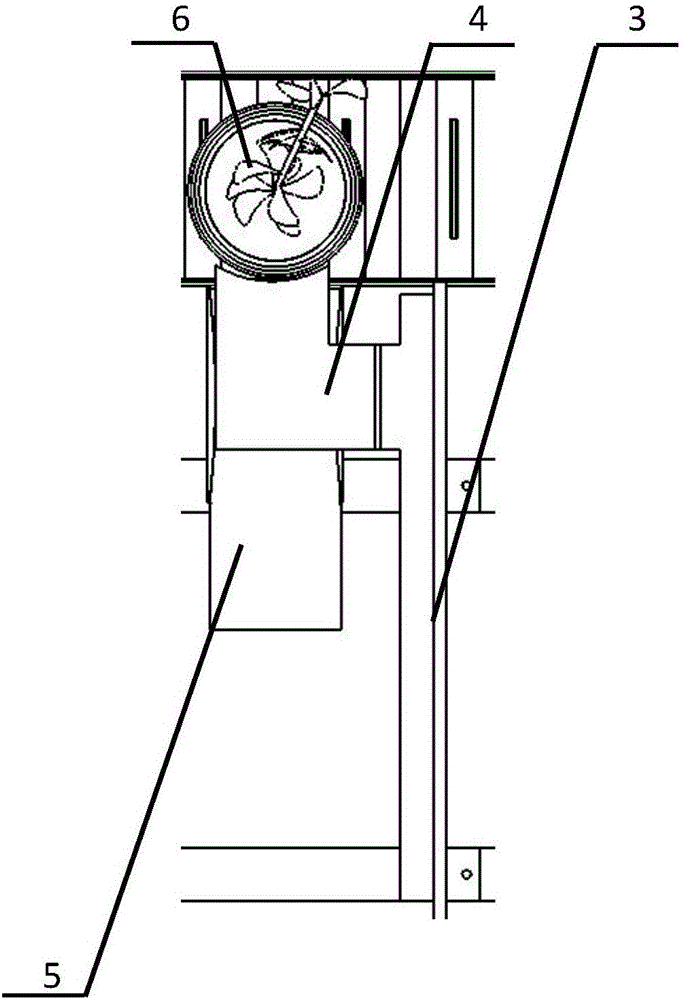

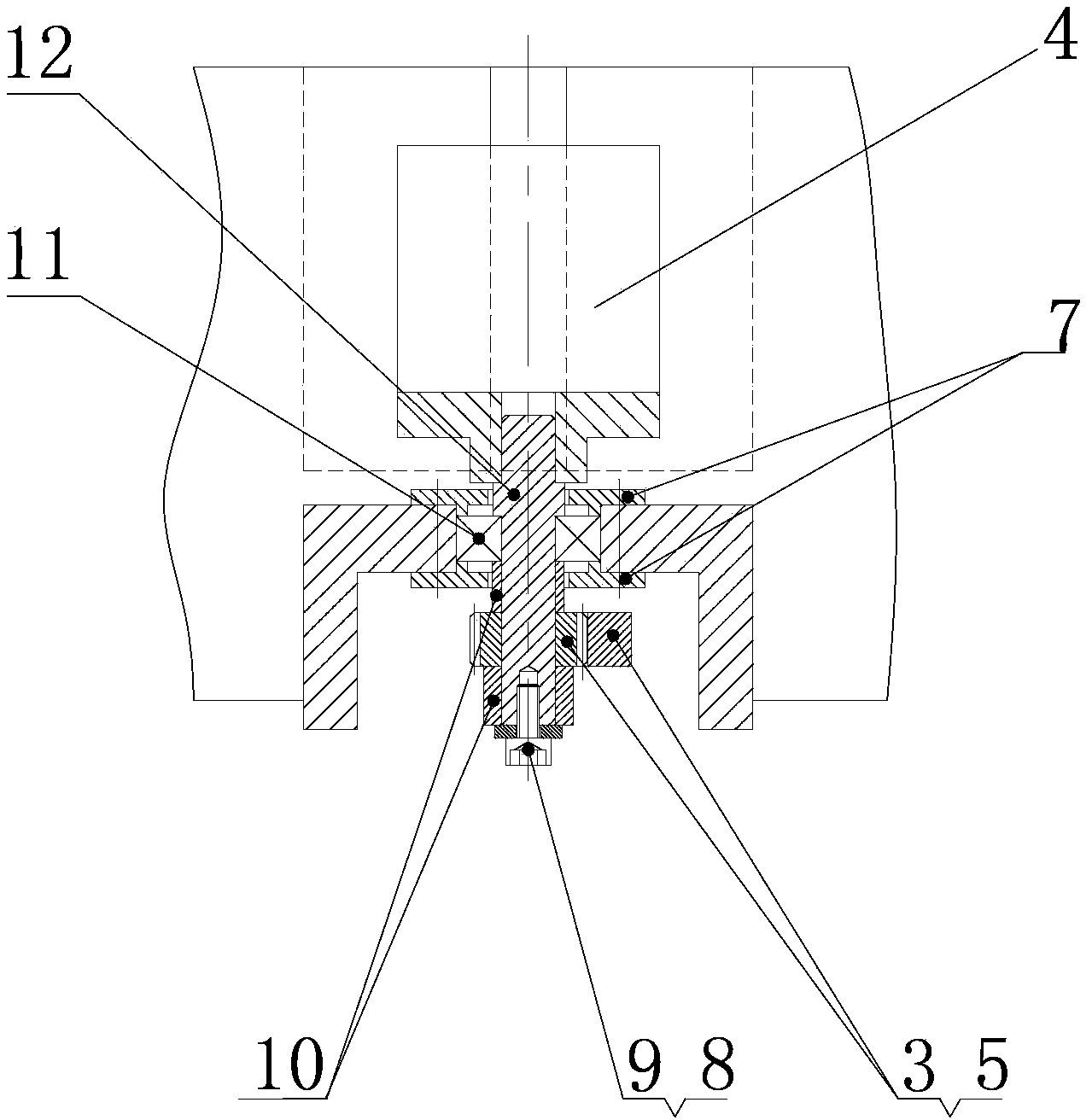

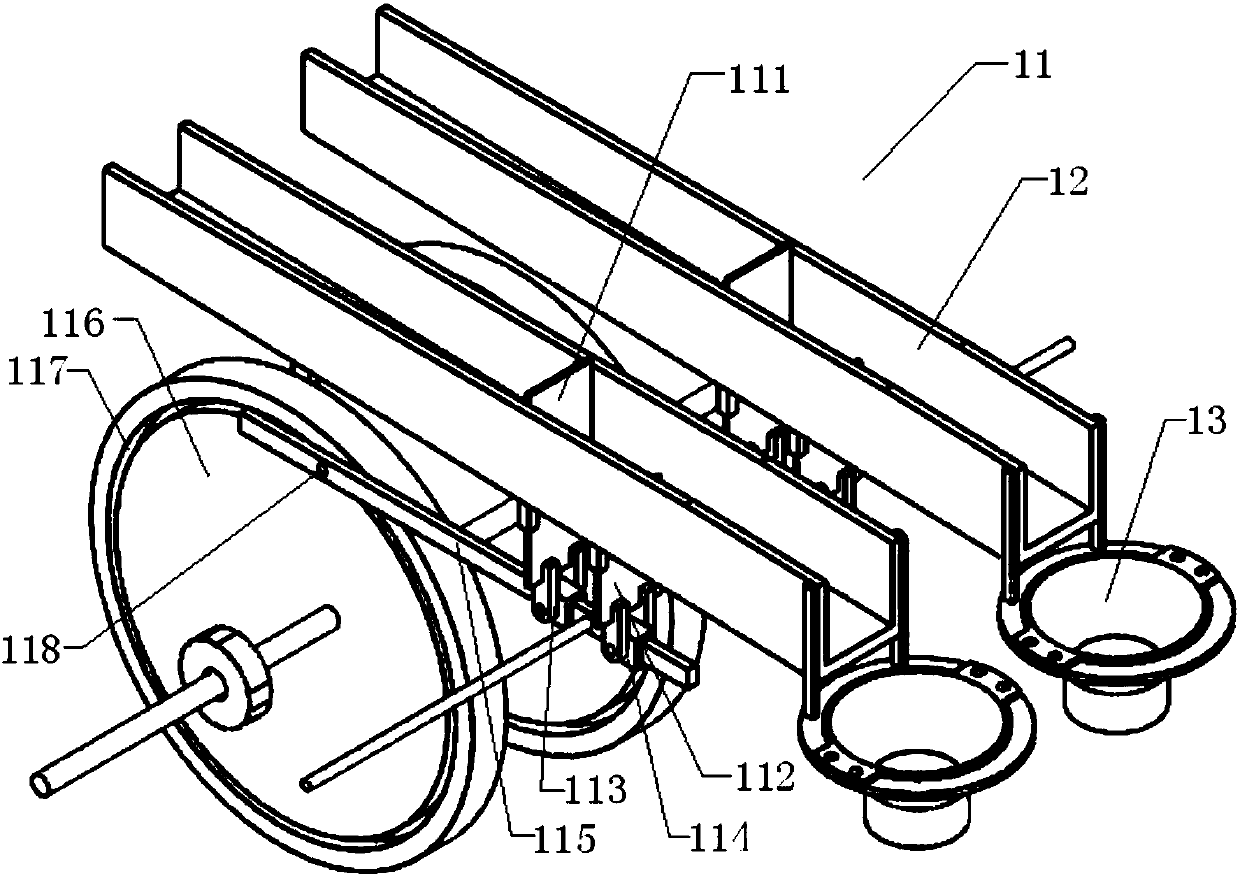

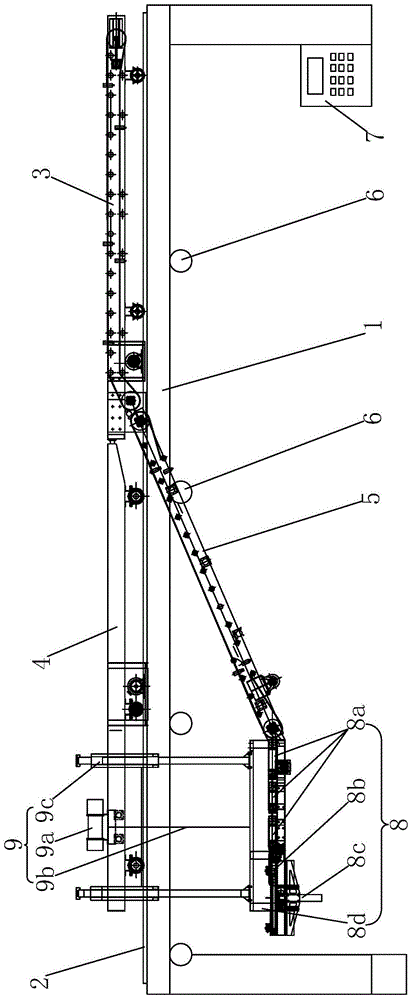

Full-automatic inspection production line for circular parts

ActiveCN102721387ARealize automatic movementAchieve permutationSpecial purpose weighing apparatusProduction lineProximity sensor

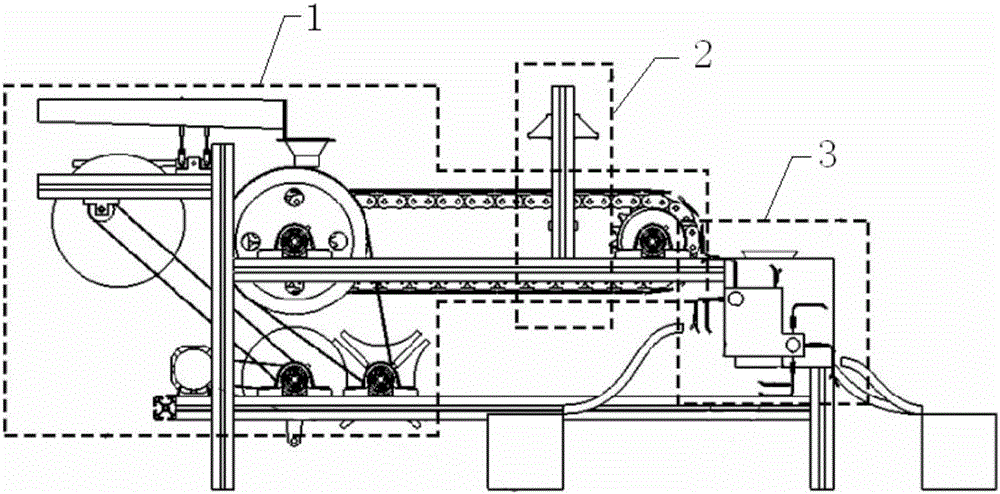

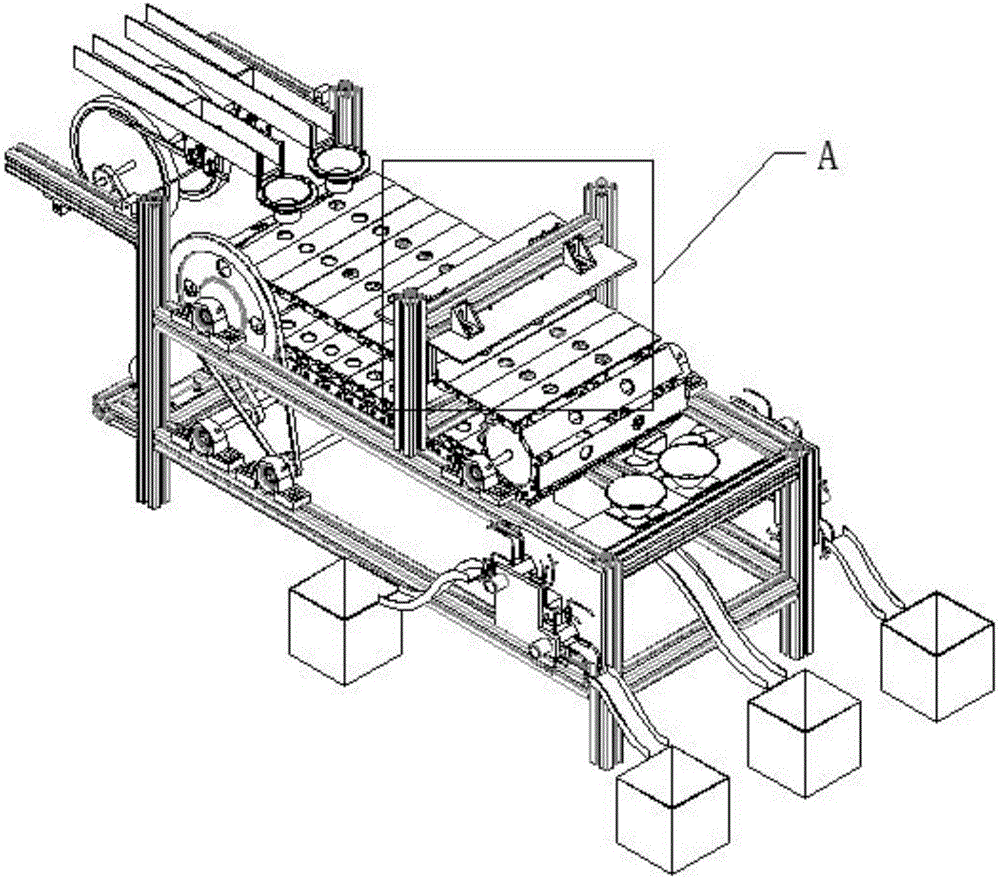

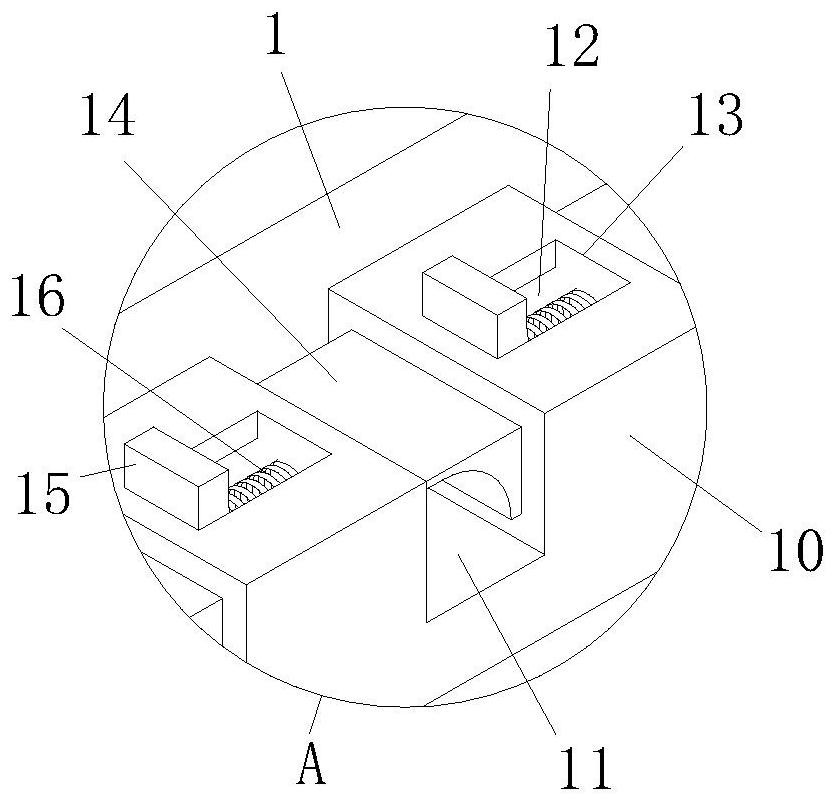

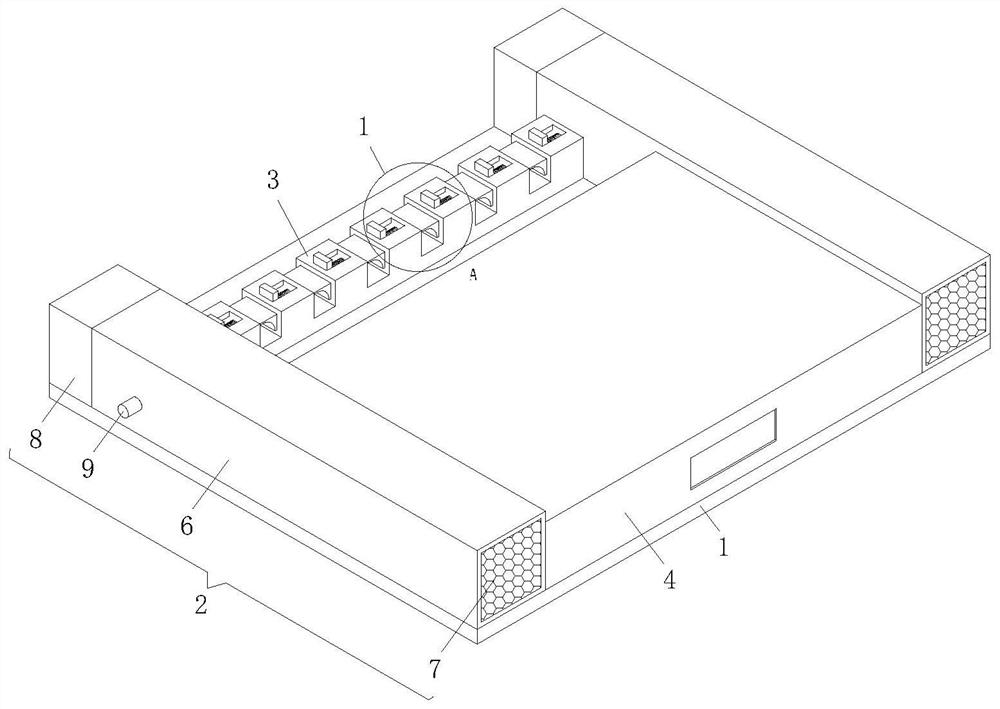

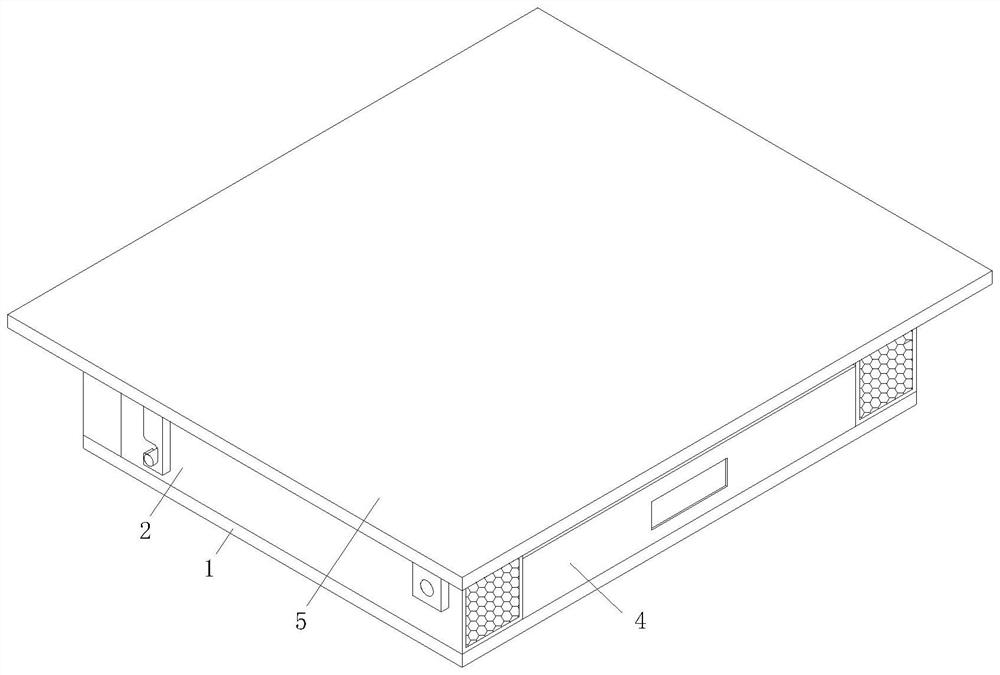

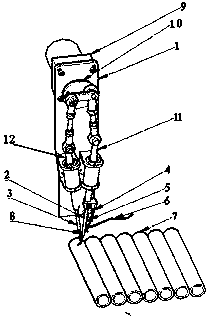

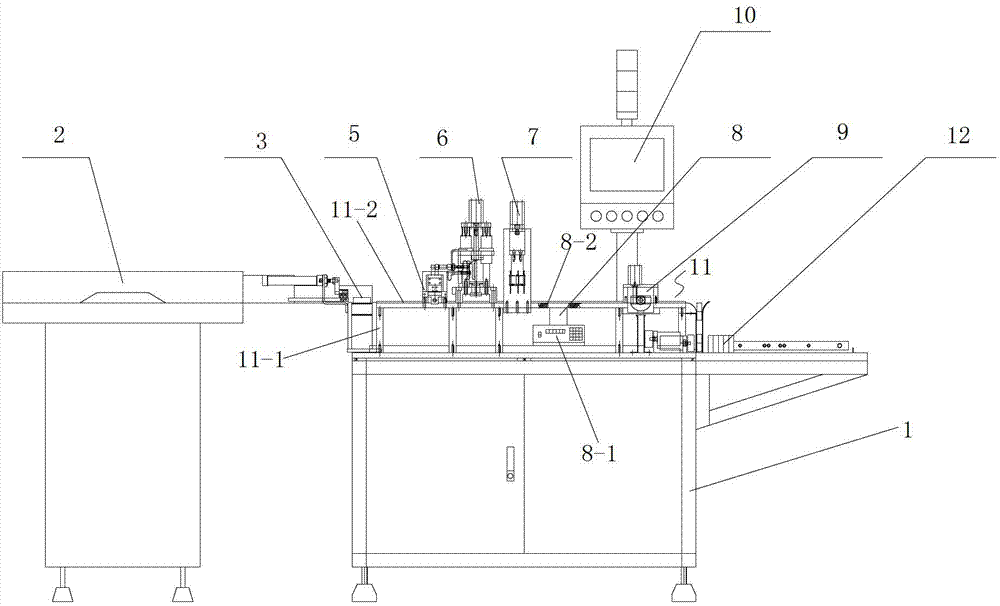

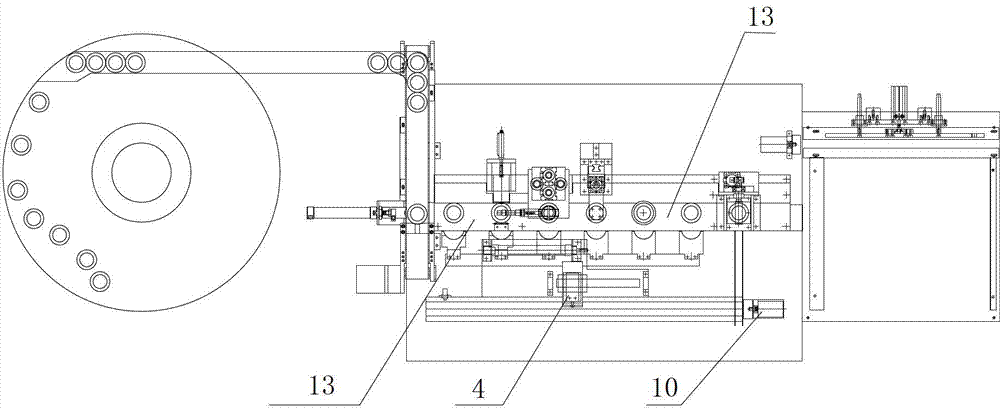

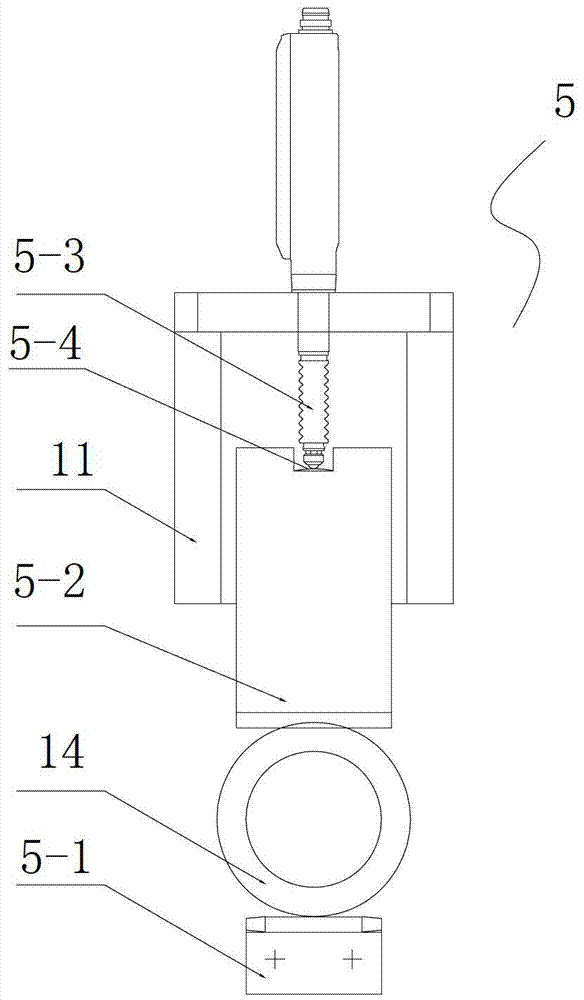

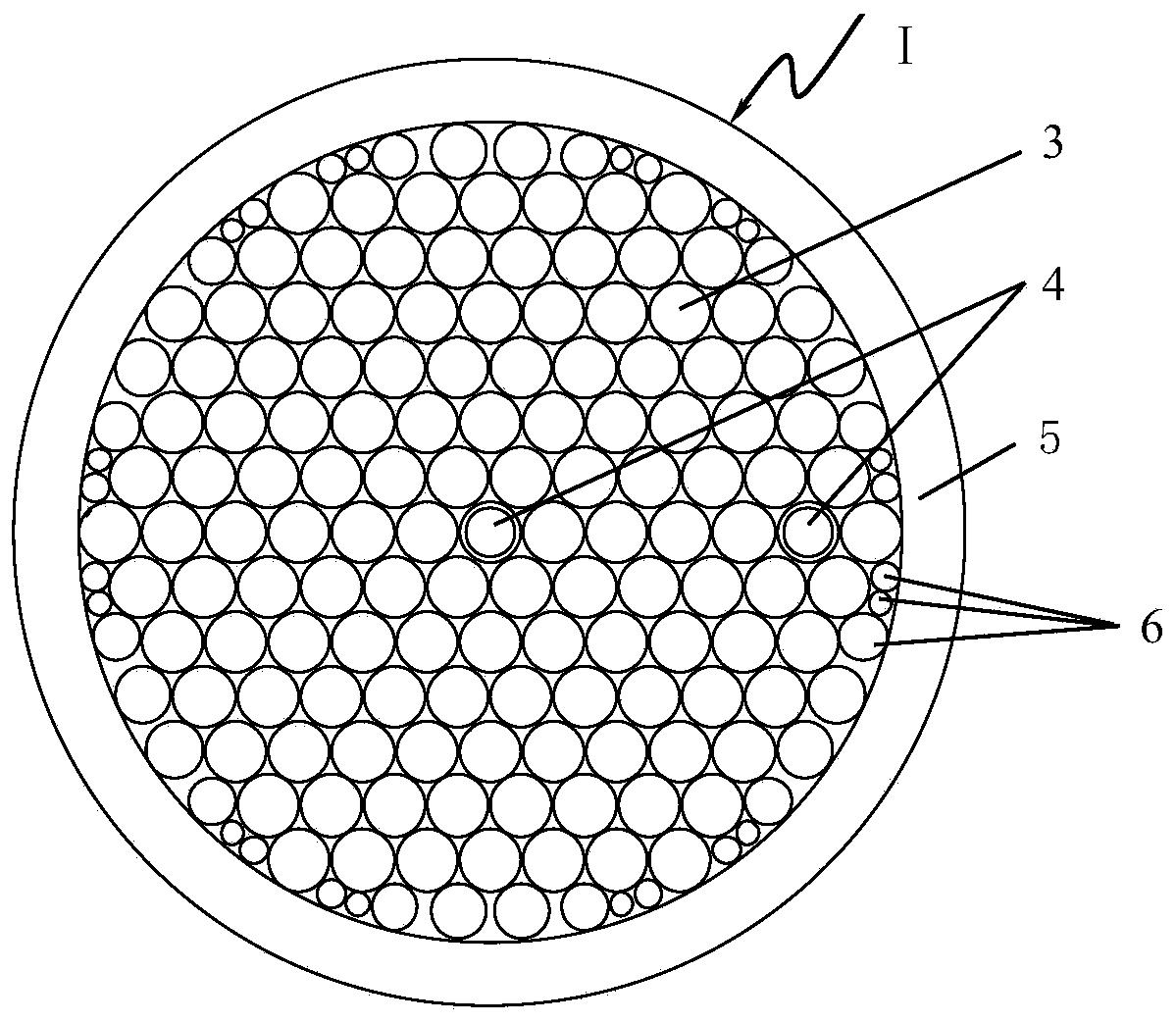

The invention belongs to detection equipment and particularly relates to a full-automatic inspection production line for circular parts. The full-automatic inspection production line is characterized in that the full-automatic inspection production line comprises a machine tool body, a disk type electromagnetic oscillation feeding device, a feeding conveyor belt device, a workpiece moving mechanism, and an external diameter detection mechanism, an internal diameter detection mechanism, a thickness detection mechanism, a weight detection mechanism and a screening mechanism which are sequentially arranged as well as a touch display screen which is fixedly connected with the machine tool body. The full-automatic inspection production line has the benefits of realization of automatic moving and arrangement as well as gradual-item detection of external diameter, internal diameter, thickness and weight. Core parts of the detection mechanism comprise an inlet high-precision contact type sensor, a linear potentiometer, a high-precision electronic scale and the like; automatic moving and inspection are realized by using a pneumatic element for driving, and thus high automatic degree and high detection precision are realized; and automatic screening and arranging can be realized and automatic control is realized by being matched with a proximity sensor.

Owner:天津市中马骏腾精密机械制造有限公司

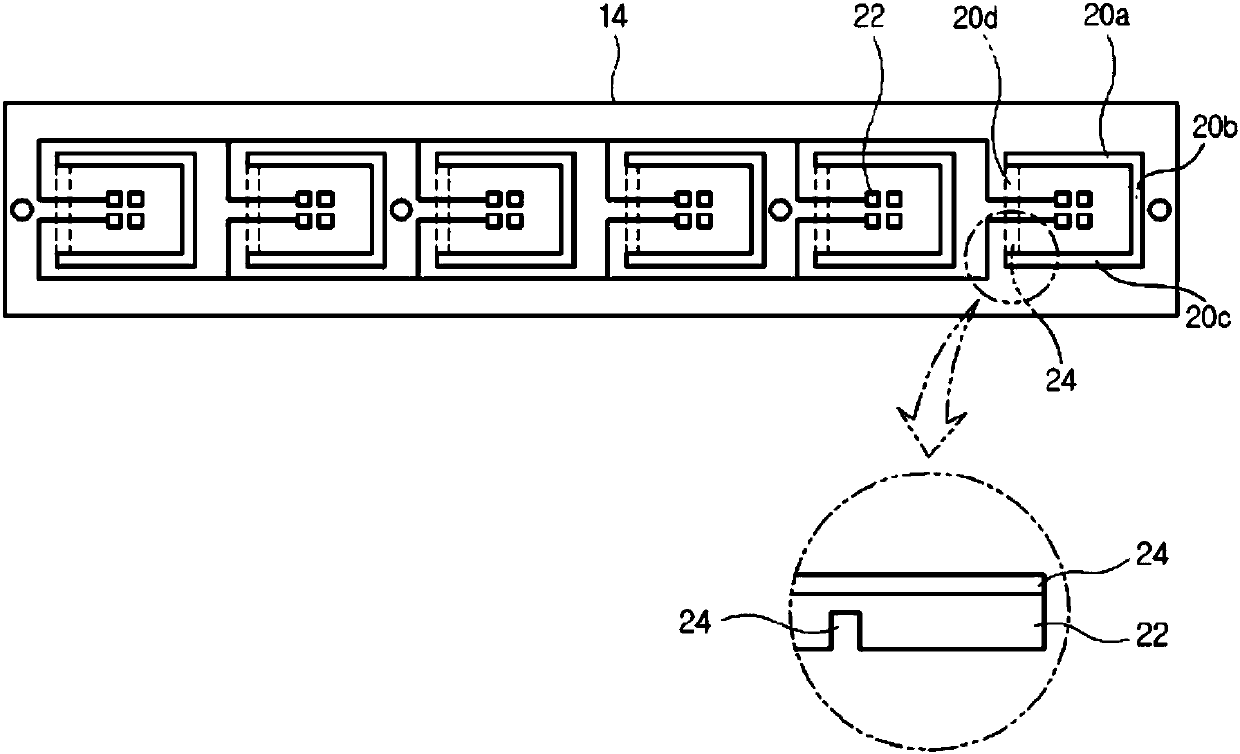

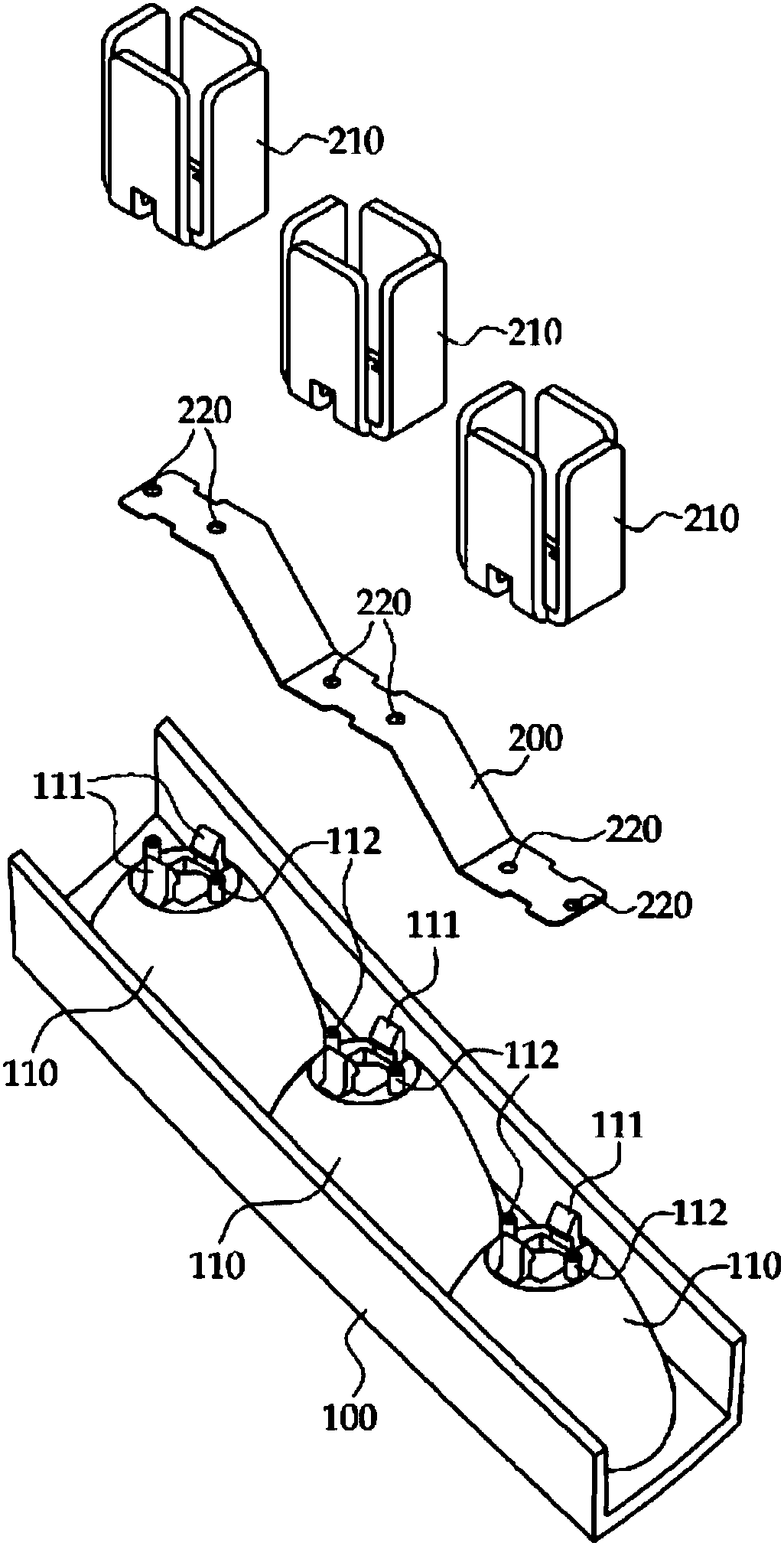

Metal PCB, headlight module having metal PCB applied thereto, and method for assembling headlight module

ActiveCN107690716AHighly integratedAchieve permutationSemiconductor/solid-state device detailsSolid-state devicesMetallic materialsLight-emitting diode

The present invention relates to a metal PCB, a headlight module having the metal PCB applied thereto, and a method for assembling the headlight module, wherein the metal PCB has a base made of a metal material and configured as a thin plate, or the base has a predetermined thickness and is bent in a desired direction through a bending groove formed on the rear surface thereof, and the base has aplurality of chip mounting portions integrally formed thereon such that one or more LED chips are mounted thereon, the chip mounting portions being spaced at a predetermined interval and having at least two parts of incision surfaces formed on one side of the base such that the chip mounting portions are inclined and installed to have a predetermined angle with regard to the base.

Owner:WENDENG AIKE WIRE HARNESS CO LTD

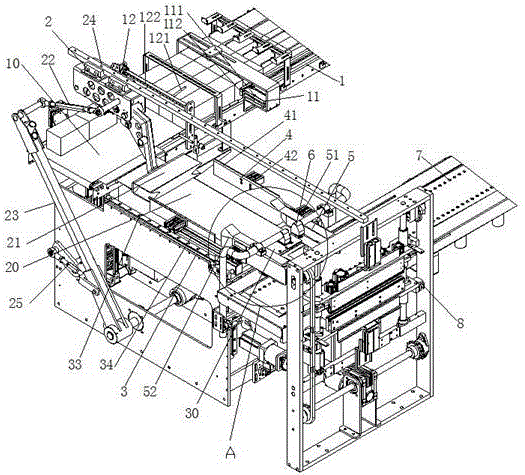

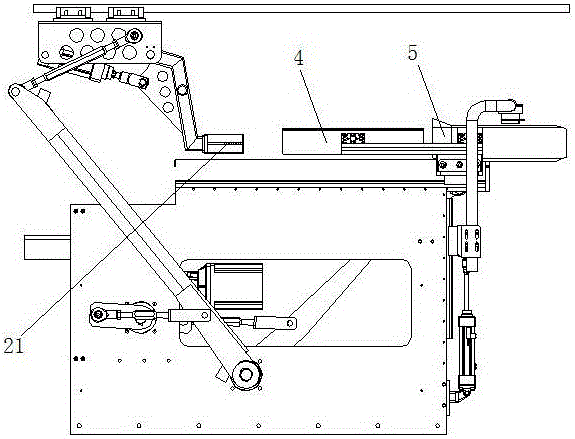

Control system of prefabricated bag packing machine

ActiveCN105857649AShort tripPrevent the situation of dumpingSolid materialRolling paperControl system

The invention discloses a control system of a prefabricated bag packing machine and relates to the technical field of mechanical control of packing machines. The control system of the prefabricated bag packing machine comprises a feeding mechanism, a pushing mechanism, a bag stretching mechanism, a bag opening mechanism and a bag conveying mechanism and is characterized by further comprising a clamping mechanism and a translation mechanism. The control system of the prefabricated bag packing machine is applicable to packing machines for packing via prefabricated bags such as small packing machines, medium packing machines and large packing machines and the like; meanwhile, the control system of the prefabricated bag packing machine is also suitable for packing materials such as facial tissues, flat paper, paper towels, blocky foods, drugs, roll paper, unpackaged foods and the like. Through the control system of the prefabricated bag packing machine, the problems that processes in single station of the prefabricated bag packing machine are complex, various packing actions are needed, the travel distance among the stations is long, the equipment occupied area is large, the material is irregular and is easy to pour, the prefabricated bags are easy to break, the material-pushing travel distance is long, the packing effect is poor, and the packaging efficiency is low in the prior art can be solved.

Owner:上海松川峰冠包装自动化有限公司

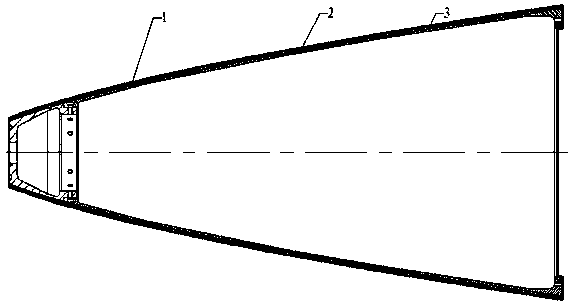

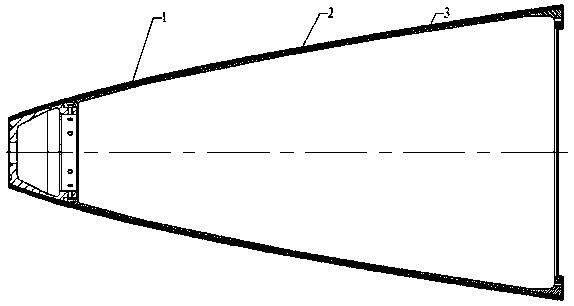

Fairing heat-proof structure and forming method thereof

ActiveCN111016004ASolve the deformationAchieve permutationAircraft power plant componentsWeight reductionAdhesive cementInsulation layer

The invention provides a fairing heat-proof structure and a forming method thereof and relates to the technical field of aircraft fairing manufacturing. The fairing heat-proof structure comprises a lining, an adhesive interface layer and a resin matrix composite ablation heat insulation layer. The forming method of the fairing heat protection structure comprises steps that A, a reinforcing material infiltrates matrix resin and then is dried and rolled to obtain continuous prepreg cloth; B, continuously cutting the prepreg cloth to obtain prepreg cloth belts; C, bonding and continuously rollingthe prepreg cloth belts to obtain a continuously-wound cloth belt; D, continuously winding the cloth belt in a variable-taper oblique stacking manner to obtain a winding skin; E, performing skin winding and curing; F, winding the skin and processing to obtain a resin-based composite material ablation heat insulation layer; G, connecting the lining and the resin-based composite material ablation heat insulation layer through an adhesive interface layer; and H, processing the heat-proof layer. The obliquely-stacked structure realizes arrangement of the cloth belt along the airflow, has better erosion resistance and ablation resistance, and can solve a problem of interface debonding of a heat-proof layer and an aluminum lining of a large-caliber (the diameter is more than 300mm) fairing.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

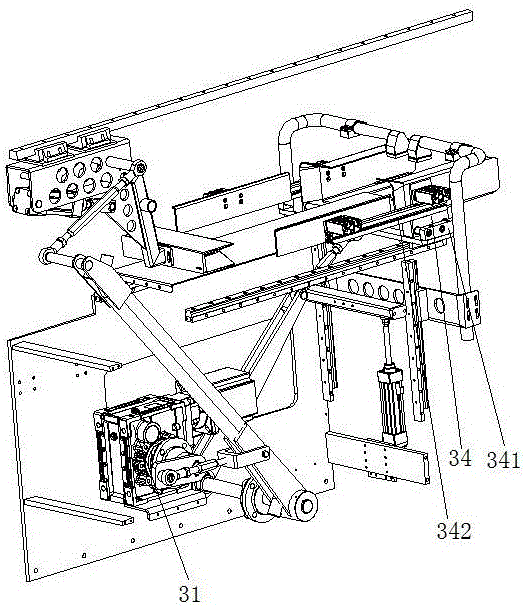

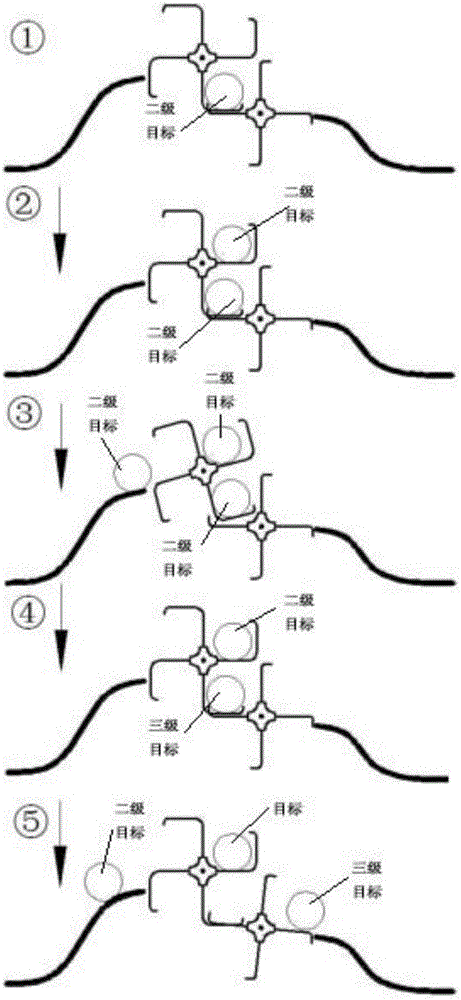

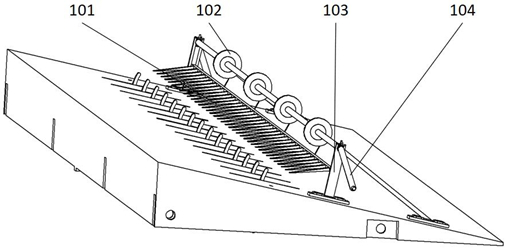

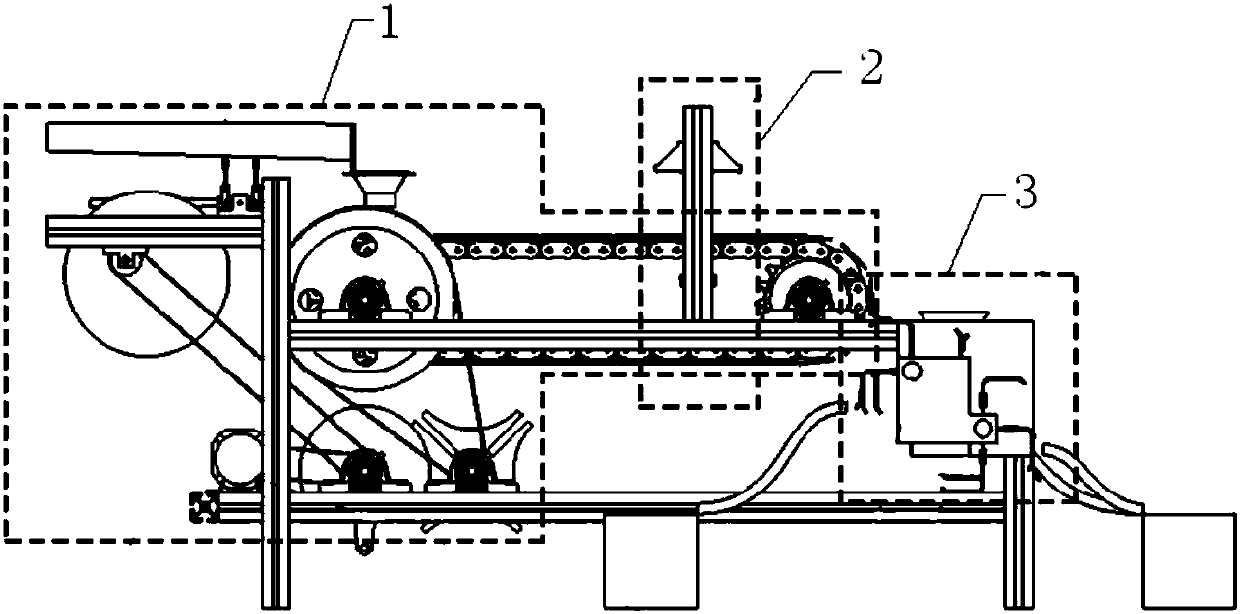

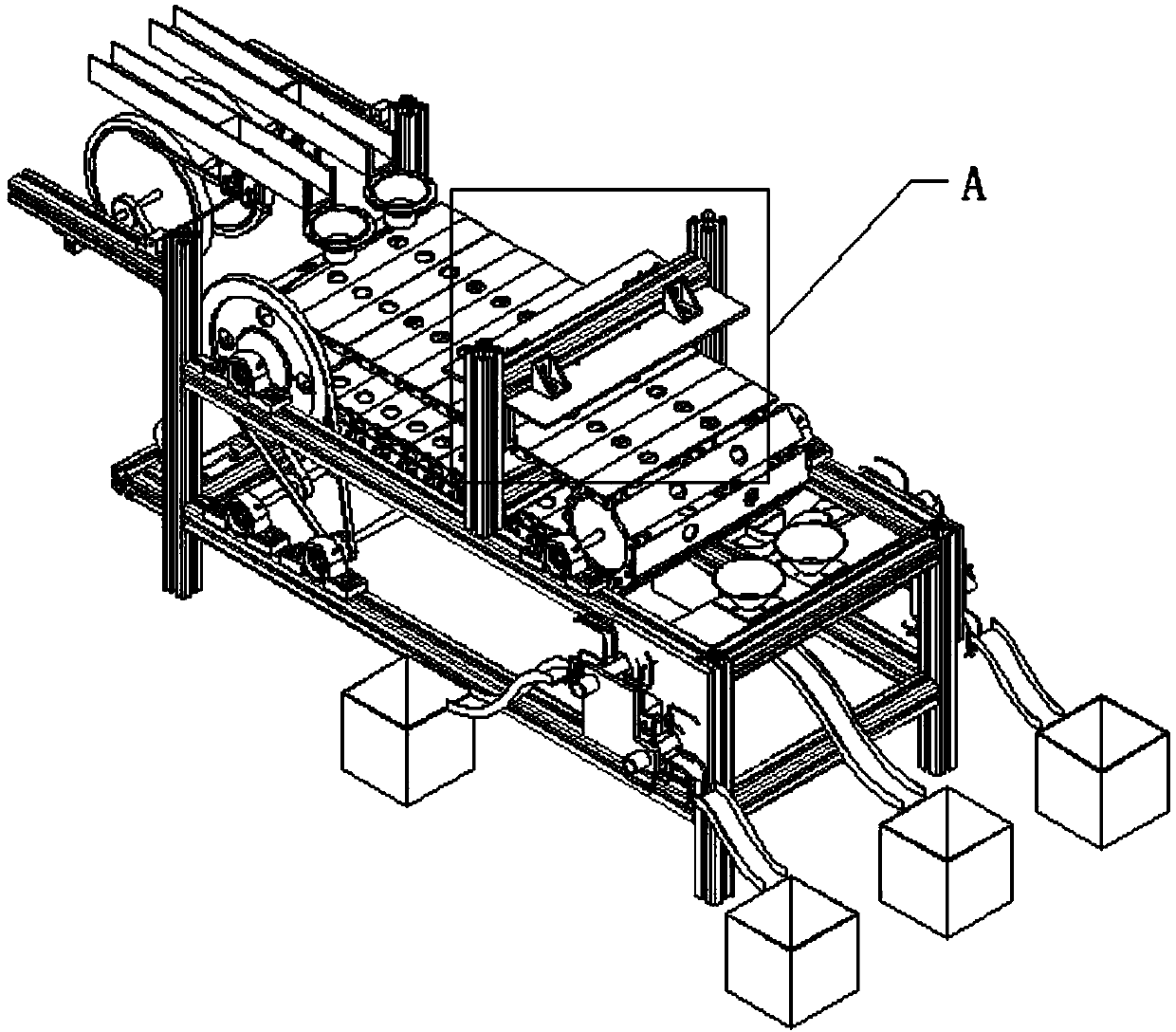

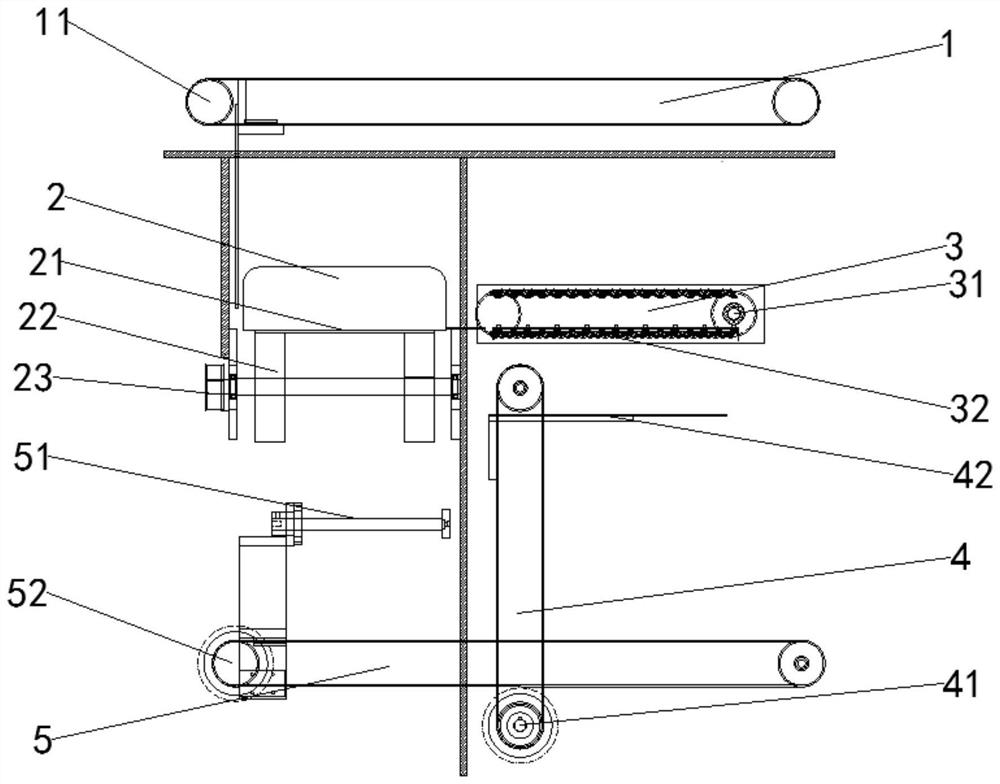

Sorting and visual detection grader

The invention discloses a sorting and visual detection grader. The sorting and visual detection grader comprises a sorting single fruit feeding mechanism, a visual detection mechanism and a grading actuating mechanism, wherein the sorting single fruit feeding mechanism is used for conveying single fruit, the visual detection mechanism is used for detecting the fruit level, and the grading actuating mechanism is used for sorting fruits according to the level. By using the sorting single fruit feeding mechanism, complex disordered target groups can be effectively and orderly arranged and are individually conveyed one by one, so that the grader is automatically operated; to-be-detected fruits can be detected and identified by the visual detection mechanism, the grading standard includes the maturity, defects, size and weight of the fruits, grading factors are diversified, the height is automated, the collision and extrusion between the fruits as well as between the fruits and the machine are effectively reduced, and the extrusion and collision damages to the fruits are greatly reduced; the fruits can be respectively sorted to corresponding collecting boxes according to the level by the grading actuating mechanism according to detection results of the visual detection mechanism, so that the automatic grading of the fruits is realized.

Owner:SOUTH CHINA AGRI UNIV

Ultrasonic standing wave type microfluidic chip and manufacturing method thereof

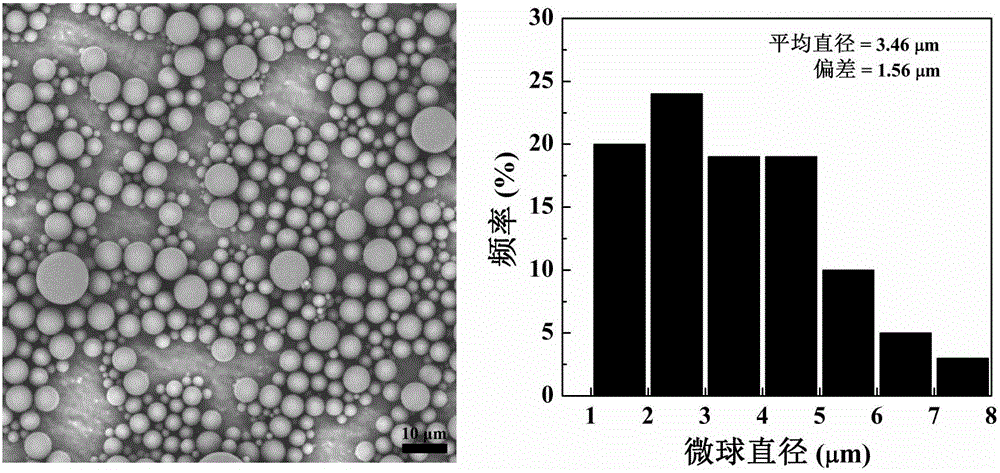

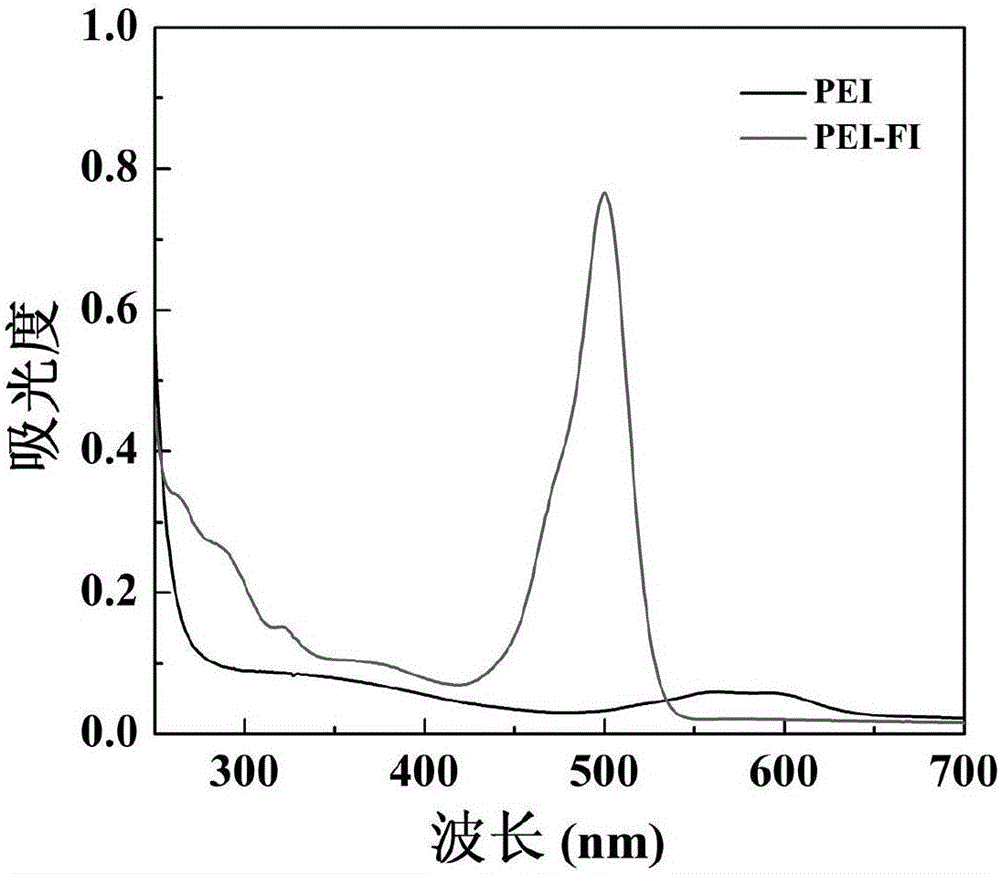

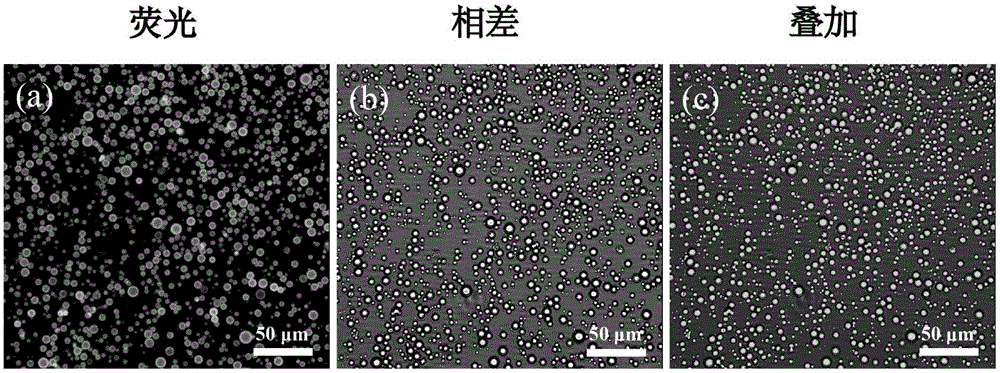

InactiveCN106076444AEasy to makeLow costLaboratory glasswaresFluid controllersElectrospinningMicrofluidic chip

The invention relates to an ultrasonic standing wave type microfluidic chip and a manufacturing method thereof. According to the chip, particles or cells are controlled, captured and separated in ultrasonic standing waves by PLGA-PEI microspheres or PLGA short nanofiber lines in a chip channel. The method comprises the steps that 1, the PLGA microspheres are synthesized through a double emulsion method and then modified by polyethyleneimine; 2, a PLGA nanofiber membrane is prepared through an electrostatic spinning method and then homogenized to obtain the short nanofiber lines; 3, the ultrasonic standing wave type microfluidic chip is manufactured. According to the chip, the particles or cells can be effectively controlled, the manufacturing process is simple, cost is low, the very high controllability and operability are achieved, and a wide application prospect is achieved.

Owner:DONGHUA UNIV

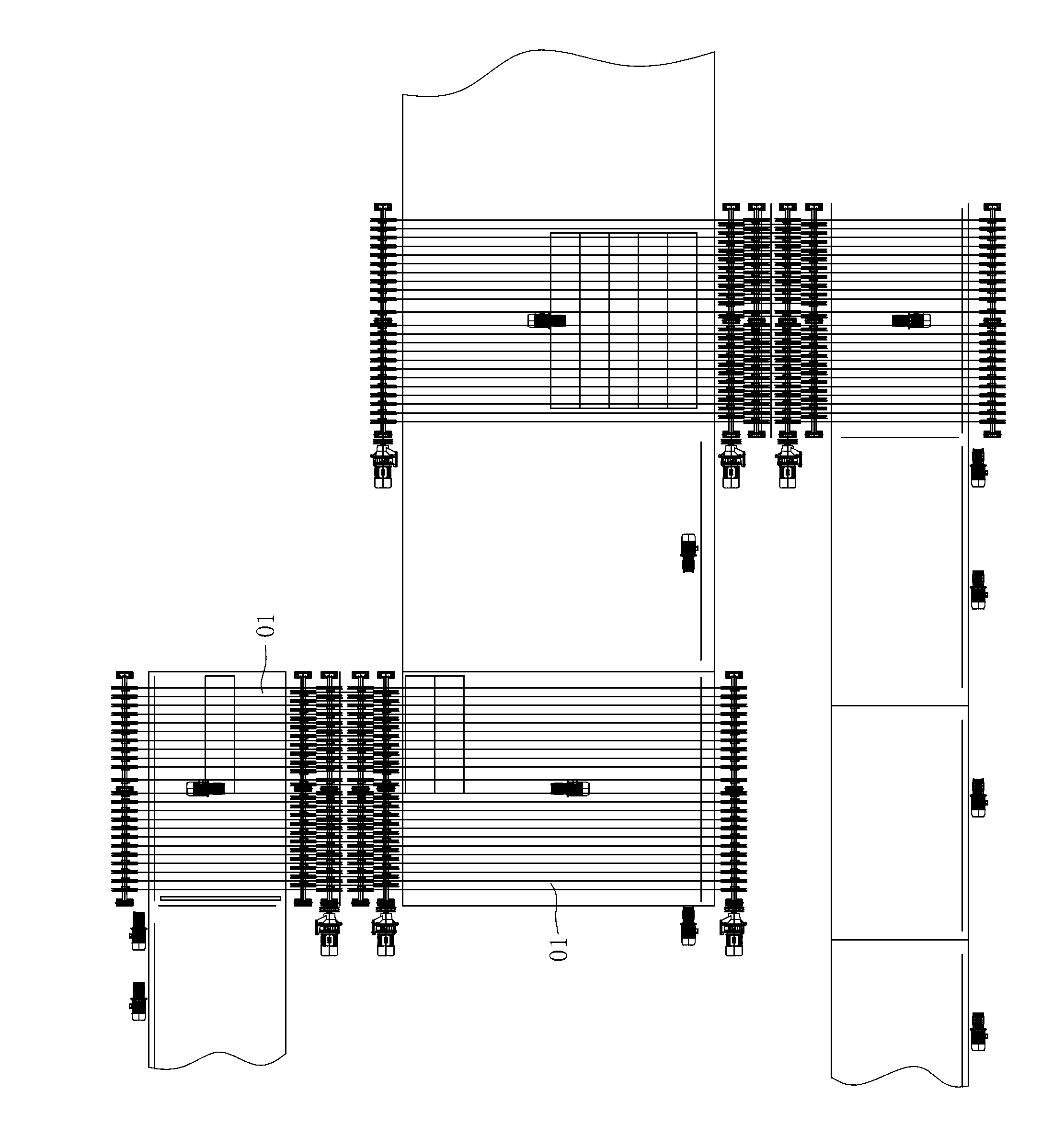

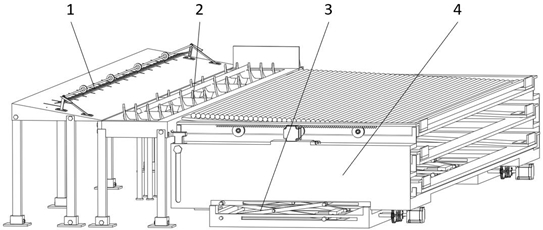

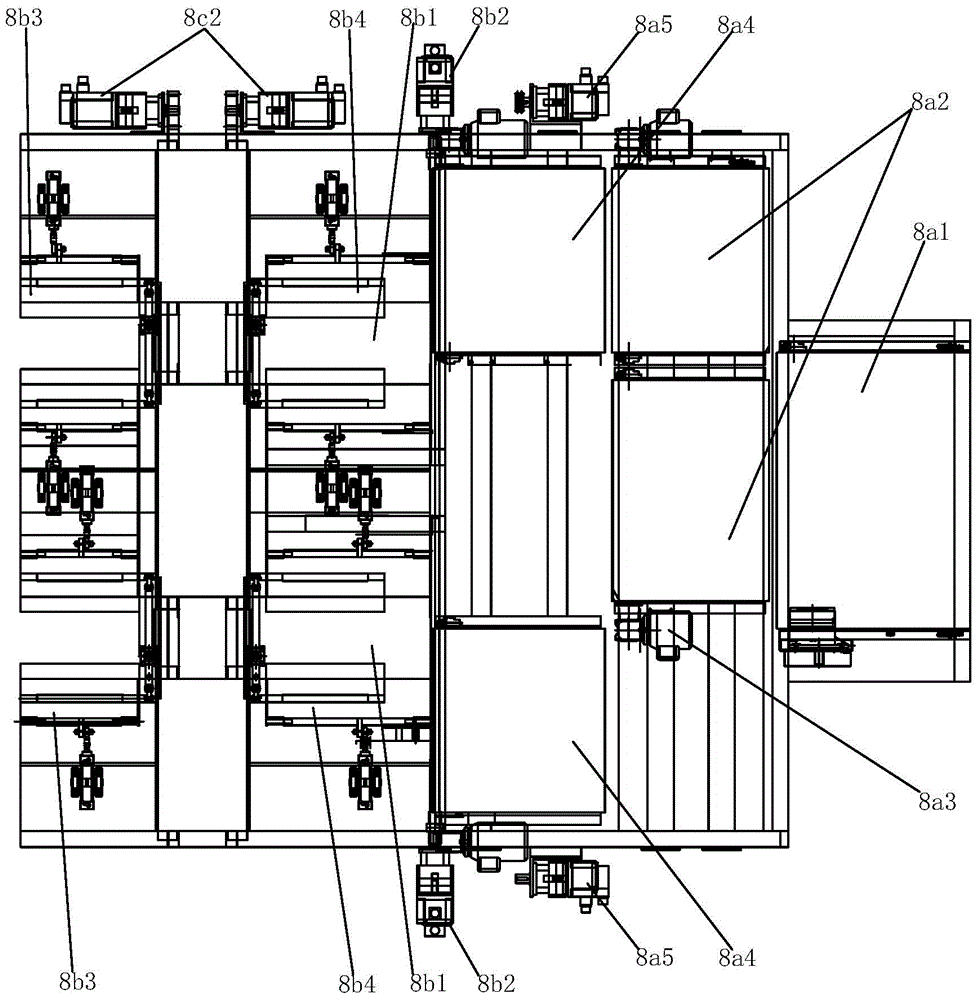

Unloading stacking assembly for bagged cement loading stacking main machine

ActiveCN104192588AReduce labor intensityKeep healthyStacking articlesLoading/unloadingEngineeringUltimate tensile strength

The invention discloses an unloading stacking assembly for a bagged cement loading stacking main machine. The unloading stacking assembly comprises an unloading device, a stacking device and a support. The unloading device and the stacking device are both mounted on the support, the input end of the unloading device can be in horizontal butt joint with the output end of a last step station, the output end of the unloading device is in vertical butt joint with the input end of the stacking device, the output end of the stacking device enables bagged cement to be vertically conveyed to specific locations, and the bagged cement conveyed to the specific locations by the stacking device is in transverse linear arrangement. According to the unloading stacking assembly for the bagged cement loading stacking main machine, the bagged cement is conveyed to the stacking device from the last step station (namely a distribution device) through the unloading device, then the bagged cement is made to be in transverse linear arrangement through the stacking device, so that stacking is completed, manual participation is needless in the whole process, hence, the labor intensity of workers is greatly lowered, the good health of the workers is guaranteed, and the unloading stacking assembly is suitable for truck loading of bagged cement.

Owner:武汉蓝海燕智能装车设备有限公司

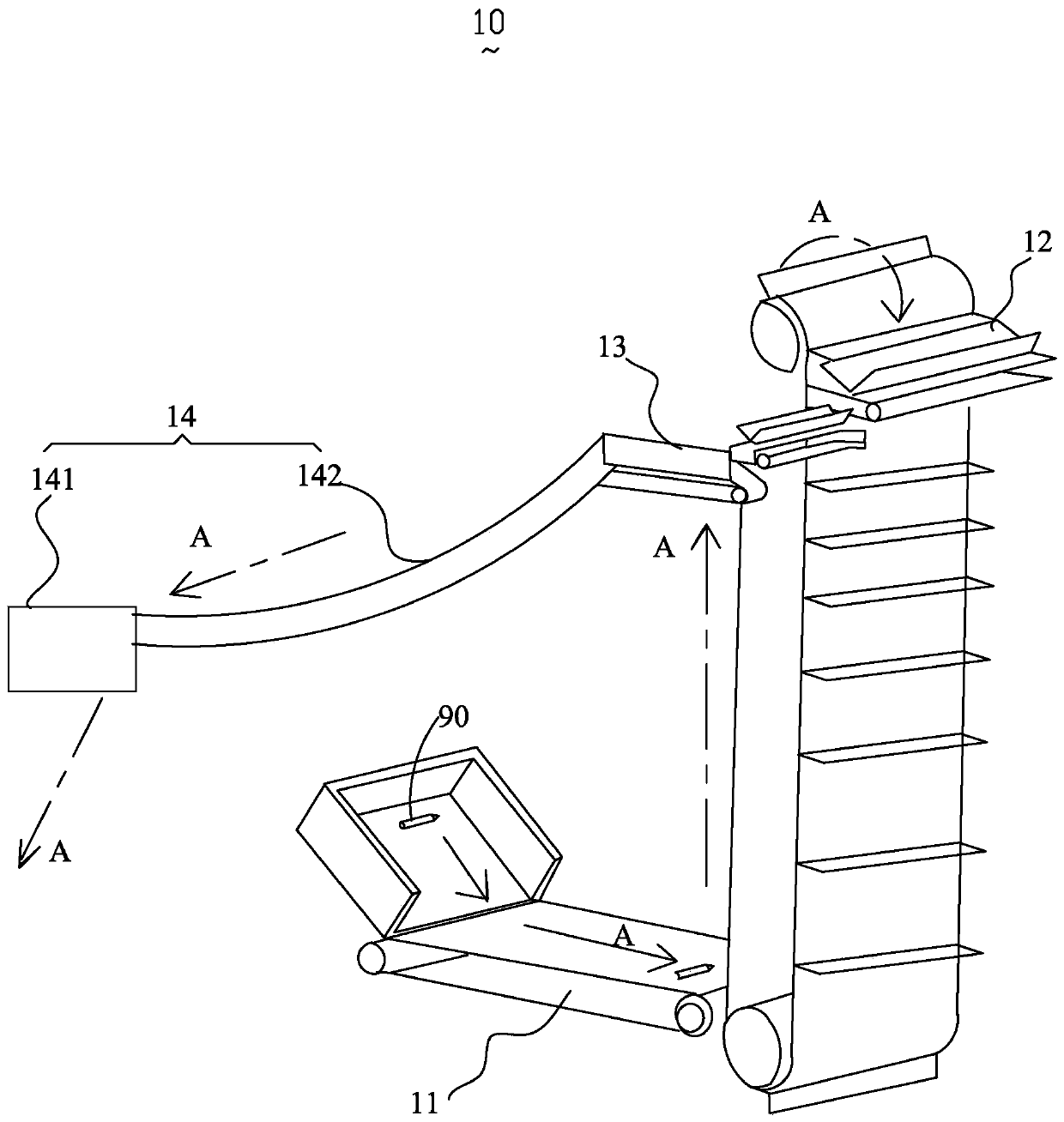

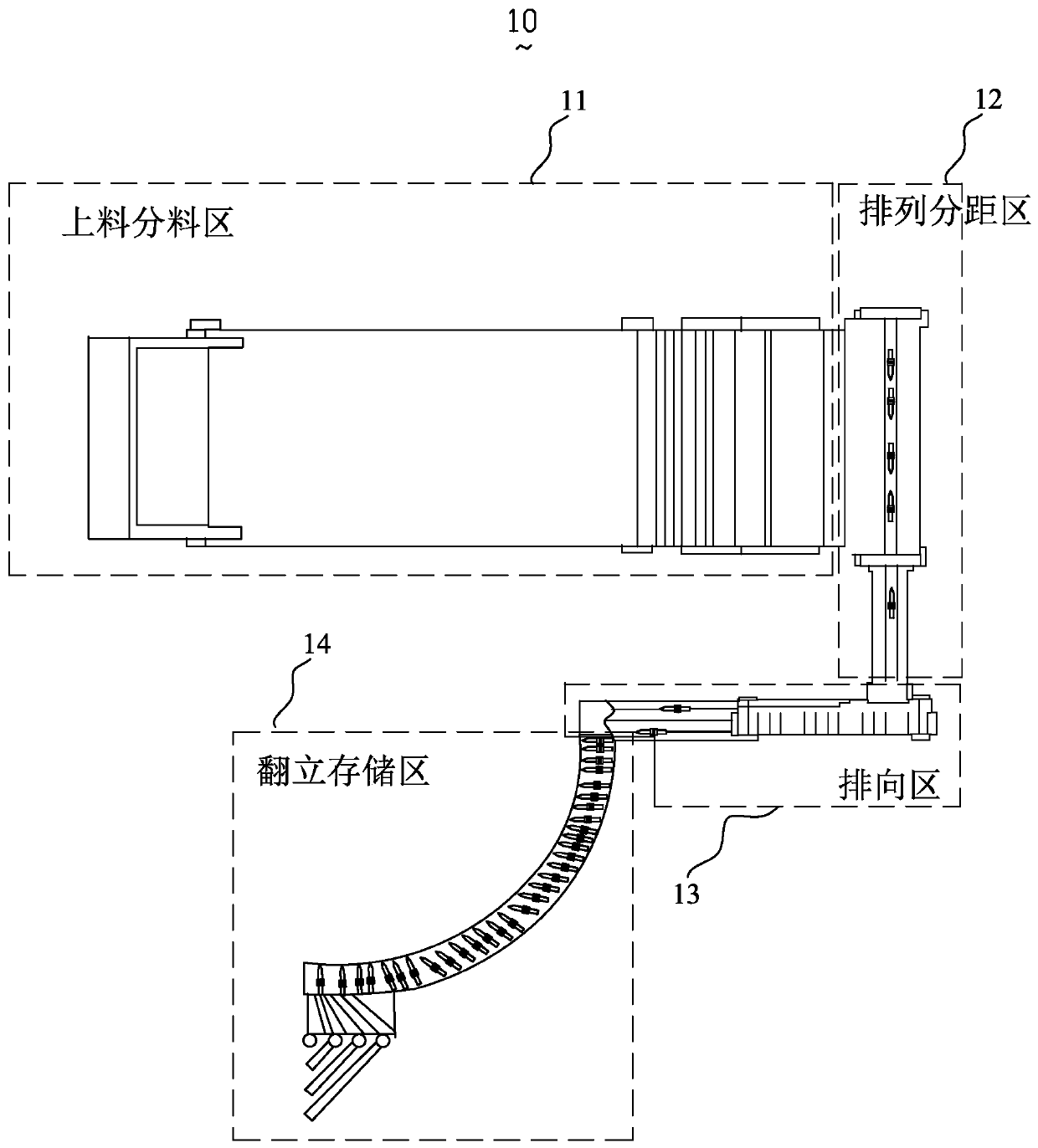

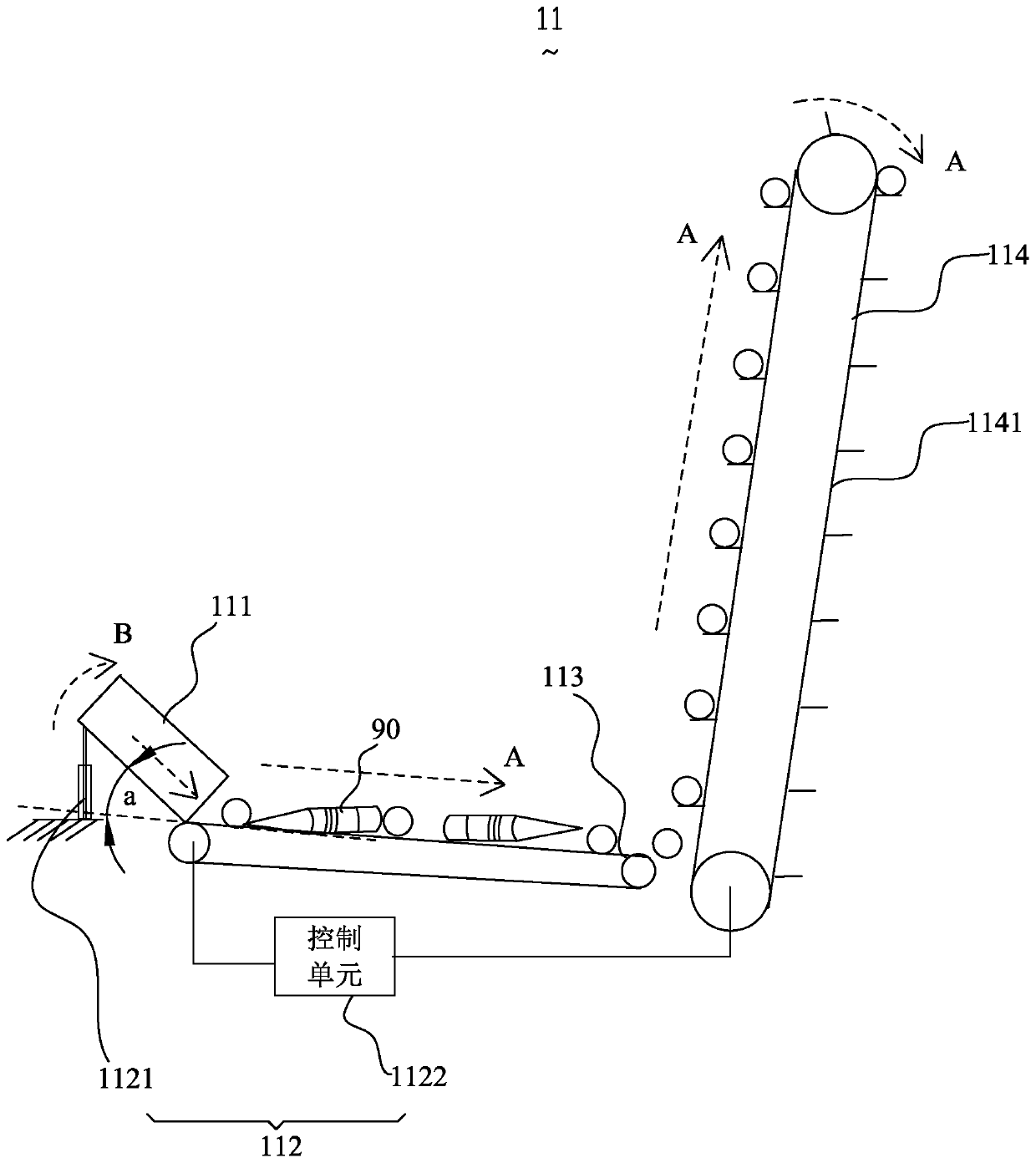

Workpiece feeding, arranging and direction arranging device and technology

Owner:SHENZHEN FUYUNDI TECH

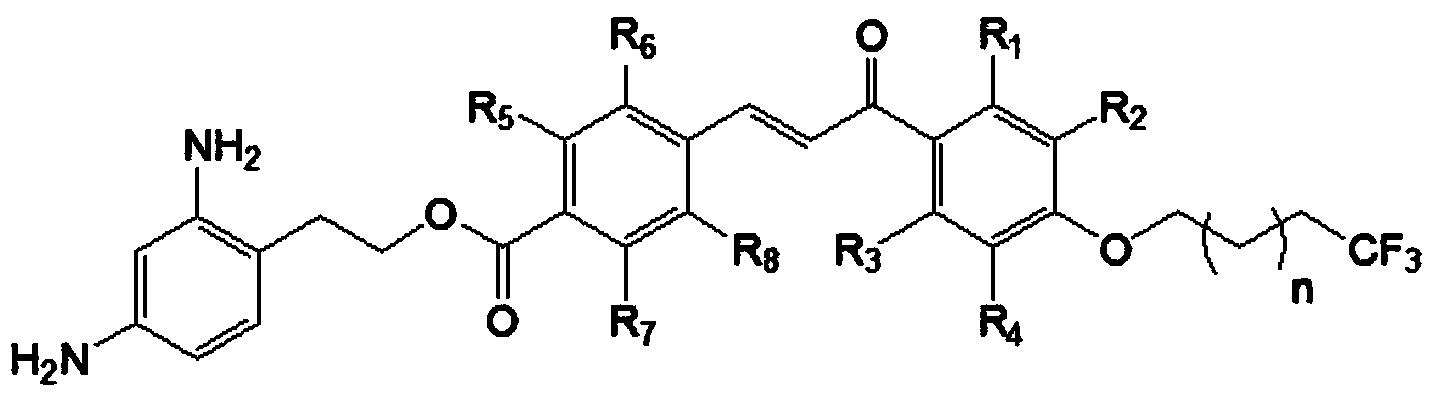

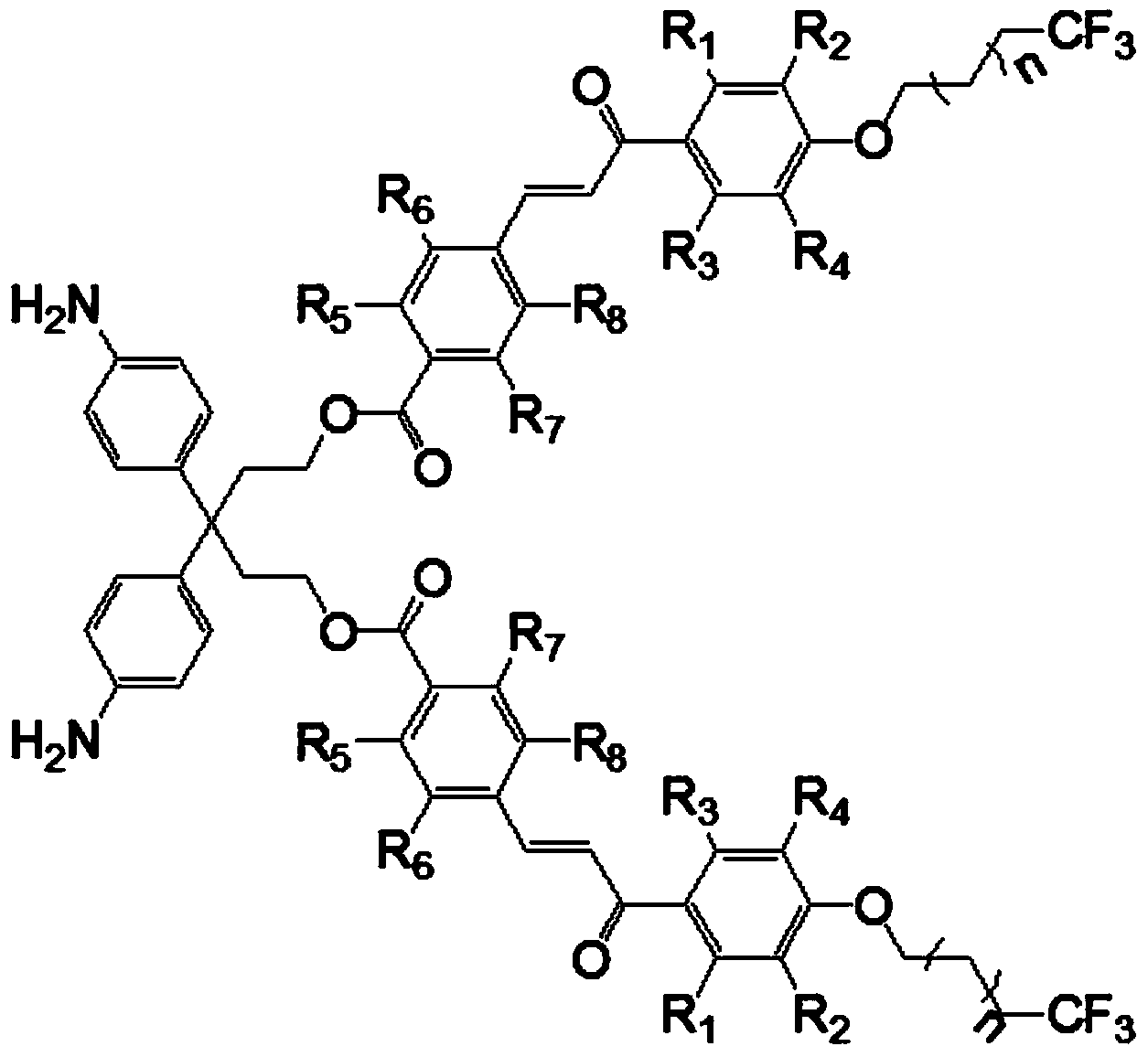

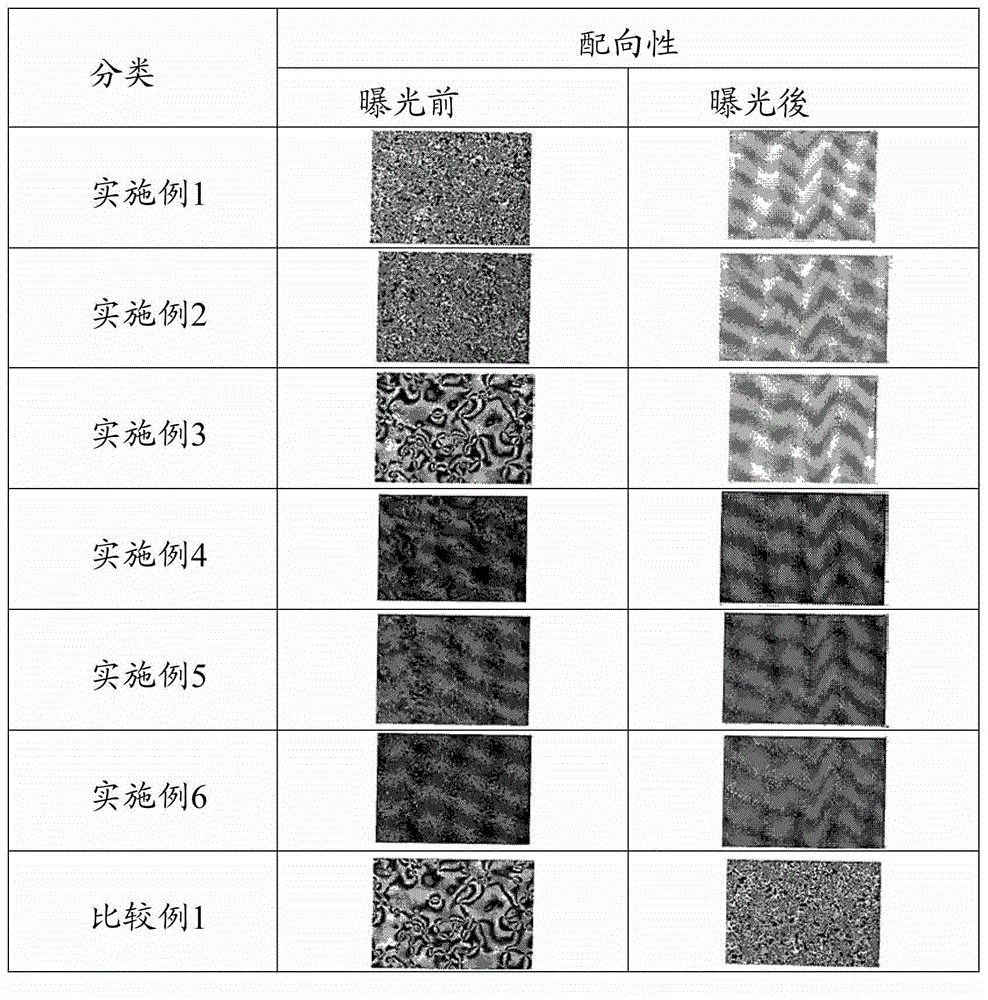

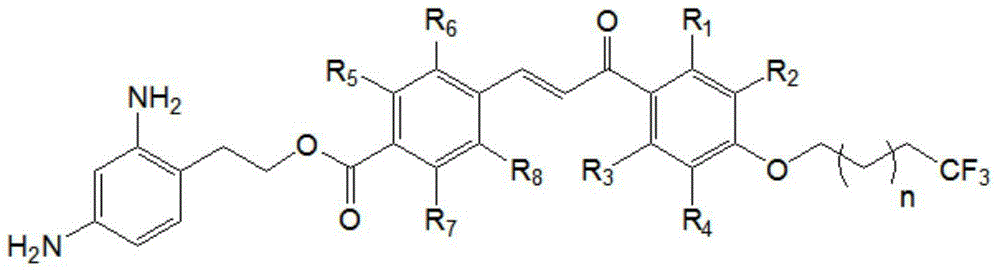

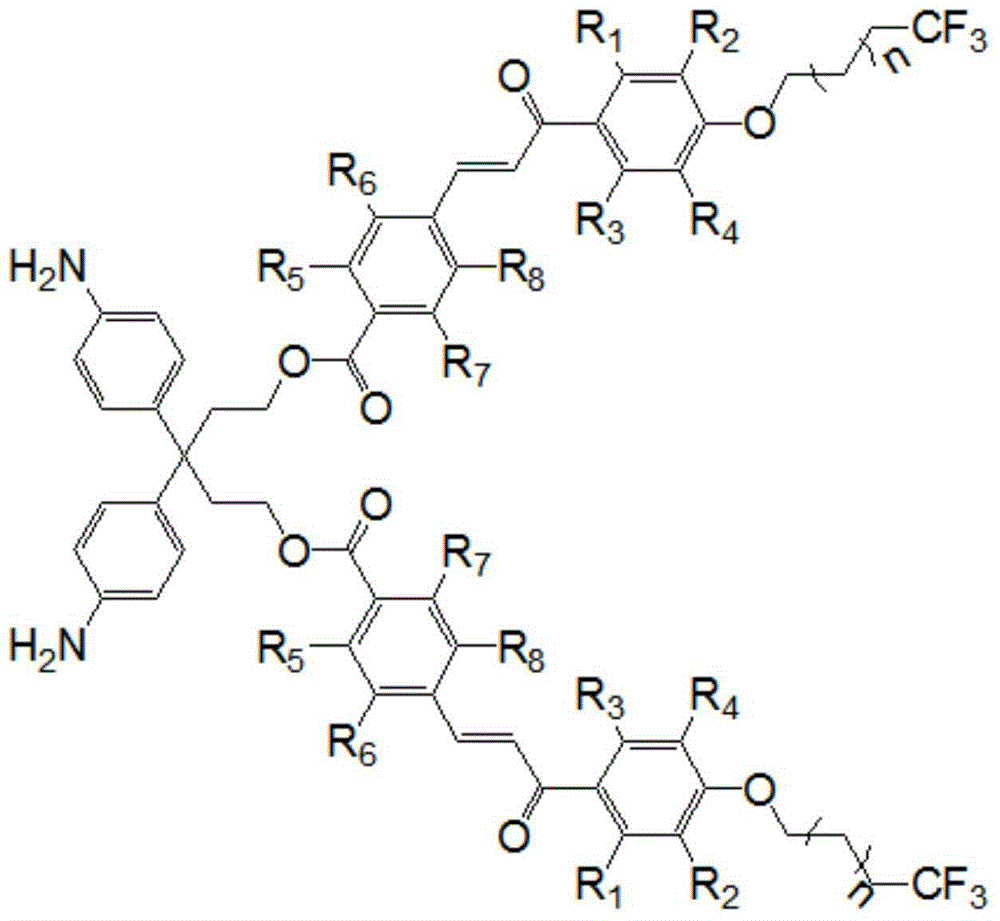

Diamine compound, method for preparing same, liquid crystal alignment agent, liquid crystal alignment film, and liquid crystal display device

InactiveCN103748068AEnsure safetyEnsure economyLiquid crystal compositionsOrganic chemistryCrystallographyLiquid-crystal display

The present invention relates to an amine compound, a method for preparing same, and a liquid crystal alignment agent, a liquid crystal alignment film, and a liquid crystal display device, having same. A liquid crystal alignment agent having polyamic acid or polyimide prepared using the amine compound of the present invention enables a liquid crystal alignment film and a liquid crystal display device having an excellent thermal stability even after forming the liquid crystal alignment film, and expressing high alignment and stability even after an ultraviolet ray irradiation.

Owner:DONGJIN SEMICHEM CO LTD

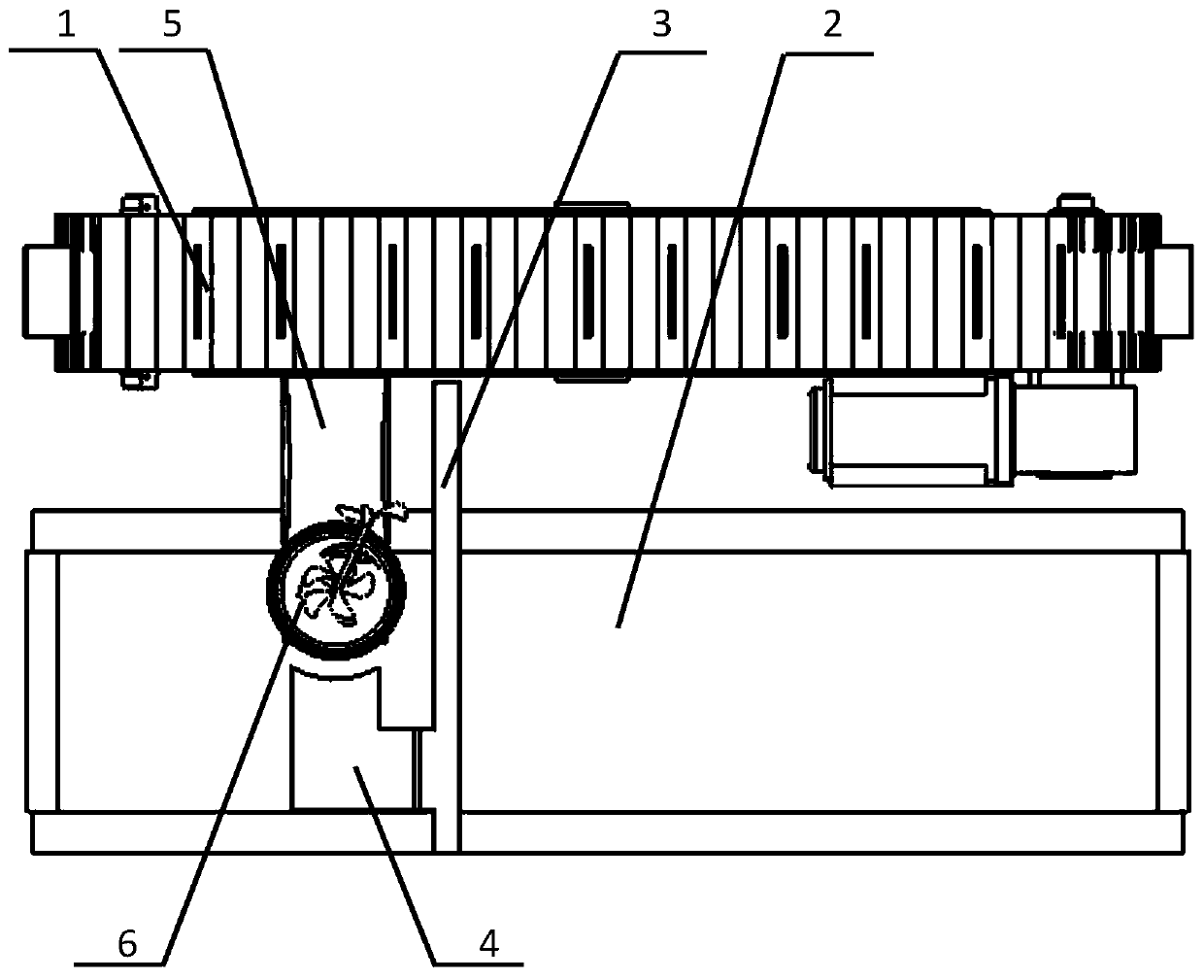

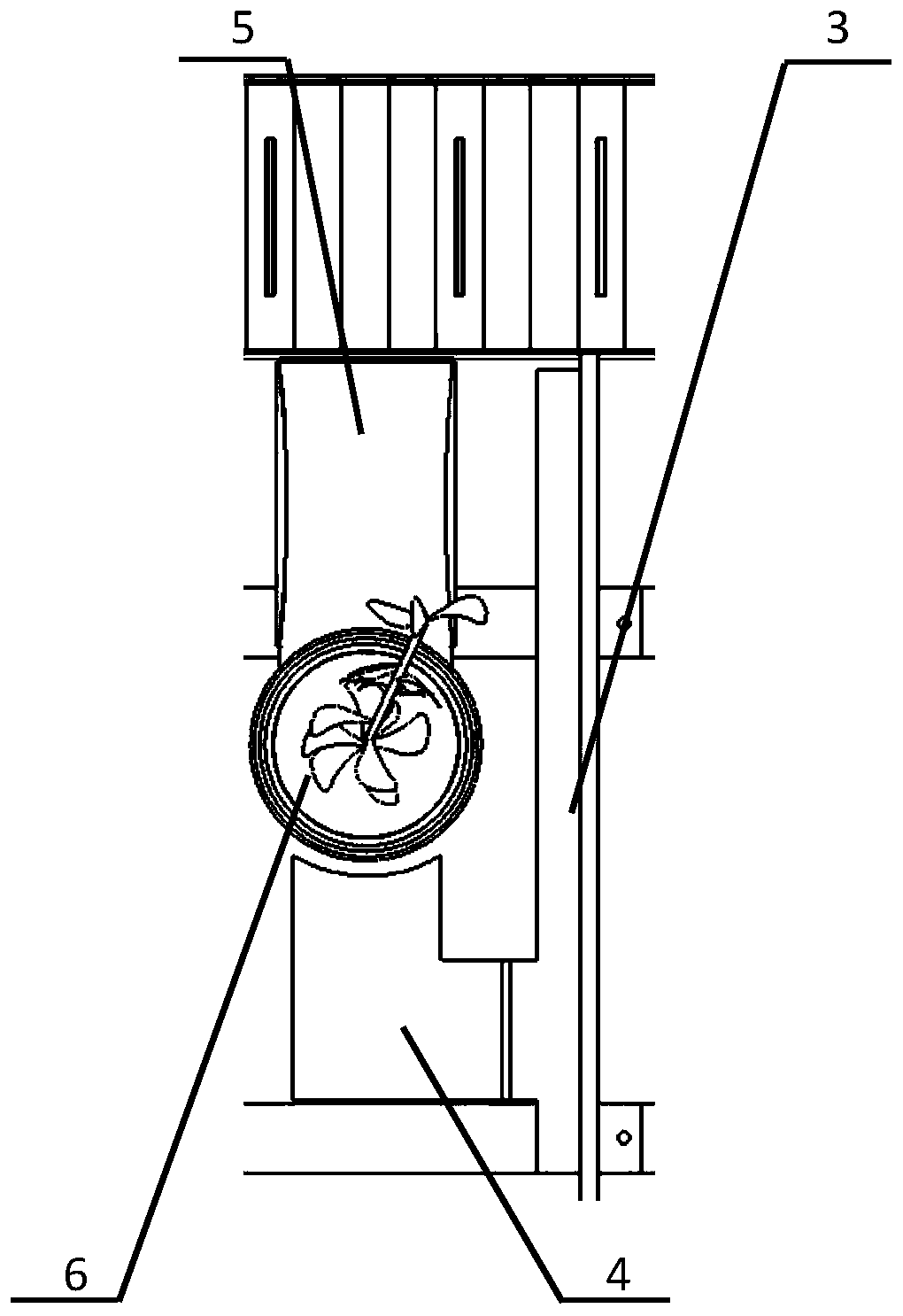

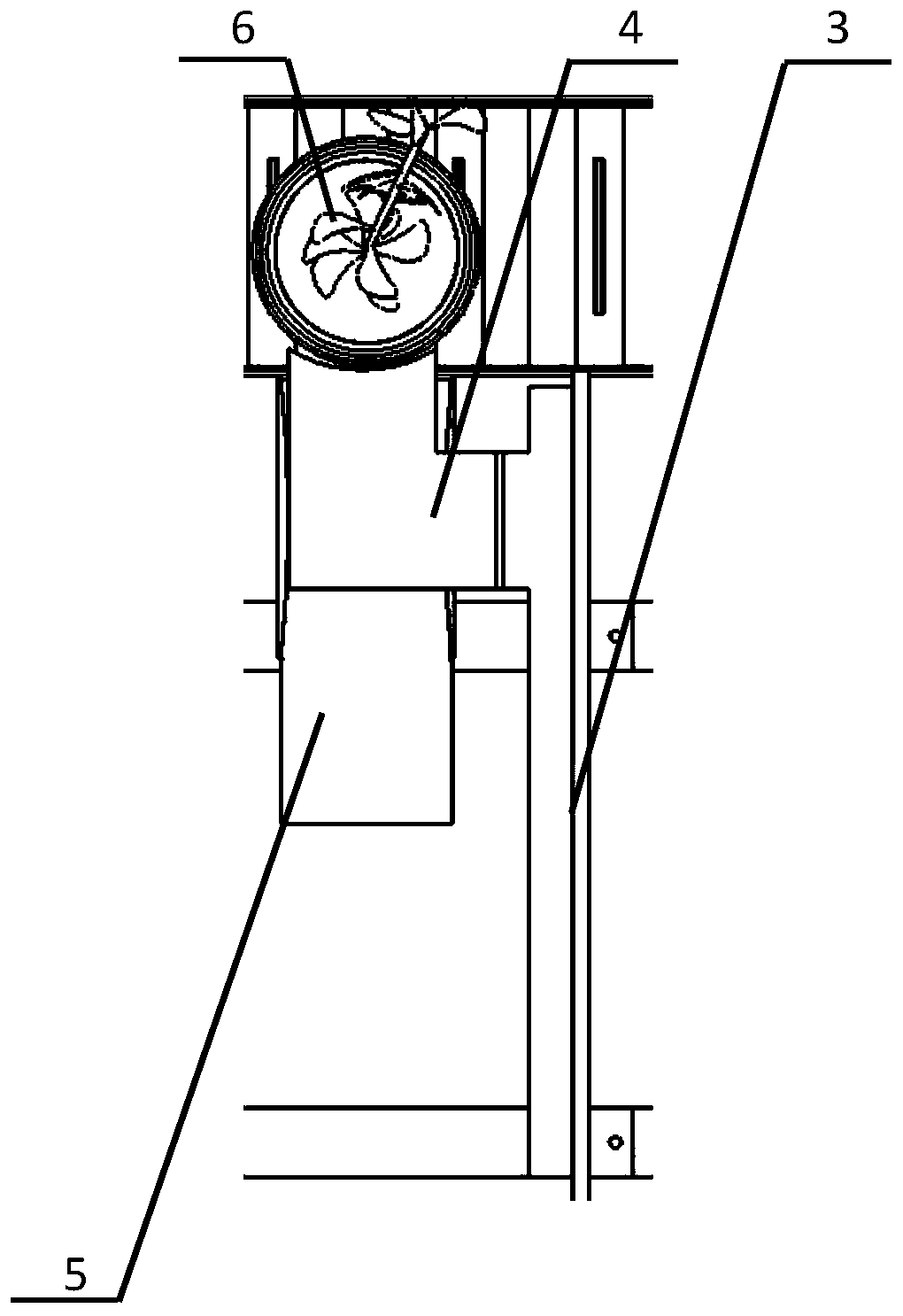

Flowerpot and flower and plant matrix separating device

ActiveCN106212091ASave time at workImprove work efficiencyConveyor partsFlower-pot cleaningEngineeringAgricultural automation

The invention discloses a flowerpot and flower and plant matrix separating device and belongs to the field of automatic equipment for facility agriculture. The flowerpot and flower and plant matrix separating device comprises an equal-separation-distance conveyor, a potted flower conveyor, a rodless air cylinder, a potted flower pushing plate, a potted flower rubbing channel and potted flowers. The potted flowers are conveyed to working positions through a conveyor and are moved to the equal-separation-distance conveyor through the potted flower rubbing channel under the pushing of the potted flower pushing plate, the potted flower pushing plate is driven by the rodless air cylinder, two sides of the potted flower rubbing channel have a certain radian, flowerpots and the matrixes in the flowerpots are extruded in the potted flower passing process to weaken the bonding force between the flowerpots and the matrix, and accordingly the flowerpot and matrix separating process is achieved. The flowerpot and flower and plant matrix separating device is one important portion of an automatic transplanting production line, flowerpot and matrix separation can be achieved in a rubbing-extruding mode, and it can be ensured that the flowerpots and the matrixes are complete after separation and the matrixes can be smoothly taken out of the flowerpots for transplanting operation.

Owner:BEIJING UNIV OF TECH

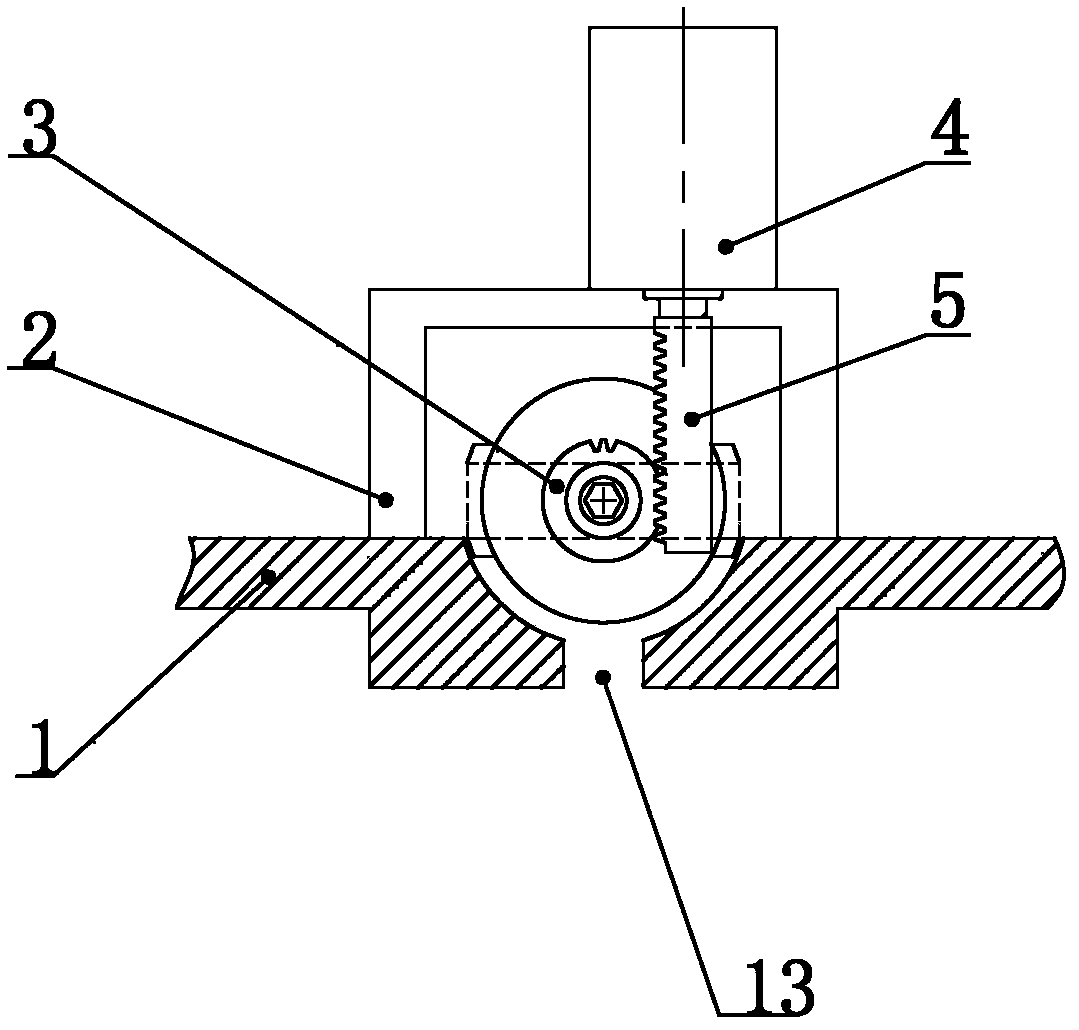

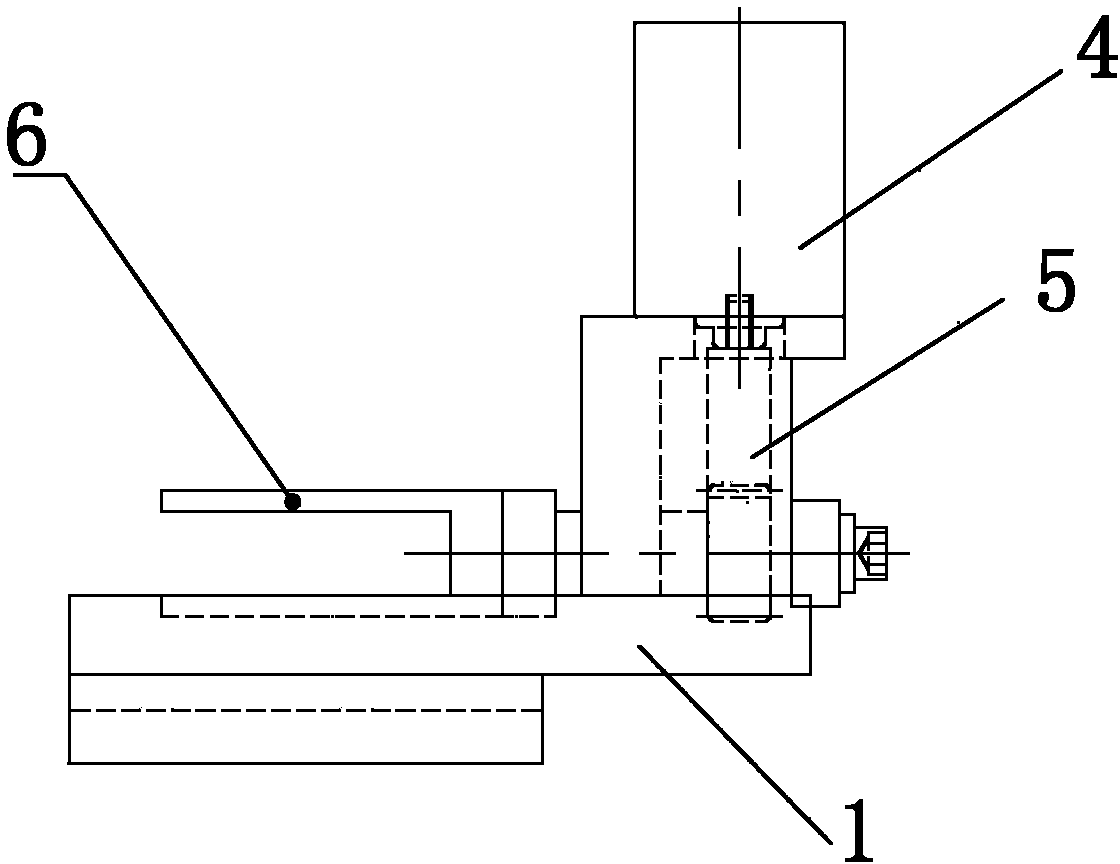

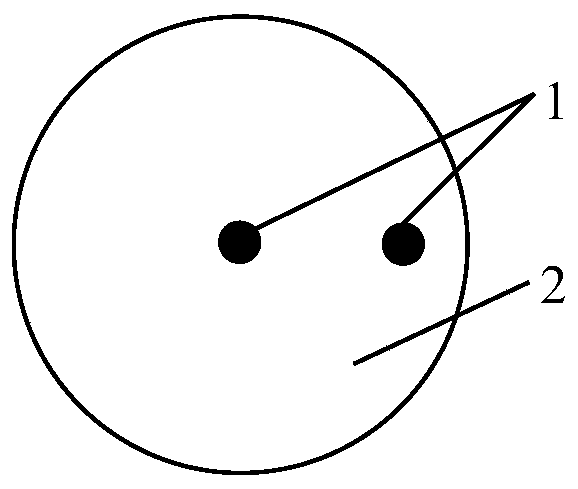

Mechanism for checking out unqualified products from circular annular parts

The invention relates to a mechanism for checking out unqualified products from circular annular parts. The mechanism is characterized by comprising a bottom plate, a bracket, an air cylinder, a rack, a gear, an overturn plate and a rotating shaft; the bracket is fixed on the bottom plate; an unqualified product dropping channel is arranged on the bottom plate; the rotating shaft is supported on the bracket; one end of the rotating shaft is in keyed joint with the overturn plate, and the other end of the rotating shaft is connected with the gear; the gear is meshed with the rack; one end of the rack is connected with a piston rod of the air cylinder. The mechanism has the benefit effects: the mechanism can be used in coordination with an automatic detecting production line to detect external diameters, internal diameters, thicknesses and weights item by item, and then checks out the unqualified products automatically. The automatic detecting production line is further completed, and automatic movement, arrangement and item-by-item detection on the external diameters, the internal diameters, the thicknesses and the weights are realized. The mechanism is driven by pneumatic elements, automatic movement and inspection are achieved, the degree of automation is high, the detection precision is high, and automatic screening and arrangement are achieved.

Owner:天津市中马骏腾精密机械制造有限公司

Fully automatic bagged cement loading machine

A fully automatic bagged cement loading machine, including a guide rail, a horizontal conveying device, a running device, an inclined conveying device, a positioning system and a controller, the input end of the inclined conveying device is connected with the output end of the horizontal conveying device, and the output end of the inclined conveying device is connected There is a loading and palletizing main engine, which is hoisted on the walking device through a lifting device; the loading and palletizing main engine includes a distribution device, an unpacking device, a palletizing device and a bracket, and the distribution device, the unpacking device and the palletizing device are sequentially installed on the On the bracket, the input end of the distribution device is docked with the output end of the inclined conveying device. The number of output ends of the distribution device is at least 2, and each output end of the distribution device is horizontally connected with the input end of an unpacking device. The output end is vertically connected with the input end of a palletizing device, and the output end of each palletizing device vertically transports the bagged cement to the designated position, and the bagged cement delivered to the designated position by all the palletizing devices is arranged in a horizontal line.

Owner:武汉蓝海燕智能装车设备有限公司 +1

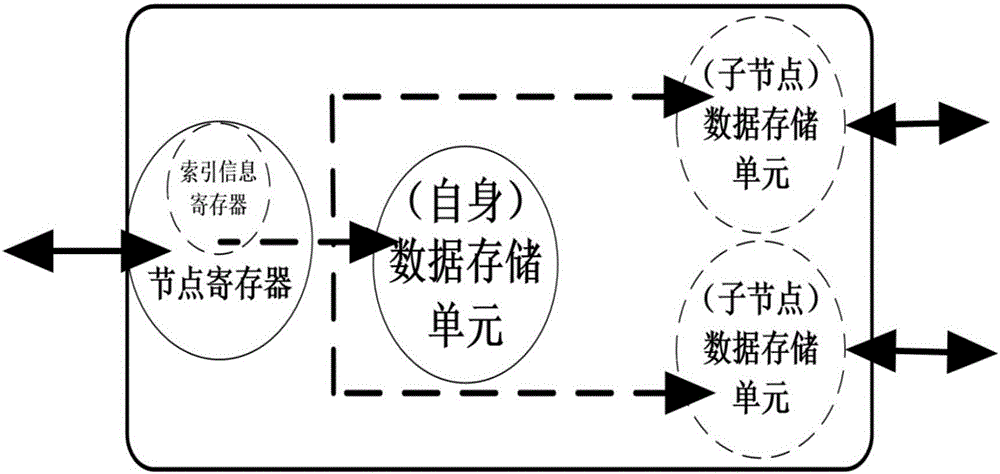

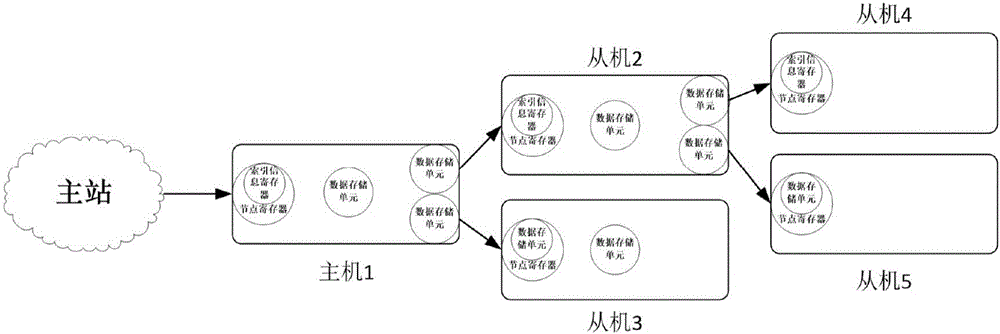

Communication device applied to intelligent network charge interactive terminal

InactiveCN106789203ASimple configurationIncrease flexibilityPower network operation systems integrationCircuit arrangementsIntelligent NetworkProcessor register

The invention discloses a communication device applied to an intelligent network charge interactive terminal. The communication device comprises an upper interface, a lower interface, an own data storage unit, a sub-node data storage unit and a node register, and further comprises an index information register, wherein the node register is used for collecting the data in the data storage units corresponding to this communication device and all lower communication devices therebelow; or the node register can collect the index information of the data through the internal index information register; the internal structures of the communication devices are consistent when the communication devices communicate with the upper or the lower, the data content corresponding to the node register is uploaded through the upper interface, and the transmission can be performed according to the required order of the upper communication device in the uploading. Therefore, an operation of independently performing master-slave configuration on each node according to a hierarchical relation between the nodes is unnecessary, the workload of the networking configuration is greatly reduced, and the communication device can be high-flexibly applied to various distribution automation fields.

Owner:ELEFIRST SCI & TECH

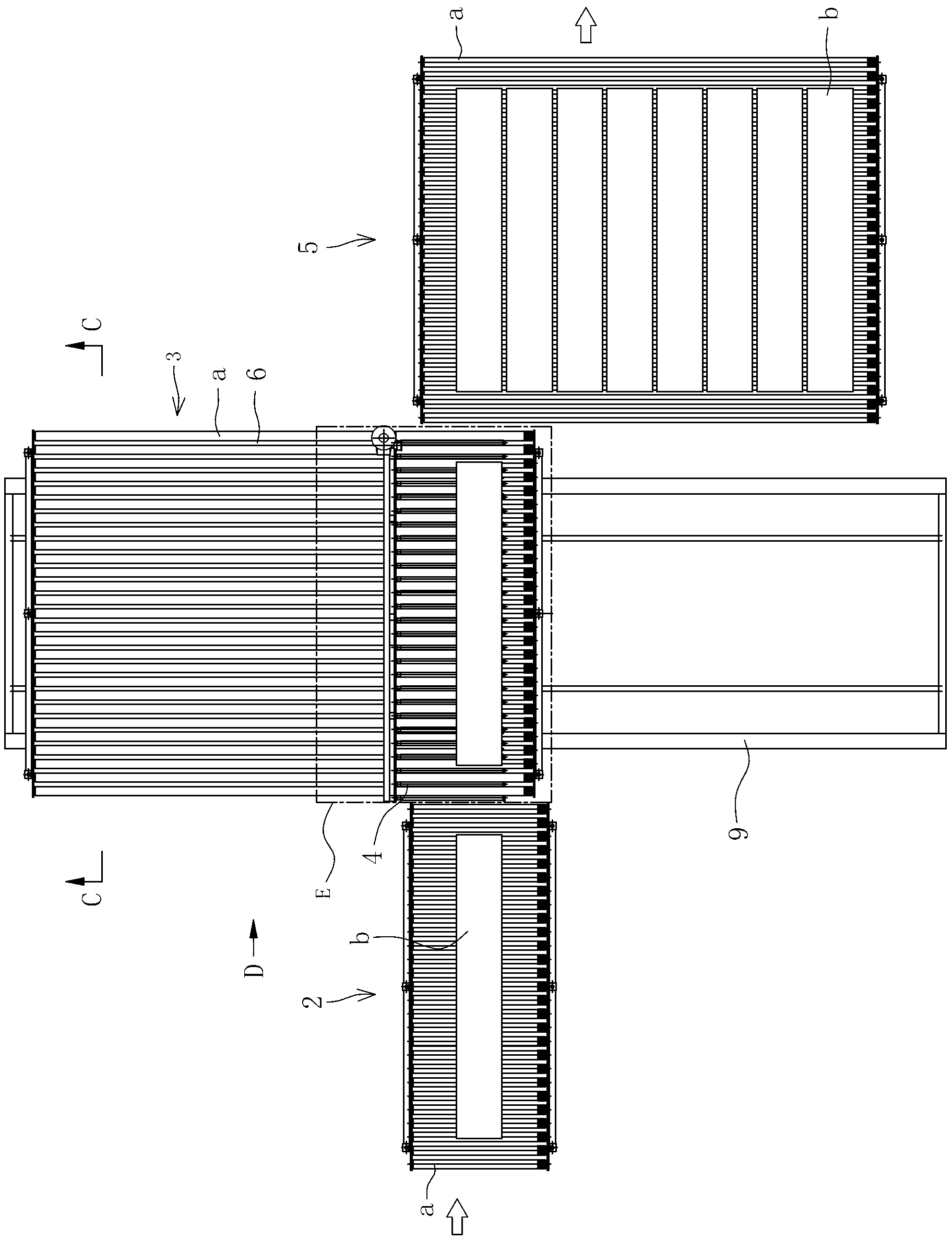

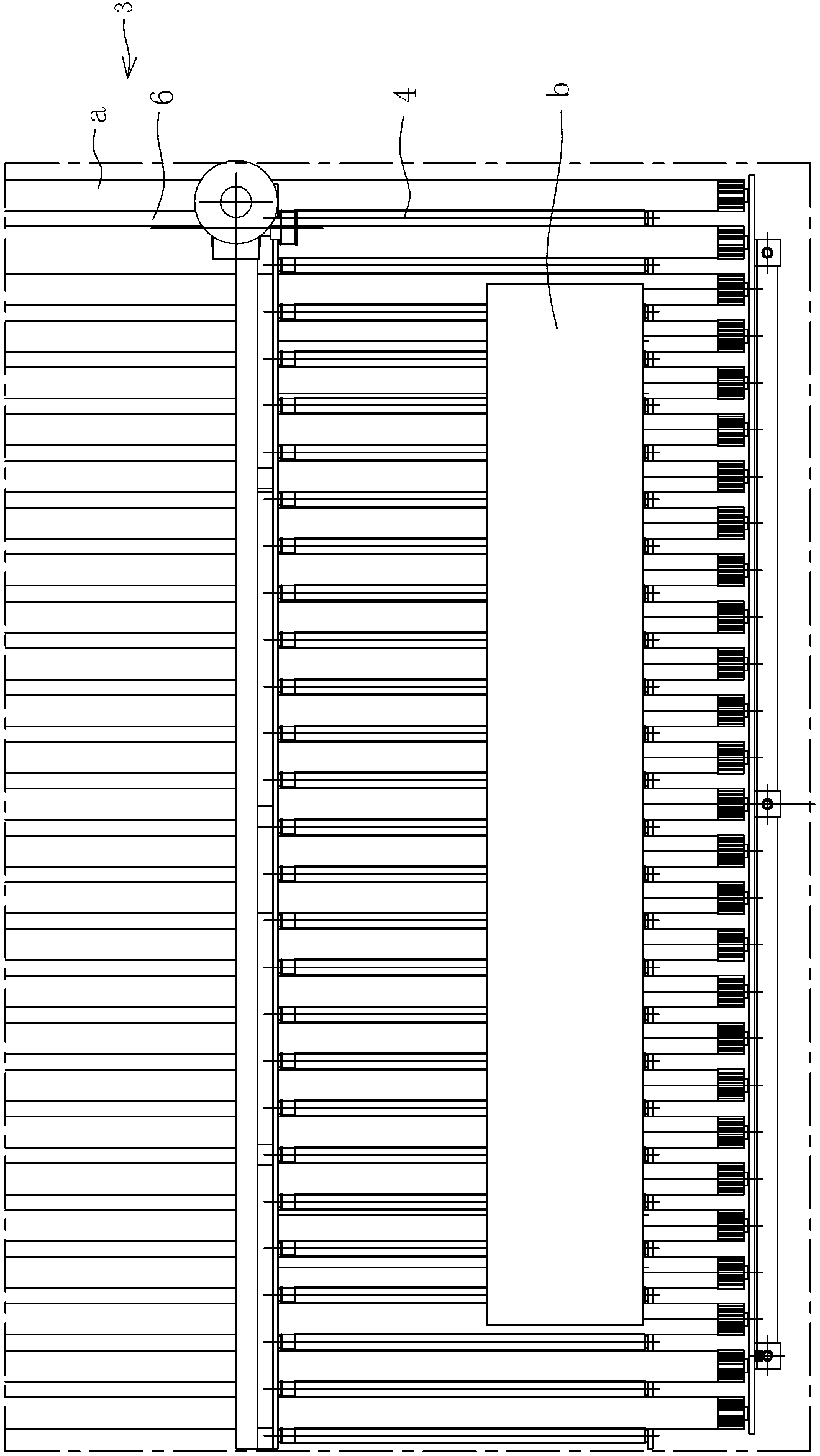

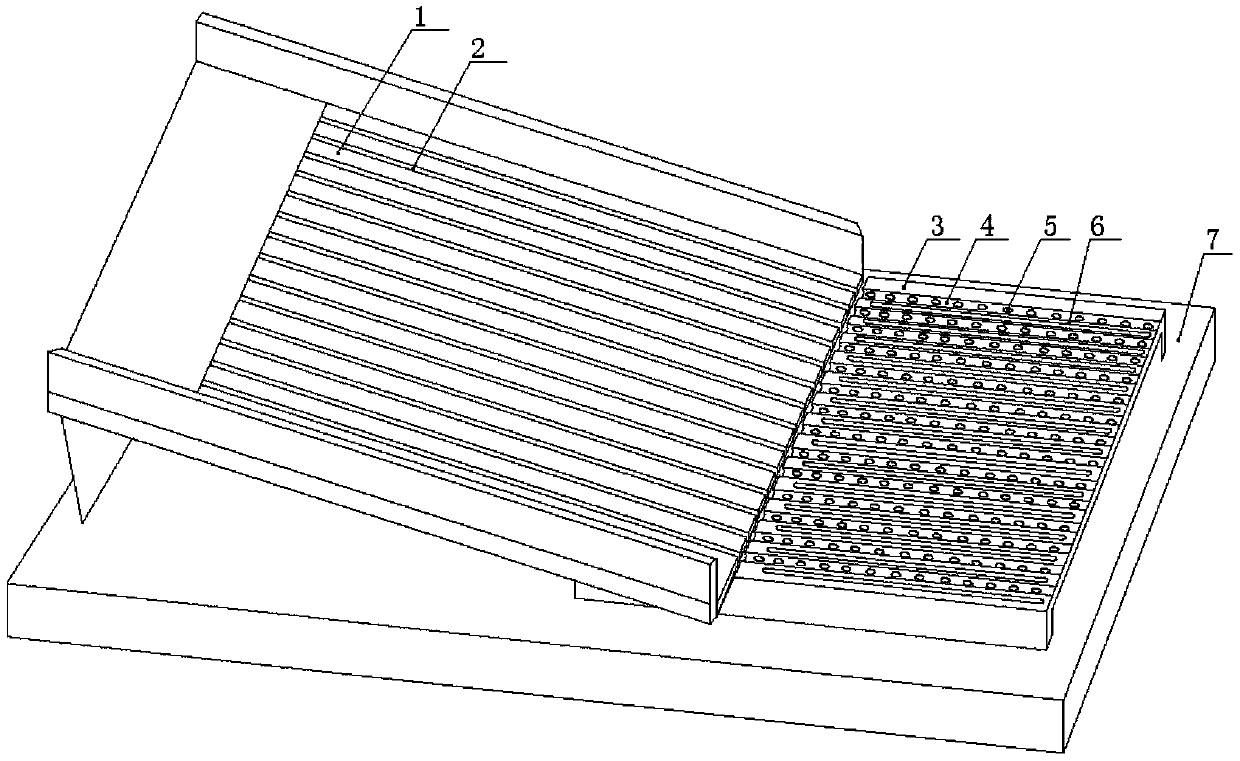

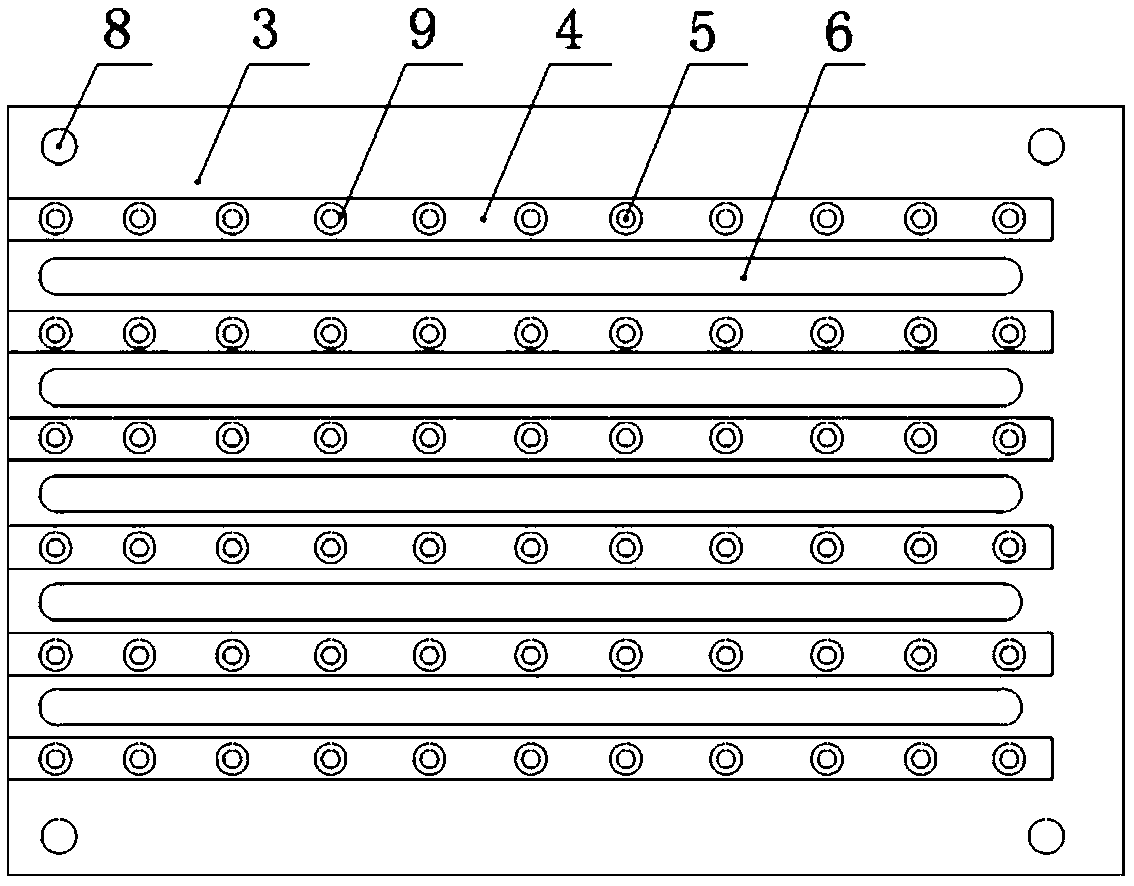

Large ceramic plate arranger

ActiveCN102837957AAchieve permutationReduce difficultyConveyor partsEngineeringMechanical engineering

The invention discloses a large ceramic plate arranger capable of largely reducing resistance, lowering the energy consumption and the repair rate, which comprises a frame, wherein a front roller table, a transverse roller table, a lifting roller table and a rear bearing roller table are arranged on the frame; the front roller table, the transverse roller table, the lifting roller table and the rear bearing roller table are formed by a plurality of roller bodies aligned at intervals horizontally; every roller table is provided with a driving device to drive the roller body of respective roller table to rotate, the arranging direction of the roller bodies of all the roller tables are in the same direction; the transverse roller table is arranged at the rear part of the delivering direction of the front roller table, and the moving direction is perpendicular to the delivering direction of the front roller table; the transverse roller table is lower than the front roller table; the rear bearing roller table is arranged at one side of the transverse roller table towards the delivering direction; the lifting roller table is arranged at the rear part of the delivering direction of the front roller table; the roller body on the lifting roller table is embedded in the gap between the roller bodies of the transverse roller table.

Owner:MODENA TECH LTD

Intelligent community super-brain all-in-one machine

PendingCN112860022AInhibit sheddingAvoid draggingDigital processing power distributionEngineeringMachine

The invention discloses a intelligent community super brain all-in-one machine, which comprises a bottom plate, the base surface of the bottom plate is fixedly connected with two symmetrically arranged heat dissipation assemblies, a wire arrangement mechanism and a super brain all-in-one machine body, and the two heat dissipation assemblies are movably provided with dustproof assemblies; the heat dissipation assembly comprises a square pipe fixedly arranged on the base face of the bottom plate, the tail end of the square pipe is fixedly connected with an exhaust fan communicated with the interior of the square pipe, the side wall of the square pipe is fixedly connected with a hanging rod, the wire arranging mechanism comprises a strip-shaped block fixedly arranged on the base face of the bottom plate, and the inner wall of a wire arranging groove is slidably connected with a wire pressing block in a penetrating mode. And one side of the wire pressing block is located in the cavity, a shifting block is fixedly connected to the top face, located in the cavity, of the wire pressing block, and a first spring connected with the side wall of the wire pressing block in a blocking mode is fixedly arranged in the cavity. The intelligent community super-brain all-in-one machine solves the problems that an intelligent community super-brain all-in-one machine is poor in heat dissipation performance, dust is not easy to clean after dust collection, and meanwhile external connecting wires are connected in a mess and are prone to being dragged off after connection.

Owner:安徽爱邻智能科技有限公司

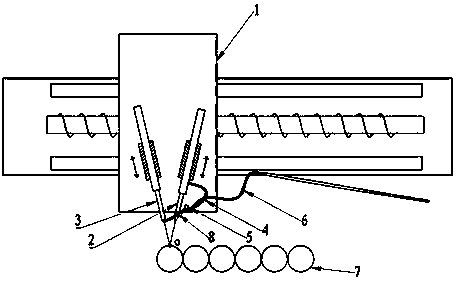

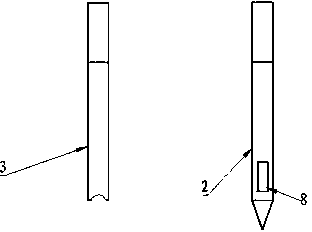

Y-shaped perforating and fuse inserting device for firework pasting assembly

The invention discloses a y-shaped perforating and fuse inserting device for firework pasting assembly. The device is formed by non-closed y-shaped arrangement of a perforating fuse traction needle and a fuse inserting needle, wherein the lower top end of the fuse inserting needle is arc-shaped; the perforating fuse traction needle is a pointed needle, and a fuse penetrating hole is formed in the lower end of the perforating fuse traction needle. With the adoption of the technical scheme, the device has the benefits that one fuse appears on a descending trajectory of the fuse inserting needle after penetrating through the fuse penetrating hole in the perforating fuse traction needle, when the perforating fuse traction needle makes fuse holes in firework cylinders and is withdrawn from the fuse holes, the fuse inserting needle descends to insert the fuse into the fuse holes just made, the perforating fuse traction needle and the fuse inserting needle perform perforation and insertion sequentially, only one hole is made in one firework cylinder, and continuous m-shaped fuse insertion can be realized on multiple firework cylinders.

Owner:欧阳锰

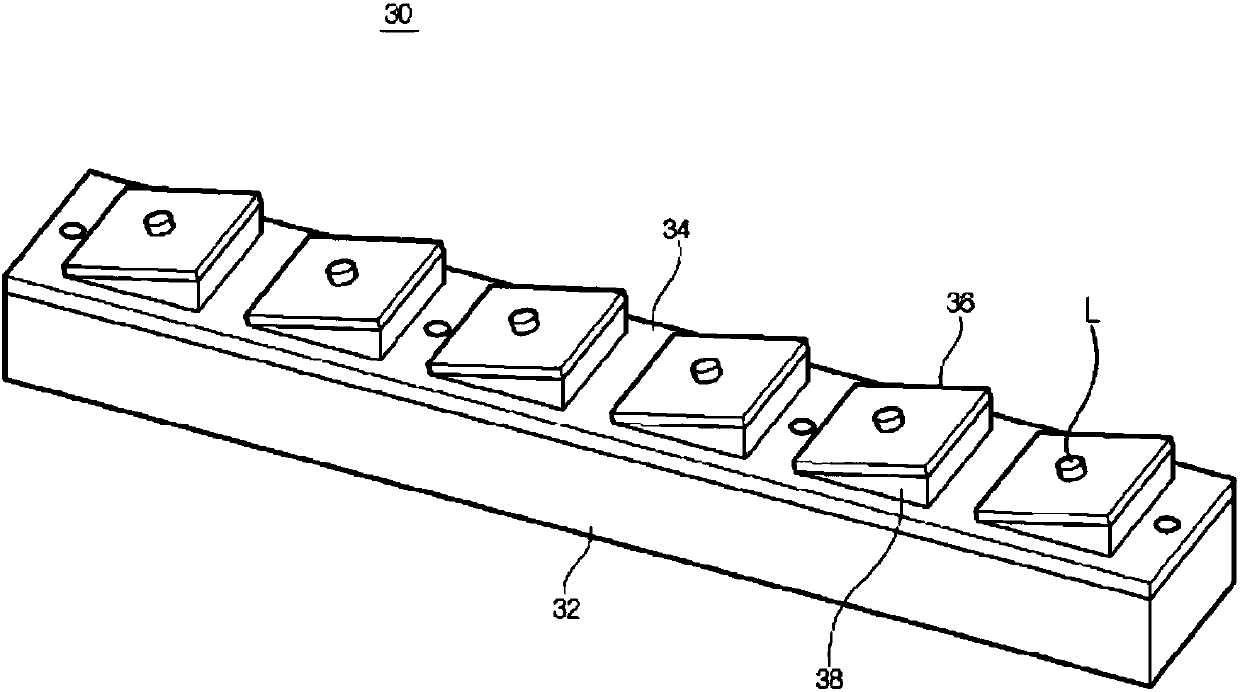

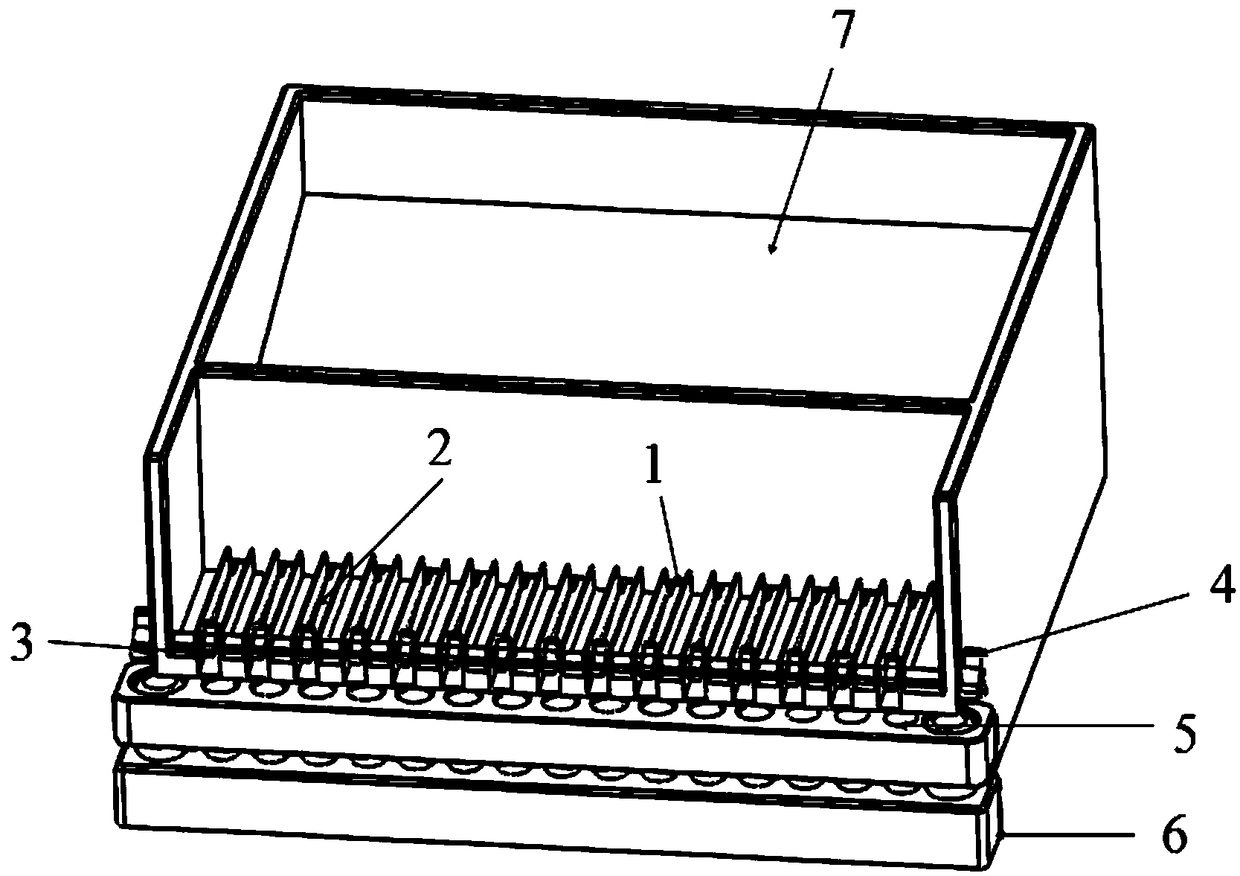

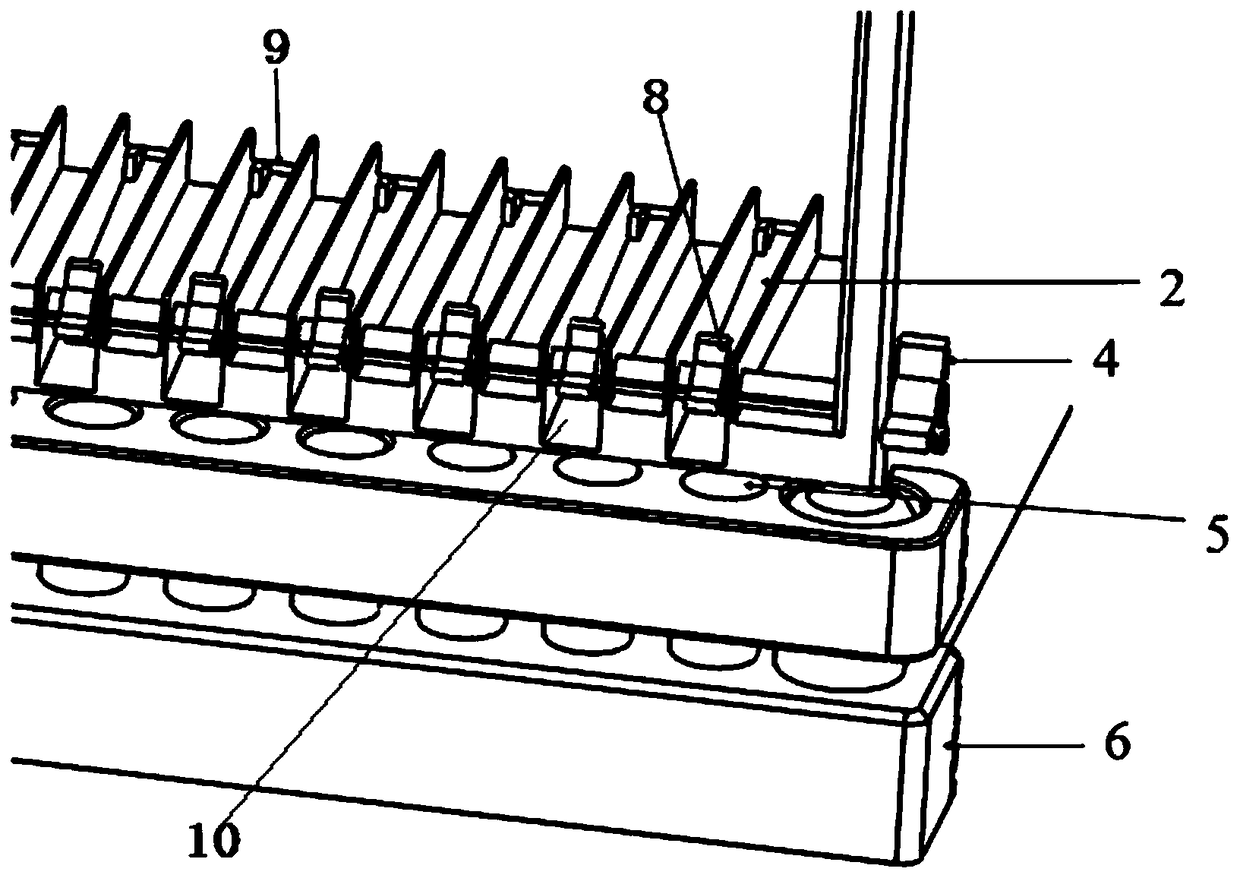

A capping device for capping a semiconductor laser and its working method

ActiveCN106129803BAffect qualityAvoid one by oneLaser detailsSemiconductor lasersEngineeringCap device

The invention relates to a cap mounting device of a semiconductor laser sealing cap and a working method thereof. The cap mounting device comprises a material disc and a guide groove group; the bottom surface of the material disc is arranged aslant; the guide groove group comprises a plurality of guide grooves arranged aslant; a bottom outlet of the guide groove is rotationally provided with a quantity limiting gear; a side wall of the material disc is provided with a sealing cap through hole for penetration of a sealing cap; and the sealing cap through hole is arranged to be opposite to an inlet of the guide groove. With the cap mounting device of the semiconductor laser sealing cap provided by the invention, manually arranging pipe caps one by one and contact with the pipe caps are avoided, and thus, influence on quality of the whole semiconductor laser caused by pollution to the pipe caps is avoided.

Owner:潍坊华光光电子有限公司

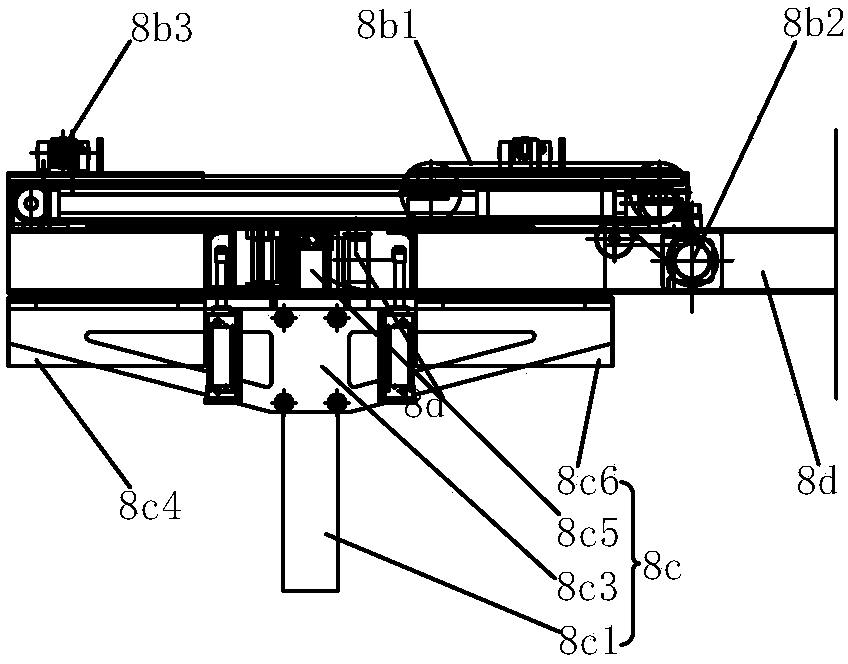

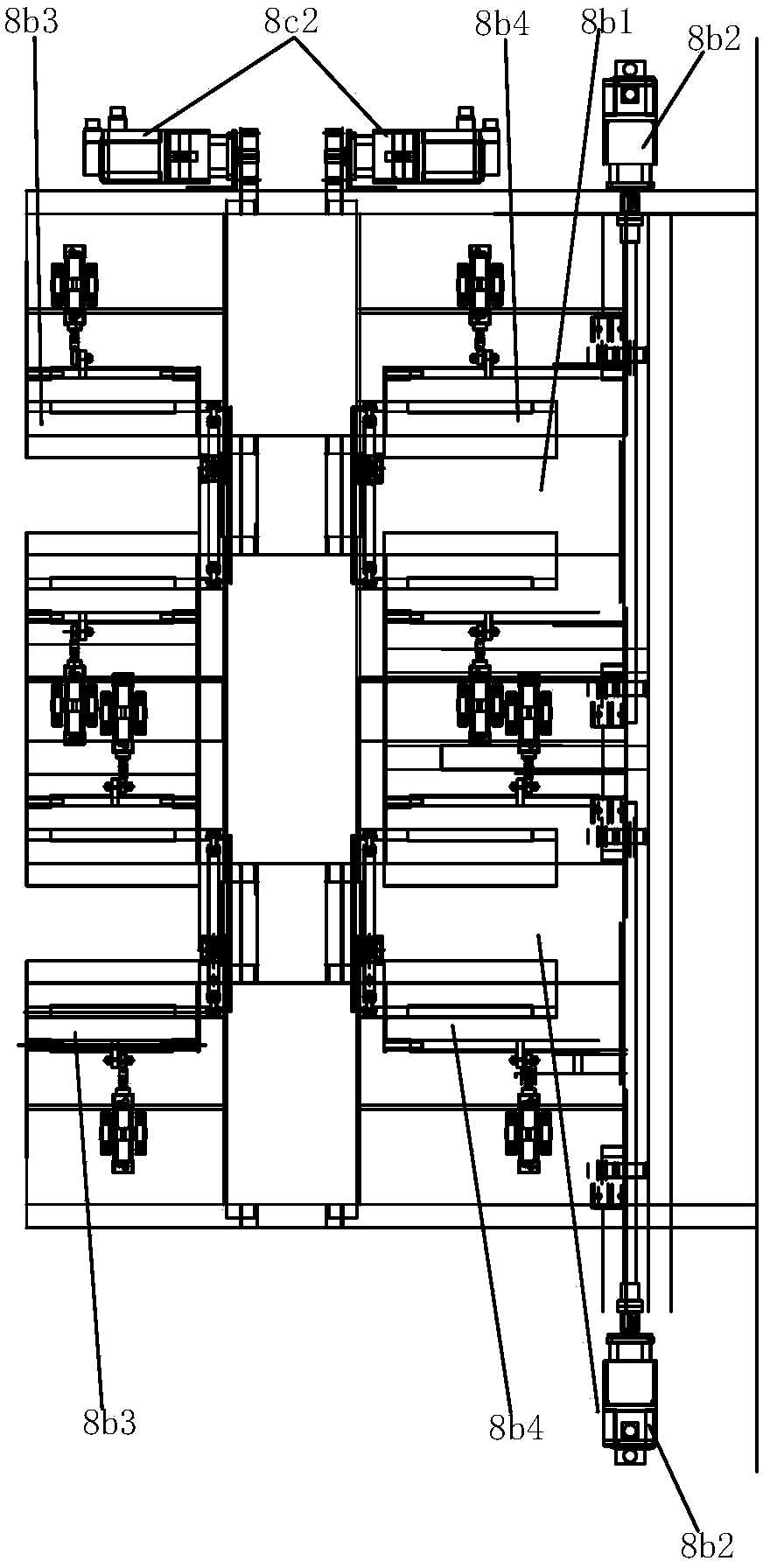

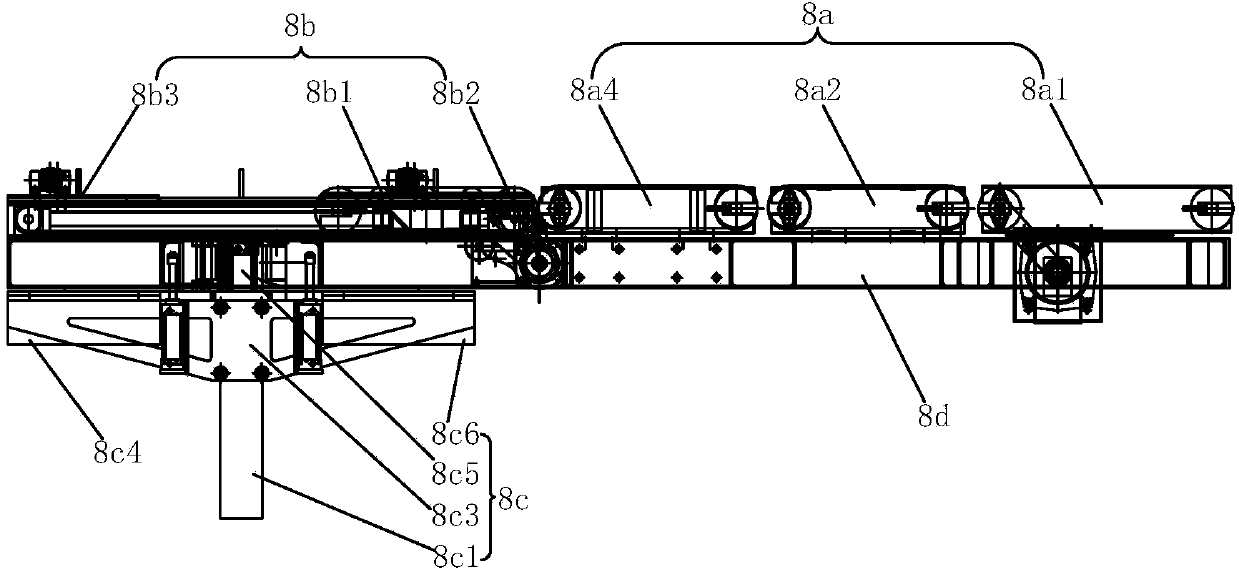

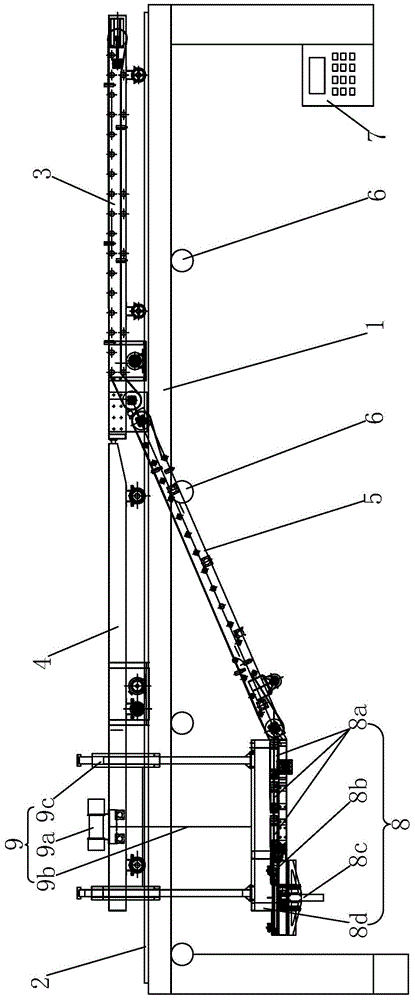

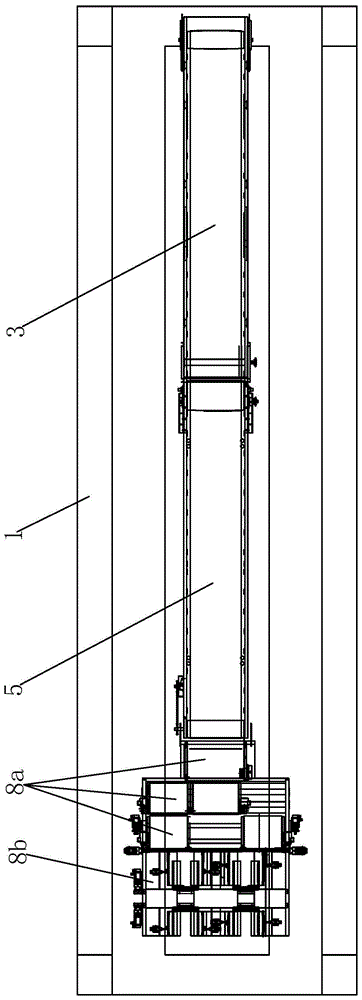

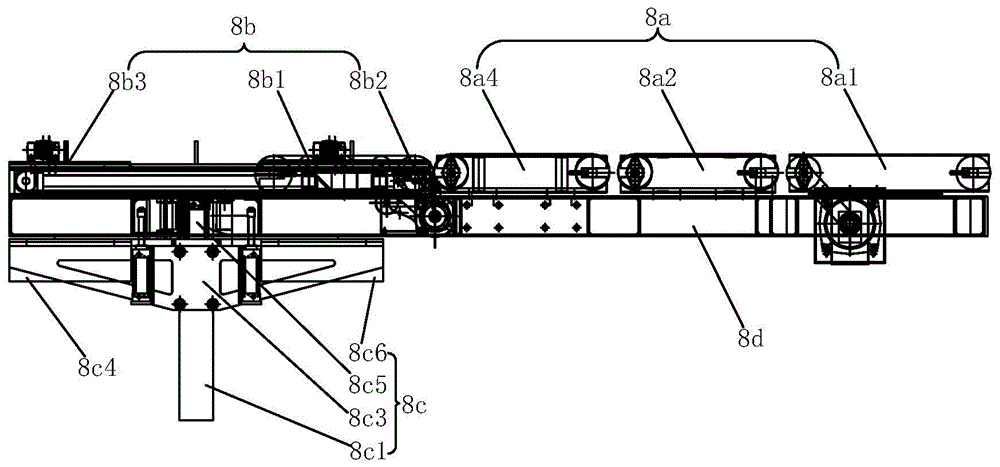

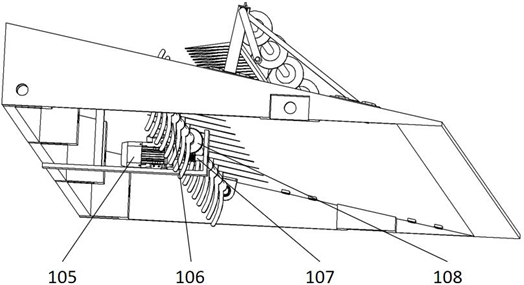

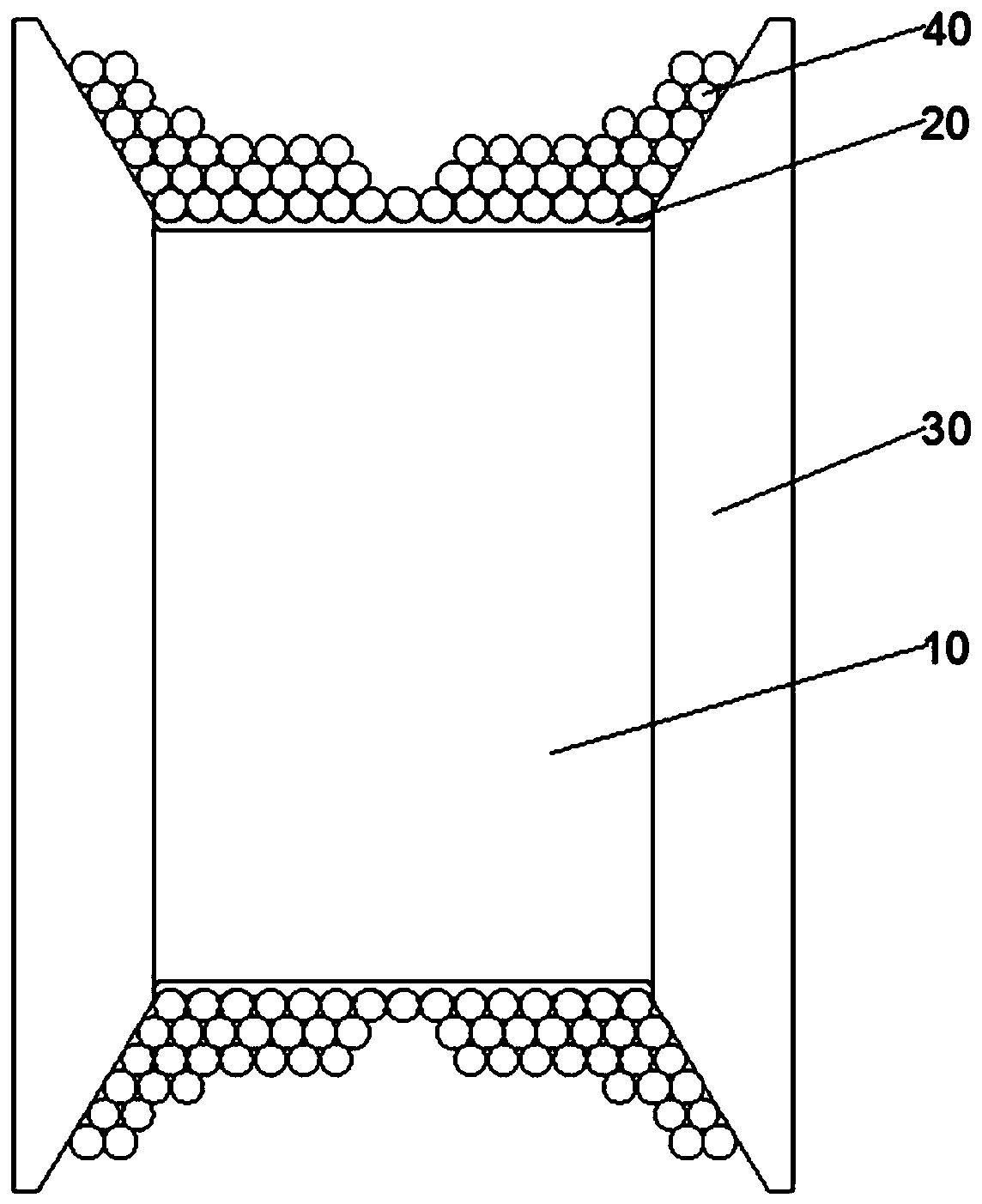

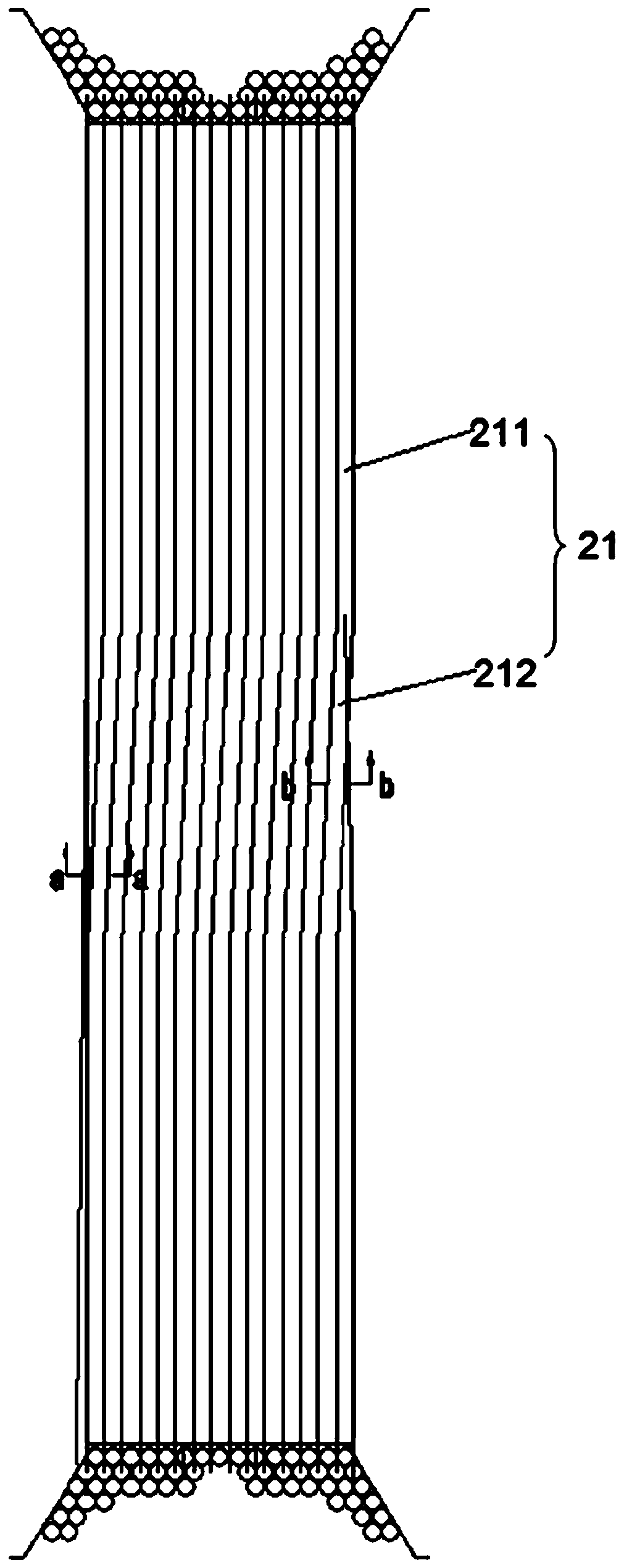

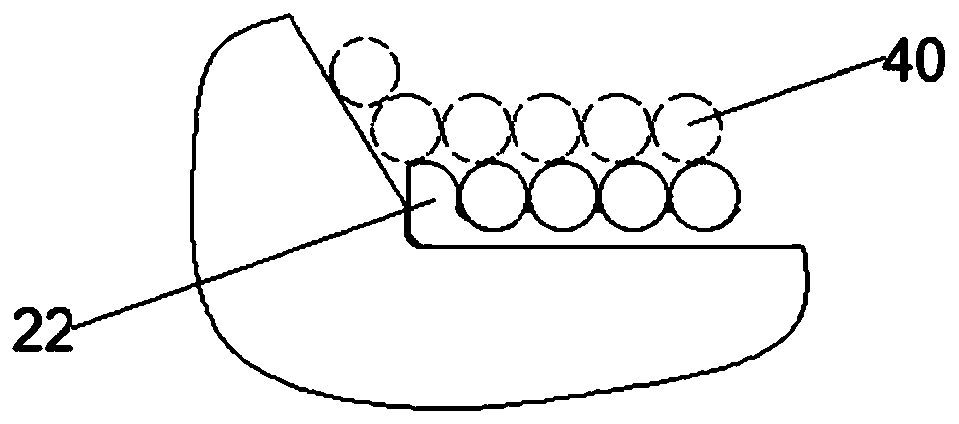

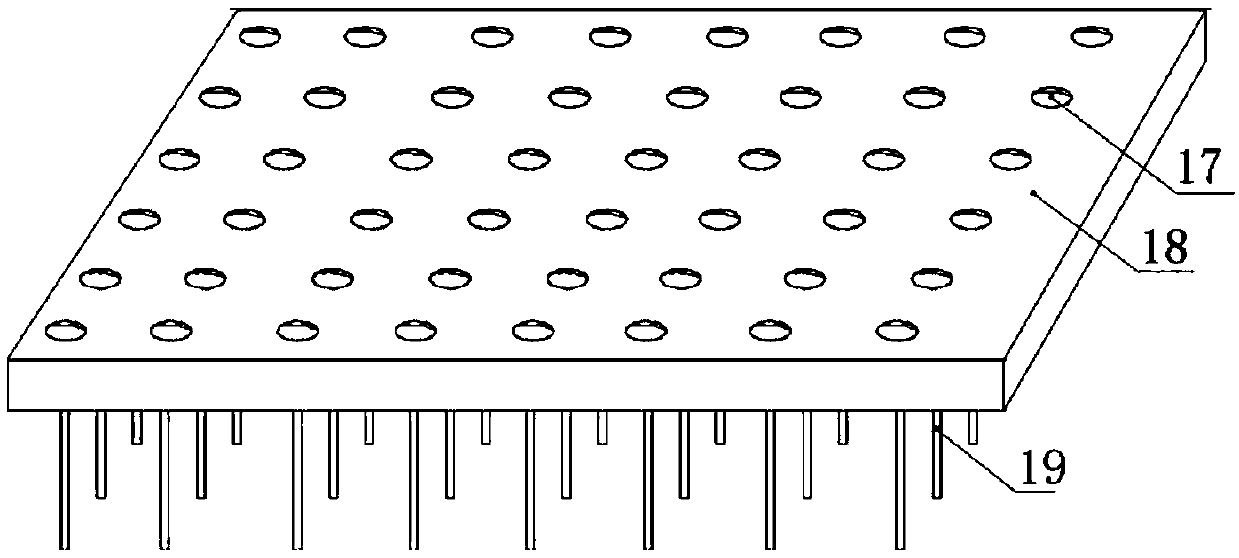

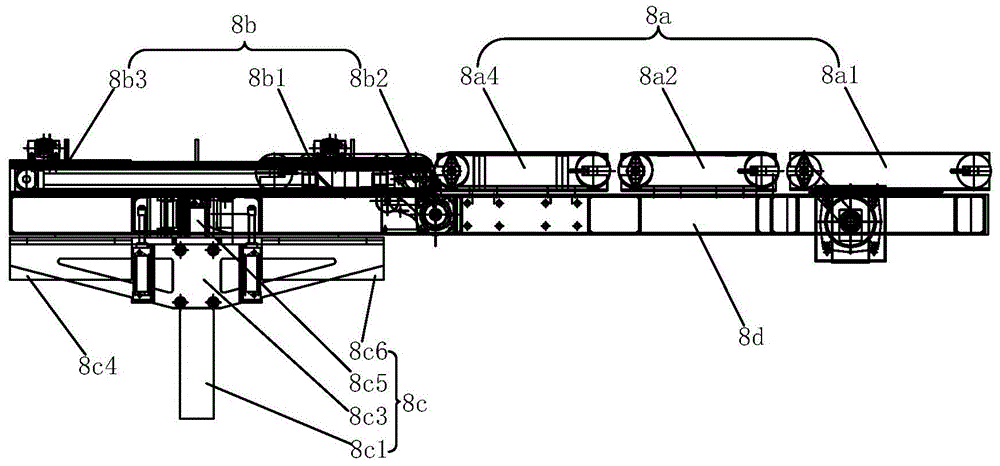

Multi-layer pipe arranging and storing device for mechanical modular workover operation

ActiveCN114737896ASmall footprintAchieve permutationDrilling rodsDrilling casingsOil fieldStructural engineering

The invention relates to the field of oil field workover treatment, and provides a mechanical modular workover treatment multi-layer pipe arranging and storing device which comprises a single-layer pipe pulling module, an aligning module, a fork type lifting module and a multi-layer oil pipe storage module. Oil pipes are placed on the slope of the pipe arranging device, multiple layers of stacked oil pipes are shifted into one layer through rotation of the rotary push rod and matching of the rotary push rod and the fork plate, and the problem that due to oil pipe stacking, the oil pipes cannot roll down or multiple layers roll down at the same time is solved. The oil pipes roll to the alignment module and are aligned to one side while being pushed forwards, and transverse and longitudinal arrangement of the oil pipes is achieved; after oil pipes with aligned ends enter the pipe storage device through the connecting part, the inclination angle of the bearing plate enables the oil pipes to slide from one side of the bearing plate to the other side of the bearing plate, due to the fact that each layer of the pipe storage device can move in the vertical direction and the front-back direction, adjustment can be conducted at any time according to the environment and work requirements, and follow-up pipe taking work is facilitated; the multi-layer structure is adopted, the occupied area is small, multiple pipes can be arranged at the same time, and the working efficiency is improved.

Owner:山东石油化工学院

Drum and hoisting equipment

PendingCN110395673AAchieve permutationAvoid tangled ropeWinding mechanismsEngineeringElectrical and Electronics engineering

The invention provides a drum and hoisting equipment. The drum comprises a drum body, drum skin and two baffles, wherein the drum skin is arranged on the periphery of the drum body and is provided with a plurality of parallel rope grooves with the outer diameter matched with that of ropes, and the rope grooves are spirally arranged in the circumferential direction of the drum body; and the two baffles are separately arranged at the two ends of the drum body in the circumferential direction of the ends of the drum body, and an obtuse angle is formed between the side face, towards the drum body,of each baffle and the outer circumferential surface of the drum body. According to the drum provided by the embodiment of the invention, the ropes can be prevented from being out of order, the friction between the ropes and the drum body and the friction between the ropes are reduced, and the service life of the ropes is prolonged.

Owner:SHANGHAI ZHENHUA HEAVY IND

Wire arrangement device

ActiveCN109616435ARealize automatic arrangementImprove efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesDiode

The invention relates to the technical field of diode processing, in particular to a wire arrangement device. The wire arrangement device comprises an obliquely-arranged feeding plate, wherein the feeding plate is connected with a driving mechanism for driving the feeding plate to vibrate, a plurality of feeding channels are arranged on the feeding plate, a material receiving mechanism for arranging pins is detachably arranged at the lower end of the feeding plate, a wiring mechanism has a multilayer structure, and each layer is respectively provided with a wire arrangement structure for collecting and rearranging the redundant pins. According to the scheme of the invention, the problem that the pins that are not successfully arranged need to be manually collected for wire re-arrangement,and troublesome operations and low efficiency are caused in the prior art can be solved.

Owner:ANHUI LONGXINWEI TECH CO LTD

A sorting visual inspection and grading machine

The invention discloses a sorting and visual detection grader. The sorting and visual detection grader comprises a sorting single fruit feeding mechanism, a visual detection mechanism and a grading actuating mechanism, wherein the sorting single fruit feeding mechanism is used for conveying single fruit, the visual detection mechanism is used for detecting the fruit level, and the grading actuating mechanism is used for sorting fruits according to the level. By using the sorting single fruit feeding mechanism, complex disordered target groups can be effectively and orderly arranged and are individually conveyed one by one, so that the grader is automatically operated; to-be-detected fruits can be detected and identified by the visual detection mechanism, the grading standard includes the maturity, defects, size and weight of the fruits, grading factors are diversified, the height is automated, the collision and extrusion between the fruits as well as between the fruits and the machine are effectively reduced, and the extrusion and collision damages to the fruits are greatly reduced; the fruits can be respectively sorted to corresponding collecting boxes according to the level by the grading actuating mechanism according to detection results of the visual detection mechanism, so that the automatic grading of the fruits is realized.

Owner:SOUTH CHINA AGRI UNIV

Diamine compound and preparation method thereof, liquid crystal alignment agent, liquid crystal alignment film, liquid crystal display element

InactiveCN103748068BAchieve permutationAchieve pre-tiltLiquid crystal compositionsOrganic chemistryCrystallographyLiquid-crystal display

Owner:DONGJIN SEMICHEM CO LTD

Full-automatic inspection production line for circular parts

ActiveCN102721387BRealize automatic movementAchieve permutationSpecial purpose weighing apparatusProduction lineProximity sensor

The invention belongs to detection equipment and particularly relates to a full-automatic inspection production line for circular parts. The full-automatic inspection production line is characterized in that the full-automatic inspection production line comprises a machine tool body, a disk type electromagnetic oscillation feeding device, a feeding conveyor belt device, a workpiece moving mechanism, and an external diameter detection mechanism, an internal diameter detection mechanism, a thickness detection mechanism, a weight detection mechanism and a screening mechanism which are sequentially arranged as well as a touch display screen which is fixedly connected with the machine tool body. The full-automatic inspection production line has the benefits of realization of automatic moving and arrangement as well as gradual-item detection of external diameter, internal diameter, thickness and weight. Core parts of the detection mechanism comprise an inlet high-precision contact type sensor, a linear potentiometer, a high-precision electronic scale and the like; automatic moving and inspection are realized by using a pneumatic element for driving, and thus high automatic degree and high detection precision are realized; and automatic screening and arranging can be realized and automatic control is realized by being matched with a proximity sensor.

Owner:天津市中马骏腾精密机械制造有限公司

Manufacturing process of LED chip array film

InactiveCN112563386APrevent crushingImprove processing yieldSolid-state devicesSemiconductor/solid-state device manufacturingThin membranePhysics

The invention discloses a manufacturing process of an LED chip array film, and relates to the technical field of LEDs; and the manufacturing process comprises the following specific steps: arranging aplurality of LED chips into an array form on the top surface of a horizontally arranged flexible film for temporary transition according to a pre-designed arrangement rule; manufacturing a colloid frame surrounding the chip array at the periphery of the chip array; injecting a liquid jelly into the colloid frame, standing for a period of time until the liquid jelly is naturally leveled, and thencuring the liquid jelly to form a flat jelly film; and separating the colloidal film with the chip array from the flexible film and taking away the colloidal film and the flexible film to obtain the required chip array film. The technology is simple, the cost is greatly reduced, meanwhile, compared with a traditional film pressing technology, the bubble phenomenon is avoided, and the yield is effectively increased.

Owner:YANGZHOU ZHONGKE SEMICON LIGHTING

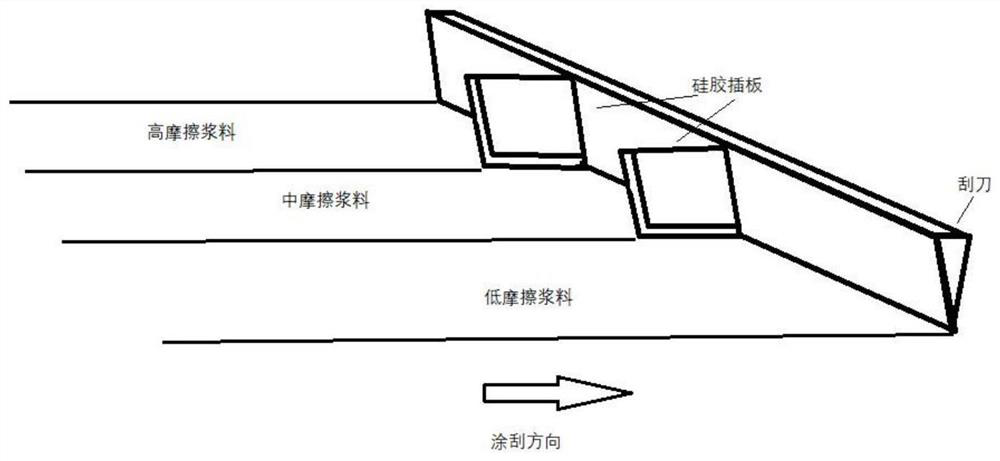

Differential friction coefficient conveying belt as well as preparation method and application thereof

PendingCN114194707AImprove automationReduce labor costsConveyorsWoven fabricsFrictional coefficientMechanical engineering

The invention belongs to the technical field of conveying belts, and particularly relates to a differential friction coefficient conveying belt and a preparation method and application thereof. The invention provides a differential friction coefficient conveying belt. The differential friction coefficient conveying belt comprises a base belt and a differential friction coefficient surface layer arranged on the surface of the base belt. The differential friction coefficient surface layer comprises a smooth surface layer, a deceleration surface layer and a standing surface layer which are located on the same plane and sequentially arranged in a contact mode in the width direction. The friction coefficient of the smooth surface layer is 0.2-0.4, and the friction pair is a steel plate; the friction coefficient of the deceleration surface layer is 0.55-0.75, and the friction pair is a steel plate; the friction coefficient of the standing surface layer is larger than or equal to 0.9, and the friction pair is a steel plate. The test result of the embodiment shows that the conveying belt with the different friction coefficients can effectively avoid sudden stop and rolling of the conveyed packages in the conveying and confluence working sections, and the packages can be arranged in a specified area.

Owner:SHANGHAI YONGLI TRANSPORTATION SYST CO LTD

A device for separating flower pots and flower substrates

ActiveCN106212091BReduce adhesionAchieve separationConveyor partsFlower-pot cleaningEngineeringAgricultural automation

The invention discloses a flowerpot and flower and plant matrix separating device and belongs to the field of automatic equipment for facility agriculture. The flowerpot and flower and plant matrix separating device comprises an equal-separation-distance conveyor, a potted flower conveyor, a rodless air cylinder, a potted flower pushing plate, a potted flower rubbing channel and potted flowers. The potted flowers are conveyed to working positions through a conveyor and are moved to the equal-separation-distance conveyor through the potted flower rubbing channel under the pushing of the potted flower pushing plate, the potted flower pushing plate is driven by the rodless air cylinder, two sides of the potted flower rubbing channel have a certain radian, flowerpots and the matrixes in the flowerpots are extruded in the potted flower passing process to weaken the bonding force between the flowerpots and the matrix, and accordingly the flowerpot and matrix separating process is achieved. The flowerpot and flower and plant matrix separating device is one important portion of an automatic transplanting production line, flowerpot and matrix separation can be achieved in a rubbing-extruding mode, and it can be ensured that the flowerpots and the matrixes are complete after separation and the matrixes can be smoothly taken out of the flowerpots for transplanting operation.

Owner:BEIJING UNIV OF TECH

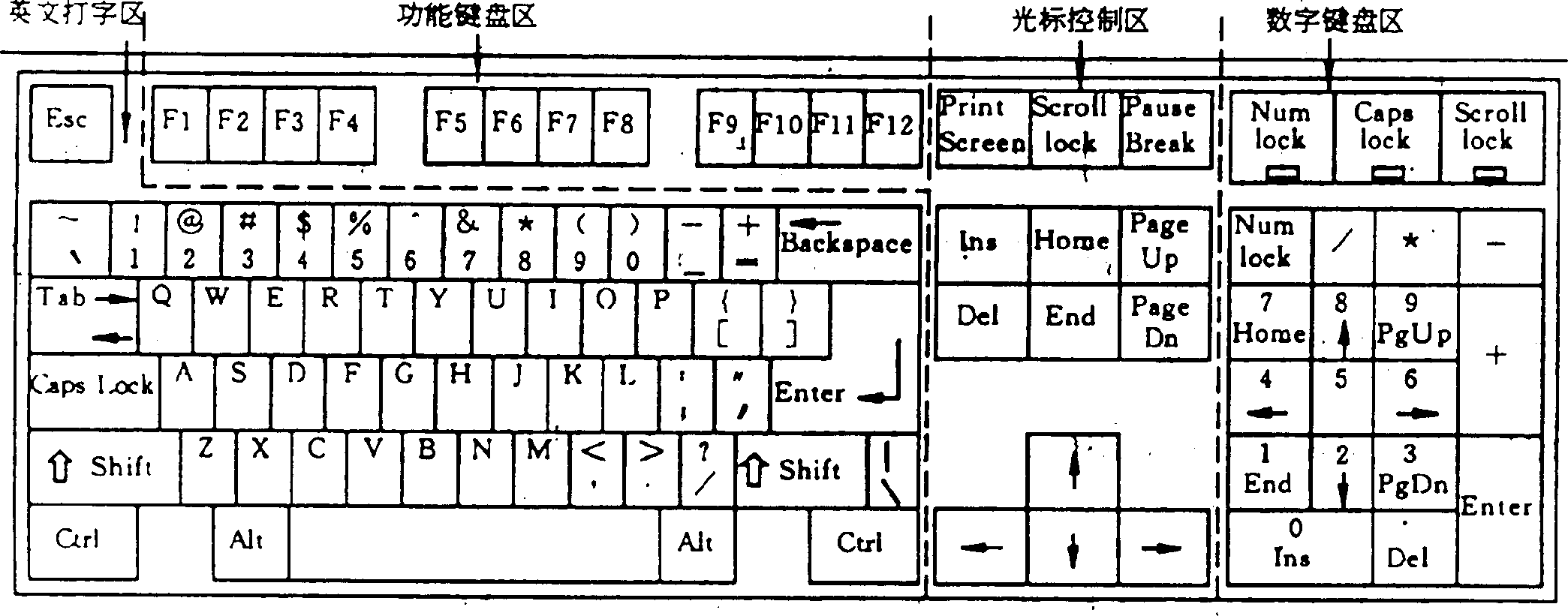

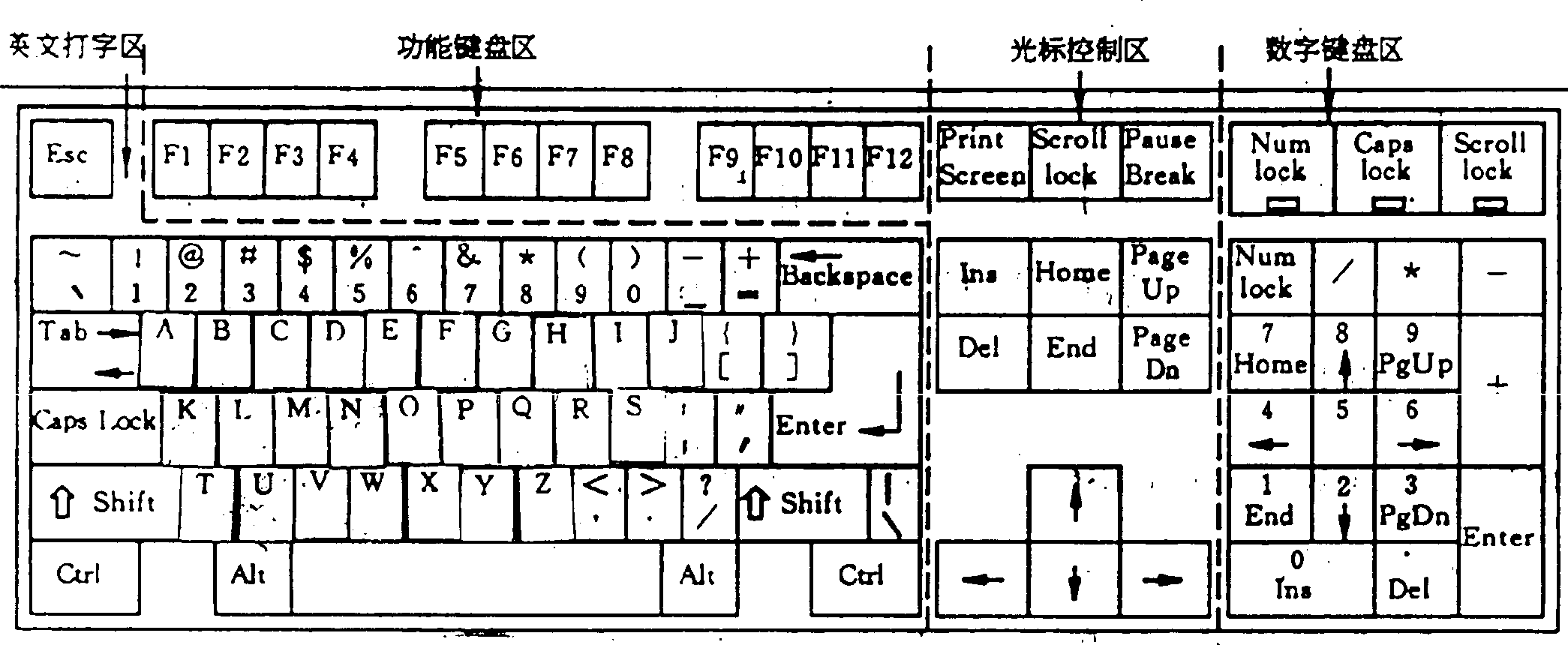

Computer keyboard alphabet layout method

InactiveCN1407427AAchieve permutationEasy to operateInput/output processes for data processingTheoretical computer scienceLettering

A computer keyboard alphabetic layout method involves the prior functional key bottons, cursor control ones, numeral ones and alphabetic ones in their original areas. It features all the alphabitic key bottons are arranged in the order of English alphabet list. This layout improves typist's operation with higher efficience.

Owner:蔡首兵

Loading and palletizing host for bagged cement truck loader

ActiveCN104192586BImprove stabilityTranslational smoothStacking articlesLoading/unloadingDocking stationOutput device

A loading and palletizing main engine for bagged cement loading machines, including a distribution device, an unpacking device, a palletizing device and a bracket, the distribution device, the unpacking device and the palletizing device are installed on the bracket in sequence, and the input of the distribution device terminal is docked with the output end of the previous step station, the number of output ends of the distribution device is at least 2, each output end of the distribution device is respectively connected horizontally with the input end of an unpacking device, and the output ends of each unpacking device are respectively It is vertically docked with the input end of a palletizing device, and the output end of each palletizing device vertically transports the bagged cement to the designated position, and the bagged cement transported to the designated position by all the palletizing devices is horizontally arranged in a straight line. The bagged cement is transported to the corresponding number of unpacking devices by at least 2 transportation lines through the distribution device, and then the bagged cement is transported to the corresponding number of palletizing devices through each unpacking device, and finally passed through all the palletizing devices Arrange the bagged cement horizontally and linearly to complete the stacking.

Owner:武汉蓝海燕智能装车设备有限公司

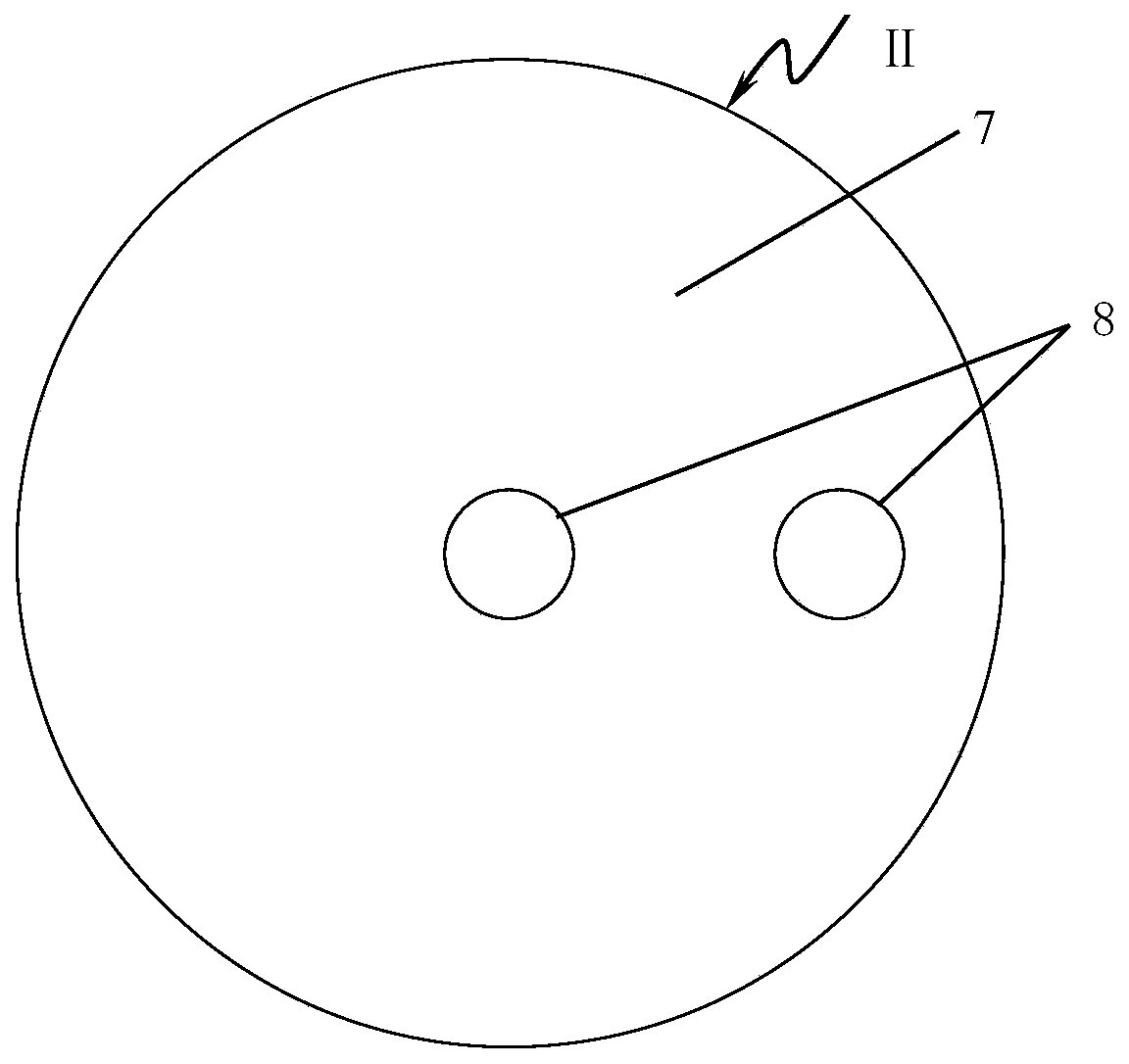

A preparation method of doped single crystal multi-core optical fiber and doped single crystal multi-core optical fiber

ActiveCN107151092BExcellent optical propertiesAchieve permutationGlass making apparatusRefractive indexSingle crystal

The invention provides a doped monocrystal multi-core optical fiber and a preparation method thereof. According to the doped monocrystal multi-core optical fiber, two or more doped monocrystal fiber cores is arranged in the same silica cladded layer, and a low-refraction-index silicon dioxide quartz glass and high-refraction-index doped monocrystal form an optical fiber waveguide structure. The preparation method comprises the following steps: acquiring porous optical fiber preforming bars; drawing the porous optical fiber preforming bars to obtain porous capillary tubes; injecting doped crystal melt in micropores in the quartz capillary tubes at high temperature and under high pressure to form polycrystal fiber cores; and finally, carrying out transverse heating and enabling the fiber cores to be subjected to monocrystal treatment and the like to prepare the silica cladded doped monocrystal multi-core optical fiber. Capillary tube porous melt injection and later-period crystal growth are combined. The doped monocrystal multi-core optical fiber which grows by the method has the advantages of controllable wire diameter and length, optional number and arrangement of the fiber cores and the like. The doped monocrystal multi-core optical fiber can be used for miniature and online photon regulation and control phase modulators, optical switches, interferometers and the like.

Owner:HARBIN ENG UNIV

Multi-layer and multi-column bag stacking device

PendingCN112849521AEasy to replaceAchieve permutationPackaging automatic controlCartonElectric machinery

The invention belongs to the technical field of bag stacking equipment, and particularly relates to a multi-layer and multi-column bag stacking device which comprises a bag stacking and pushing belt, a bag stacking mechanism is arranged on the left side of the lower portion of the bag stacking and pushing belt and comprises a bag stacking clamping plate, two synchronous wheels are arranged on the lower end face of the bag stacking clamping plate, and a bag stacking platform is also driven by a third motor. The bag stacking platform can do lifting motion in the vertical direction according to the bag stacking stroke and the number of layers until the set number of bag stacking layers is reached, the bag stacking platform descends to a box entering and bag pushing station, a box entering and bag pushing belt is also driven by a fourth motor, the bag pushing stroke is controlled through a PLC, all stacked materials are pushed into a carton / box / large bag at a time through a bag pushing plate at a time, so that the problems that in the prior art, huge accessory equipment is needed for supporting, specification replacement of an industrial camera positioning system is troublesome, a clamp suction cup needs to be adjusted, the speed is not high, due to the influence of other stations such as bag pushing, enough time must be reserved for stopping to complete the action, and the bag folding speed is low are solved.

Owner:杭州沃锦机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com