A capping device for capping a semiconductor laser and its working method

A technology of semiconductors and lasers, which is applied in semiconductor lasers, lasers, laser components, etc., can solve problems such as single function and single tube cap arrangement function, and achieve the effects of improving work efficiency, rich functions, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

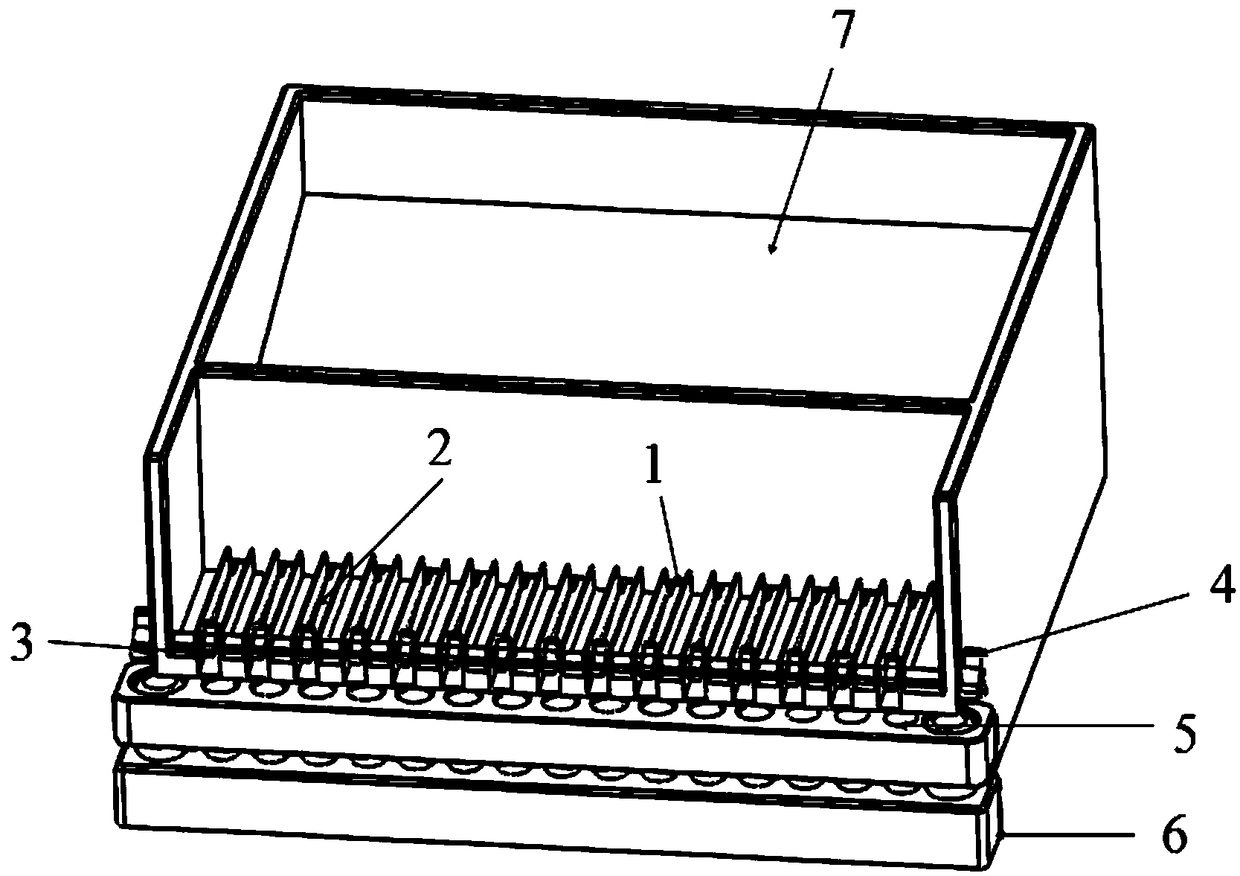

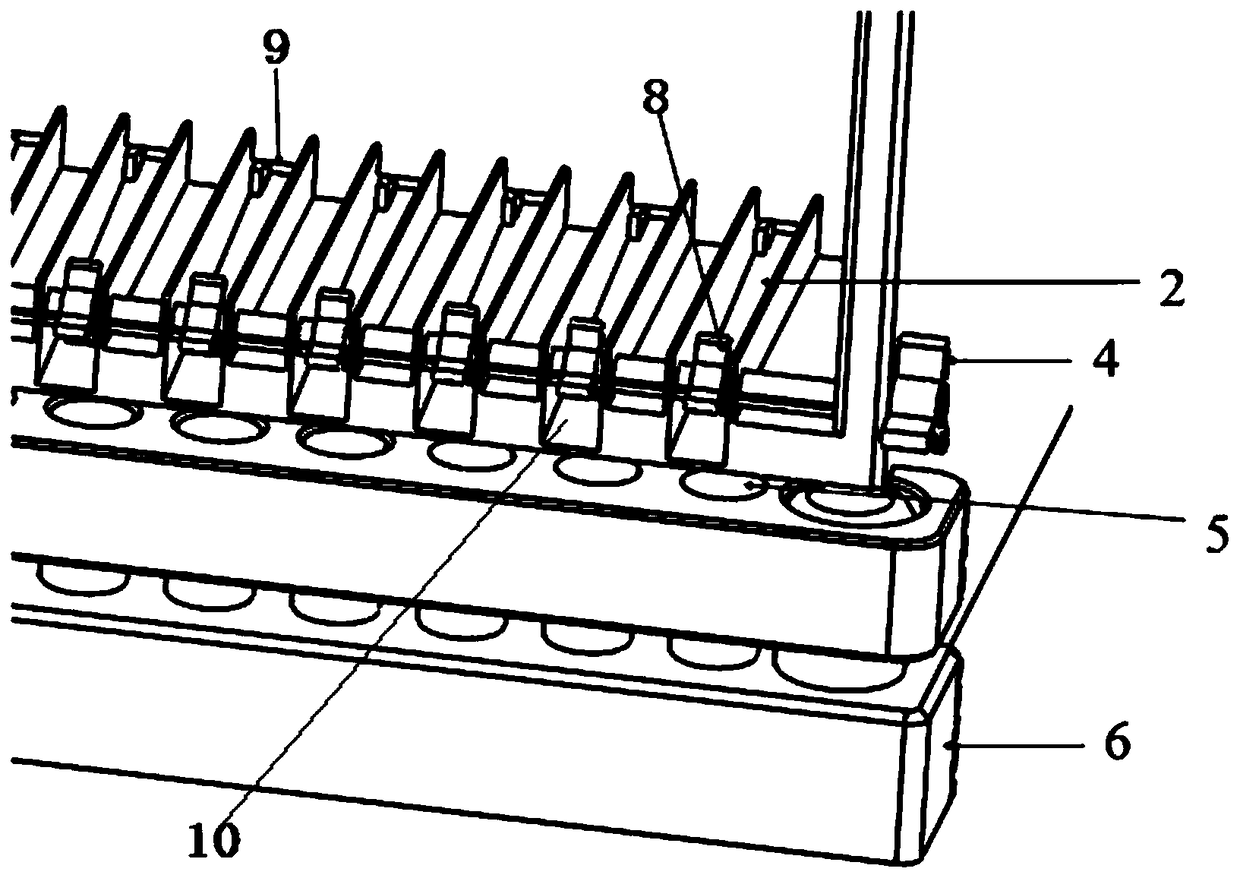

[0039] as the picture shows.

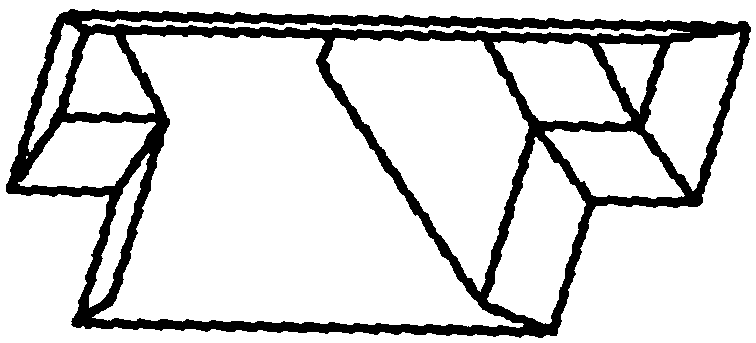

[0040] A capping device for capping a semiconductor laser, comprising a material tray 7 and a guide groove group; the bottom surface of the material tray 7 is inclined; the guide groove group includes 15 inclined guide grooves 2; the bottom outlet of the guide groove 2 is rotated and provided with The limited gear 3; the side wall of the tray 7 is provided with a cap through hole 1 for the cap to pass through; the cap through hole 1 is set opposite to the entrance 9 of the guide groove.

Embodiment 2

[0042] The capping device for capping a semiconductor laser as described in Embodiment 1 is different in that the limiting gear includes 3 teeth; the angle between adjacent teeth is 120°. Through the rotation of the limited gear 3, the pinion is inserted into the bottom end jack of the semiconductor laser sealing cap, so as to realize the limited transfer of the sealing cap.

[0043] The angle between the guide groove 2 and the horizontal plane is 30°. The advantage of the design here is that one of the gear teeth is set parallel to the guide groove 2, the gear teeth are socketed with the cap, and the limit gear is rotated 120°. After the cap is moved to a vertical plane, the cap falls into the seal by its own gravity. In the cap hole 5, the third pinion just arrives at the initial position, that is, the position parallel to the guide groove 2, and there is no need to adjust the position of the pinion, which further improves the production efficiency.

Embodiment 3

[0045] The capping device for capping a semiconductor laser as described in Embodiment 2 is different in that the width of the pinion is 2-3 mm smaller than the inner diameter of the cap.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com