Mechanism for checking out unqualified products from circular annular parts

A qualified product, circular technology, applied in the field of testing equipment, can solve the problems of low labor efficiency, a large number of labor and man-hours, and labor intensity of workers, and achieve the effect of high degree of automation and high detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

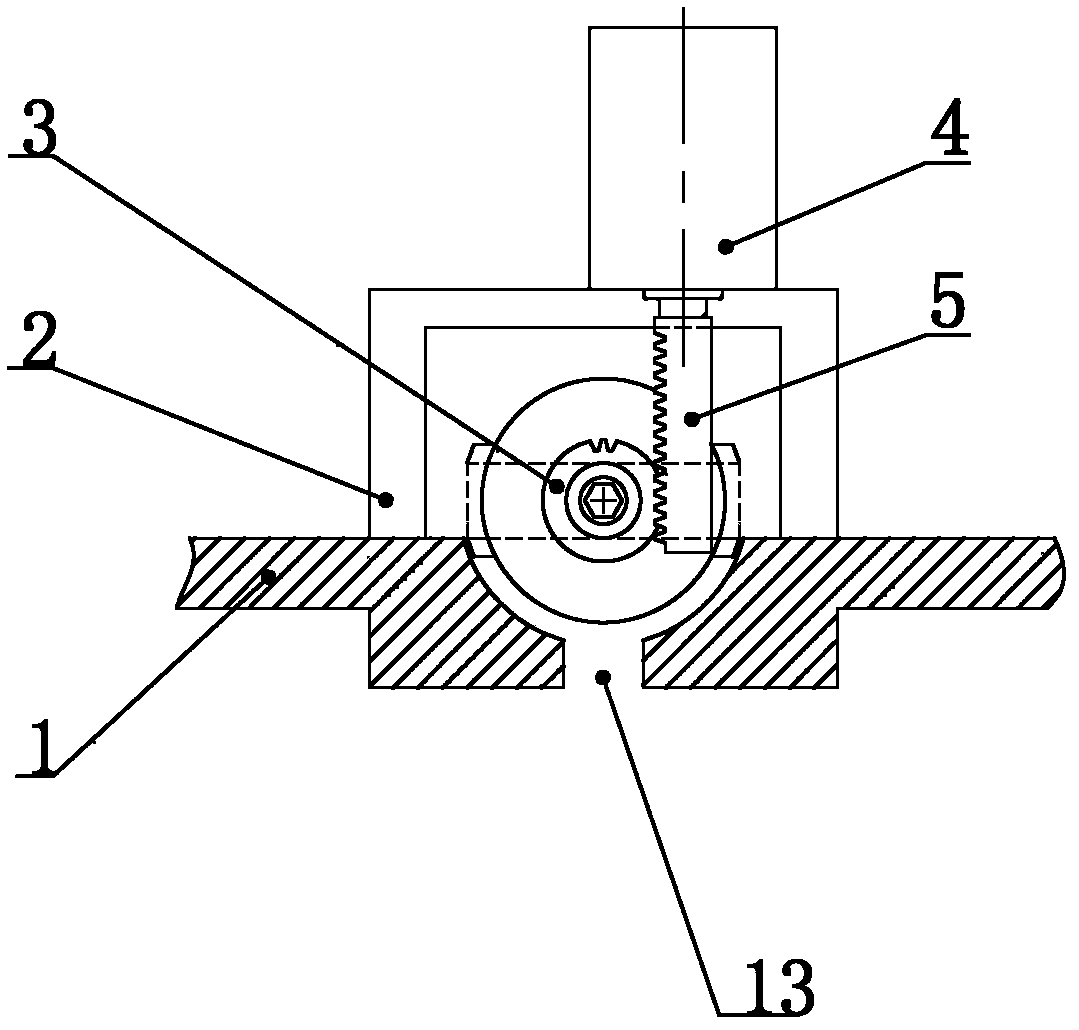

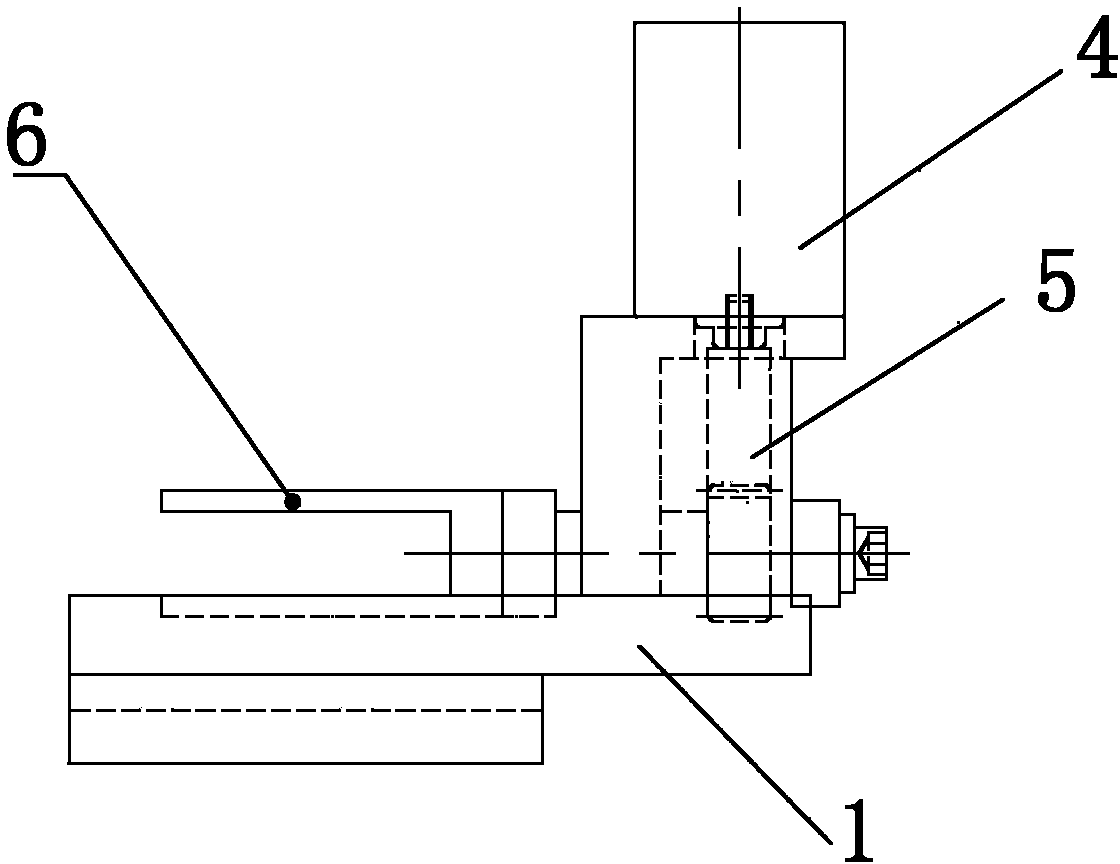

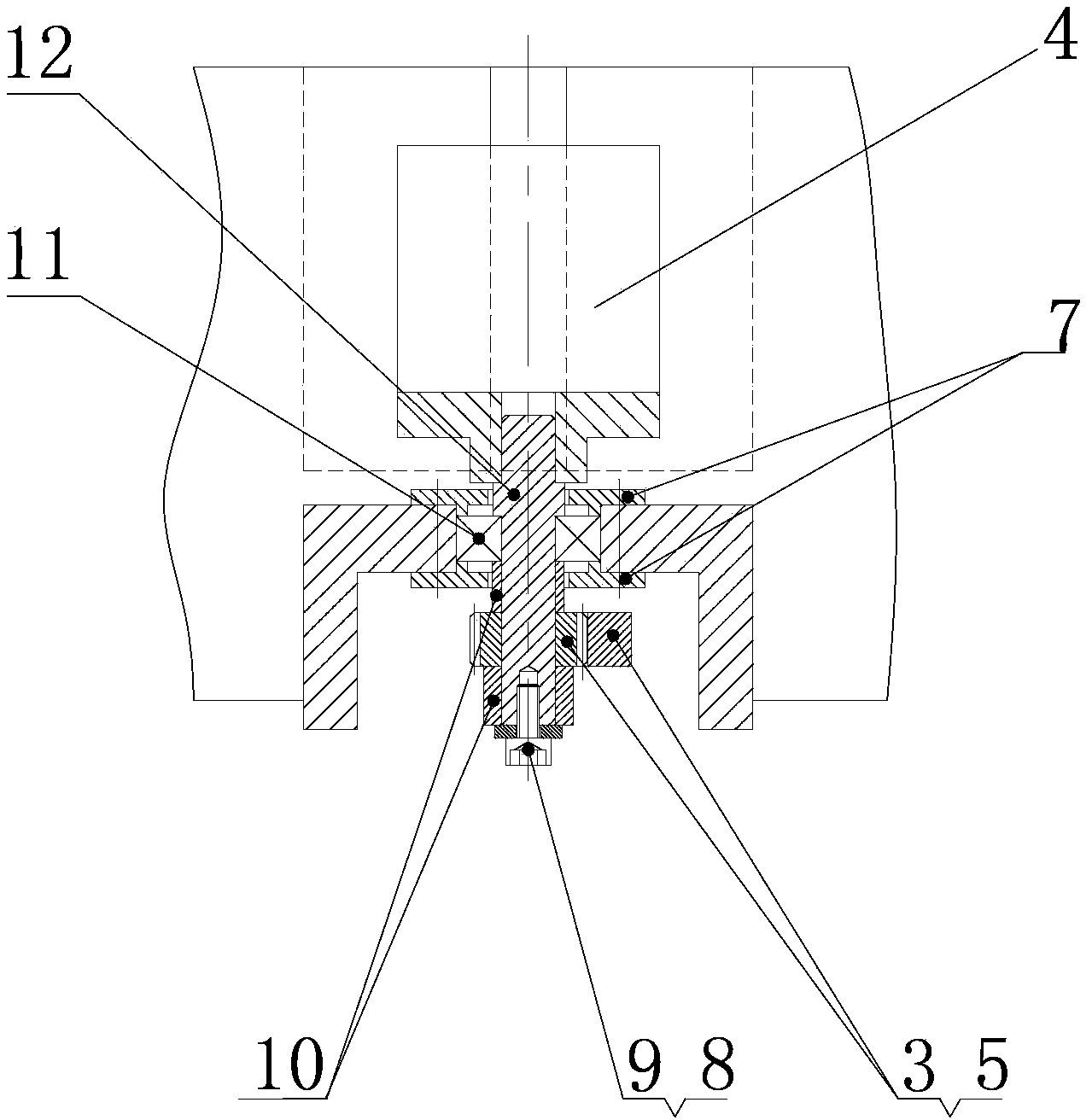

[0015] Below in conjunction with the preferred embodiment, the specific embodiment provided according to the present invention is described in detail as follows: See the accompanying drawings for details, a detection mechanism for a circular part defective product, the bracket 2 is fixed on the base plate 1, and the base plate 1 There is a reject drop channel 13. Bearing 11 is contained in support 2, and two ends are pressed with end cover 7, and it can not axially move on support 2. Rotating shaft 12 is installed on the bearing 11, and its front end is installed flip plate 6; The cylinder 4 is installed on the top of the support 2, and the rack 5 is connected with the piston rod of the cylinder and meshed with the gear 3.

[0016] Working process: The workpieces 14 are arranged and transported to the feeding conveyor belt in an orderly manner by the disc-type electromagnetic oscillation feeding device, and the feeding conveyor belt pushes the workpieces to the worktable, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com