Metal PCB, headlight module having metal PCB applied thereto, and method for assembling headlight module

一种印刷电路板、金属的技术,应用在金属印刷电路板、应用金属印刷电路板的前灯模块及前灯模块组装领域,能够解决无法应用多面体及多方向构造物、难以应用等问题,达到热传递容易、实现弯曲作业和安装作业、防止受损的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

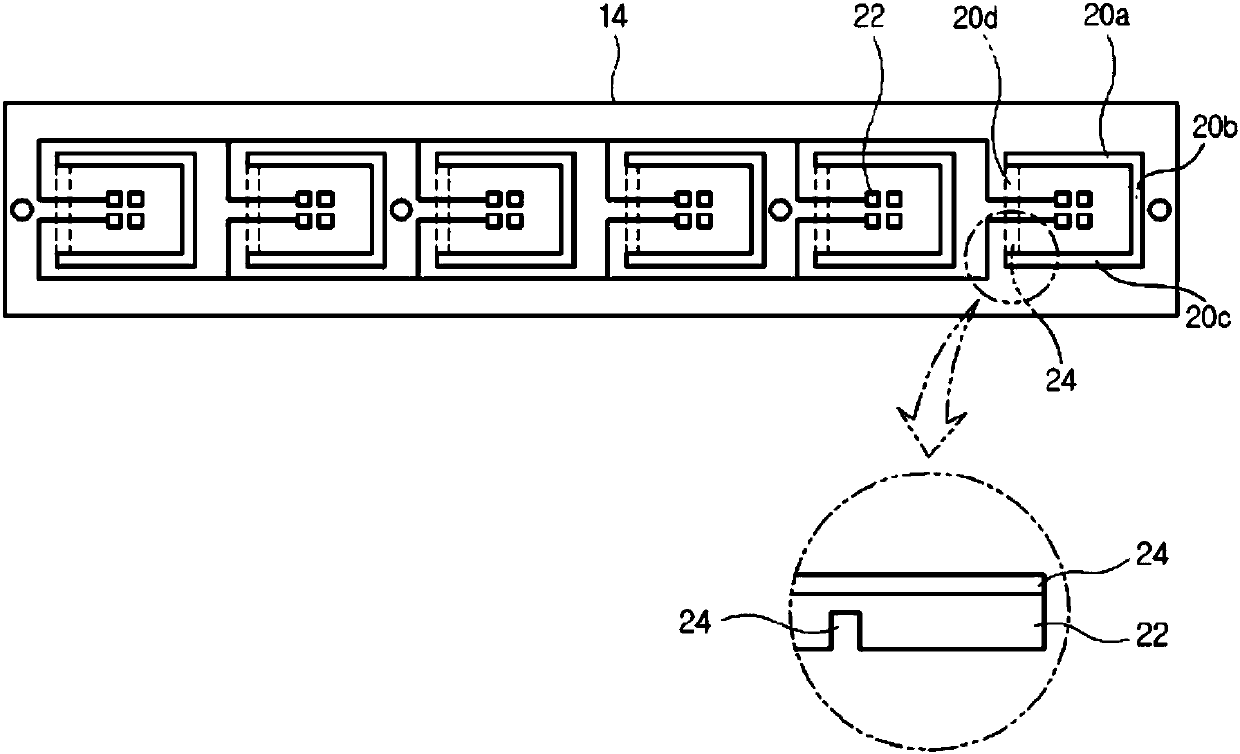

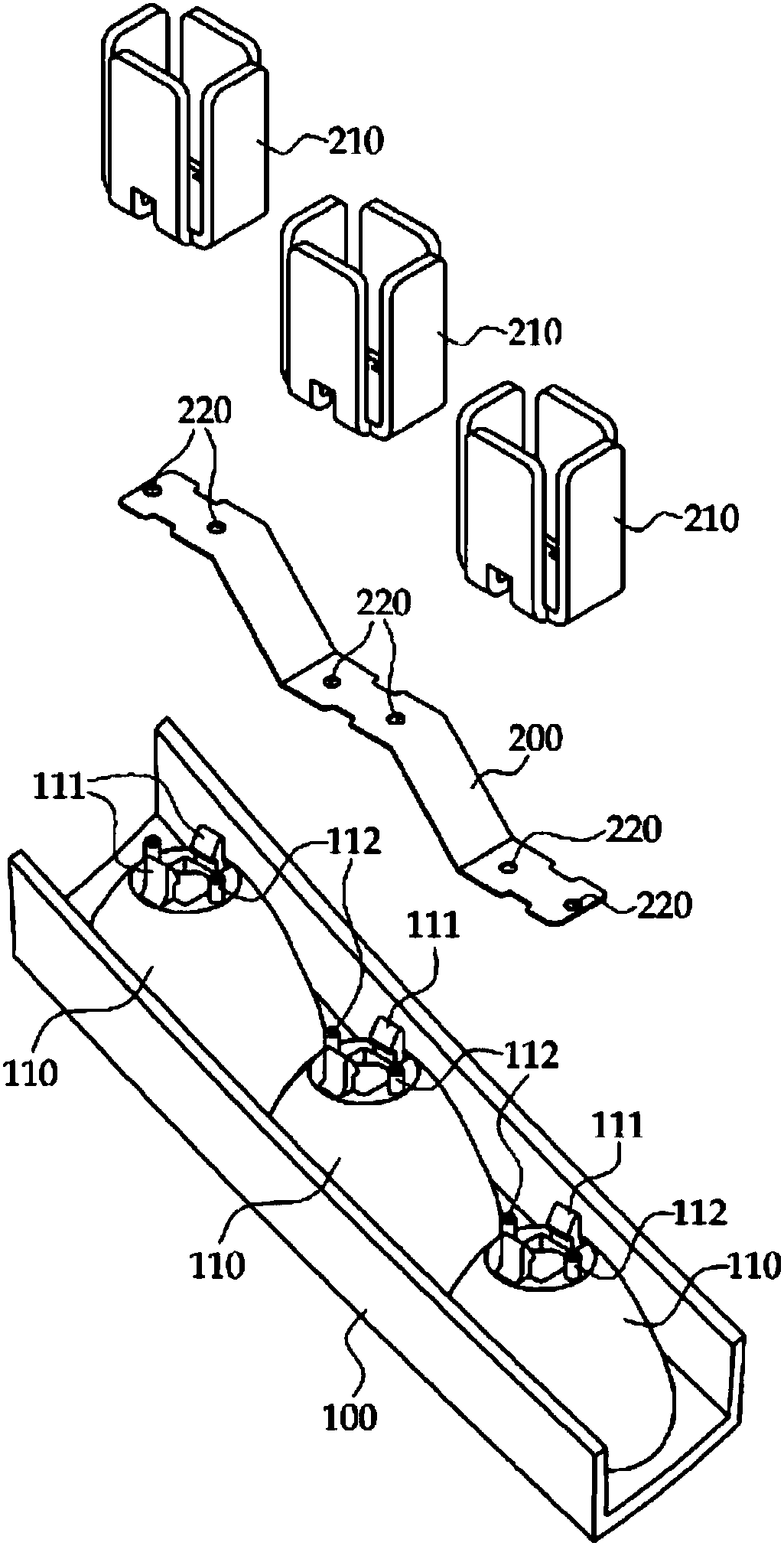

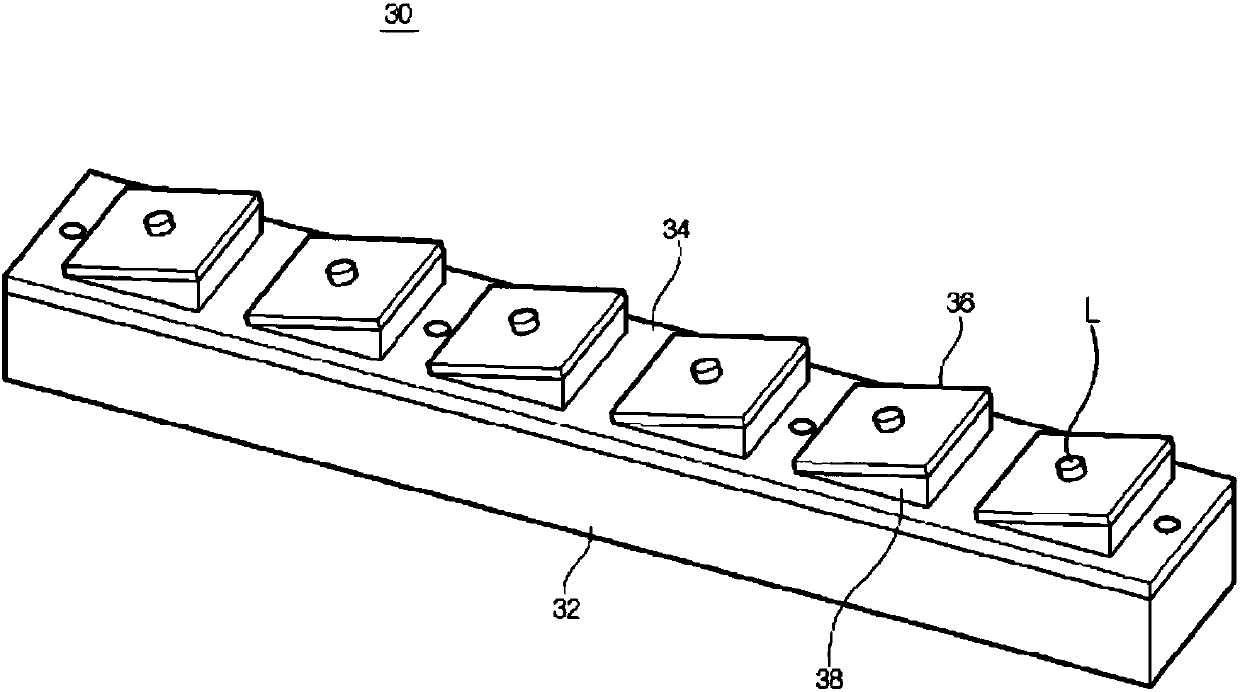

[0064] The structure of the metal printed circuit board 500 of the present invention is such that a pattern 503 is integrally formed on an upper portion of a heat conductor base 501 formed of aluminum, copper, or the like, so that a light emitting diode chip 550 can be mounted thereon.

[0065] Moreover, the metal printed circuit board 500 forms a plurality of chip mounting parts 530 on the base 501, and at least one LED chip 550 is mounted on the chip mounting parts 530, and the chip mounting parts 530 are connected to Substrate 501.

[0066] Here, the chip mounting portion 530 is provided to be separated from the base by at least two cutting surfaces 580 on one side of the base.

[0067] Here, the base 501 includes two structures, a structure integrally formed with a pattern on the upper portion and a structure formed by integrally bonding the flexibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com