A preparation method of doped single crystal multi-core optical fiber and doped single crystal multi-core optical fiber

A technology of multi-core optical fiber and holey optical fiber, which is applied in the field of optical fiber, can solve the problems that the fiber core is difficult to ensure single crystal, pollution, and cannot form single crystal, etc., and achieves the effect of simple and practical preparation process, simple manufacturing process and less crystal defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

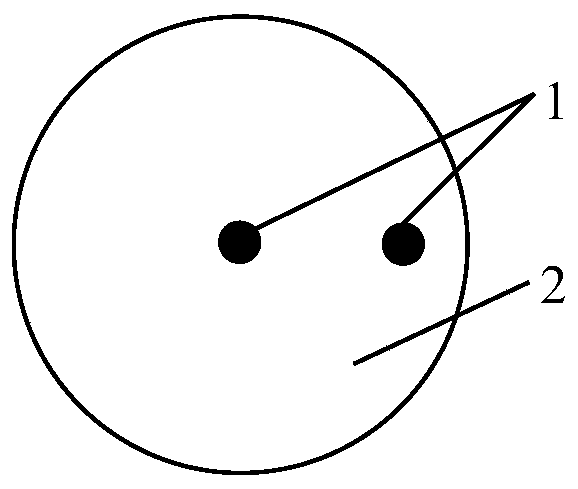

[0041] figure 1 It is a cross-sectional schematic diagram of the first magnesium ion-doped lithium niobate single crystal double-core optical fiber of the present invention. The core 1 is a magnesium ion-doped lithium niobate single crystal, and the position of the fiber core is asymmetrically distributed, and the cladding 2 is For quartz, the refractive index of the core 1 is greater than that of the cladding 2.

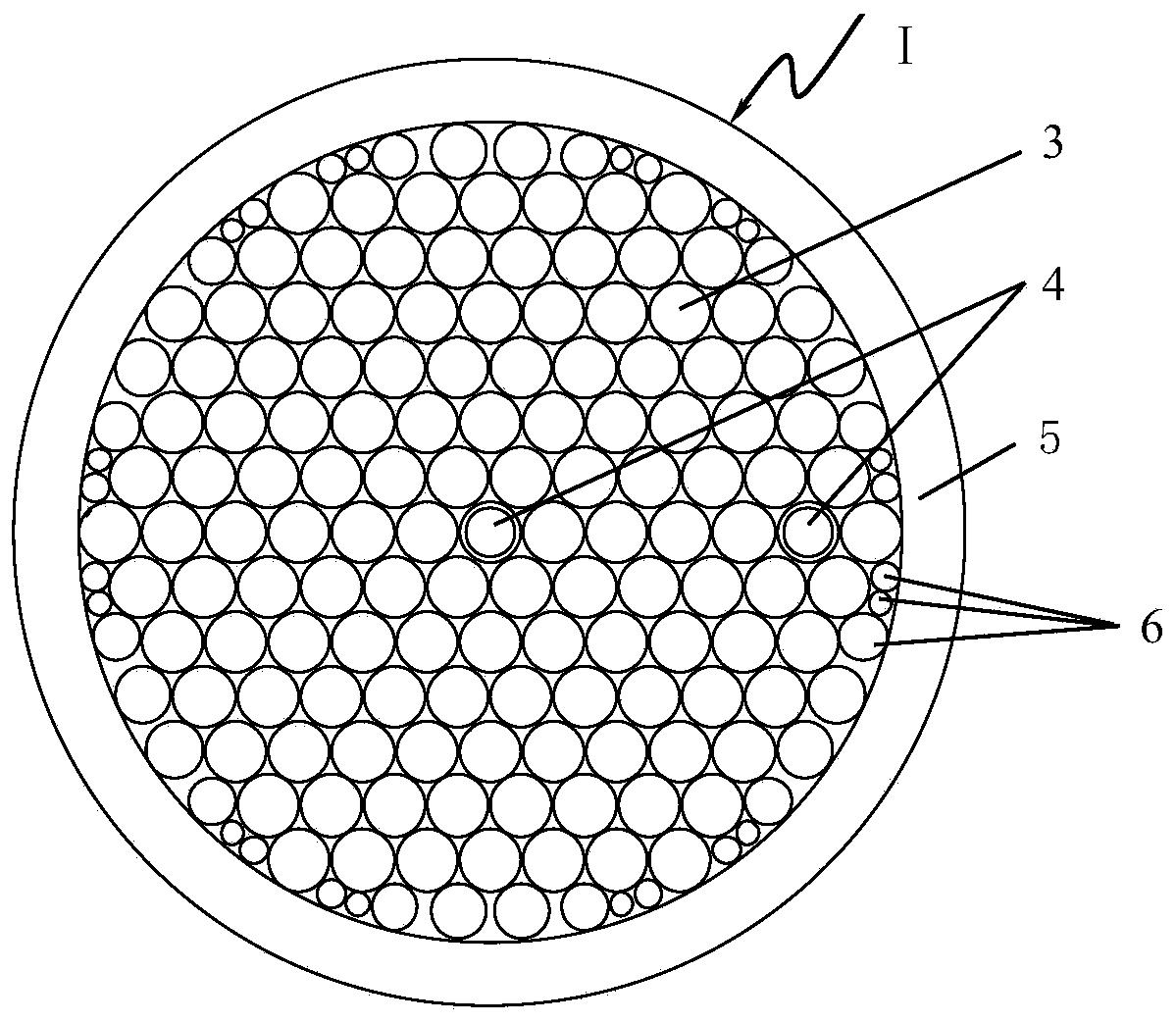

[0042] Used inner and outer double crucibles in the manufacturing process of the present invention. to combine Image 6 The outer crucible 21 is made of tungsten, with a tungsten sealing cover V on it, and a high temperature resistant (1800°C) alumina fiber sealing gasket VI is filled between the two. The outer crucible sealing cover V contains a sealing nut VII, which is porous After the capillary 17 passes through the small hole 31 on the sealing nut VII and the conical hole 28 on the crucible sealing cover V, it is inserted into the melt 23 of the inner crucibl...

Embodiment 2

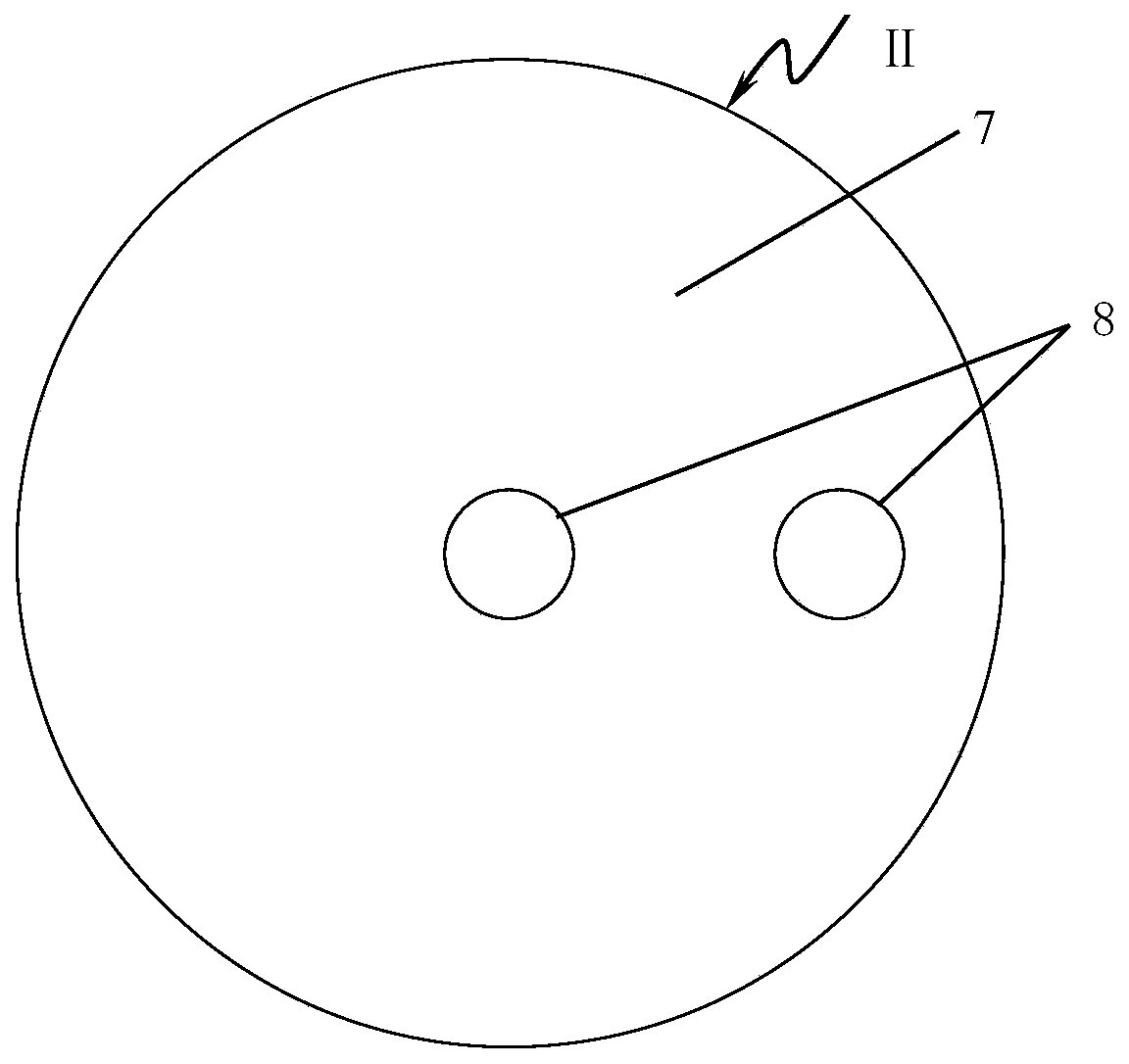

[0048] combine image 3 and Figure 4 , another preparation method of magnesium ion-doped lithium niobate single crystal double-core optical fiber of the present invention is, in a section of diameter Two diameters are punched on a solid quartz rod II with a length of 70mm 8 holes, and then weld a thin-walled quartz tube with the same outer diameter on one end of the quartz rod, heat and seal the other end of the porous quartz rod with an oxyhydrogen flame, forming a welded double-hole optical fiber preform, which is installed at one end of the quartz tube The inflating device is used to inflate the inside of the hole 8 to maintain a positive pressure of ~1000Pa; draw the double-hole optical fiber preform to the outer diameter at a temperature above 1900°C on the drawing tower The dual-bore capillary III, the dual-bore capillary contains two The asymmetric micropore 9, and the quartz cladding 10. All the other technological processes are identical with embodiment one. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com