Patents

Literature

117results about How to "Reduce crystal defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

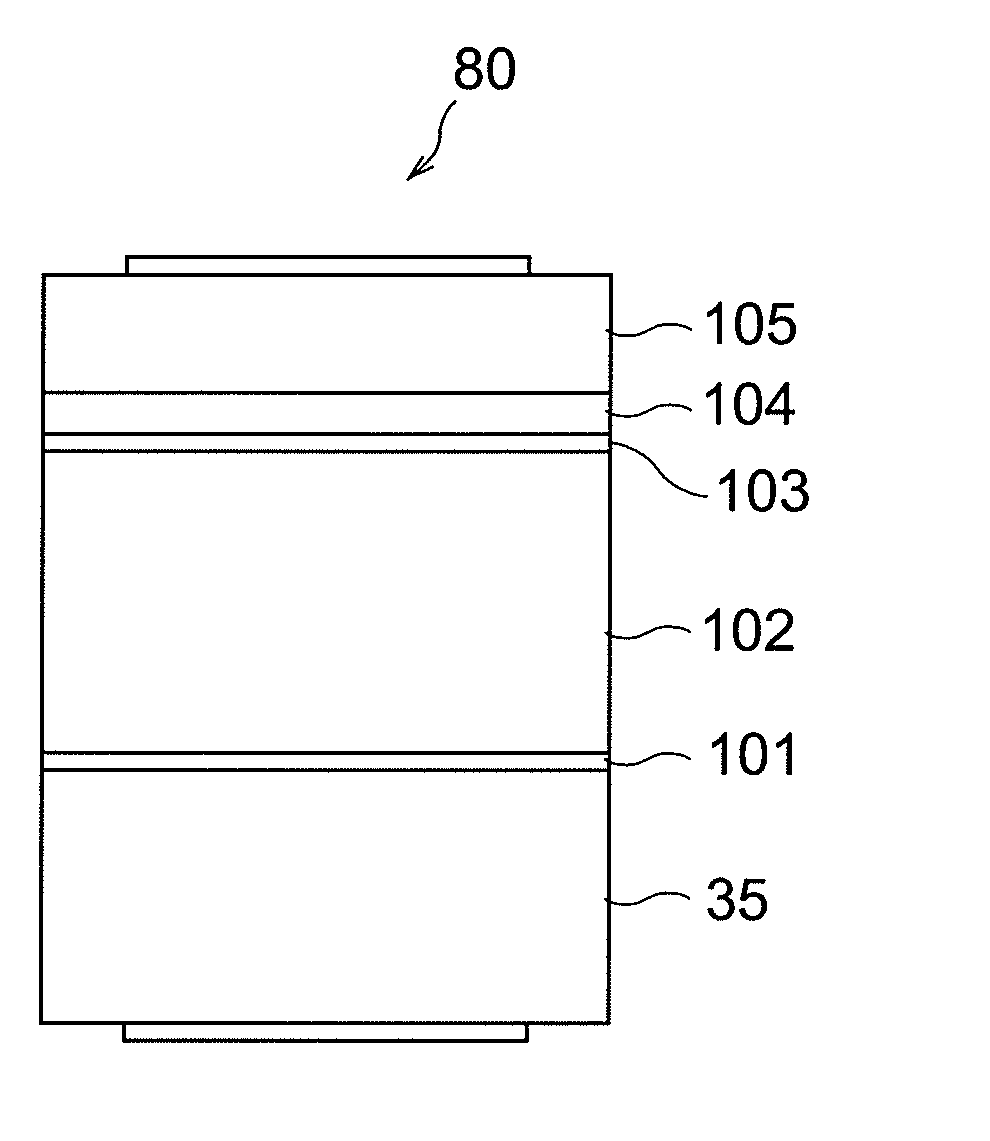

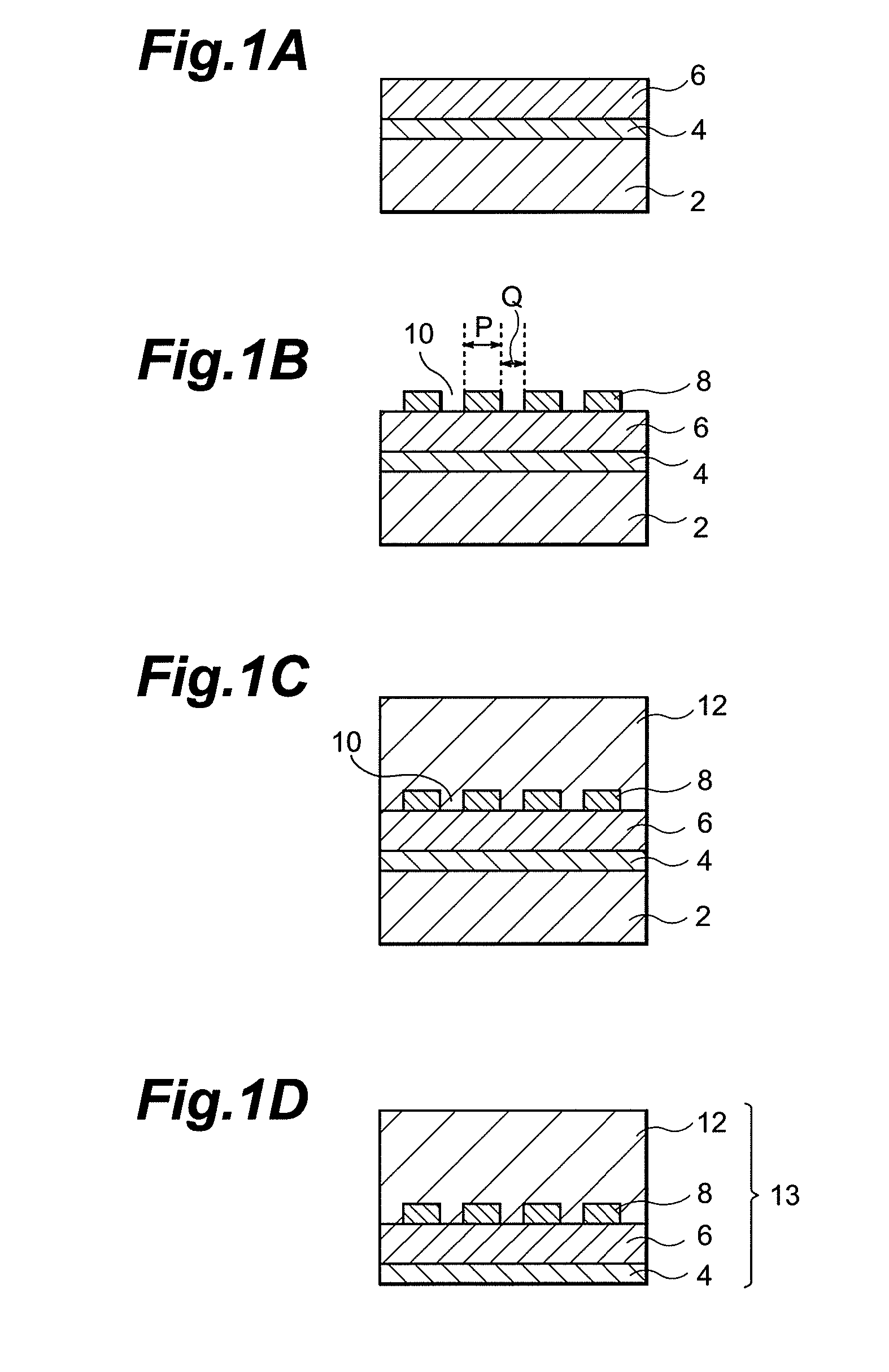

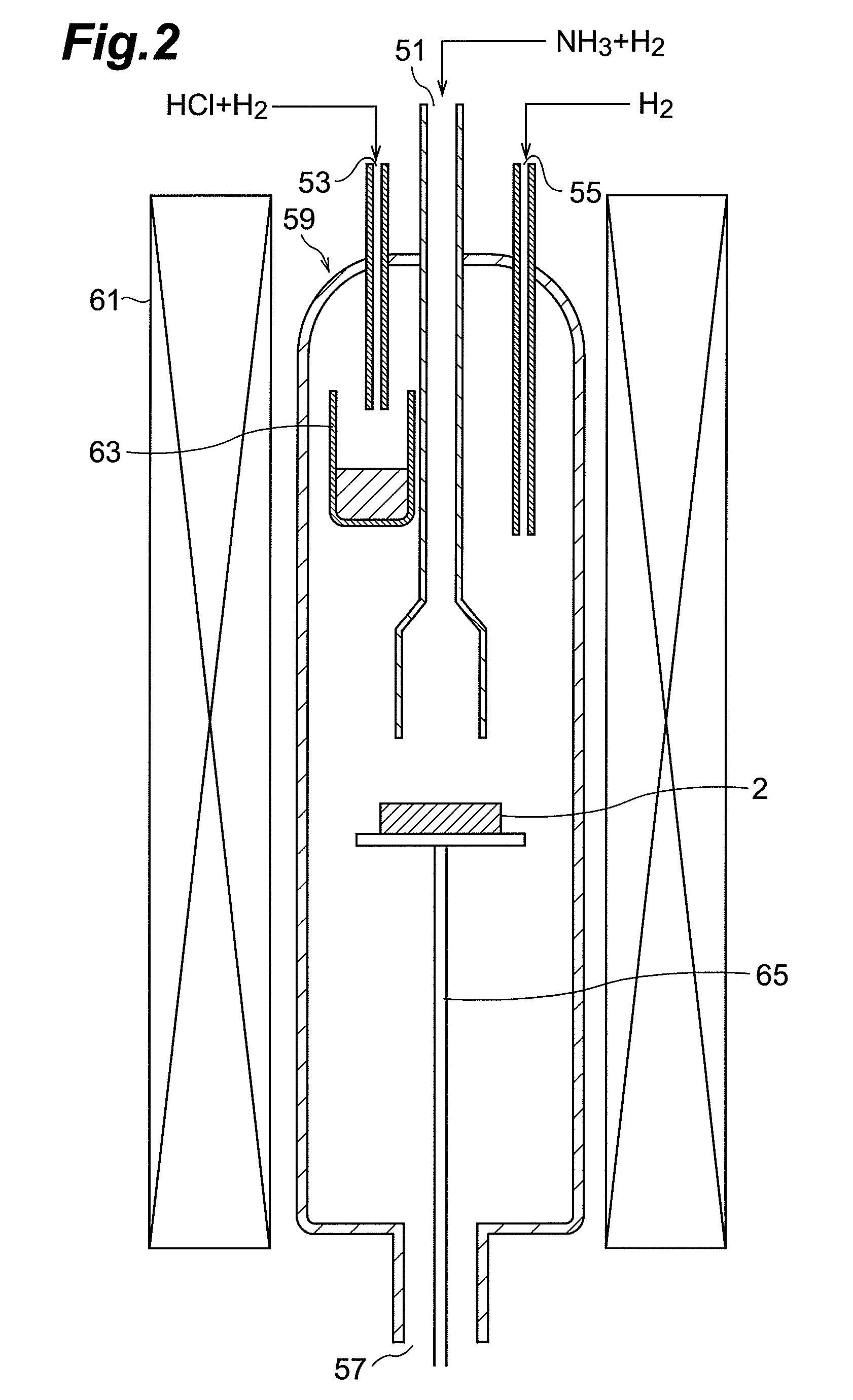

GaN single crystal substrate and method of making the same

InactiveUS20070105351A1Avoid crystal qualityLarge warpagePolycrystalline material growthLaser detailsSingle crystal substrateOptoelectronics

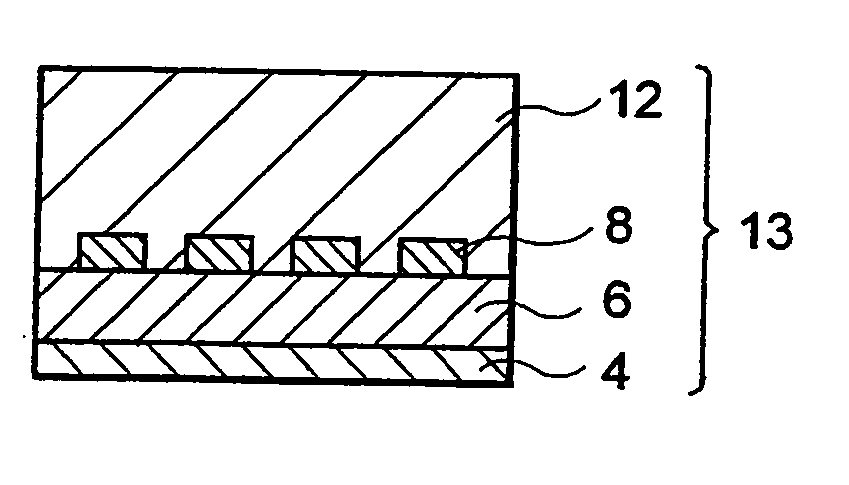

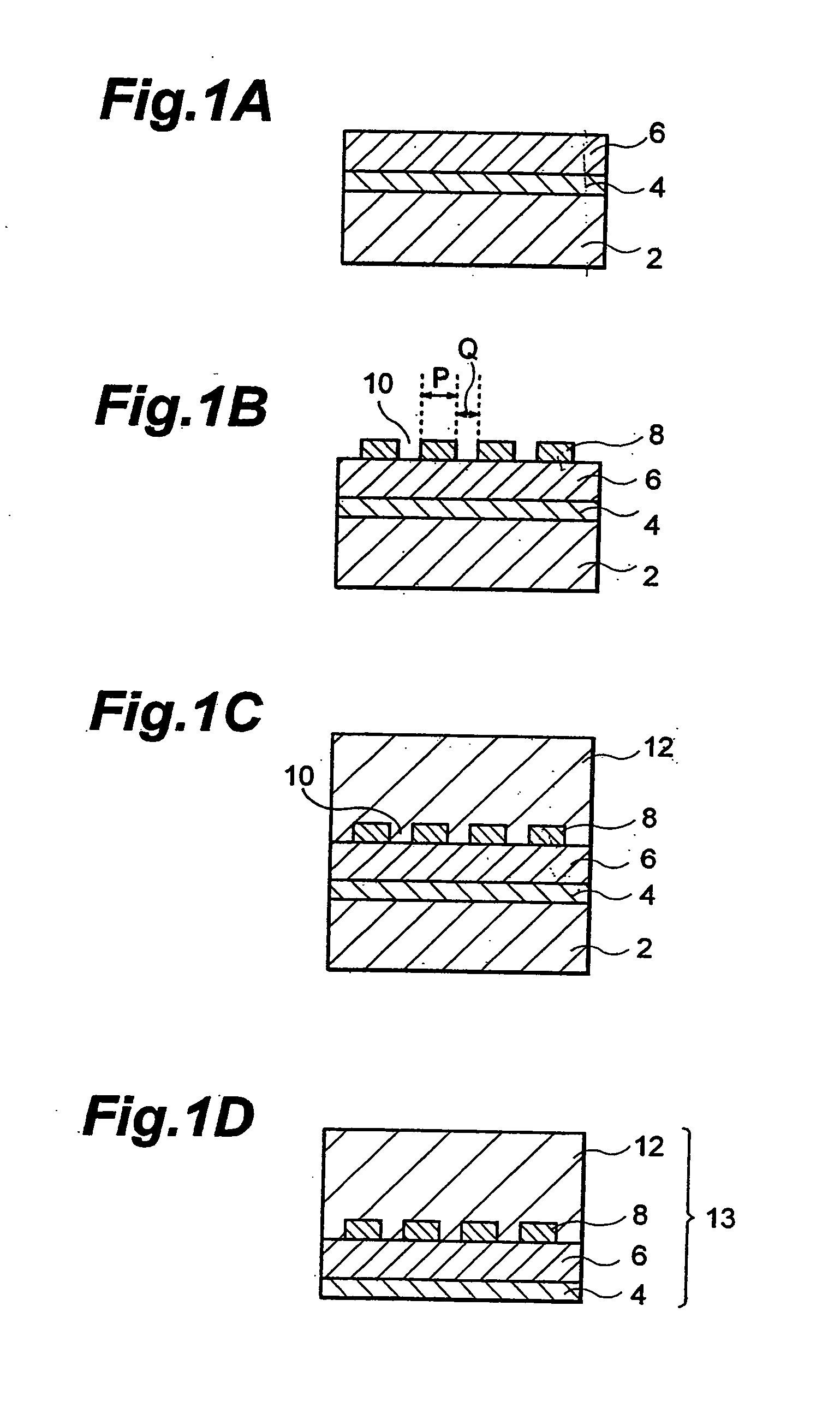

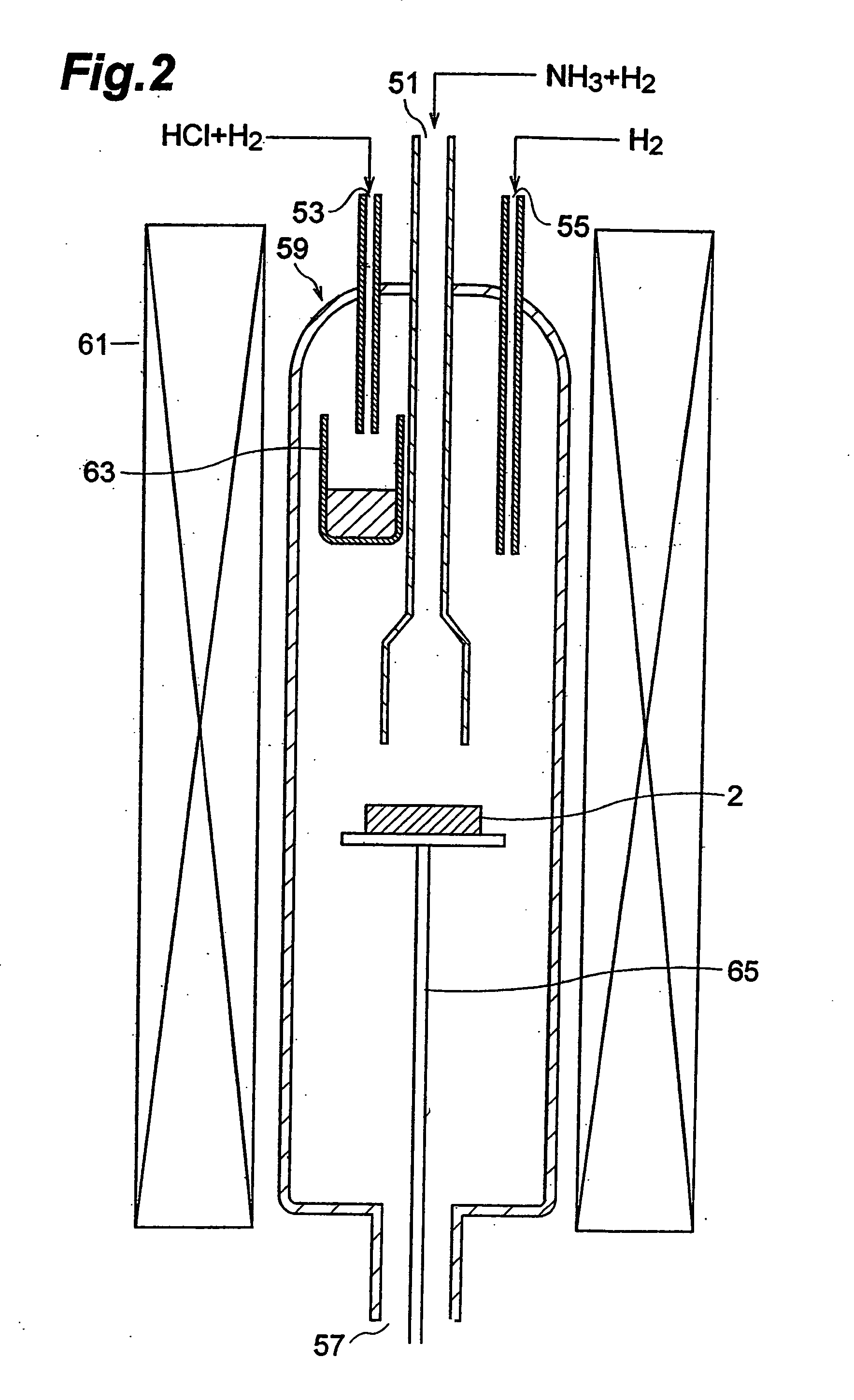

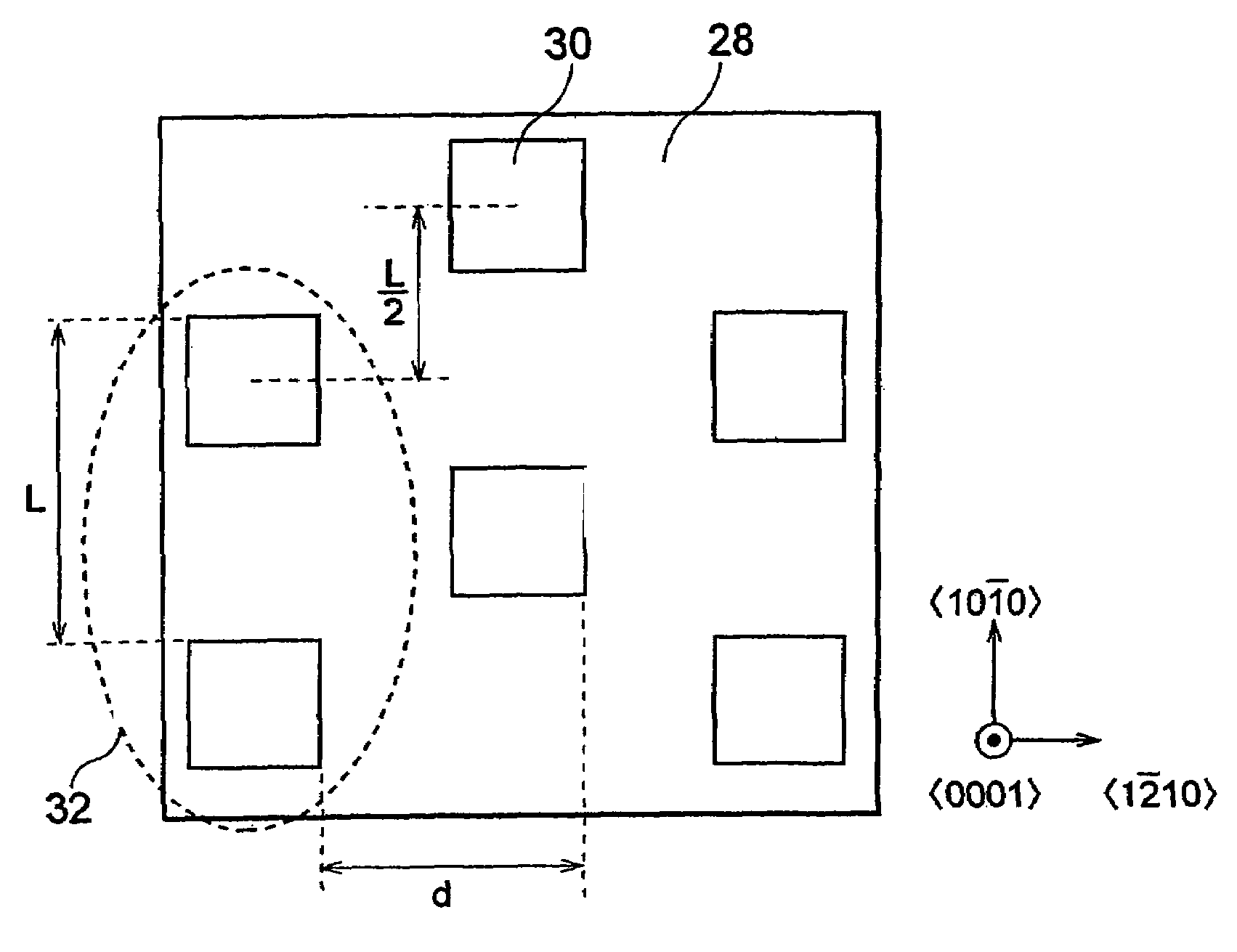

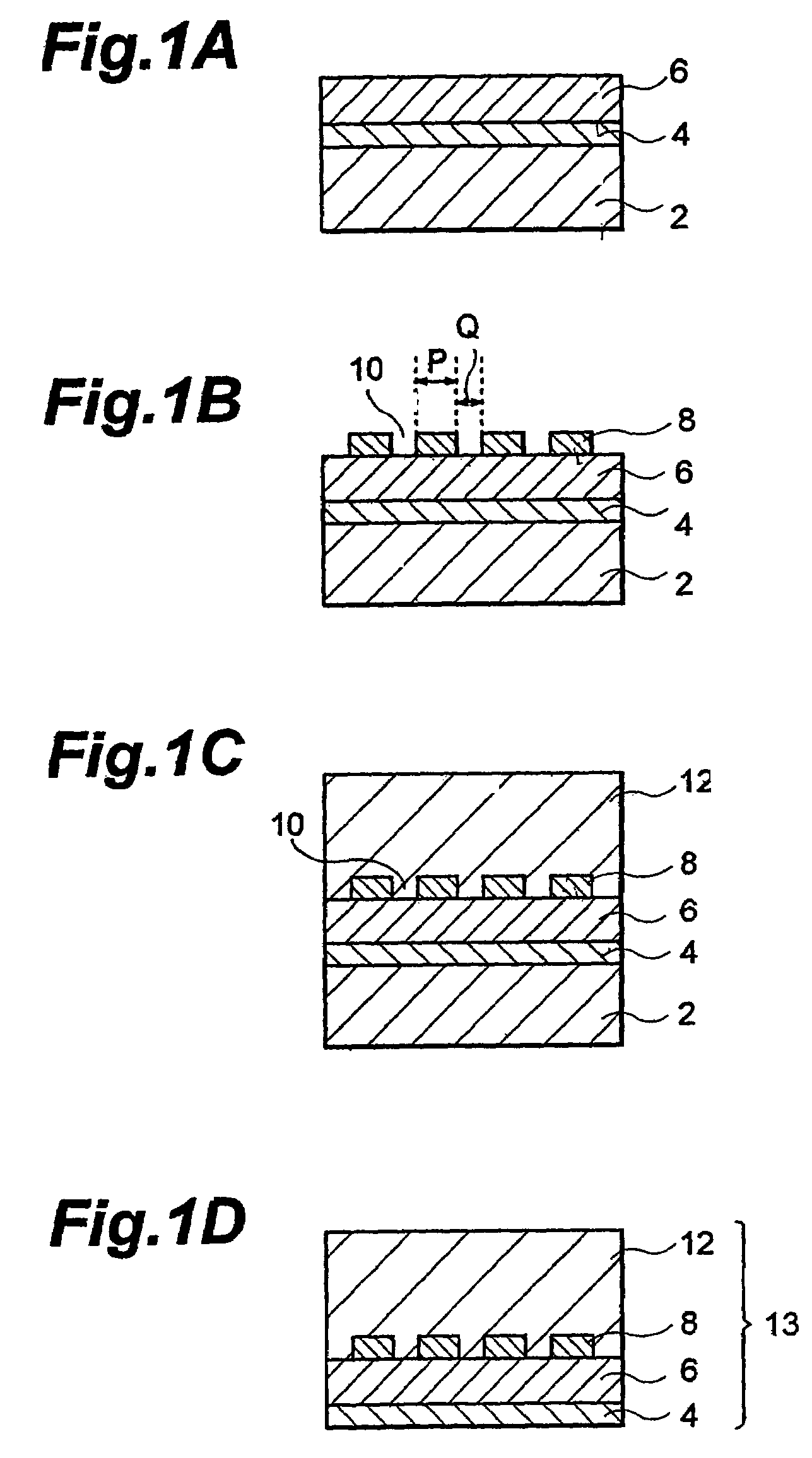

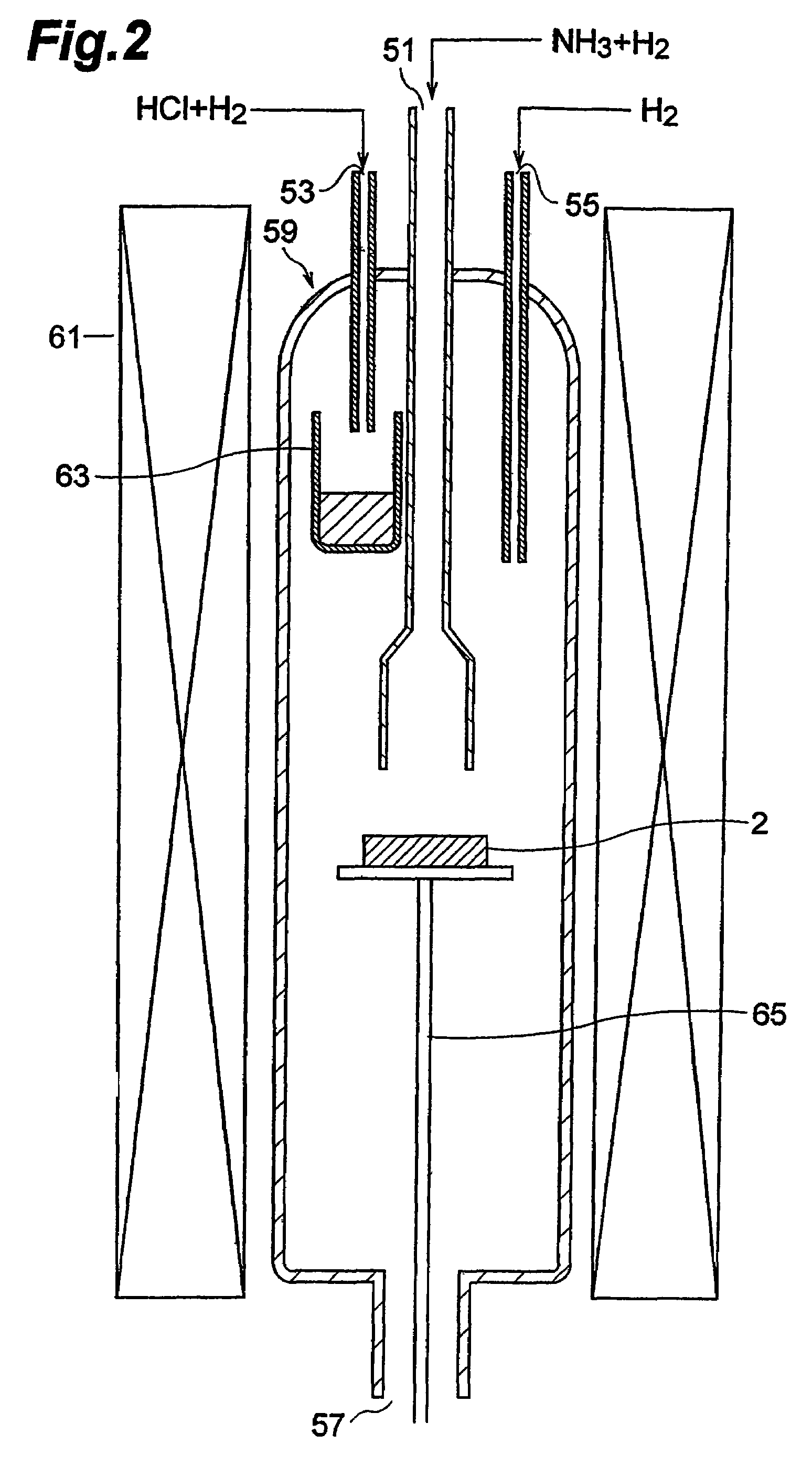

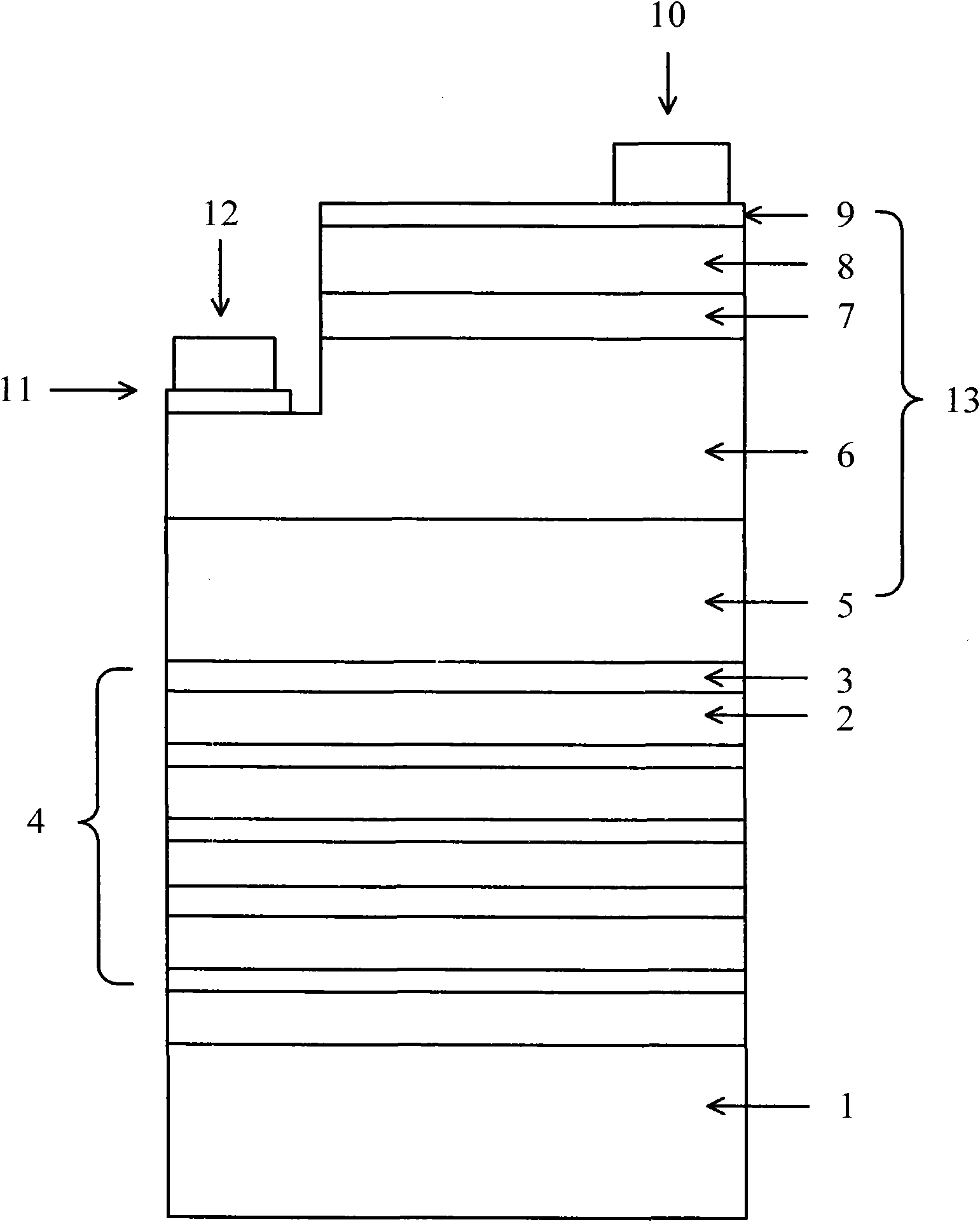

The method of making a GaN single crystal substrate comprises a mask layer forming step of forming on a GaAs substrate 2 a mask layer 8 having a plurality of opening windows 10 disposed separate from each other; and an epitaxial layer growing step of growing on the mask layer 8 an epitaxial layer 12 made of GaN.

Owner:SUMITOMO ELECTRIC IND LTD

Light-emitting diode and method for manufacturing same

InactiveUS9281446B2Reduce crystal defectImprove luminous efficiencySemiconductor devicesActive layerLight-emitting diode

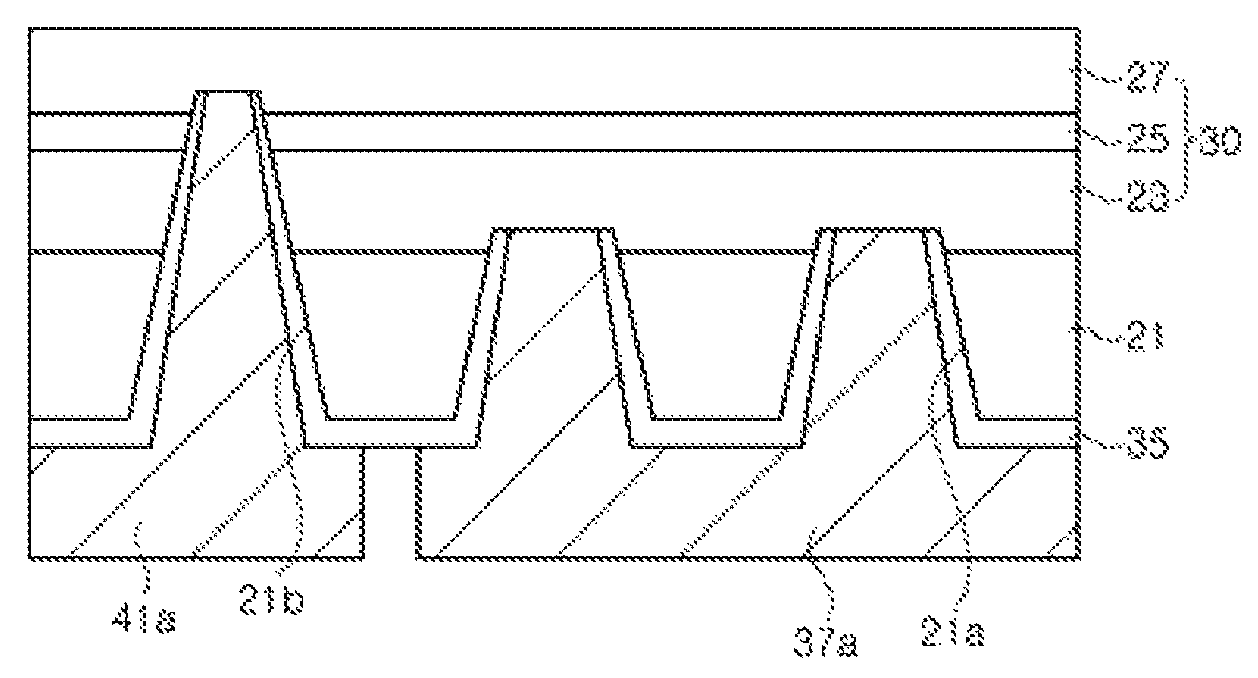

Disclosed are a light emitting diode and a method of fabricating the same. The light emitting diode includes a GaN substrate having a plurality of through-holes; a GaN-based semiconductor stack structure placed on the substrate and including a first conductive-type semiconductor layer, an active layer, and a second conductive-type semiconductor layer; and a first electrode electrically connected to the first conductive-type semiconductor layer via the through-holes. The light emitting diode can reduce crystal defects and prevent reduction in light emitting area.

Owner:SEOUL VIOSYS CO LTD

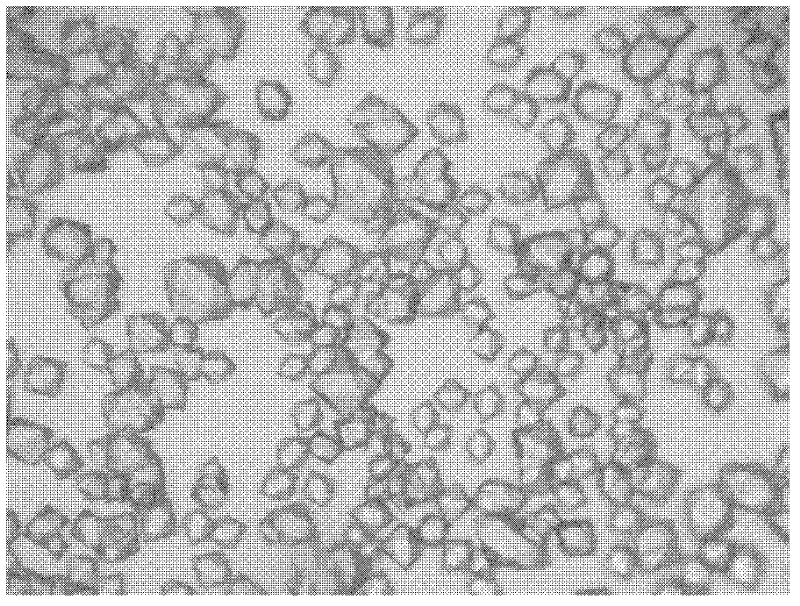

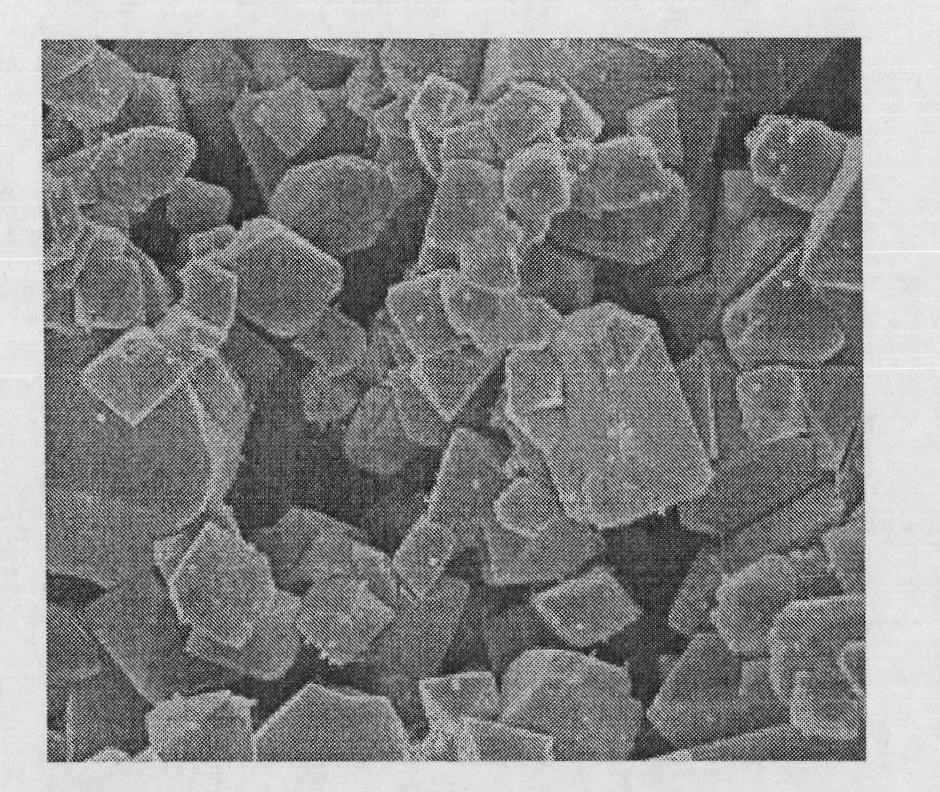

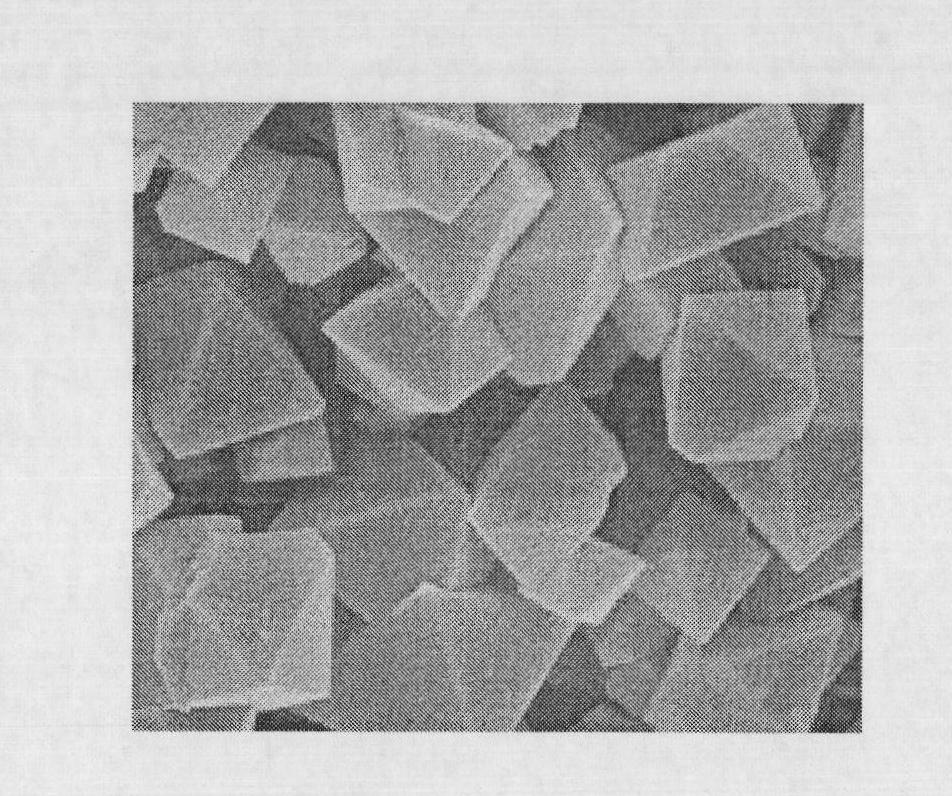

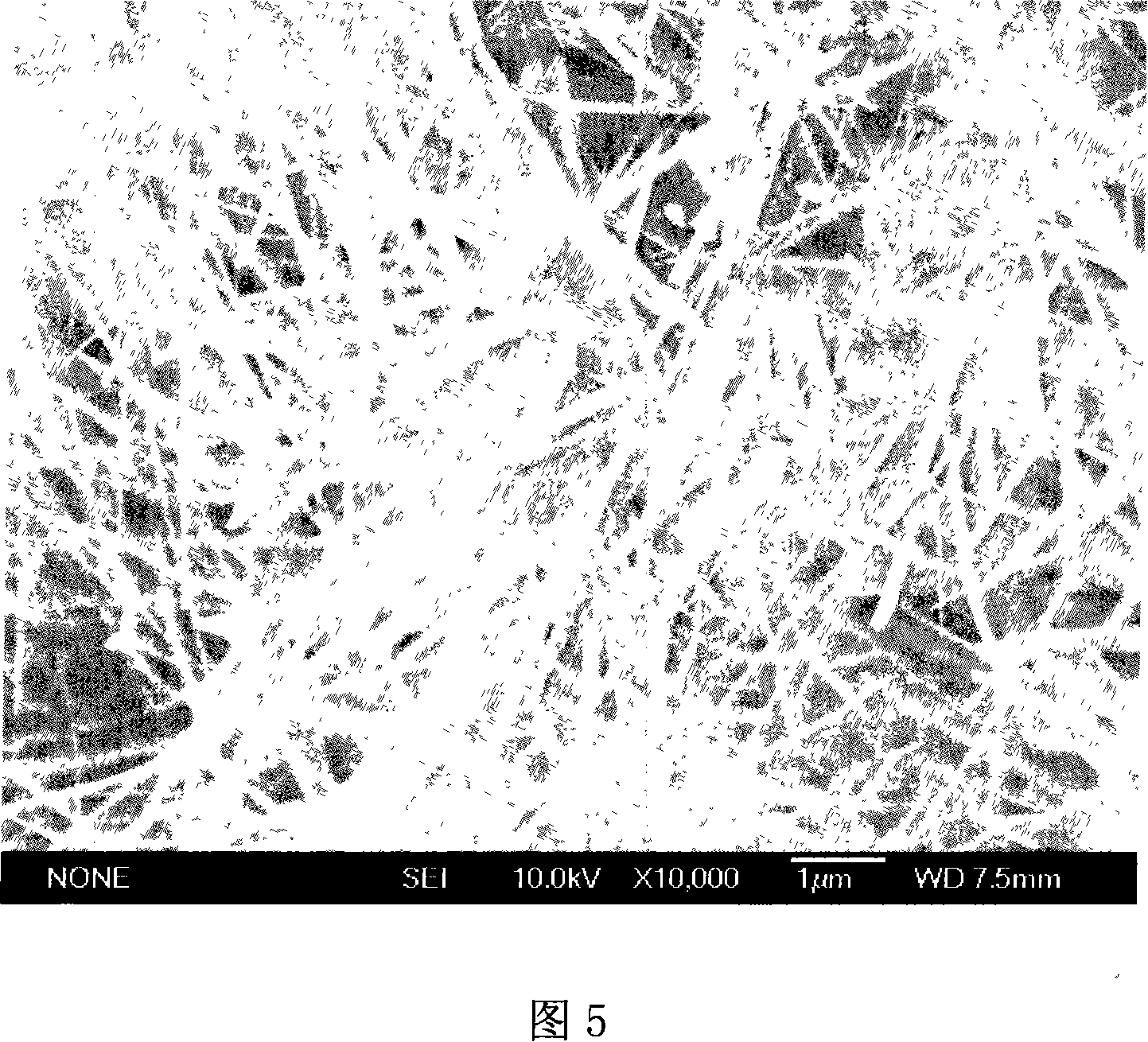

Method for preparing high-quality energetic crystal material fine particles

ActiveCN102320903AReduce crystal defectsReduced Shockwave SensitivityExplosive working-up apparatusShock waveFOX-7

The invention relates to a method for preparing high-quality energetic crystal material fine particles. Various high-quality energetic crystal material fine particle products, such as pentaerythritol tetranitrate (PETN), cyclotrimethylene trinitramine (RDX), cyclotetramethylenetetranitramine (HMX), hexanitrohexaazaisowurtzitane (CL-20), DADNE (FOX-7), ammonium perchlorate (AP), and the like can be prepared by adopting an ultrasound solvating-out crystallization method in the traditional solvating-out crystallization process. The high-quality energetic crystal material fine particle product prepared by the preparation method disclosed by the invention has subglobular particle form, narrow granularity distribution, average particle diameter of 5-50 microns or so, transparent crystals, high particle density, crystal theoretical density of more than 99.9 percent and obviously reduced shock wave sensitivity and is used for pouring or pressing PBX (Plastic-bonded explosives). The method for preparing the high-quality energetic crystal material fine particles has the advantages of simple process flow and mild reaction conditions and is suitable for mass industrialized production.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Gallium and indium doped single crystal silicon material for solar battery and preparation method thereof

ActiveCN101805925AReduce precipitationReduce crystal defectsPolycrystalline material growthBy pulling from meltIndiumHearth

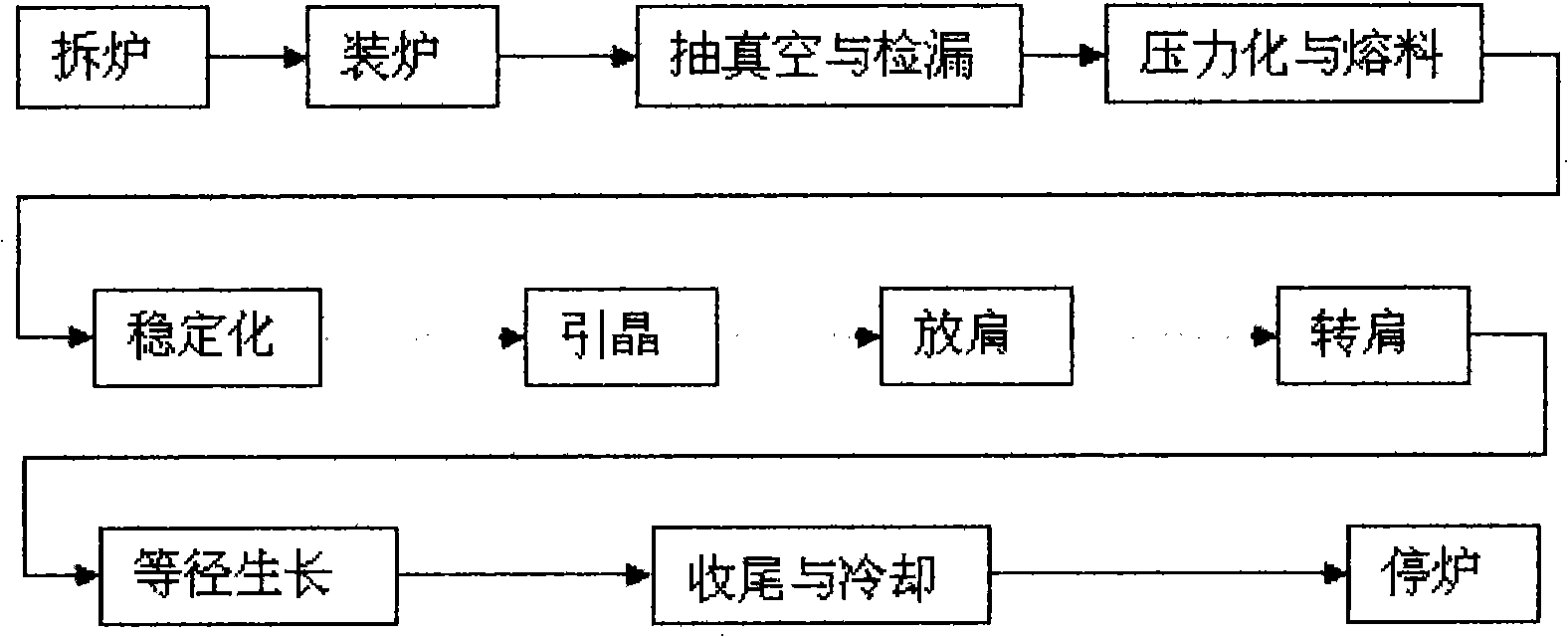

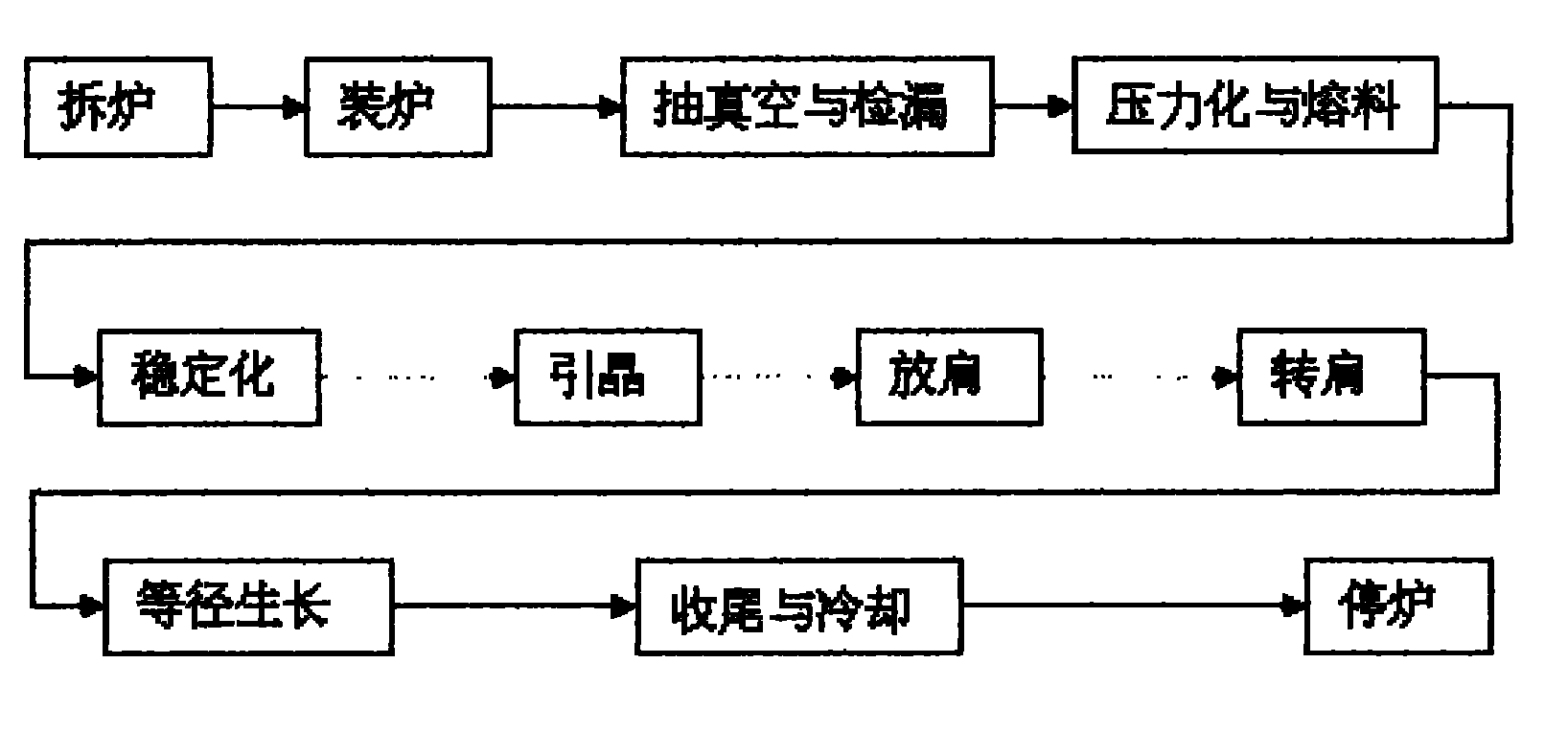

The invention discloses a gallium and indium doped single crystal silicon material for a solar battery, which consists of the following components according to atom number per cubic centimeter of the single crystal silicon material: 1.0X10<14> to 1.0X10<18> gallium, 5.0X10<12> to 5.0x10<16> indium and the balance of single crystal silicon. The invention also discloses a method for preparing the gallium and indium doped single crystal silicon material for the solar battery, which is implemented by the following steps of: dismantling a furnace by using a regular method, cleaning a hearth and assembling the furnace; vacuumizing the inside of a single crystal furnace and detecting the leakage of the single crystal furnace by using a regular method; pressuring materials and smelting the materials; stabilizing the melt; seeding crystals; performing shouldering; performing shoulder rotation; performing isodiametric growth; performing ending and cooling the obtained product; and stopping the furnace. The gallium and indium doped single crystal silicon material for the solar battery has the advantages of high conversion efficiency, low light attenuation, low oxide content in the single crystal silicon and uniform radial distribution in a single crystal silicon rod; and the preparation method of the invention effectively controls the thermal conversion of silicon melt and grows the high-quality gallium and indium doped single crystal silicon material for the solar battery.

Owner:LONGI GREEN ENERGY TECH CO LTD

Light emitting diode chip structure and manufacturing method thereof

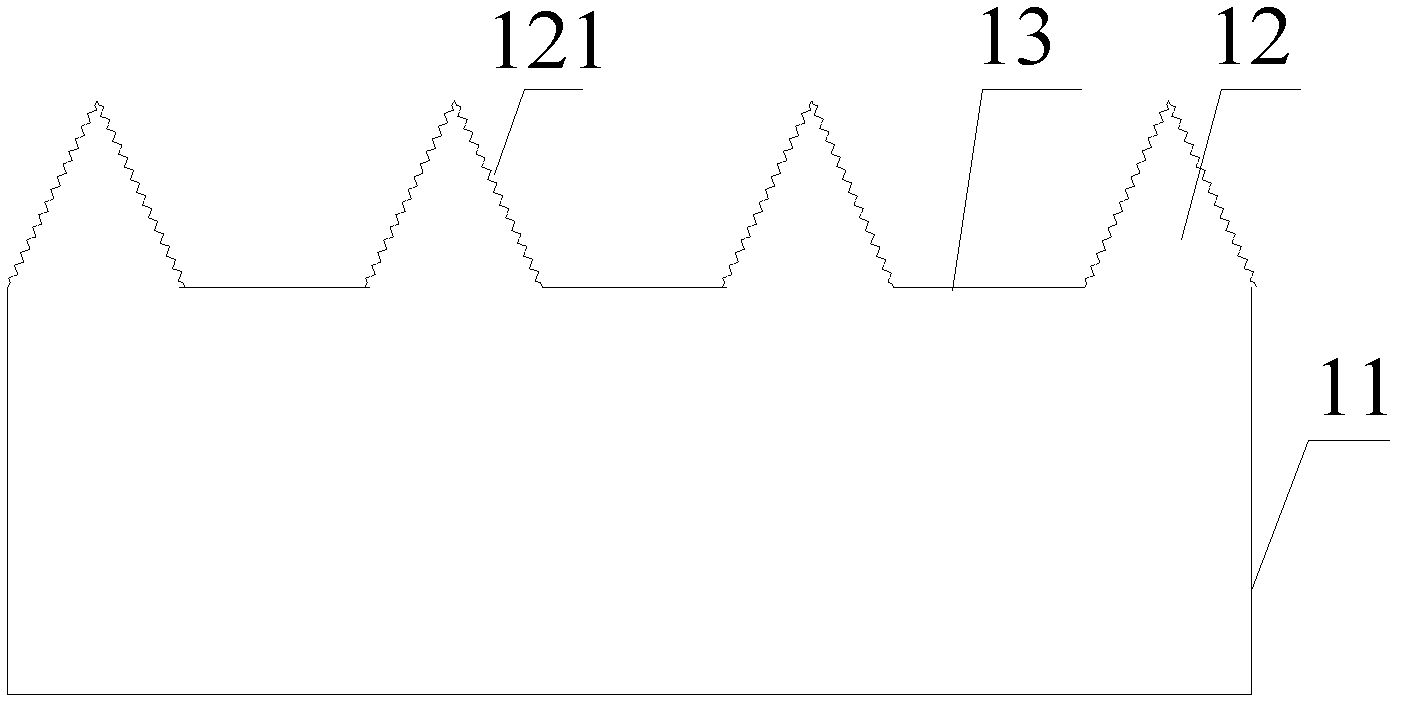

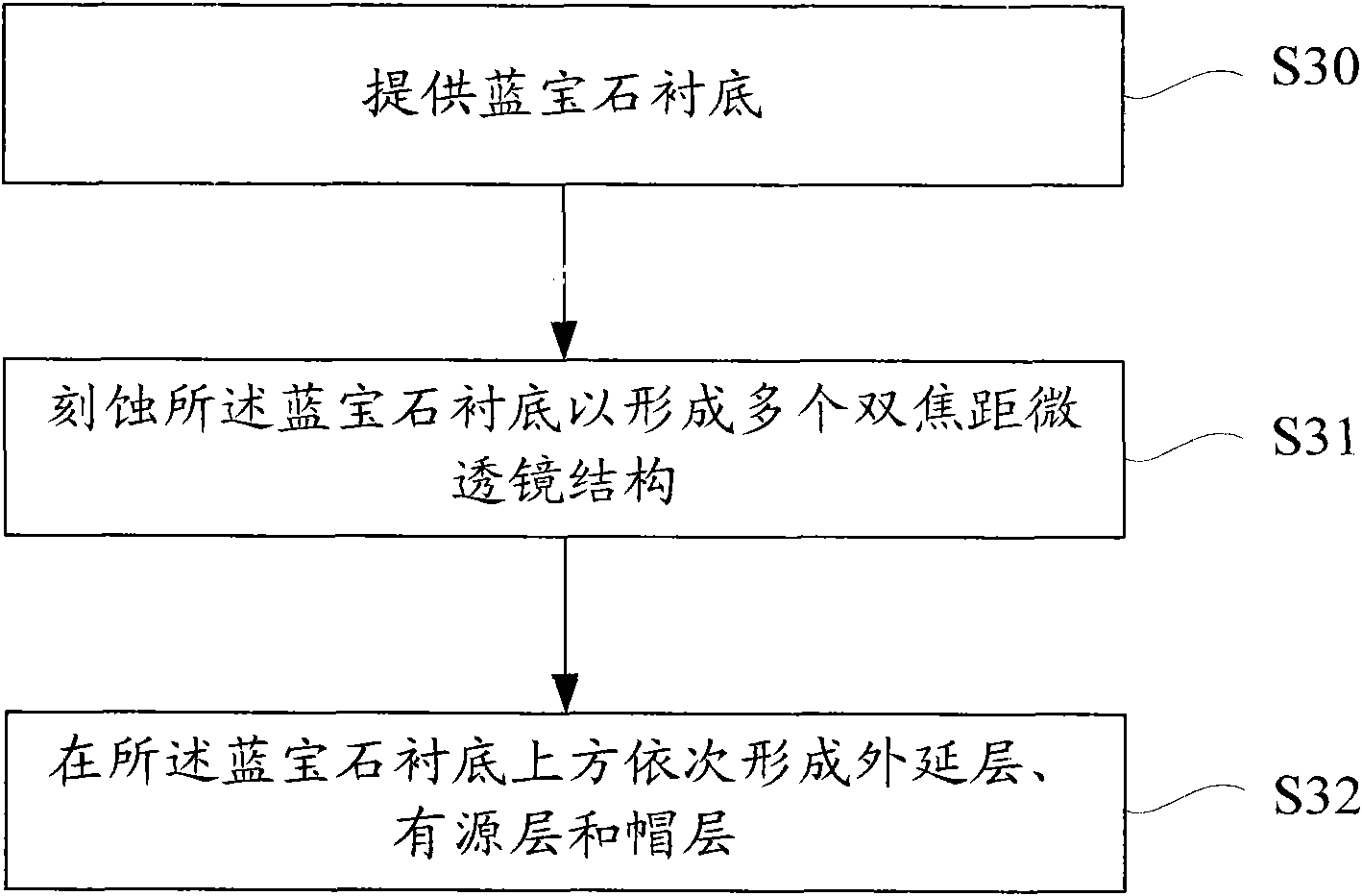

ActiveCN101582479AReduce crystal defectsQuality improvementSemiconductor devicesCrystallographic defectLight-emitting diode

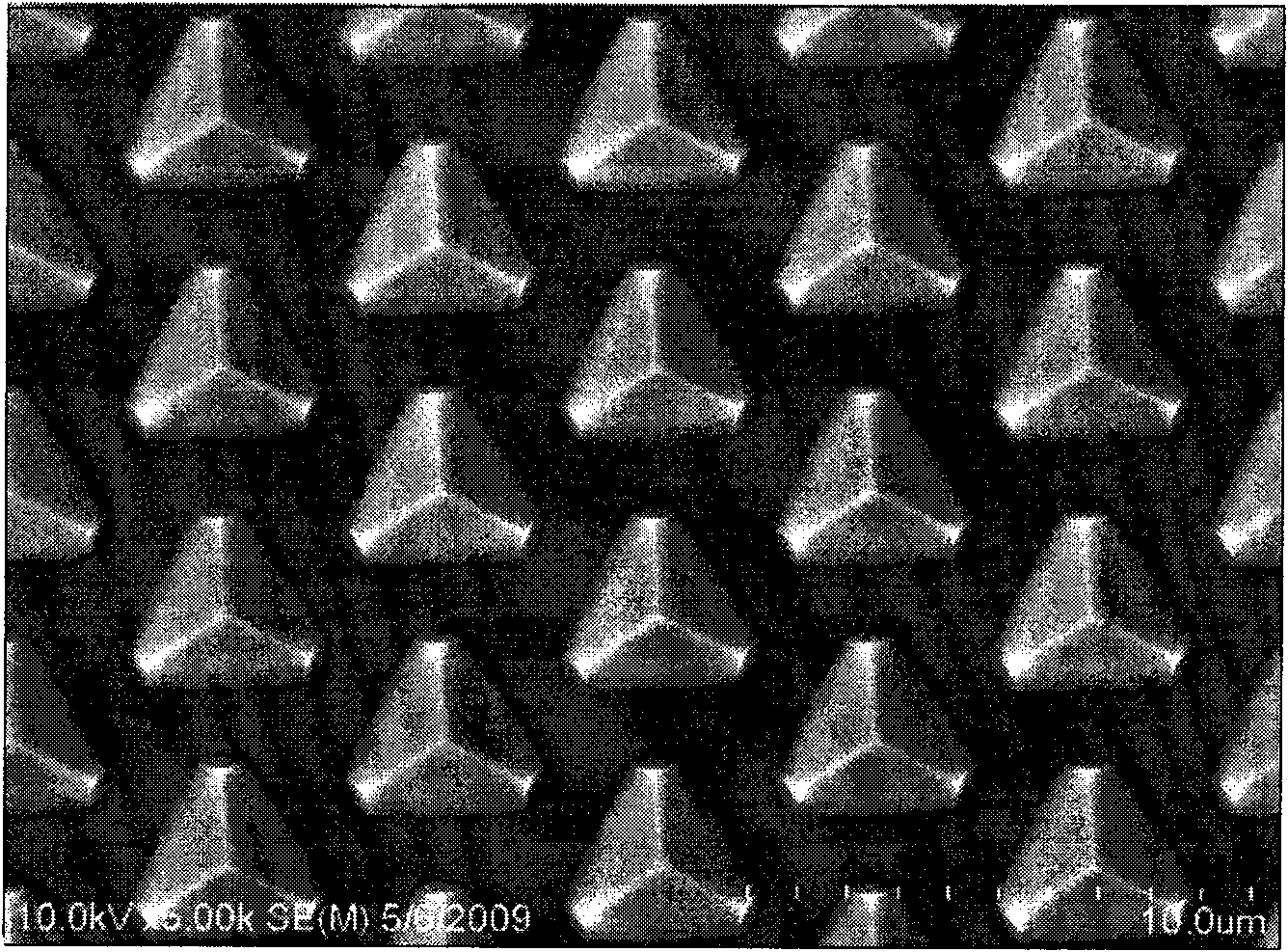

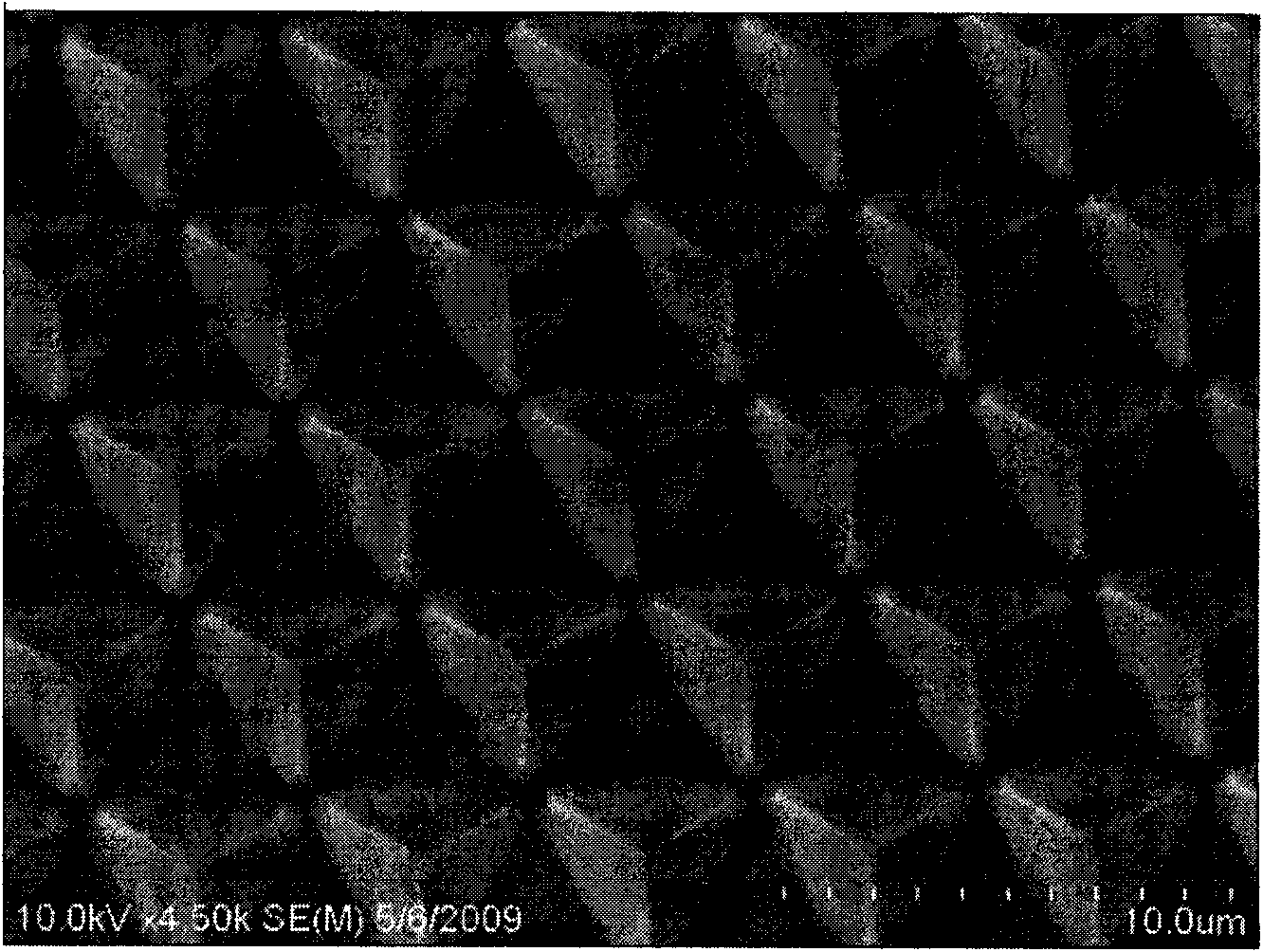

The invention relates to a light emitting diode chip structure, comprising a sapphire substrate layer; wherein, the sapphire substrate layer is provided with triangular pyramid microstructures arranged periodically. The invention also relates to a manufacturing method of the light emitting diode chip structure, including the following steps: 1) a graph is transferred onto the sapphire substrate by applying dry etching technology; 2) the graph on the sapphire substrate is formed in periodically arranged triangular pyramid by applying wet etching. The invention can greatly reduce boundary reflection and internal absorption as periodically arranged high quality triangular pyramid microstructures are formed on the sapphire substrate; and crystal defect of the sapphire is greatly reduced after wet etching, thus high crystal quality epitaxial layer can be grown on the surface and the quality and luminous efficiency of the light emitting diode are greatly improved.

Owner:EPILIGHT TECH

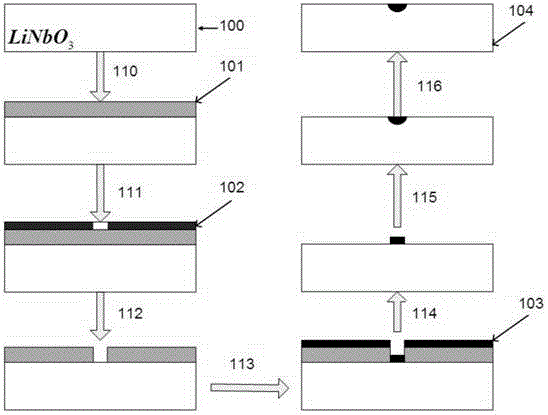

Method for preparing substrate having monocrystalline film

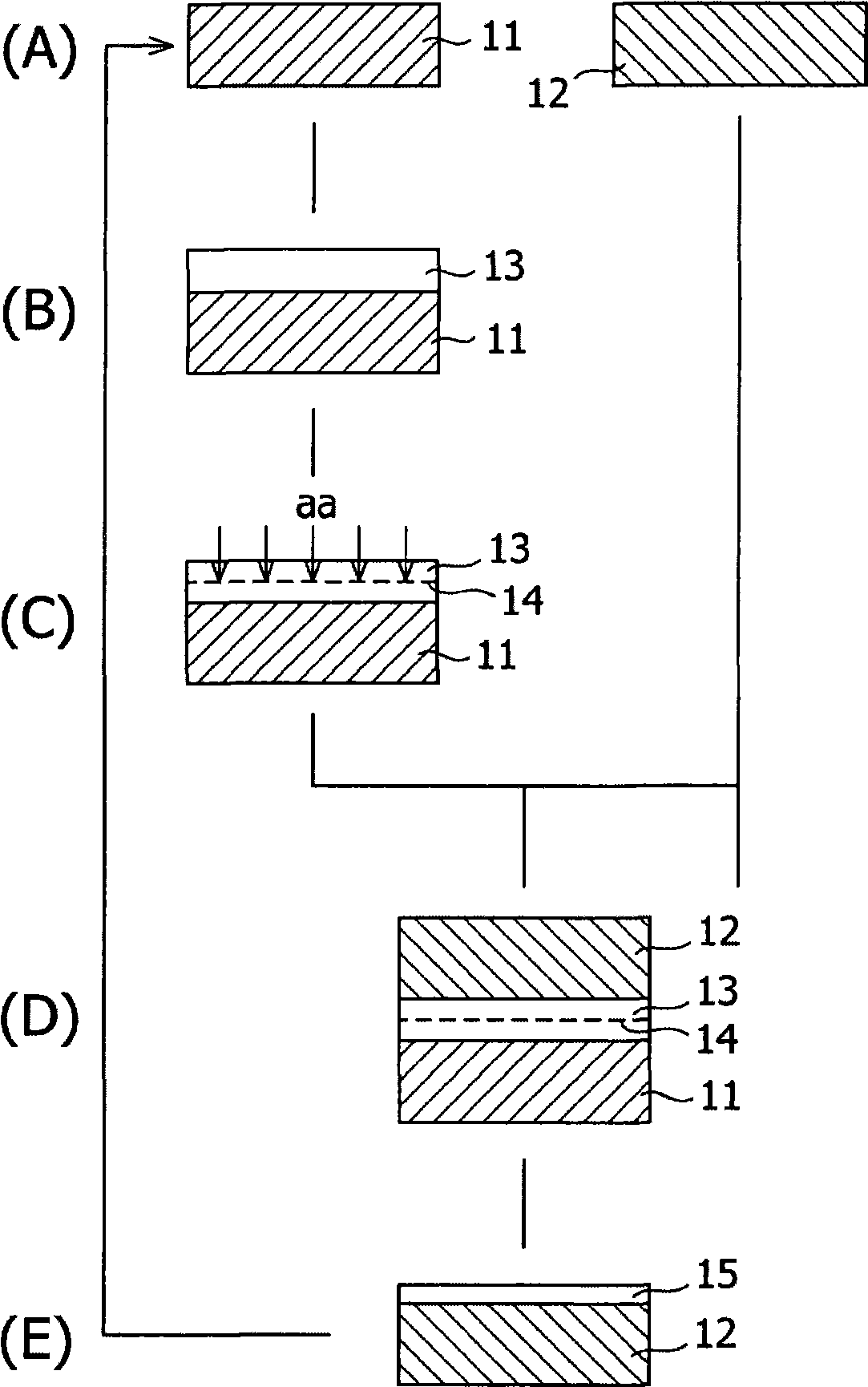

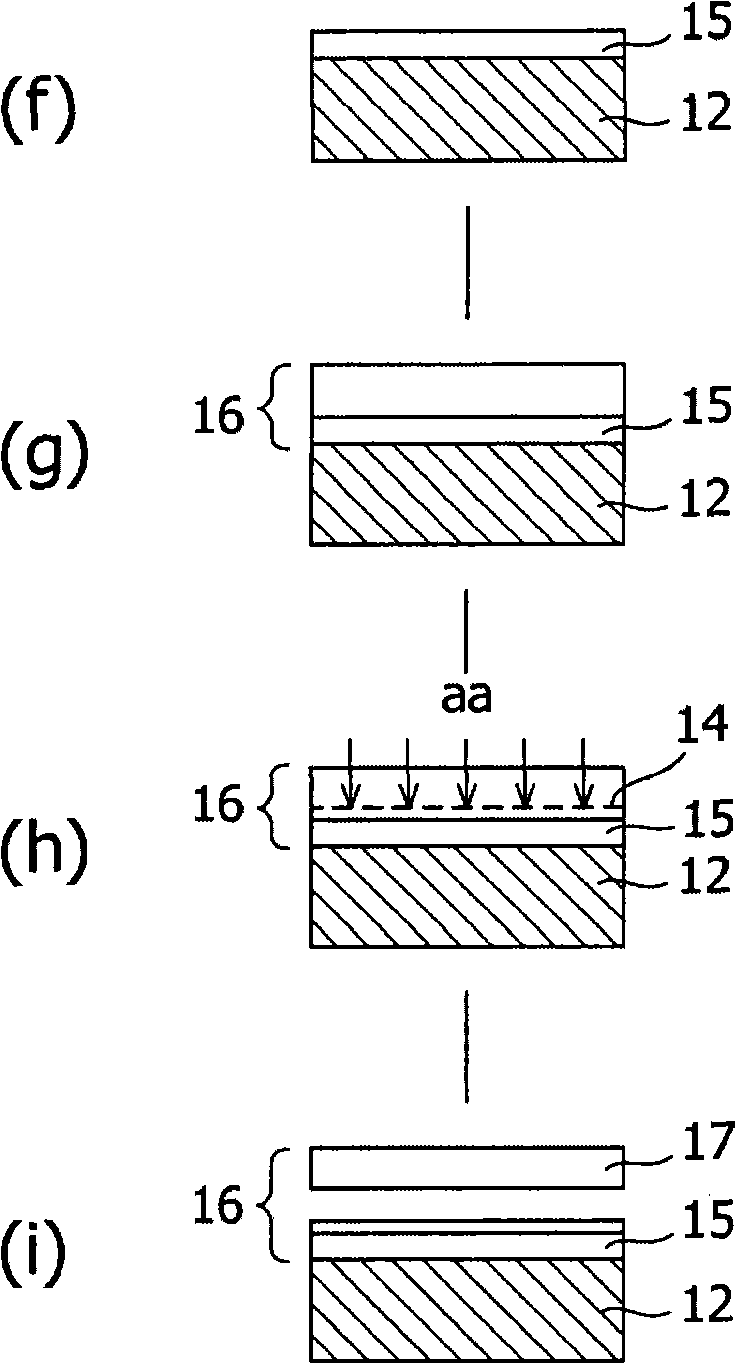

ActiveCN101521155AReduce crystal defectsReduce defectsSemiconductor/solid-state device manufacturingSingle crystalCrystallographic defect

Provided is a method for easily preparing a substrate comprising a monocrystalline film thereon or thereabove with almost no crystal defects without using a special substrate. More specifically, provided is a method for preparing a substrate comprising a monocrystalline film formed on or above a handle substrate, the method comprising: a step A of providing a donor substrate and the handle substrate; a step B of growing a monocrystalline layer on the donor substrate; a step C of implanting ions into the monocrystalline layer on the donor substrate so as to form an ion-implanted layer; a step D of bonding a surface of the monocrystalline layer of the ion-implanted donor substrate to a surface of the handle substrate; and a step E of peeling the bonded donor substrate at the ion-implanted layer existing in the monocrystalline layer so as to form the monocrystalline film on or above the handle substrate; wherein at least the steps A to E are repeated by using the handle substrate having the monocrystalline film formed thereon or thereabove as a donor substrate.

Owner:SHIN ETSU CHEM IND CO LTD

Method for directly growing carbon nano tube array on fiber substrate

ActiveCN104310372AIncrease coverageReduce interdiffusionMaterial nanotechnologyPre treatmentCarbon nanotube

The invention provides a method for directly growing a carbon nano tube array on a fiber substrate. The method comprises the following steps: (1) pre-treating the fiber substrate; (2) attaching a catalyst precursor on the surface of the substrate obtained in the step 1, wherein the catalyst comprises transitional metal elements such as Fe, Co, Ni, Cu, Au, Pt, Mo or Ag; (3) putting the substrate obtained in the step (2) in a reaction furnace, heating the substrate to a first temperature and maintaining for a preset time, and introducing inert gas to remove organic matters in the catalyst precursor; (4) heating to a second temperature and maintaining for a preset time, continuously introducing inert gas, introducing mixed gas of reductive gas and carbon source gas, maintaining the pressure in the reaction furnace, and growing high-density carbon nano tubes on the surface of the substrate; and (5) after reaction, stopping introduction of the reductive gas and carbon source gas, and continuously introducing inert gas till the temperature is reduced to room temperature.

Owner:4MICRO TECH COMPANY

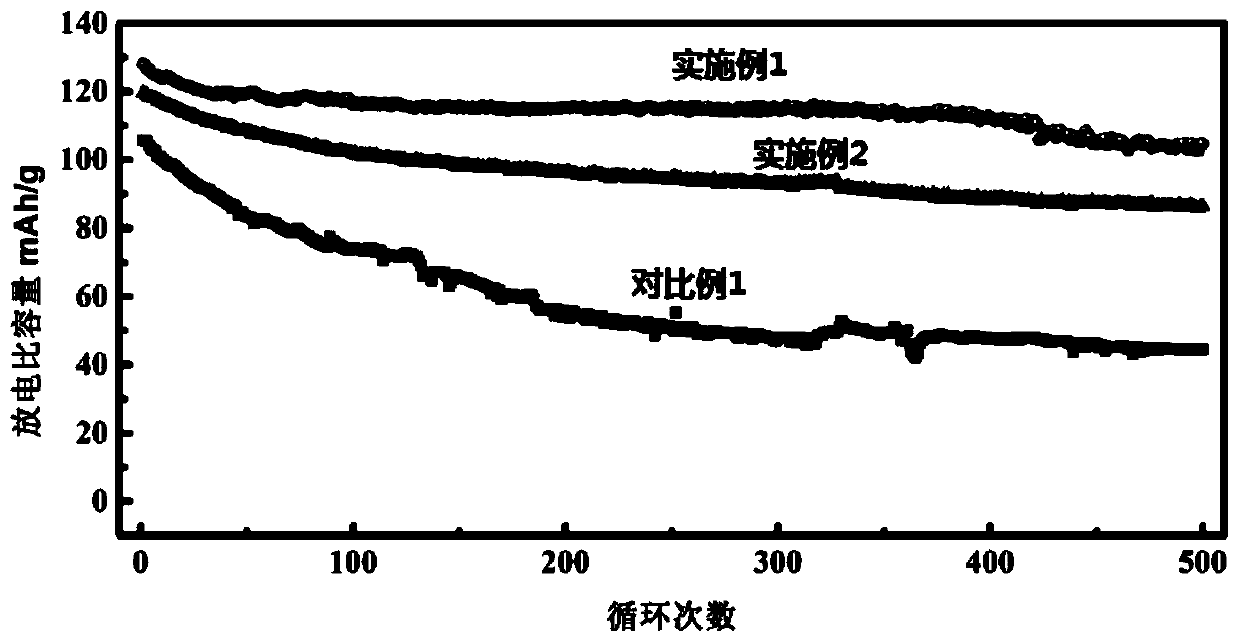

Prussian blue positive electrode material, sodium ion battery and preparation method and application thereof

ActiveCN111377462AControllable crystallization rateReduce crystal defectsIron cyanidesSecondary cellsSodium cyanideEthylenediaminetetraacetic acid

The invention discloses a prussian blue positive electrode material, a sodium ion battery, and a preparation method and application thereof. The molecular formula of the prussian blue positive electrode material is NaxM [Fe (CN) 6] y.nH2O, wherein M is transition metal, x is less than or equal to 2 and greater than or equal to 1.8; y is less than or equal to 1 and greater than or equal to 0.95; and n is less than or equal to 2 and greater than or equal to 0. The prussian blue positive electrode material has low lattice defect and stable performance; and the sodium ion battery prepared from thematerial is high in capacity and good in cycle performance. The preparation method comprises the following steps of: S1, adding an aqueous solution of weak acid into an aqueous solution of sodium ferrocyanide and transition metal ethylenediamine tetraacetic acid sodium salt to obtain a precipitate; and S2, drying the precipitate. The preparation method can be adopted to control the crystallization speed, and has advantages of simple process, low production cost, non-toxicity, harmlessness and short production period.

Owner:浙江钠创新能源有限公司

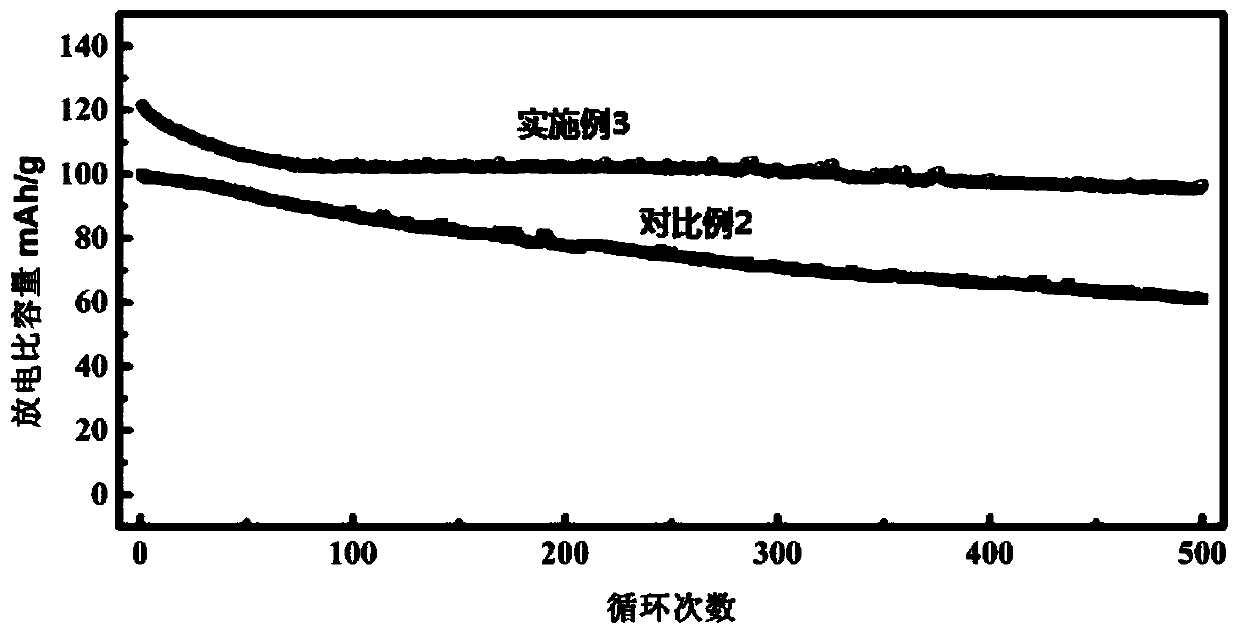

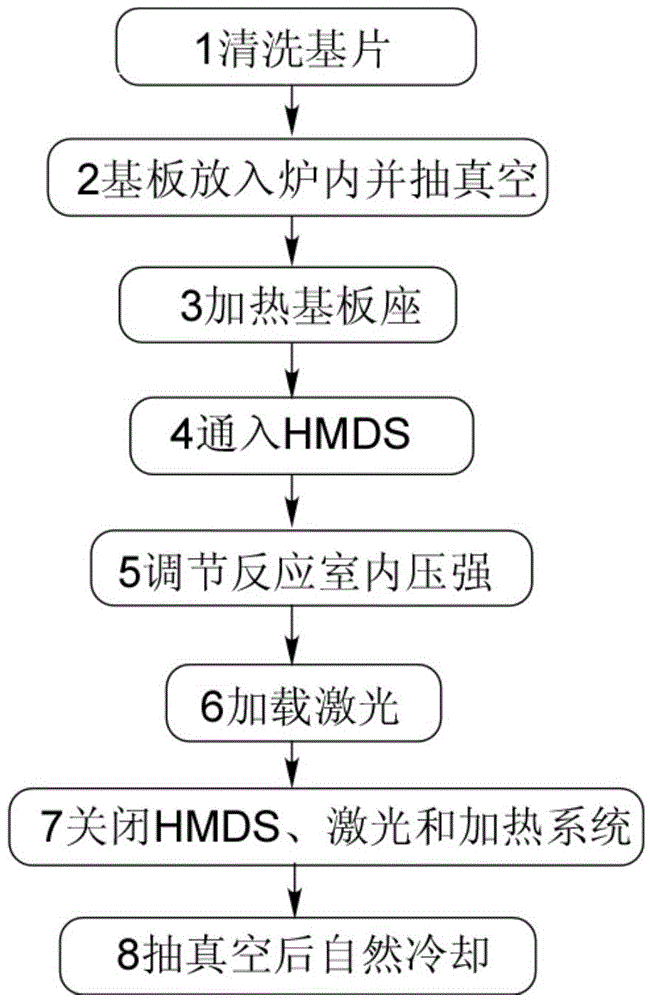

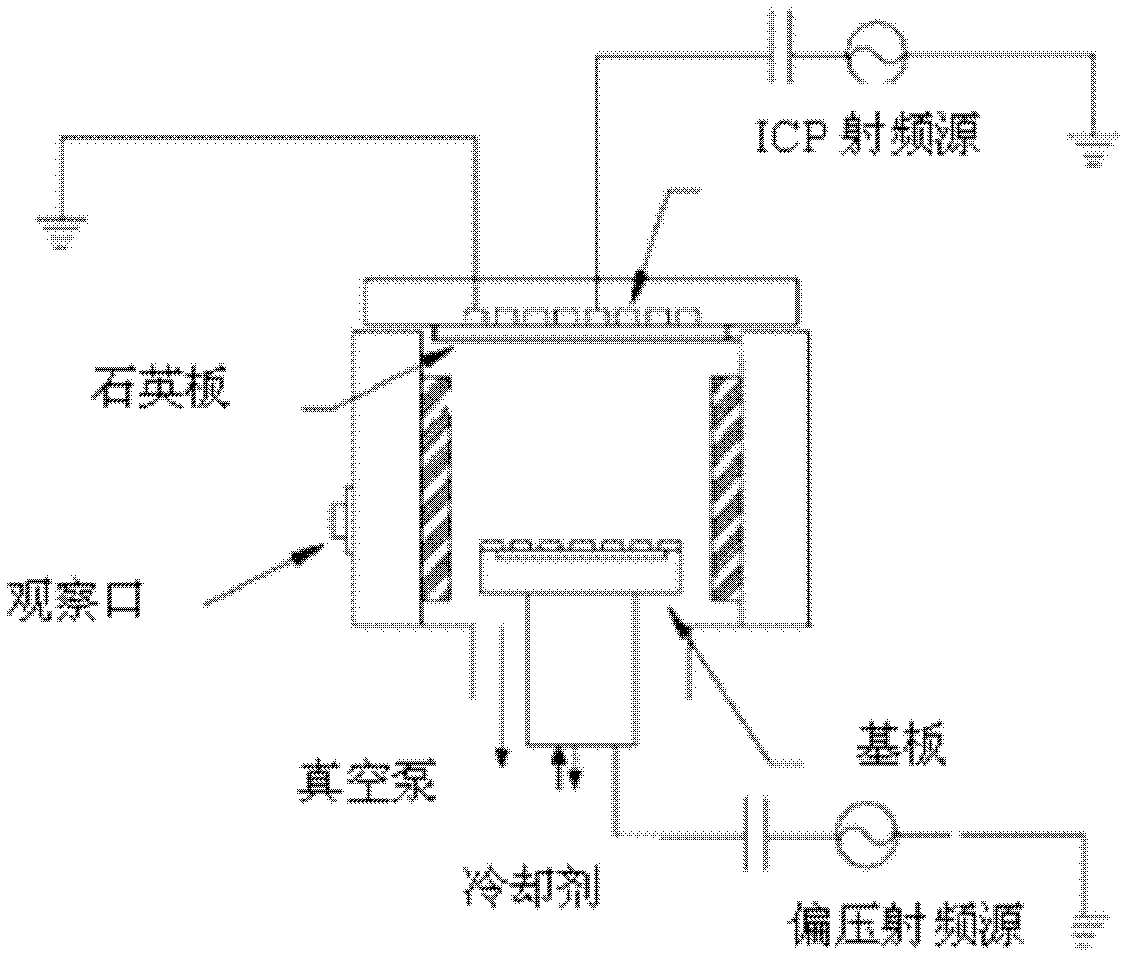

Preparation method of cubic silicon carbide film

ActiveCN104087909AReduce crystal defectsFast deposition rateChemical vapor deposition coatingCubic silicon carbideGas phase

The invention discloses a preparation method of a cubic silicon carbide film. The preparation method comprises the following steps of (1) placing a monocrystalline silicon substrate on a substrate seat of a cold-wall type laser induced chemical vapor deposition device, vacuumizing, and heating the substrate seat to 100-900 DEG C; (2) introducing HMDS-containing carrier gas to a reactor and regulating the vacuum degree to 10-10000Pa, wherein the flux of HMDS is 1-20sccm; (3) loading continuous laser to irradiate the surface of the silicon substrate at the wavelength of 750-1150nm and the power of 10-150W for 1-10min; (4) stopping the introduction of the HMDS-containing carrier gas, closing the laser, stopping heating, vacuumizing, and naturally cooling to room temperature to obtain the cubic silicon carbide film. A planar defect of the cubic silicon carbide film prepared by the invention trends to grow towards the growth direction of the film, and the self-disappearance phenomenon can be generated when adjacent defects meet, so that crystal defects in the material are effectively reduced.

Owner:武汉拓材科技有限公司

Method for preparing high-quality fine granules of energy-containing crystal material

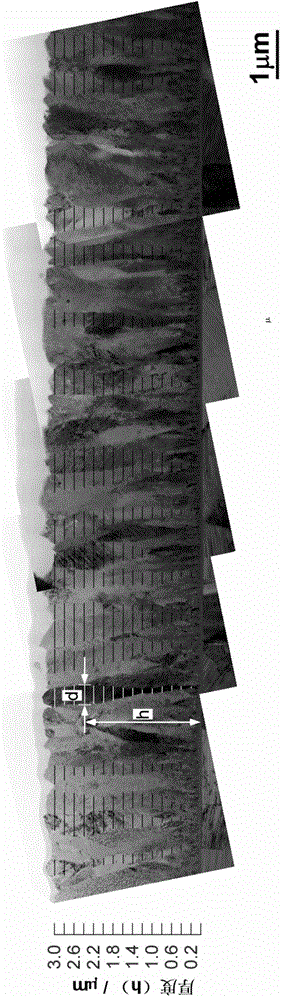

ActiveCN102230227AReduce crystal defectsHigh sphericityPolycrystalline material growthFrom normal temperature solutionsApparent densityMicrometer

The invention discloses a method for preparing high-quality fine granules of an energy-containing crystal material. In the core content of the method, the power ultrasound technology is introduced in the process of cooling crystallization, and a high-quality fine granular product, which has the average grain diameter of about between 10 and 50 micrometers, of the energy-containing crystal material is prepared by a method of ultrasound cooling crystallization, namely the method comprises the following steps of: (1) dissolving the ordinary energy-containing crystal material in different solvents at high temperature to form saturated crystallization solution; (2) cooling the crystallization solution according to a certain speed, and stirring and performing ultrasound processing; and (3) whenthe temperature of the crystallization solution is close to a given temperature, stopping the ultrasound processing, cooling and stirring, filtering, washing and drying to obtain the high-quality fine granular product of the energy-containing crystal material. In the method of ultrasound cooling crystallization, the high-quality fine granular product of the energy-containing crystal material has few defects and is good in appearance of the granules, high in sphericity and narrow in distribution of granularity, the apparent density of crystals reaches the theoretical density of the crystals ofmore than 99.9 percent, and the sensitivity of impact waves is reduced obviously.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

GaN SINGLE CRYSTAL SUBSTRATE AND METHOD OF MAKING THE SAME

InactiveUS20110163323A1Quality improvementImprove featuresPolycrystalline material growthSemiconductor/solid-state device manufacturingSingle crystal substrateOptoelectronics

The method of making a GaN single crystal substrate comprises a mask layer forming step of forming on a GaAs substrate 2 a mask layer 8 having a plurality of opening windows 10 disposed separate from each other; and an epitaxial layer growing step of growing on the mask layer 8 an epitaxial layer 12 made of GaN.

Owner:SUMITOMO ELECTRIC IND LTD

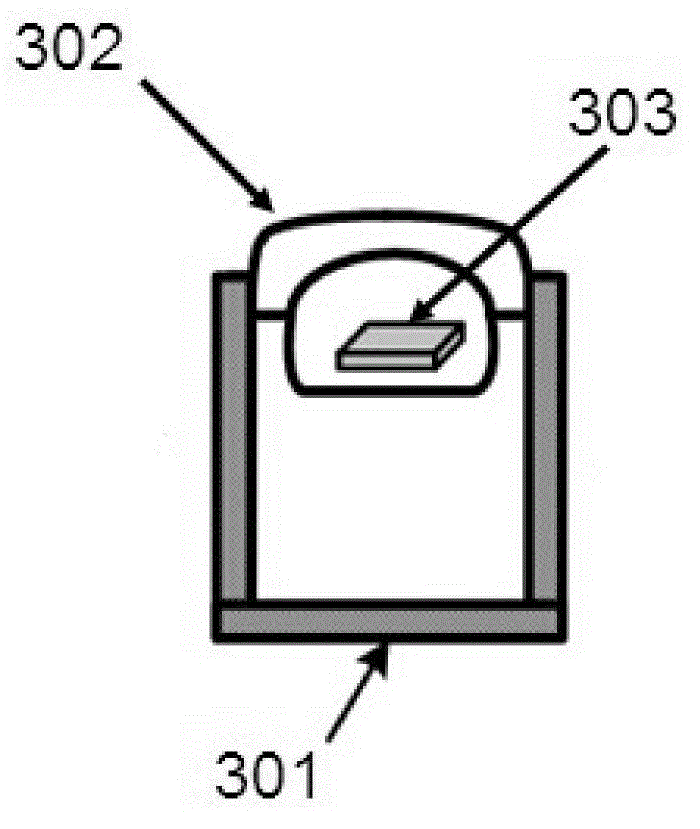

Perovskite solar cell with black phosphorus being hole transfer layer and preparation method thereof

ActiveCN106129256AGood chemical stabilityLow costFinal product manufactureSolid-state devicesTitanium disulfideHole transport layer

The invention provides a perovskite solar cell with black phosphorus being a hole transfer layer. A perovskite structure light-absorption layer, an electron transfer layer and a transparent conductive electrode are arranged in sequence on the black phosphorus hole transfer layer; and a positive electrode is prepared on the back surface of the black phosphorus hole transfer layer. The black phosphorus hole transfer layer, compared with an organic matter hole transfer layer, has more excellent chemical stability and lower cost, and improves output power and photoelectric conversion efficiency of the solar cell; and furthermore, titanium disulfide is doped in the black phosphorus hole transfer layer, and titanium disulfide molecules can be nested easily in defect positions of black phosphorus crystal, thereby reducing crystal defect of the black phosphorus hole transfer layer and furthermore, improving photoelectric conversion efficiency.

Owner:ANHUI HUASUN ENERGY CO LTD

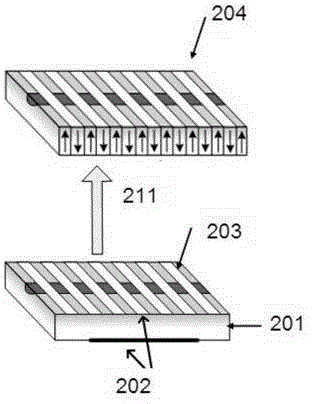

Periodically poled Ti-diffusion near-stoichiometry lithium niobate slab waveguide and preparation method

InactiveCN104536089AExcellent lossReduce crystal defectsOptical waveguide light guideStoichiometryChemistry

The invention discloses a preparation method of a periodically poled Ti-diffusion near-stoichiometry lithium niobate slab waveguide. The preparation method includes the eight steps of sample preparation, photoetching, sputtering of a Ti-metal film, stripping, pre-diffusion of the Ti-metal film, Li-rich VTE processing, polishing of an optical waveguide end surface and periodical poling. Compared with the prior art, the optical waveguide is good in performance, small in loss and good in optical uniformity, has a few crystal defects, has the unique advantages of being high in speed, low in noise, high in efficiency and free of chirping in the wavelength conversion process, converts multiple wave lengths downwards and upwards simultaneously at the same efficiency, and can realize fully transparent conversion.

Owner:TIANJIN UNIV

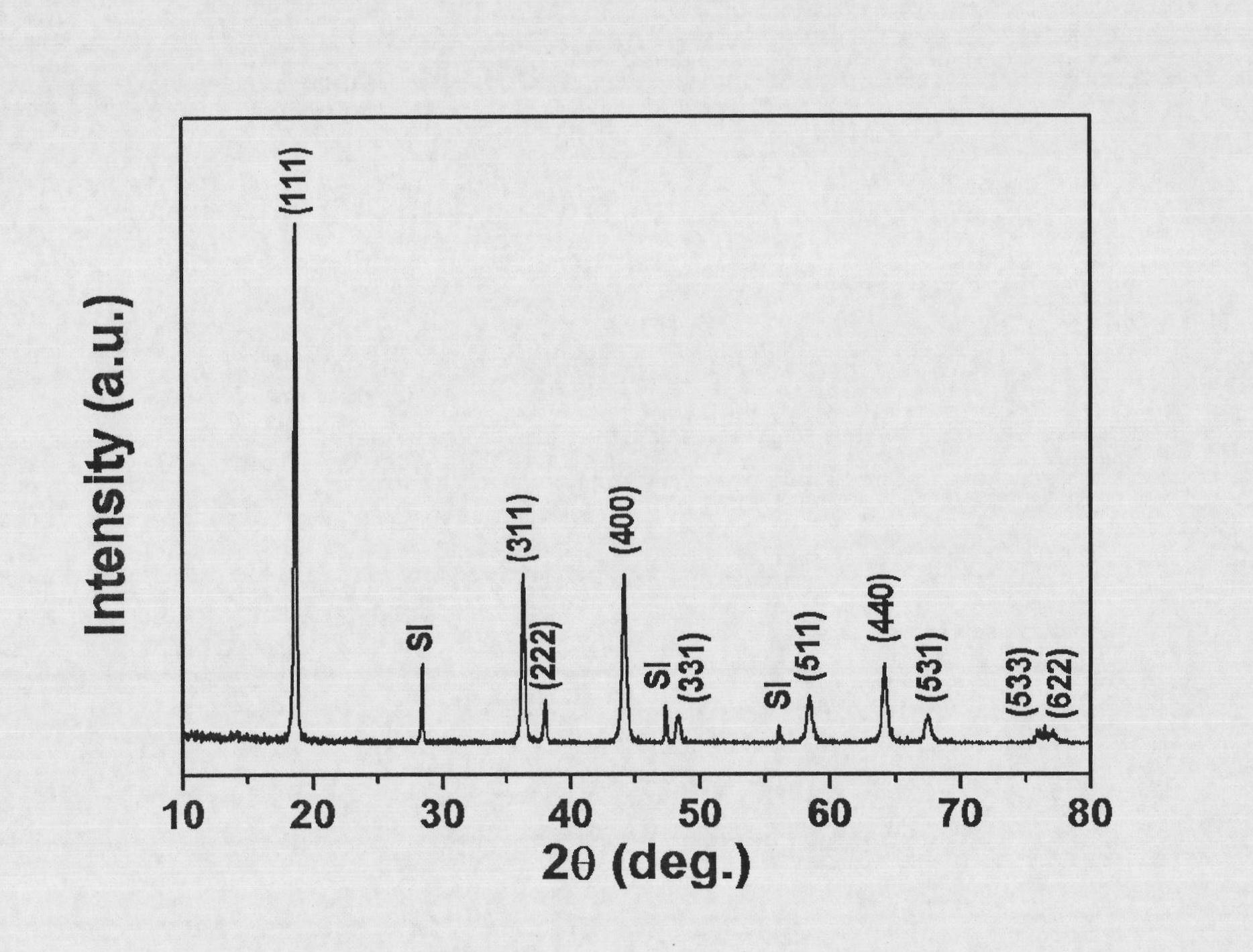

Preparation method of spinel type lithium manganate with high crystallinity used in lithium ion battery

InactiveCN101807686AReduce oxygen deficiencyImprove structural stabilityCell electrodesManganateLithium compound

The invention relates to a preparation method of spinel type lithium manganate with high crystallinity used in the lithium ion battery, comprising the following steps: (1) selecting the raw materials: selecting the battery grade electrolytic manganese oxide with the grain size of 3-25 mum and the battery grade Li-containing compound with the average grain size less than or equal to 8 mum and the impurity content less than or equal to 0.5%; (2) mixing the manganese oxide and the Li-containing compound evenly according to the Mn / Li mole ration of 1:0.56-0.58, ball milling and pressing into block mixture; (3) adding the mixture into the continuous sintering furnace, and heating under 730-810 DEG C with constant temperature for 12-24 h in the oxygen containing atmosphere with the oxygen content larger or equal to 30%; after the sintering reaction, cooling under the normal temperature in the continuous sintering furnace for 10-30 h, examining in grade and obtaining the product of Li1+xMn2O4, wherein 0<x<0.2. The method of the invention has simple process, and the crystallinity and the circulating performance of the product are improved with the enhancement of the oxygen content in the sintering atmosphere.

Owner:兰州金里能源科技有限公司

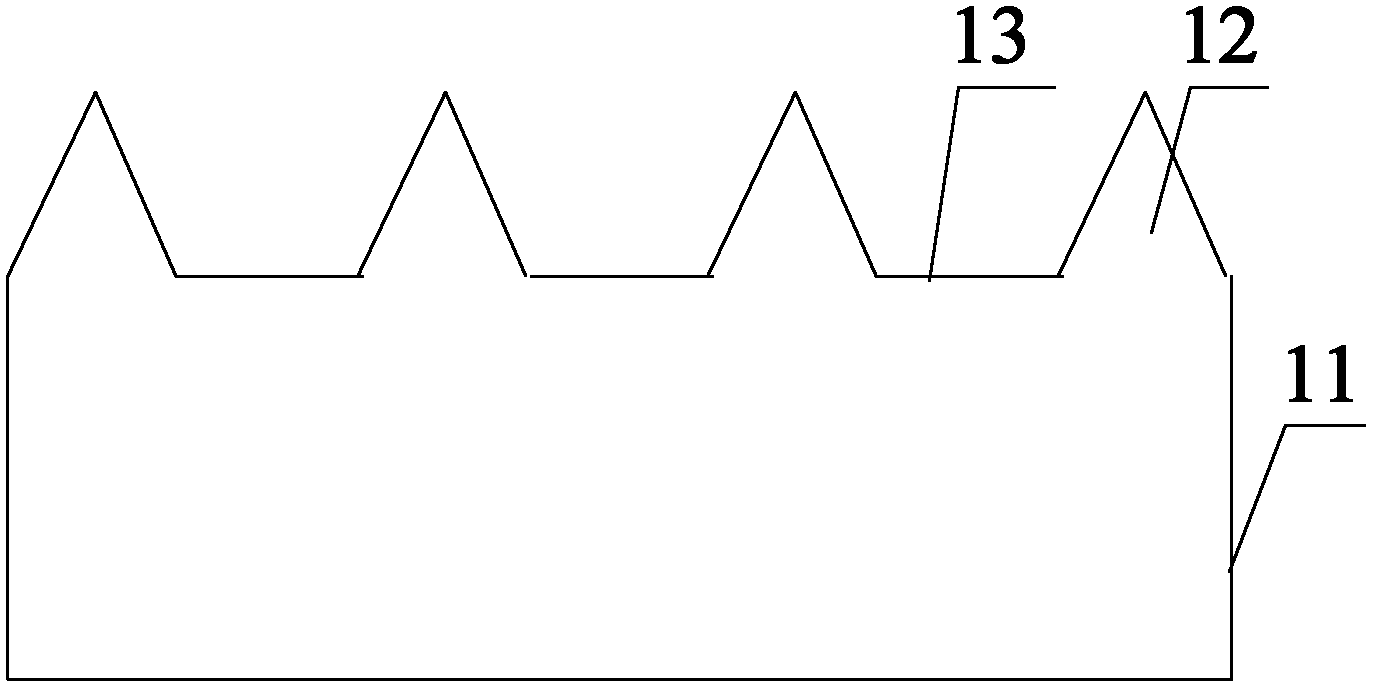

Patterned substrate for controlling gallium nitride nucleating growth position and preparation method thereof

ActiveCN102437258AReduce crystal defectsImprove crystal qualitySemiconductor devicesIonPatterned substrate

The invention provides a patterned substrate for controlling a gallium nitride nucleating growth position and a preparation method thereof. The method comprises the following steps that: the first-time etching is performed on a sapphire substrate, convex micro structures and clerance platforms which are periodically arranged are formed on the surface of the sapphire substrate, then fluoride ion is used for treating the surface of the patterned substrate on the basis of the characteristics that the sapphire has different physical properties and chemical properties in different crystallographic orientations, the surface of the convex micro structure in the fluoride ion is corroded into a coarse surface, the clearance platform between every two adjacent convex micro structures is not influenced, when extension of the patterned substrate after the surface treatment is grown, the convex micro structure surface is corroded into the coarse surface, no growth platform exists during the extension growth process, the nucleation cannot be formed; and since a large platform is arranged between the convex micro structures, a gap between the convex micro structures can be promoted to nucleat in the vertical direction. By adopting the extension layer which is grown in the above way, the flaw of the crystal is obviously reduced, the crystal quality can be improved, and the brightness of a chip can be improved.

Owner:EPILIGHT TECH

Process for producing single crystal of silicon carbide

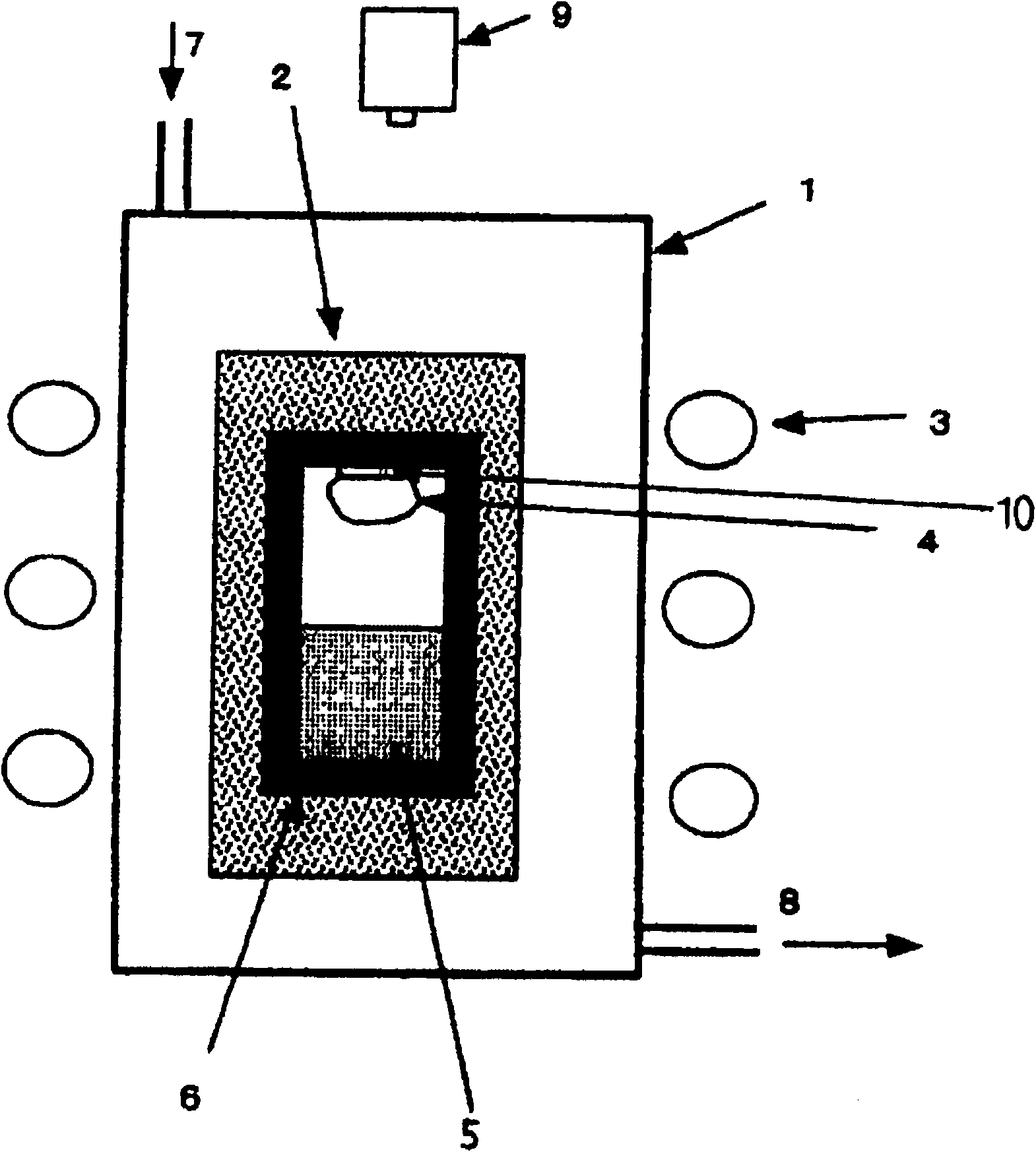

ActiveCN101553604AReduce crystal defectsHigh yieldAfter-treatment apparatusPolycrystalline material growthCrucibleRoom temperature

A process for producing a single crystal of silicon carbide which comprises setting a low-temperature region and a high-temperature region in a crystal-growth crucible (6), disposing a seed-crystal substrate made of a single crystal of silicon carbide in the low-temperature region of the crystal-growth crucible, disposing raw silicon carbide in the high-temperature region, and precipitating a sublimation gas formed from the raw silicon carbide on the seed-crystal substrate to grow a single crystal of silicon carbide. In the process, the crucible member where the seed crystal is disposed is a member which differs from silicon carbide in the coefficient of room-temperature linear expansion by 1.0x10 / DEG K or less. Silicon carbide may be used as the crucible member where the seed crystal is disposed.

Owner:RESONAC CORP

GaN single crystal substrate and method of making the same

InactiveUS7357837B2Quality improvementImprove featuresFrom gel statePolycrystalline material growthSingle crystal substrateOptoelectronics

The method of making a GaN single crystal substrate comprises a mask layer forming step of forming on a GaAs substrate 2 a mask layer 8 having a plurality of opening windows 10 disposed separate from each other; and an epitaxial layer growing step of growing on the mask layer 8 an epitaxial layer 12 made of GaN.

Owner:SUMITOMO ELECTRIC IND LTD

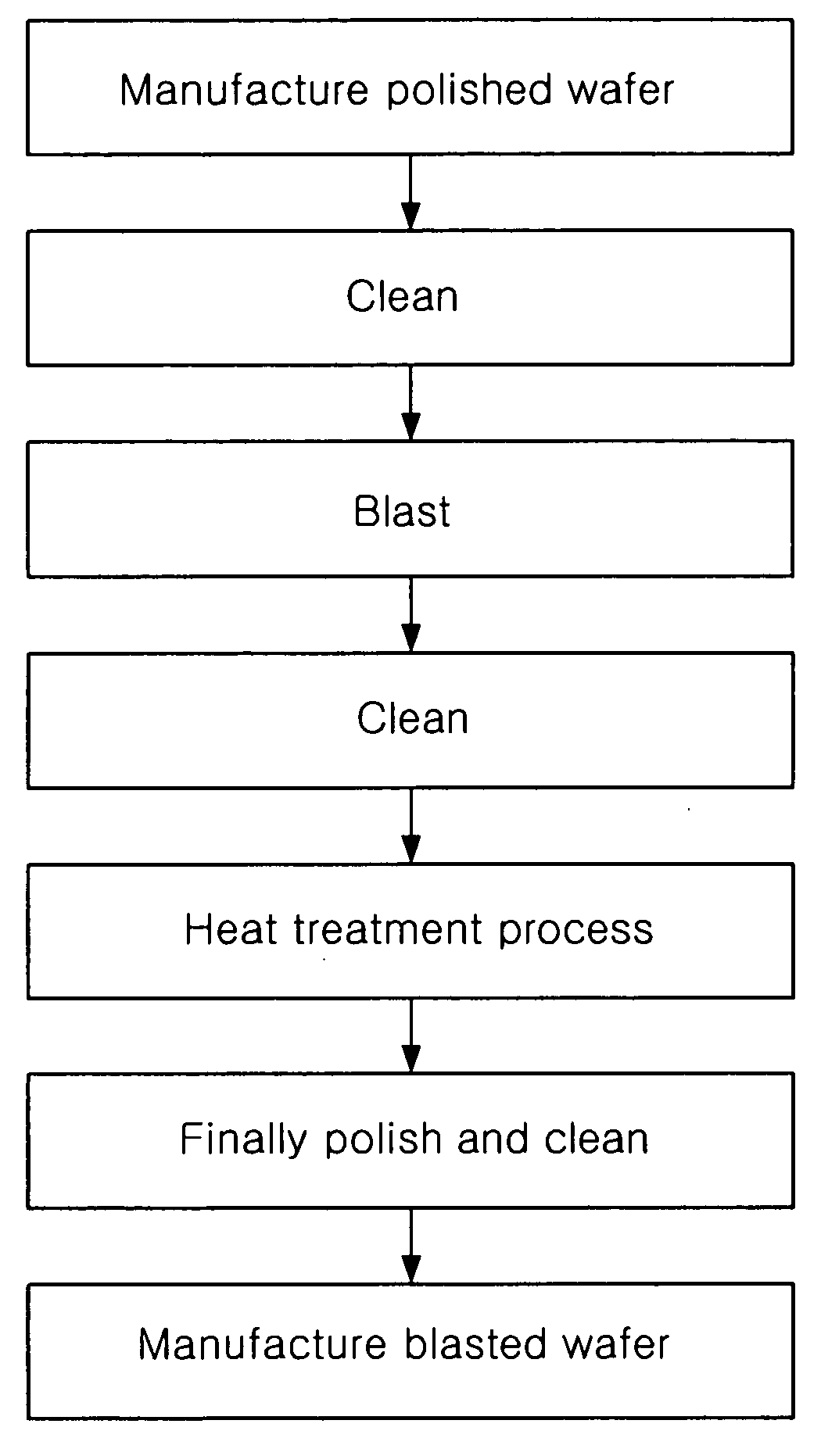

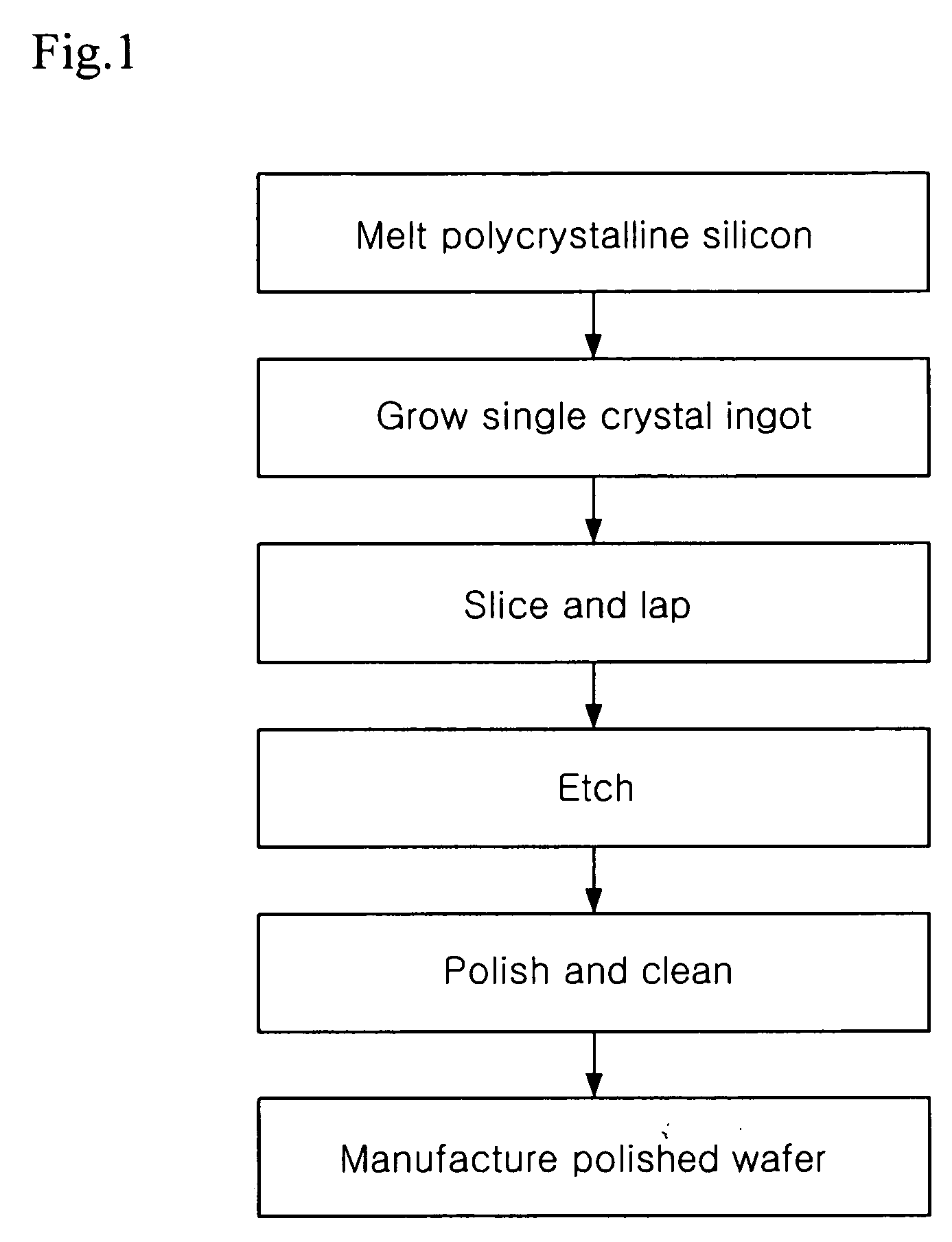

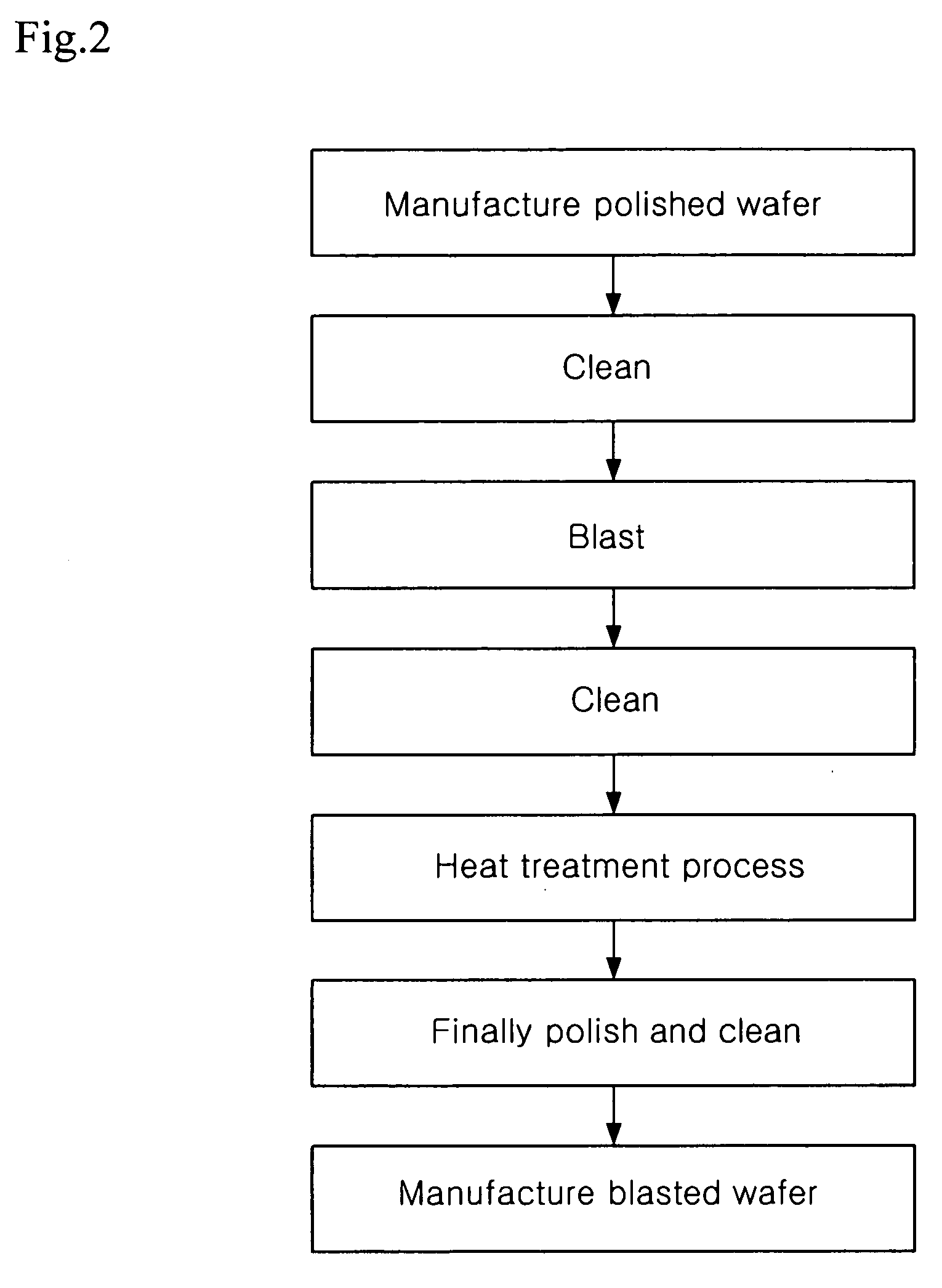

Production method of solar grade czochralski monocrystalline silicon

InactiveCN104328495AReduce crystal defectsIncrease distancePolycrystalline material growthBy pulling from meltChemistryMonocrystalline silicon

The invention discloses a production method of solar grade czochralski monocrystalline silicon, relating to the technical field of czochralski monocrystalline silicon. The production method comprises the following eight steps: charging, melting, stabilizing temperature, performing seeding, shouldering, performing constant-diameter growth, ending and the like. In a constant-diameter growth process, a phenomenon that the distance between the liquid level of a silicone liquid and a flow guide cylinder is unchanged can be ensured by adopting crucible rise compensation according to the change of the liquid level with the radian of a quartz crucible in a crystal pulling process, and in addition, diameter compensation can be increased according to the variation trend of diameters so as to control the tail diameter deviation within 2mm. The method disclosed by the invention is simple and convenient to operate and easy to implement, crystal defects possibly generated in a crystallization process can be effectively reduced, the problems of black chips and black corner sheets in czochralski monocrystalline silicon can be solved, the quality of monocrystals is improved, the service life of the monocrystals can be significantly improved, return of goods caused by product quality defects can be avoided, and unnecessary waste of money can be saved for enterprises.

Owner:XINGTAI JINGLONG ELECTRONICS MATERIAL

Bipolar plate material with TiNxOy coating deposited on surface of stainless steel and preparation method and application of bipolar plate material

PendingCN112144027AImprove corrosion resistanceBeautiful golden lusterFinal product manufactureVacuum evaporation coatingCoated surfaceThin membrane

The invention relates to a bipolar plate material with a TiNxOy coating deposited on the surface of stainless steel and a preparation method and application of the bipolar plate material. A preparation method of the surface-modified 304 stainless steel bipolar plate material comprises the following steps of by taking 304 stainless steel as a matrix, depositing a TiNxOy coating on the surface of the matrix by using a closed field non-equilibrium magnetron sputtering ion plating technology to obtain a thin-film stainless steel bipolar plate with high corrosion resistance. The surface-modified 304 stainless steel bipolar plate material is applied to a proton exchange membrane fuel cell bipolar plate. The coating is low in production cost and shorter in production period than a C coating, thesurface of the coating has ultra-high hardness and ultra-high elasticity modulus, meanwhile, the coating has better corrosion resistance and good conductivity than metal nitride, and the application standard of American DOE 2025 of proton exchange membrane fuel cell bipolar plates can be met.

Owner:ZHEJIANG UNIV OF TECH

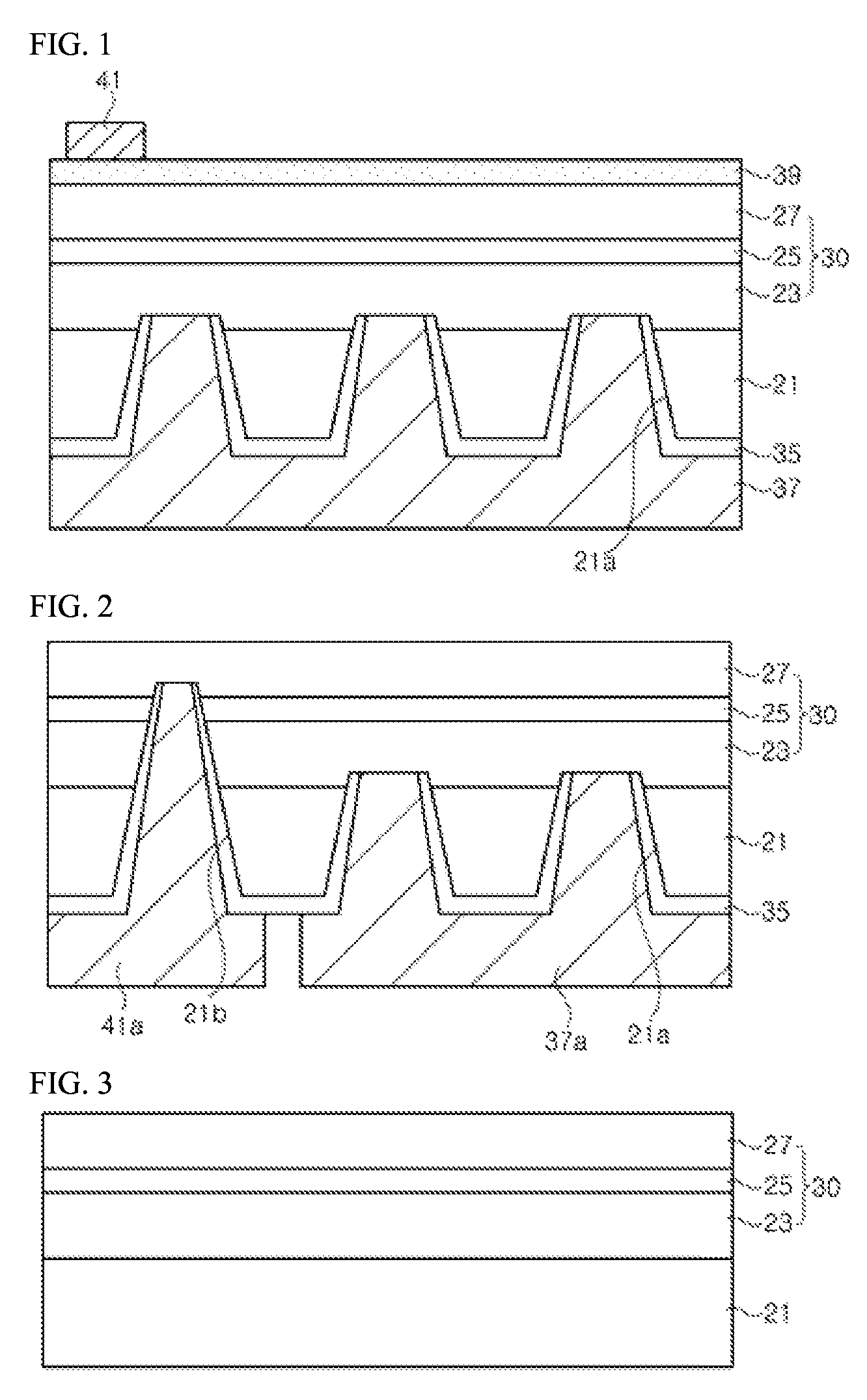

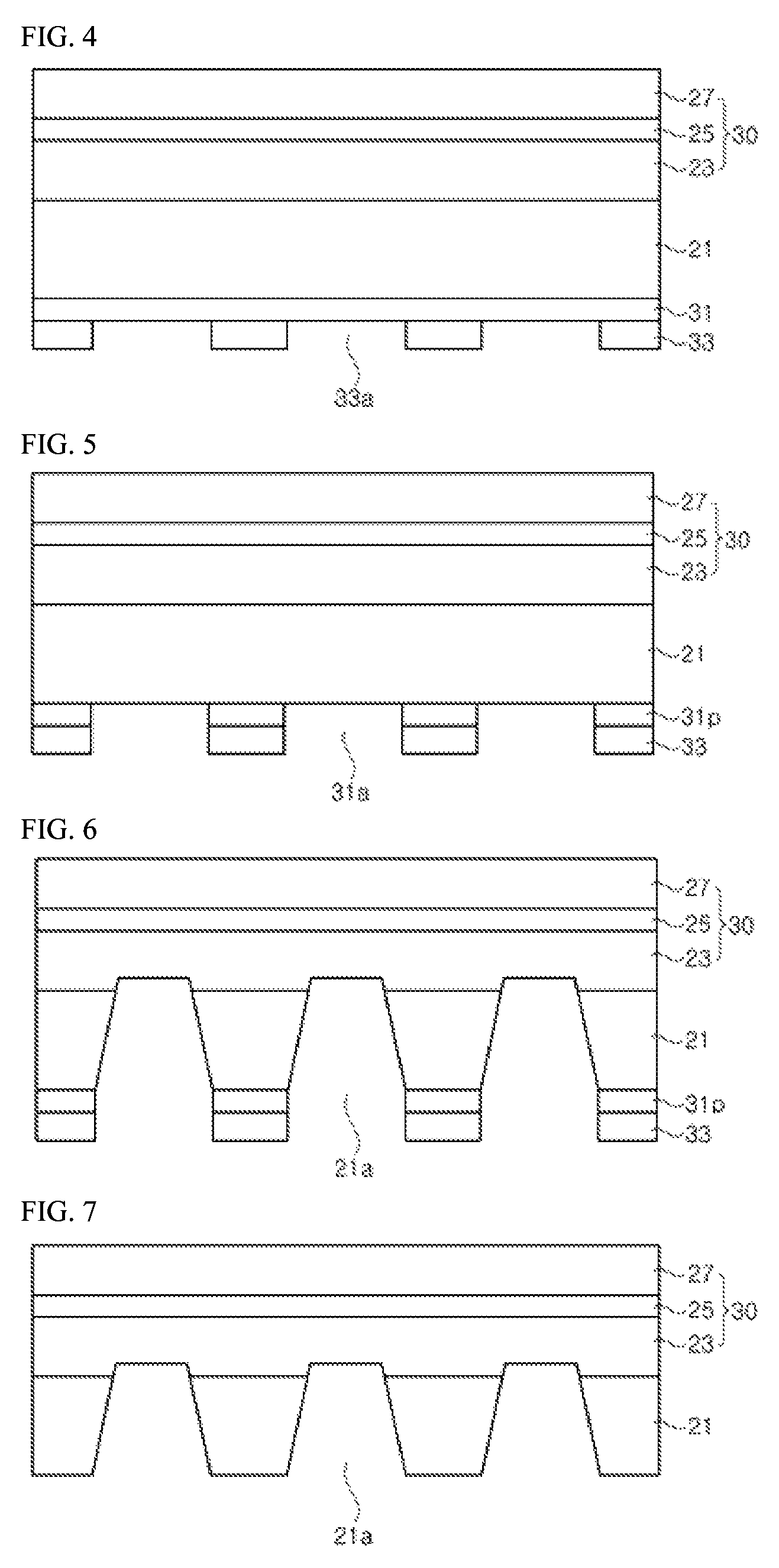

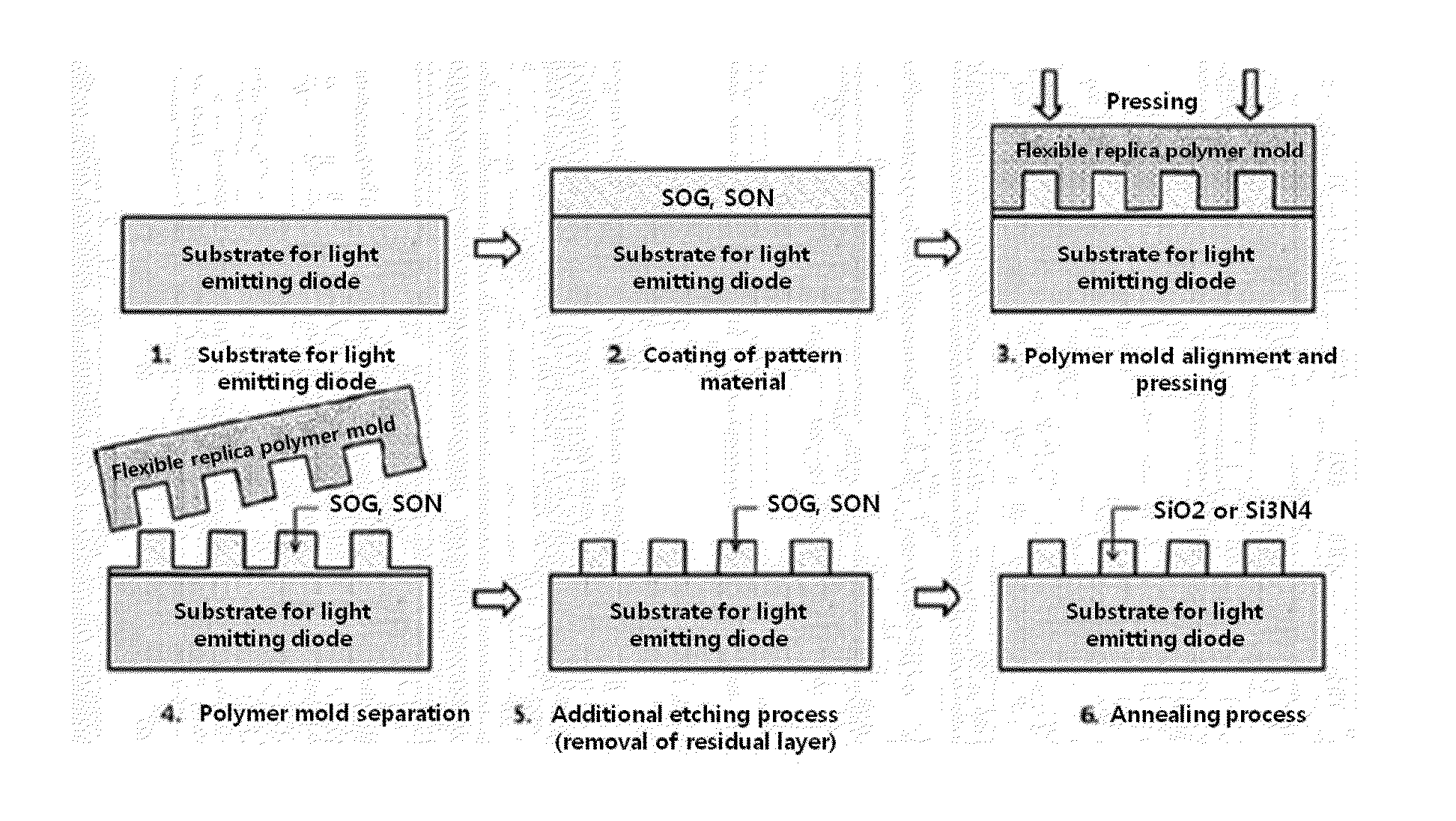

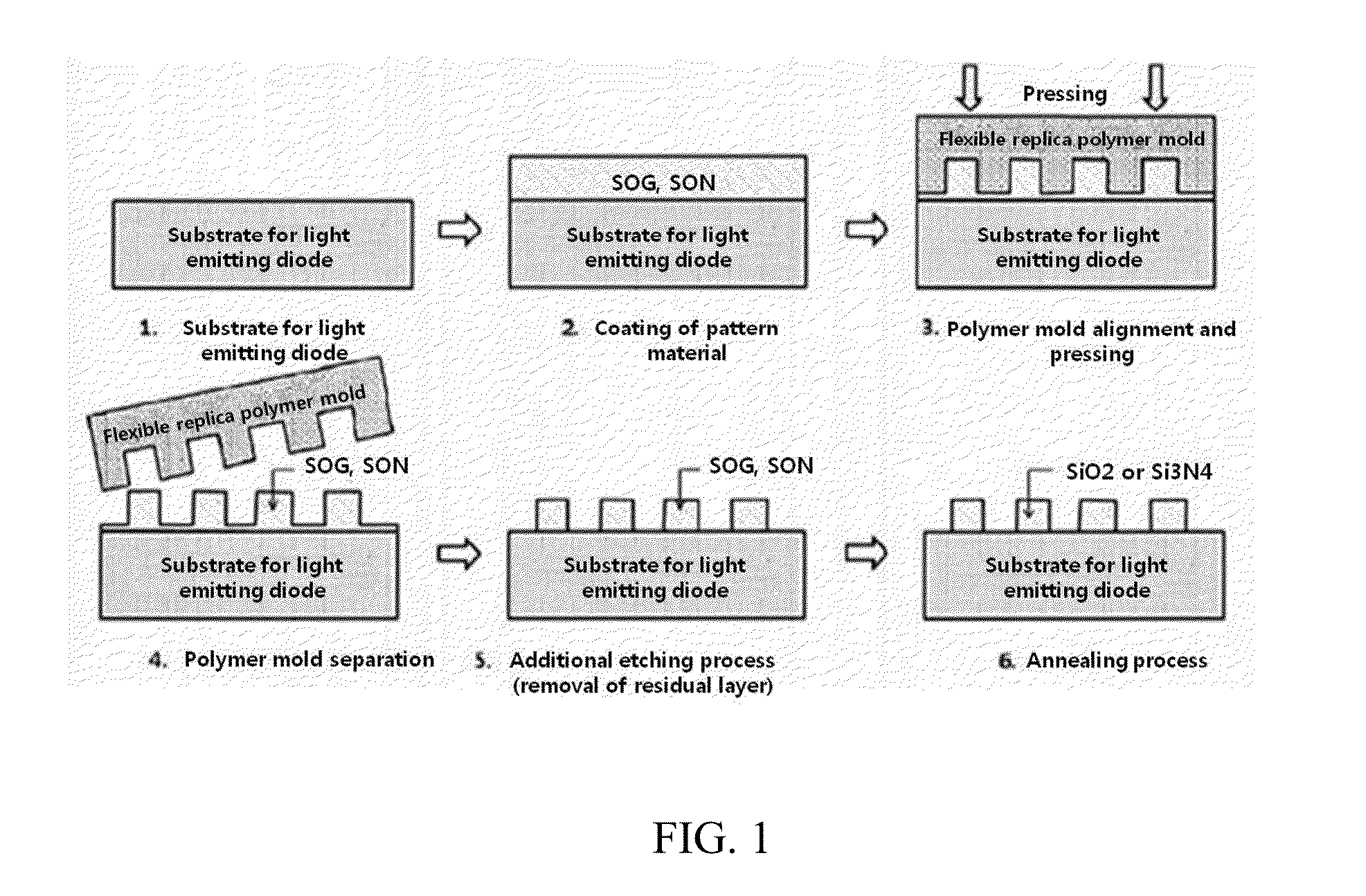

Method for fabricating nano-patterned substrate for high-efficiency nitride-based light-emitting diode

ActiveUS20150093847A1Improve production yieldIncrease production capacitySemiconductor/solid-state device manufacturingSemiconductor devicesPatterned substrateNitride

Provided is a method of manufacturing a substrate for a light emitting diode including a convex section forming step and a crystallization / crystallizing step. According to the method and the substrate for the light emitting diode, light extraction is significantly improved and nano to micron sized pattern, economically formed.

Owner:HUNET PLUS

Casting method for polycrystalline silicon ingot

ActiveCN104562193AUniform grainGrains are good for maintainingPolycrystalline material growthSingle crystal growth detailsCrystalliteSilicon nitride

The invention discloses a casting method for a polycrystalline silicon ingot. The casting method comprises the steps of charging, namely filling a crucible with a silicon nitride coating with a silicon material; heating, namely heating the crucible by using a polycrystalline furnace, wherein the crucible is obtained in the former step; melting and nucleating, namely melting the silicon material in the crucible through heating, and immediately opening a cage to cool when the silicon material floats from the bottom of the crucible to form a crystal nucleus; and growing a crystal, namely growing a silicon crystal. The polycrystalline silicon ingot produced by using the method disclosed by the invention has the characteristics of short production period, low cost, high silicon ingot quality and the like, and the obtained polycrystalline silicon wafer has the characteristics of uniform grain size, small defect density, high photoelectric conversion efficiency and the like.

Owner:YANGZHOU RONGDE NEW ENERGY TECH

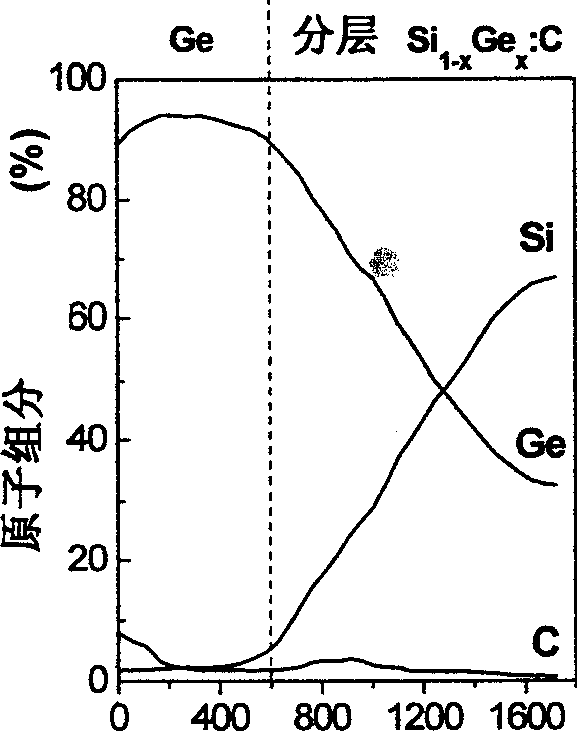

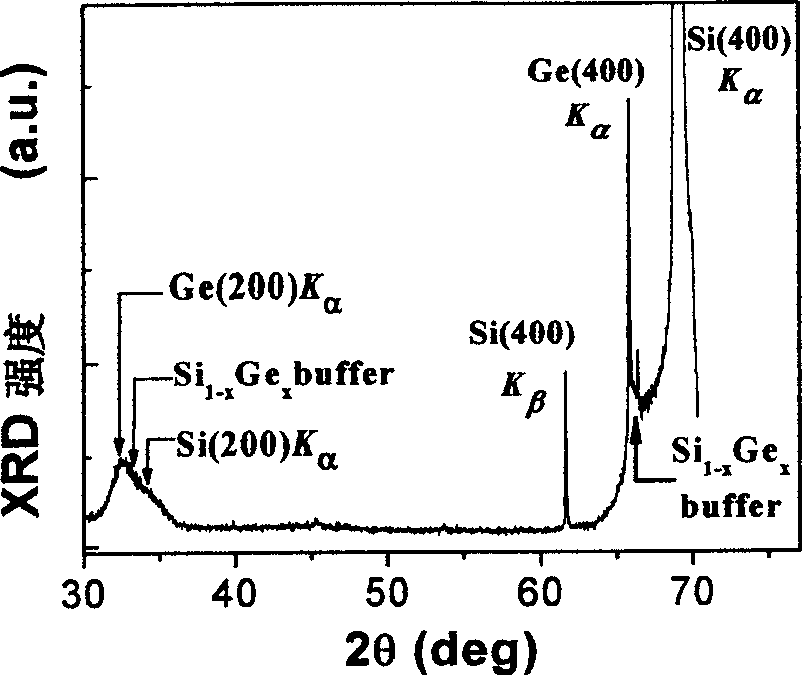

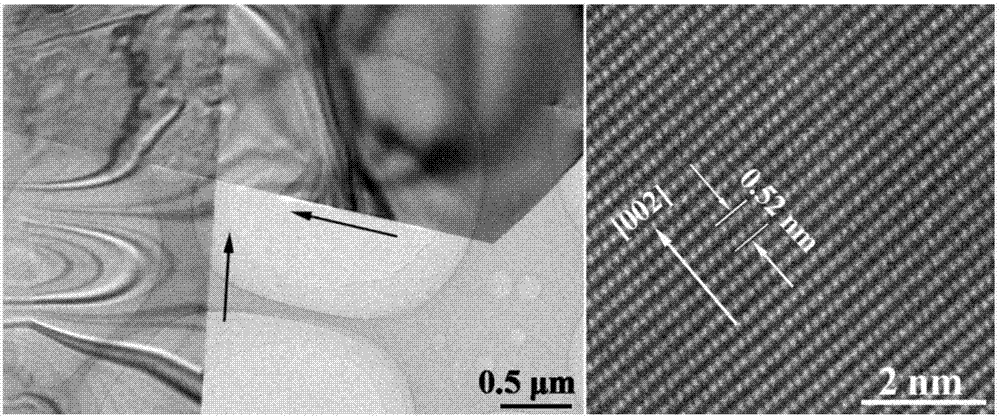

Method of chemical gas phase precipitation for growing carbon doped silicon germanium alloy buffer layer and germanium film

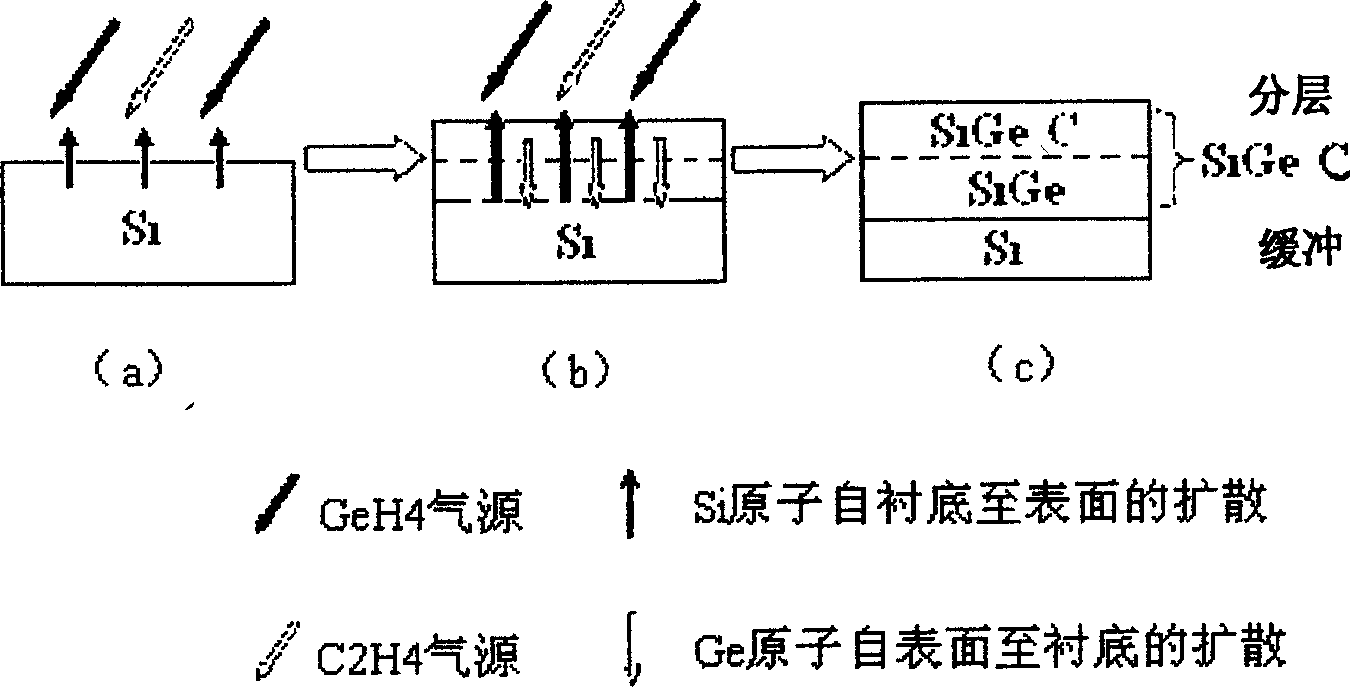

InactiveCN1800445AReduce crystal defectsReduce defectsChemical vapor deposition coatingSilicon alloyGas phase

The invention relates to a chemical gas phase deposition growth carbon germanium-silicon alloy isolating switch and growth germanium thin film method, which uses GeH4, C2H4 as reacting gas at 700-850 deg. and 10-100Pa compression intensity, wherein the C2H4 divider board is 0.01-0.15 Pa; the GeH4 divider board 0.10-1.10 Pa; the gas souse reactes with Si to combine the Ge of the epitaxial layer so that it generates a layer of Ge component anamorphic Si1-xGex: C buffer layer on the substrate surface with the thickness 0.5-10 micrometer; and then it generates Ge thin film especially at 400-600 deg and 15-100Pa compression intensity, wherein the GeH4 divider board is 0.07-1.11Pa.

Owner:NANJING UNIV

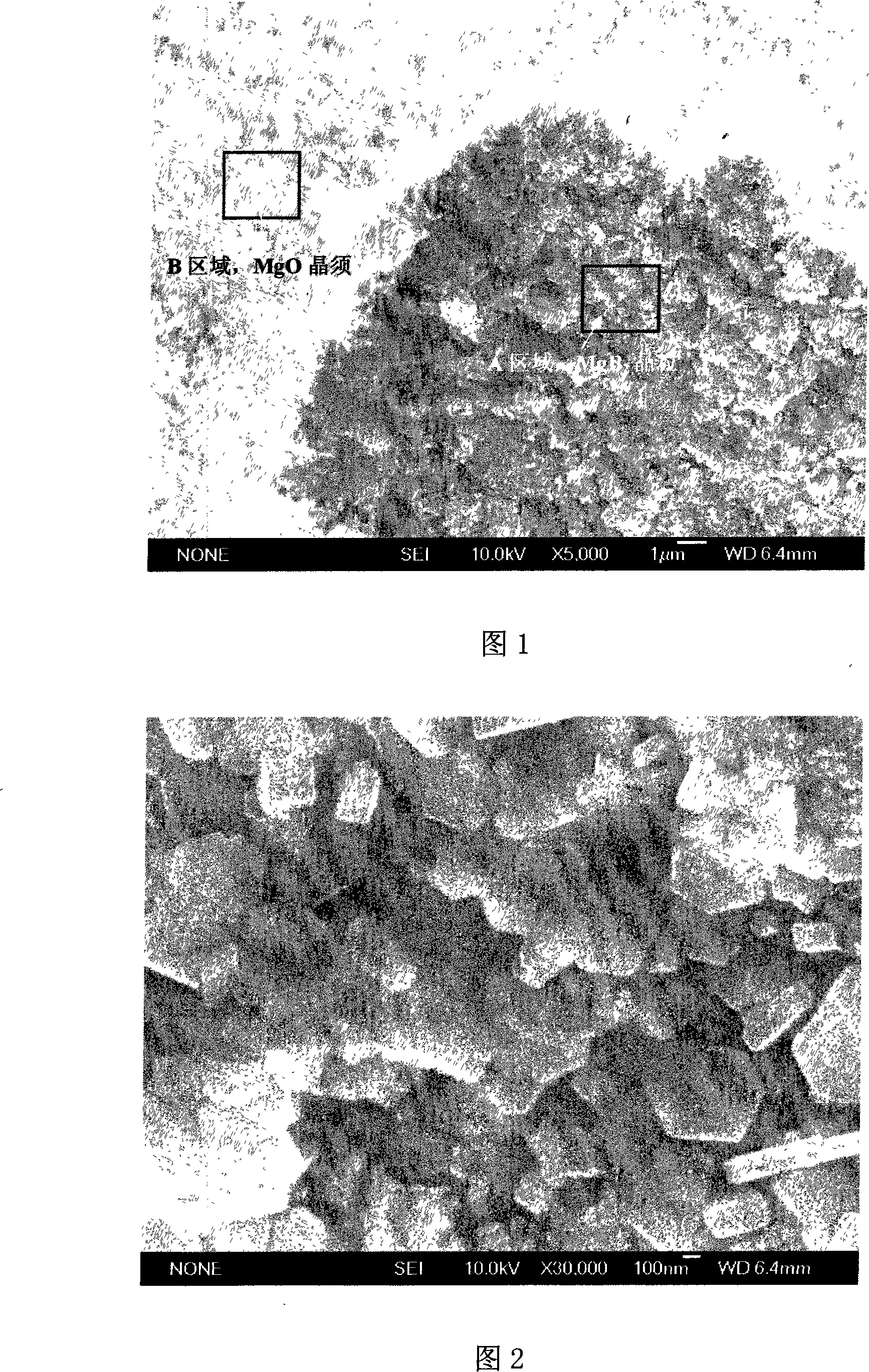

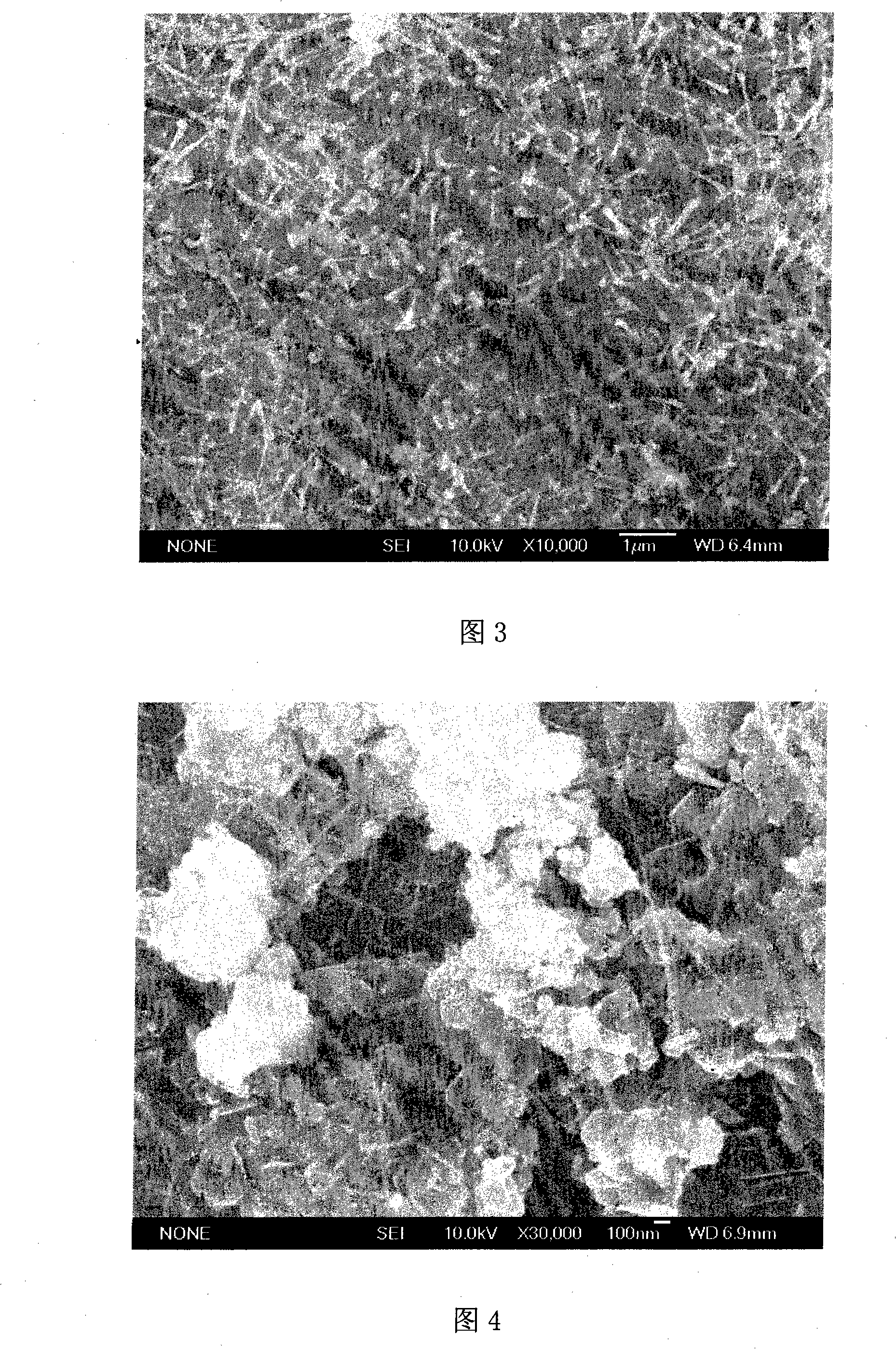

Low-temperature method for manufacturing nano-MgO crystal whisker

InactiveCN101220516AControl supersaturationControl shapePolycrystalline material growthFrom chemically reactive gasesCrucibleRoom temperature

The invention relates to a method for preparing nanometer MgO whiskers at the low temperature and the method is that magnesium powders and amorphous boron powders are mixed according to atomic ratio of MG:B being equal to 1 to 1.5:2 and the mixture is grinded for 30 to 120 minutes for thorough mixing, and after the mixed powders are made into a lump sinter under the pressure of 5 to 10 kg / cm<3> by a press machine, the lump sinter is put into a crucible which is put into a heating zone of an evacuated tubular furnace. The evacuated tubular furnace is sealed, vacuumized to 1 to 10 Pa and filled with argon the oxygen content of which is 2 percent to 5 percent and the flow rate of the mixed gas is 5 to 20 lit. per minute to heat the sample up to 650 to 750 DEG C at the heating rate of 5 to 20 K per minute, and the sample is decreased to the room temperature at the same heating rate after the temperature is kept for 0 to 120 minutes. The surface of the sample forms nanometer MgO whiskers with various appearances and sizes. When reaching 650 DEG C, magnesium evaporates and reacts with the little filled oxygen to produce MgO vapour, and under the lower over-saturation state, MgO whiskers are deposited on a substrate. The method for preparing MgO whiskers needs temperature much lower than the previous and greatly increases the practicality of preparing MgO whiskers.

Owner:TIANJIN UNIV

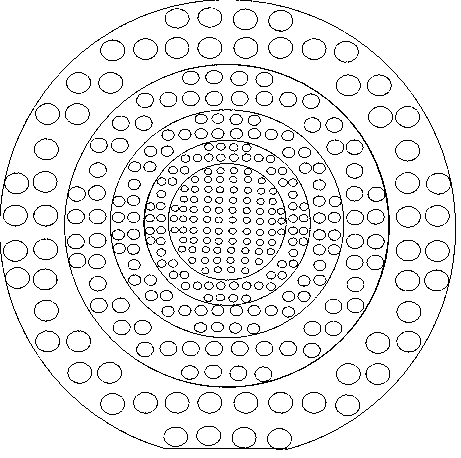

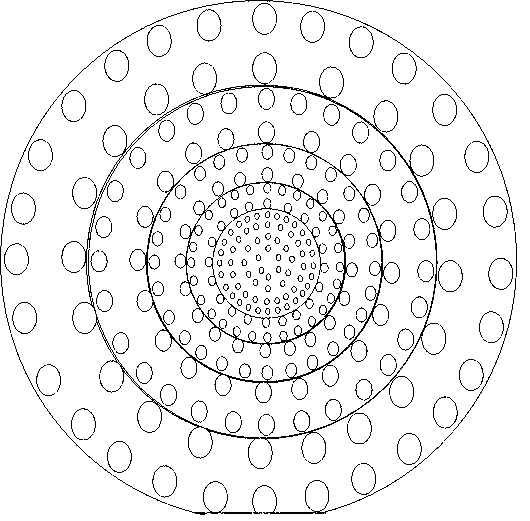

Light emitting diode provided with patterned substrate

InactiveCN103050596AReduce residual stressReduce crystal defectsSemiconductor devicesCrystallographic defectPatterned substrate

The invention provides a light emitting diode provided with a patterned substrate. The substrate is divided into 5-8 concentric circular areas with the center as the center of a circle. The distance from the size of a pattern in a same circular area to the pattern is equal, and the distances of the sizes of the patterns in different circular areas to the patterns are increased sequentially from inside to outside. According to the invention, the residual stress in the epitaxial growth process can be reduced, the crystal defect is reduced, and the internal quantum efficiency is improved, so that, the wavelength uniformity of a chip is improved, the chip leakage is improved, and the brightness of the chip is improved. The technology has a more remarkable effect when a large growth substrate is used, so that the warpage of the light emitting diode can be reduced.

Owner:DALIAN MEIMING EPITAXIAL WAFER TECH

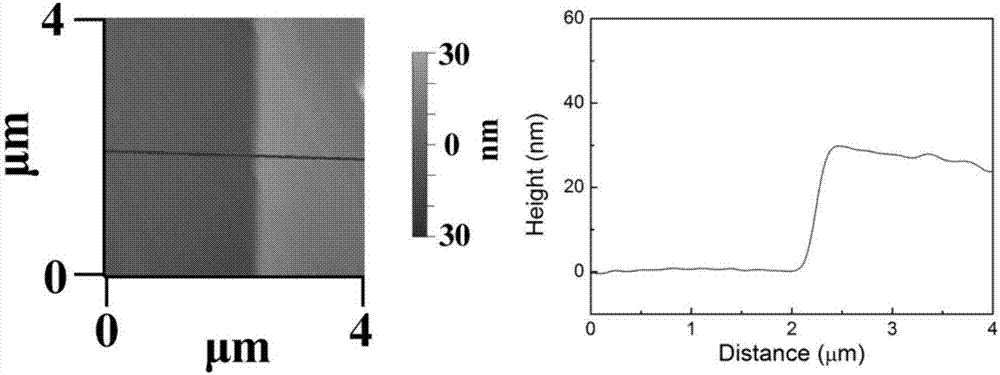

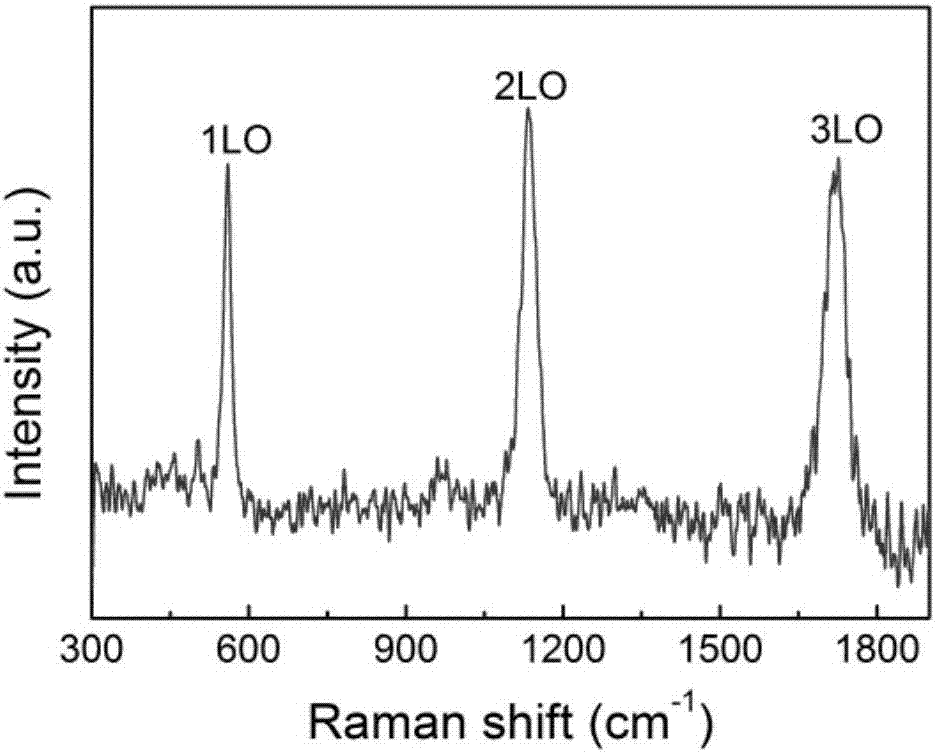

Manufacturing method for high sensitivity semiconductor nano ultraviolet light detector

InactiveCN106898664AHigh speedHigh sensitivityFinal product manufactureSemiconductor devicesUltraviolet lightsSingle crystal

The invention discloses a manufacturing method for a high sensitivity semiconductor nano ultraviolet light detector. According to the method, firstly, a two-dimensional ultrathin structure monocrystalline ZnO nano material is manufactured; the two-dimensional ultrathin structure monocrystalline ZnO nano material is transfered from a growth substrate; the two-dimensional ultrathin structure monocrystalline ZnO nano material is mixed with organic solution or deionized water; ultrasonic dispersion of the two-dimensional ultrathin structure monocrystalline ZnO nano material solution is carried out; the two-dimensional ultrathin structure monocrystalline ZnO nano material solution is coated on a surface of a semiconductor, insulation and conductive substrate; along a length direction of the two-dimensional ultrathin structure monocrystalline ZnO nano material, and conductive metal electrodes are plated at two ends; a mask is utilized to cover the two-dimensional ultrathin structure monocrystalline ZnO nano material, an insulation oxide covering layer is plated, an insulation oxide half-covering or symmetric covering structure is formed, and the two-dimensional ultrathin structure monocrystalline ZnO nano ultraviolet light detector is acquired. The method has advantages of simple structure, small volume, rapid response and high sensitivity.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

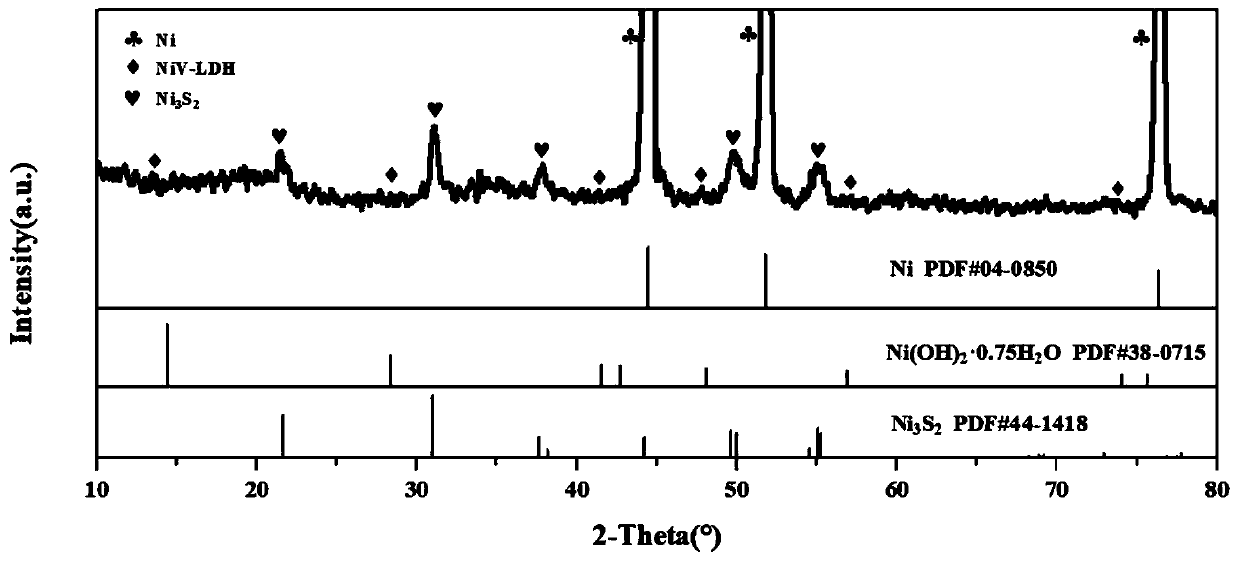

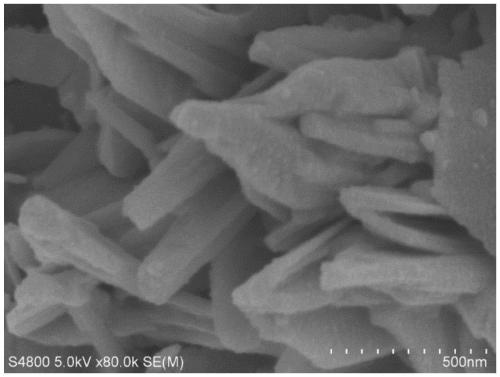

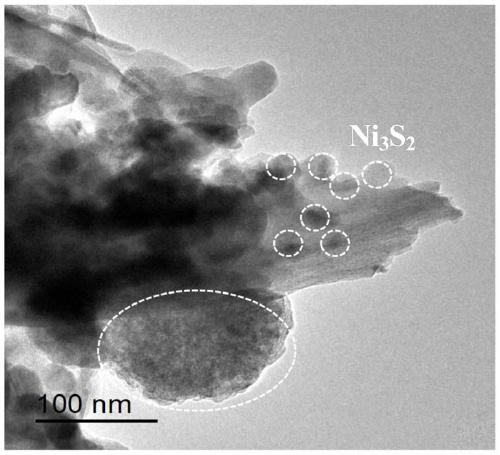

Preparation method of Ni3S2/NiV-LDH heterogeneous nanocone electrocatalyst

ActiveCN111468140ALarge electrochemical active areaGood for material stabilityCatalyst activation/preparationElectrodesHydrogen productionSolvothermal reaction

The invention relates to a preparation method of a Ni3S2 / NiV-LDH heterogeneous nanocone electrocatalyst, which adopts a hydrothermal-solvothermal method to prepare the electrocatalyst, and comprises the following steps: soaking foamed nickel in an aqueous solution containing a nickel source, a vanadium source and an alkali source, and carrying out hydrothermal reaction to obtain a precursor with ananosheet array structure; preparing a Ni3S2 / NiV-LDH heterogeneous nanocone electrocatalyst through immersing the precursor in an isopropanol solution containing an organic sulfur source and carryingout a solvothermal reaction, wherein the Ni3S2 / NiV-LDH heterogeneous nanocone electrocatalyst is formed by covering a foamed nickel substrate with a nanoscale morphology formed by embedding a large amount of Ni3S2 nanoparticles into the surface of NiV-LDH pyramids. The method provided by the invention is mild in condition; produced products are uniform in morphology, the pyramidal structure can significantly increase the electrochemical active area, nickel sulfide has low overpotential, the embedding of the nanoparticles can effectively increase the length of the edge state to increase the number of active sites, and the interlacing of the nanocones facilitates the improvement of the stability of the material and greatly improves the electro-catalytic hydrogen production and oxygen production activity of the material.

Owner:SHAANXI UNIV OF SCI & TECH

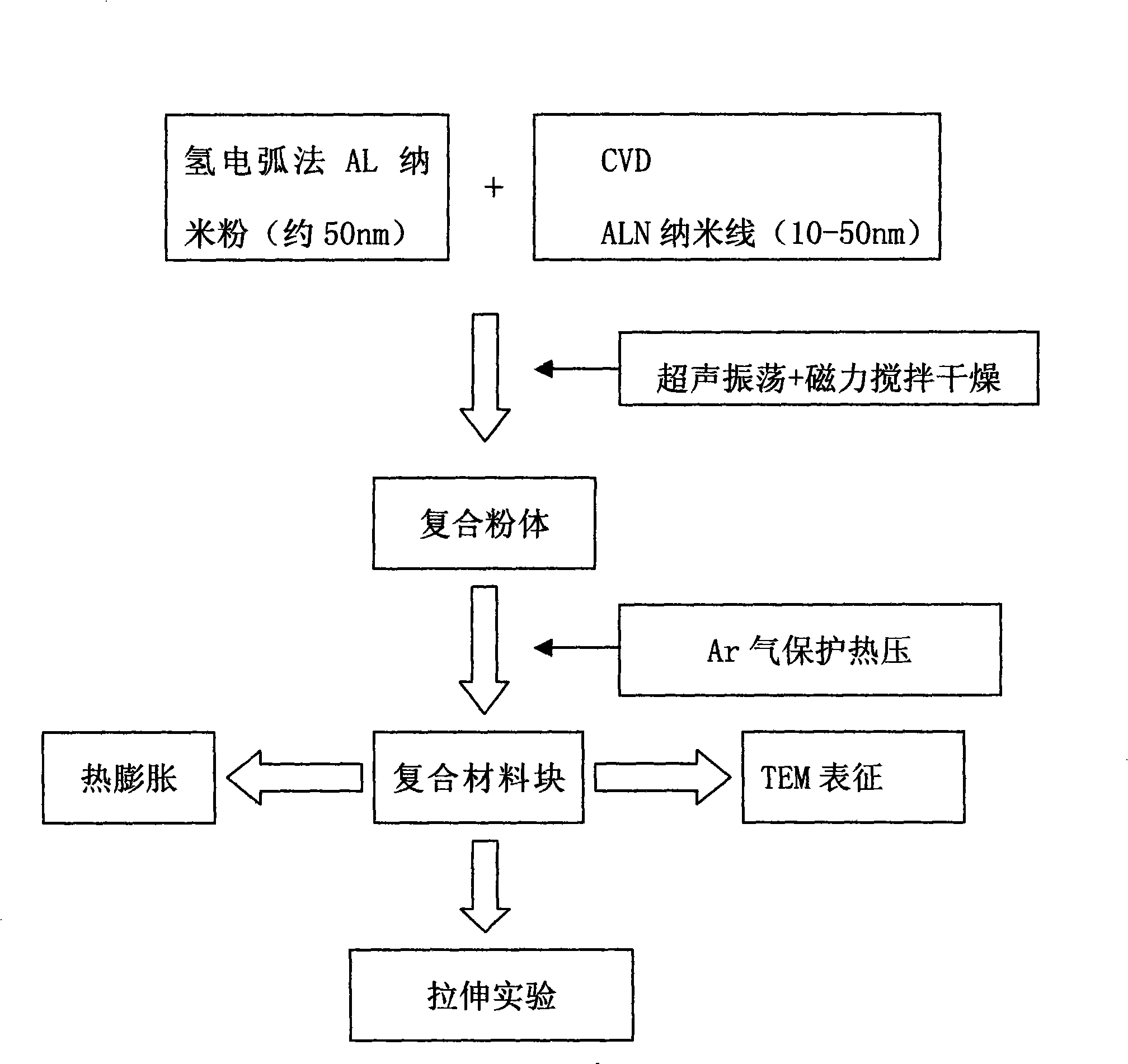

High-strength low thermal expansion A1N nano wire and A1 composite material

The present invention relates to a high-strength low-thermal-expansion AlN nano-wire and an Al composite material. On the basis of AlN nano-wire with a purity of more than 95%, a high-density AlN nano-wire / Al composite material is prepared by melting point hotpressing method, Al nano-grains are prepared by H2 by arc discharge method; with Al, AlCl3, Al2O3 and NH3 as the reactants, AlN nano-fiber at gram level is deposited on a quartz substrate by gas phase CVD method, which is a monocrystalline AlN nano-wire with a purity of 95%, the diameter is between 10nm and 50nm, 1-15% by volume of AlN nano-wire and Al nano-grains are uniformly mixed, the dried mixing powder is hotpressed into a block. AlN nano-wire is evenly dispersed in a matrix, the interface is well bonded, AlN nano-wire is an idea intensifier for optimizing the force property and thermophysical property of metal-matrix electronic composite material, the AlN nano-wire and Al composite material are hopeful to be high-strength low-thermal-expansion new electronic packaging material.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Semiconductor structure with rare earth oxide

ActiveCN102903739AImprove integration densityRealize 3D integrationSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureThree dimensional integration

The invention provides a semiconductor structure with a rare earth oxide. The semiconductor structure comprises a semiconductor substrate, and multiple isolation oxide layers and multiple single crystal semiconductor layers which are formed on the semiconductor substrate and are alternately stacked, wherein the materials of the isolation oxide layer contacted with the semiconductor substrate are rare earth oxide or silicon dioxide, and the materials of other isolation oxide layers are single crystal rare earth oxide. According to the semiconductor structure provided by the embodiment of the invention, through lattice matching between the isolation oxide layers and the single crystal semiconductor layers, the crystal defect of the semiconductor structure can be obviously reduced, so that a three-dimensional semiconductor device with high performance and high density can be further formed on the semiconductor structure, the integrated density of the device is greatly improved, and simultaneously, the three-dimensional integration of different devices can also be realized.

Owner:TSINGHUA UNIV

LED (light-emitting diode) and manufacturing method thereof

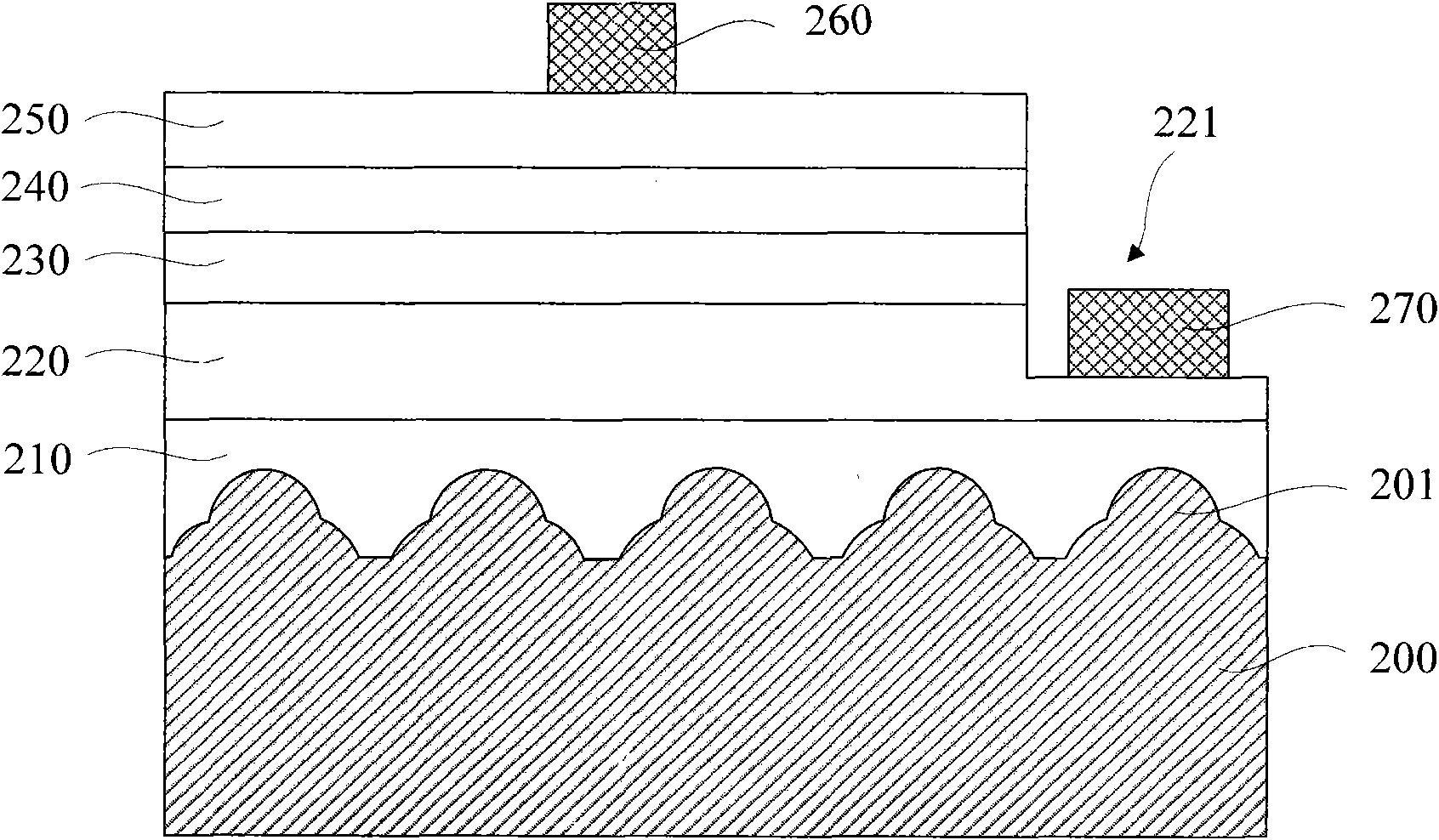

InactiveCN102024898AImprove external quantum efficiencyImprove light utilizationSemiconductor/solid-state device manufacturingSemiconductor devicesQuantum efficiencyCrystallographic defect

The invention discloses an LED (light-emitting diode) and a manufacturing method thereof, wherein the LED comprises a sapphire substrate, an epitaxial layer, an active layer and a cap layer, which are sequentially positioned above the sapphire substrate, wherein, a plurality of bifocal lenticule structures are arranged on the surface of the sapphire substrate, which is near to the epitaxial layer. The bifocal lenticule structures can increase the reflection of light of the sapphire substrate, improve external quantum efficiency of the LED, and further improve light utilization ratio of the LED; moreover, as a plurality of bifocal lenticule structures are formed, lattice matching degree between the sapphire substrate and other membranous layers can be improved, the crystal defect of the membranous layers formed on the sapphire substrate is reduced, and internal quantum efficiency of the LED is improved.

Owner:XIAN SHENGUANG ANRUI PHOTOELECTRIC TECH

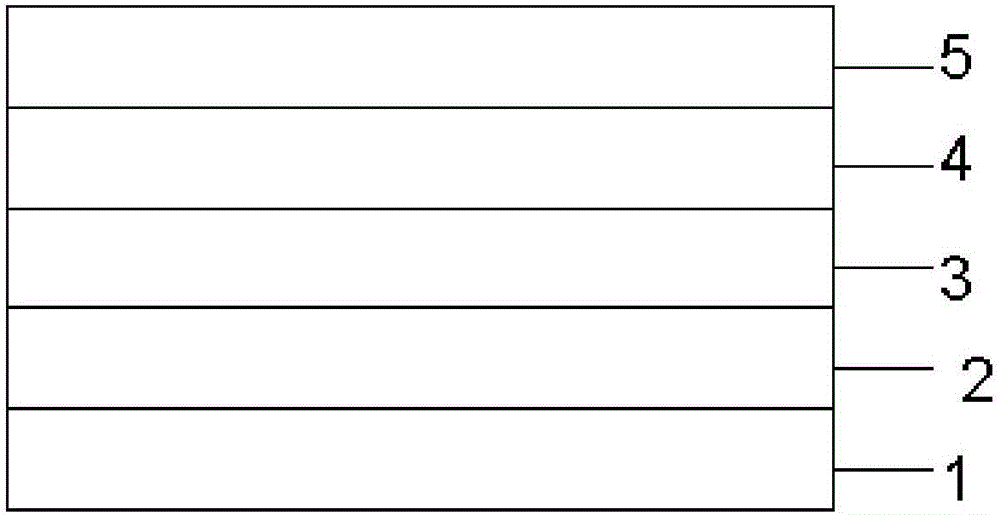

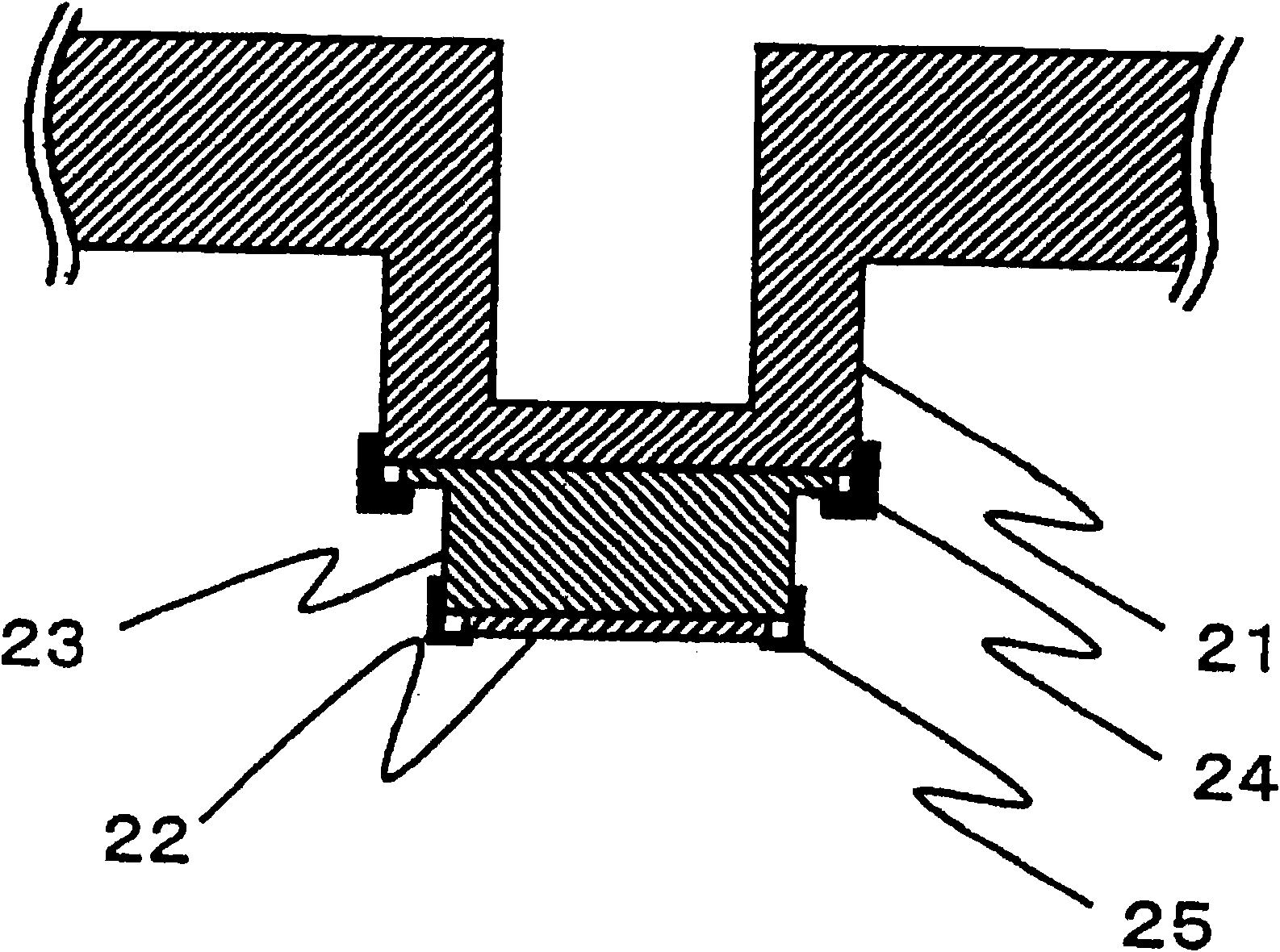

Gallium nitride semiconductor and method of manufacturing the same

ActiveUS20060145187A1Reduce crystal defectImprove performancePolycrystalline material growthSemiconductor/solid-state device manufacturingManufacturing cost reductionGallium nitride

The present invention provides to a gallium nitride (GaN) semiconductor and a method of manufacturing the same, capable of reducing crystal defects caused by a difference in lattice parameters, and minimizing internal residual stress. In particular, since a high-quality GaN thin film is formed on a silicon wafer, manufacturing costs can be reduced by securing high-quality wafers with a large diameter at a low price, and applicability to a variety of devices and circuit can also be improved.

Owner:LG SILTRON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com