Method for preparing high-quality fine granules of energy-containing crystal material

A crystal material and high-quality technology, applied in the field of energetic crystal material preparation, can solve the problems of not meeting the requirements of explosive fine particle products, difficulty in preparing fine particle products, increasing the process, etc., achieving high sphericity, reduced shock wave sensitivity, Effect of narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: Ultrasonic cooling crystallization of RDX in butyrolactone solvent

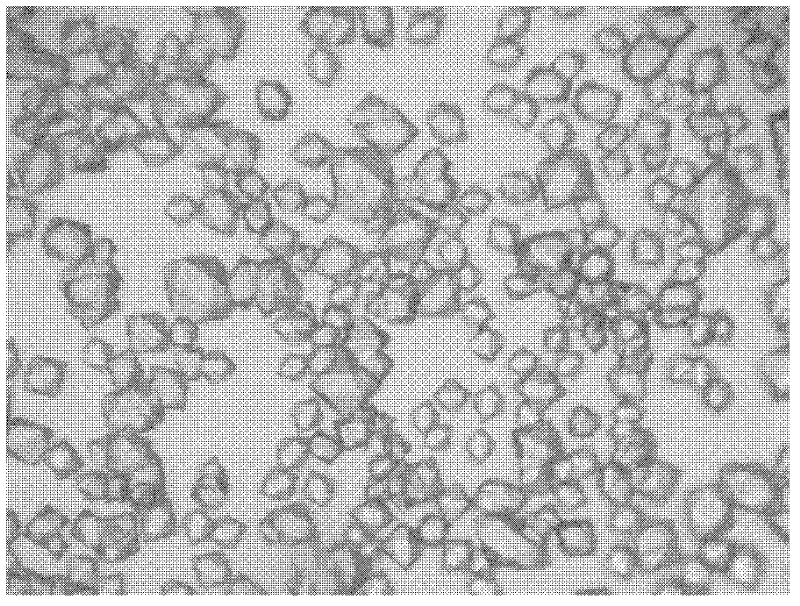

[0015] At room temperature, add 50ml of butyrolactone into the ultrasonic crystallizer, add 20g of ordinary RDX under stirring, raise the temperature of the solution to 75°C, start the ultrasonic field after it is completely dissolved, the frequency of the ultrasonic field is 68kHz, and the power density of the ultrasonic field is 0.1 W·cm -3 , and then at a cooling rate of 5°C / min to a solution temperature of 30°C, filtered, washed, and dried to obtain 10.2g of high-quality RDX fine particle product (see the appendix figure 1 ), crystal density 1.7979g cm 3 , density distribution 1.7976g cm 3 to 1.7982g·cm 3 , average particle size 50.2μm, D 10 = 40μm, D 90 =60μm, the particle size distribution is a normal distribution.

Embodiment 2

[0016] Embodiment 2: Ultrasonic cooling crystallization of RDX in cyclohexanone solvent

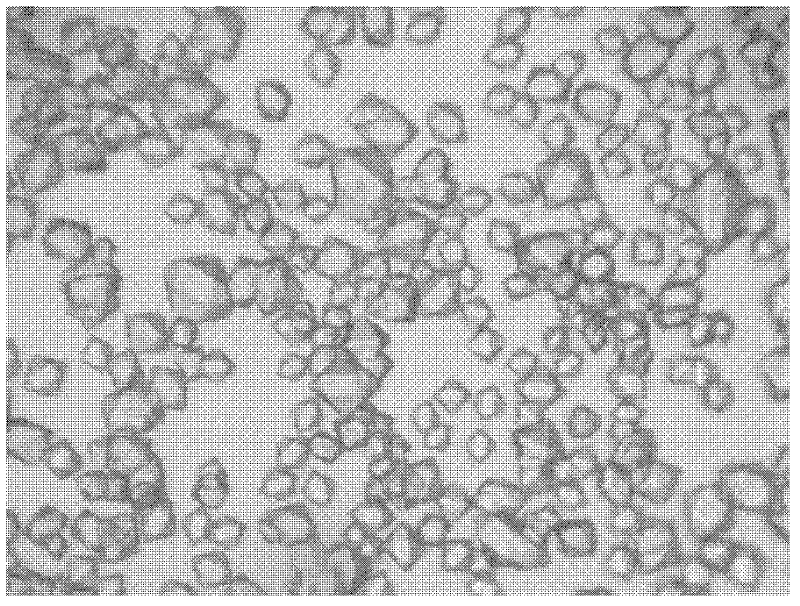

[0017] At room temperature, add 100ml of cyclohexanone into the crystallizer, and then add 20g of ordinary hexogen under stirring, raise the temperature to 80°C, and start the ultrasonic field after it is completely dissolved. The frequency of the ultrasonic field is 28kHz, and the power density of the ultrasonic field is 0.04W·cm -3 , and then at a cooling rate of 1°C / min until the solution temperature is 30°C, filter, wash, and dry to obtain 8g of high-quality RDX fine particle product (see the appendix figure 2 ), crystal density 1.7980g cm 3 , density distribution 1.7976g cm 3 to 1.7983g·cm 3 , average particle size 30μm, D 10 = 15 μm, D 90 =60μm, the particle size distribution is a normal distribution.

Embodiment 3

[0018] Embodiment 3: Ultrasonic cooling crystallization of HMX in butyrolactone solvent

[0019] At room temperature, add 50ml of butyrolactone into the ultrasonic crystallizer, add 20g of ordinary HMX under stirring, raise the temperature of the solution to 85°C, start the ultrasonic field after it is completely dissolved, the frequency of the ultrasonic field is 28kHz, and the power density of the ultrasonic field is 0.1 W·cm -3 , and then at a cooling rate of 5 °C / min to a solution temperature of 30 °C, filtered, washed, and dried to obtain 9 g of high-quality HMX fine particle product with a crystal density of 1.9020 g cm -3 , density distribution 1.9015g cm -3 to 1.9023g·cm -3 , average particle size 10.3μm, D 10 =5μm, D 90 =25μm, the particle size distribution is a normal distribution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com