High-strength low thermal expansion A1N nano wire and A1 composite material

A low thermal expansion, composite material technology, applied in the field of nanomaterials, to achieve the effect of increasing the turn-on voltage, reducing the electric field enhancement effect, and solving the shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

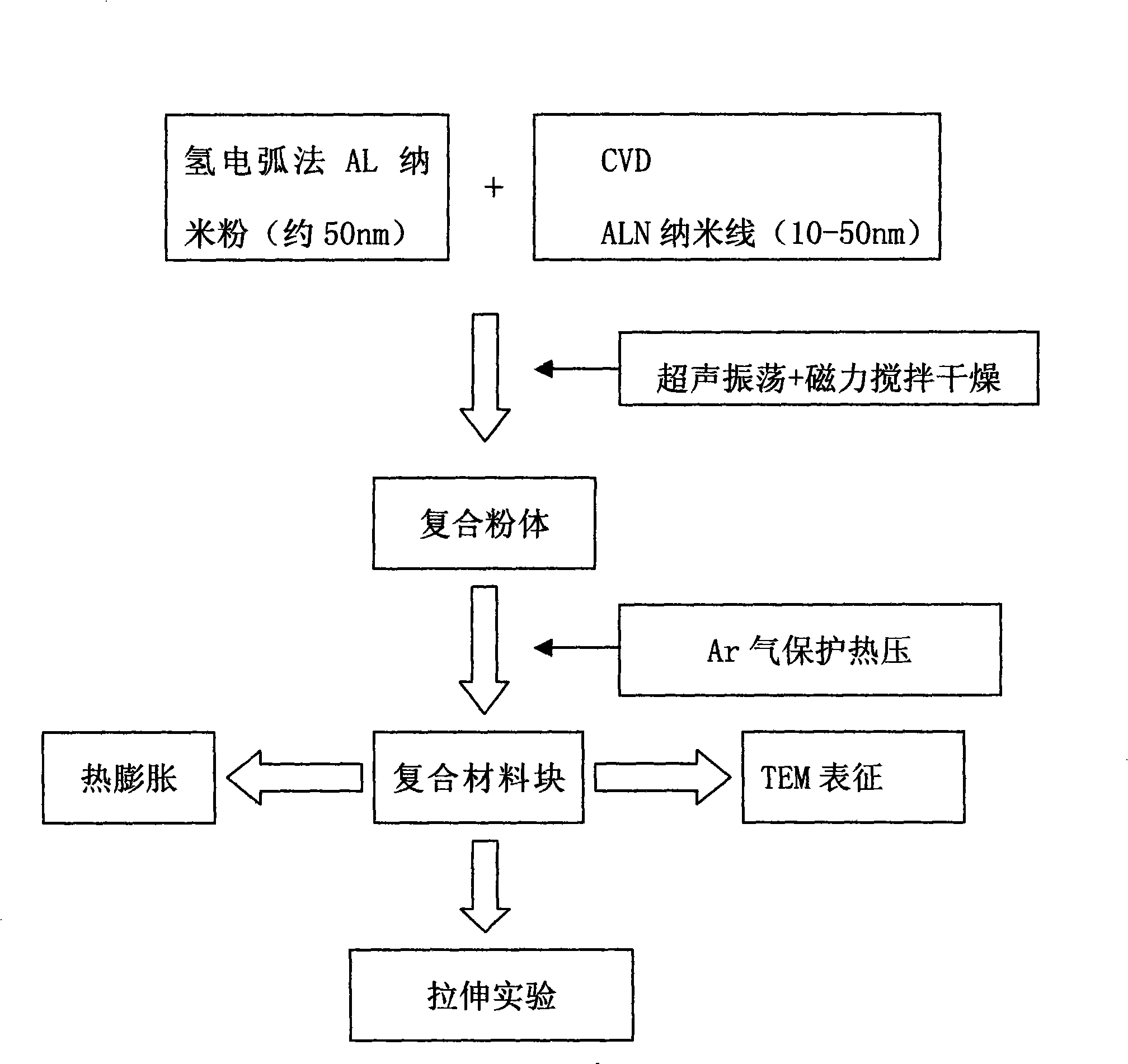

Method used

Image

Examples

Embodiment 1

[0019] The yield strength and tensile strength of the composite without AlN nanowires are about 60MPa and 131MPa, respectively. The thermal expansion test in the range of 20-250C shows that the thermal expansion coefficient is 22.29×10 -6 / K.

Embodiment 2

[0021] The AlN nanowires and Al nanoparticles with a volume composition of 4.5vol% are evenly mixed, and the dried mixed powder is hot-pressed into a block. The yield strength and tensile strength of the composite containing 4.5% AlN nanowires are about 3.2 times and 3.3 times that of the matrix without nanowires, respectively. The thermal expansion test in the range of 20-250C shows that adding AlN nanowires can effectively reduce the thermal expansion coefficient of Al, and the thermal expansion coefficient of the composite material containing 4.5% AlN nanowires is 15.24×10 -6 / K, which is 31.6% lower than that of the matrix without nanowires.

Embodiment 3

[0023] The AlN nanowires and the Al nanoparticles with a volume composition of 10.5vol% are evenly mixed, and the dried mixed powder is hot-pressed into a block. The yield strength and tensile strength of the composite containing 10.5% AlN nanowires are about 3.7 times and 4.2 times that of the matrix without nanowires, respectively. The thermal expansion test in the range of 20-250C shows that adding AlN nanowires can effectively reduce the thermal expansion coefficient of Al, and the thermal expansion coefficient of the composite material containing 10.5% AlN nanowires is 11.75×10 -6 / K, which is 47.3% lower than that of the matrix without nanowires.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com