Microwave filter packed shielded box and producing method thereof

A technology of microwave filters and production methods, applied in the fields of magnetic/electric field shielding, electrical components, etc., can solve problems such as neglect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

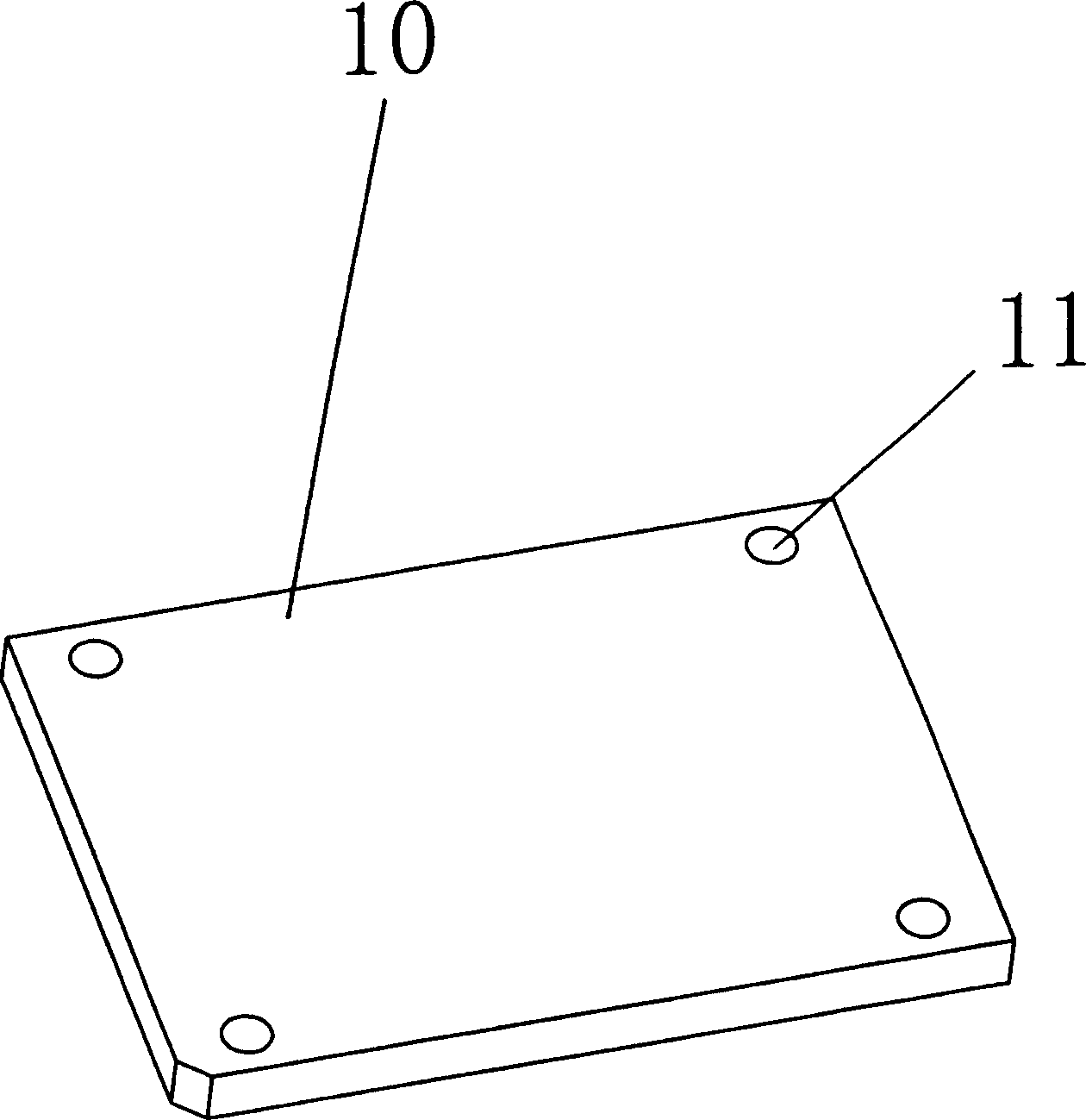

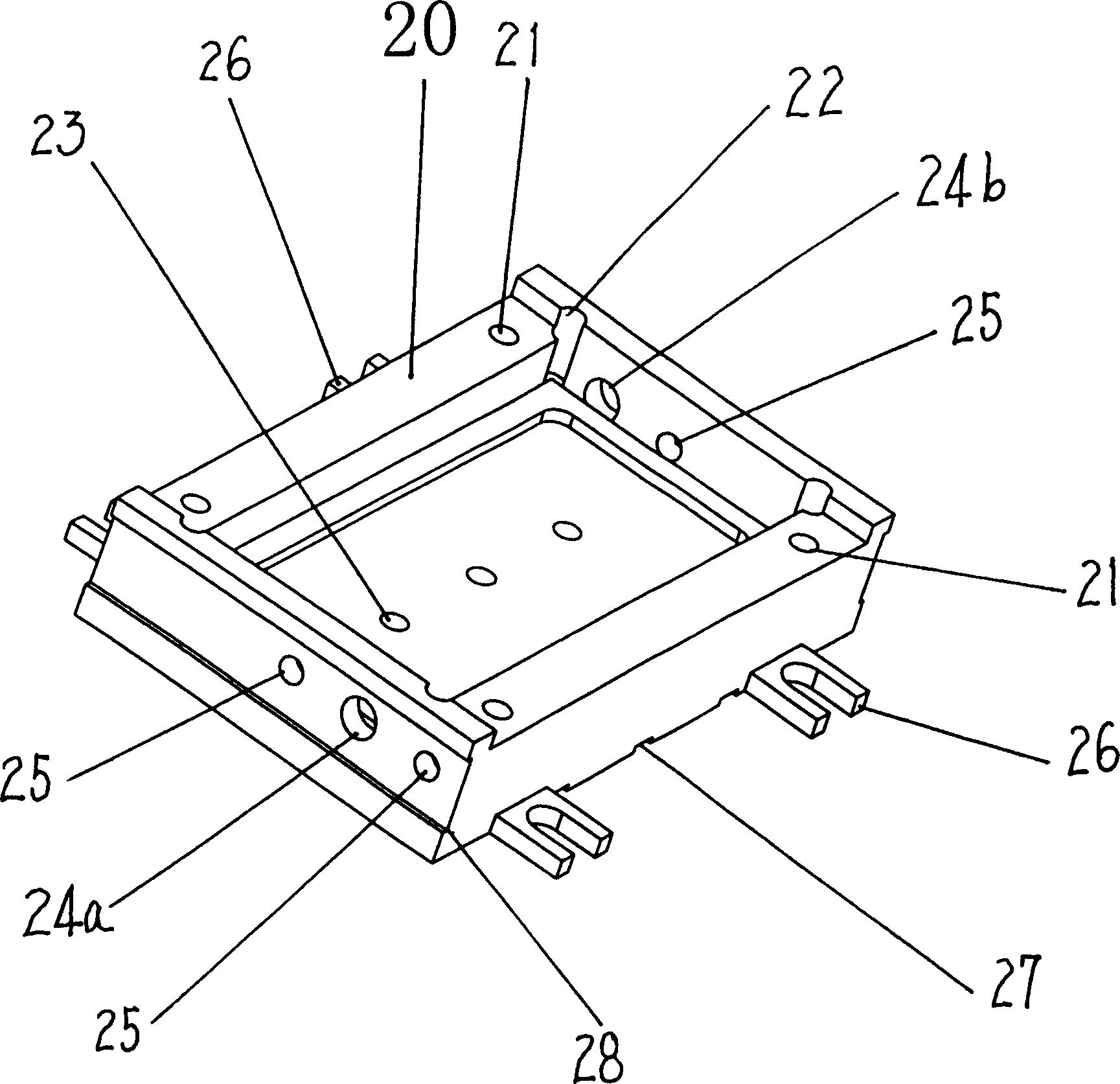

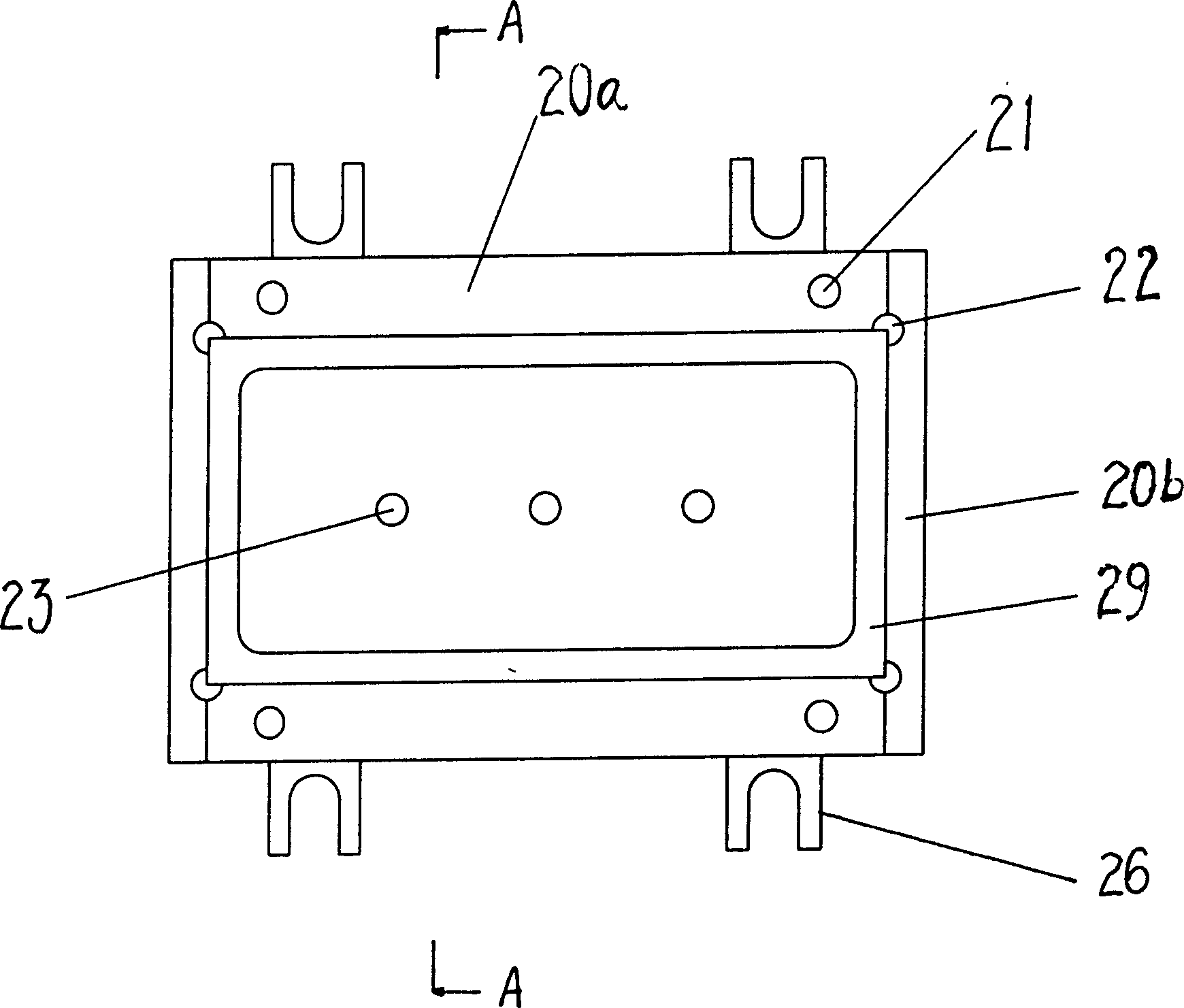

[0024] Embodiment 1: a kind of microwave filter packaging shielding box (see Figure 1-7 ), which is characterized in that it is composed of three parts, the filter work sheet 33 welded on the box base support frame 29 in a suspended shape according to the bottom, the box cover 10, the box base 20, the said box cover 10 There are screw holes 11 for fixing and connecting; on the edge of said box base 20, there are also screw holes 21 communicating with the screw holes 11 of the box cover 10 and used for fixing the box cover 10, and the corners of the box base 20 There is a 270° arc arc exhaust hole 22 at the junction that includes the right angle of the base box, and there is also a vent hole 23 at the bottom of the box base. There is a support frame 29 for the filter work piece 33 in the middle of the box base 20. There are air vent grooves 27, base fixing brackets 26 and base fixing screw holes 30; a pair of opposite sides 20b of the box base 20 have symmetrical input and out...

Embodiment 2

[0034] Embodiment 2: The above-mentioned box base 20 is made of copper.

[0035] The welding layer 31 of the above-mentioned welding filter working piece 33 on the support frame 29 in the middle of the shielding box base 20 may be an indium-silver alloy layer.

Embodiment 3

[0036] Embodiment 3: The material of the box base 20 mentioned above is aluminum alloy.

[0037] The welding layer 31 of the above-mentioned welding filter working piece 33 on the support frame 29 in the middle of the shielding box base 20 may be an indium-tin alloy layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com