Three-dimensional structured micropore material and preparation method therefor

A technology of microporous materials and three-dimensional structures, applied in electrolytic coatings, metal processing equipment, magnetic layers, etc., can solve the problems that cannot further reduce the thickness of equipment, increase the overall manufacturing cost of equipment, occupy equipment assembly space, etc., and achieve space heat conduction and Good impact resistance, solve the comprehensive problem of heat conduction and electromagnetic shielding, good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

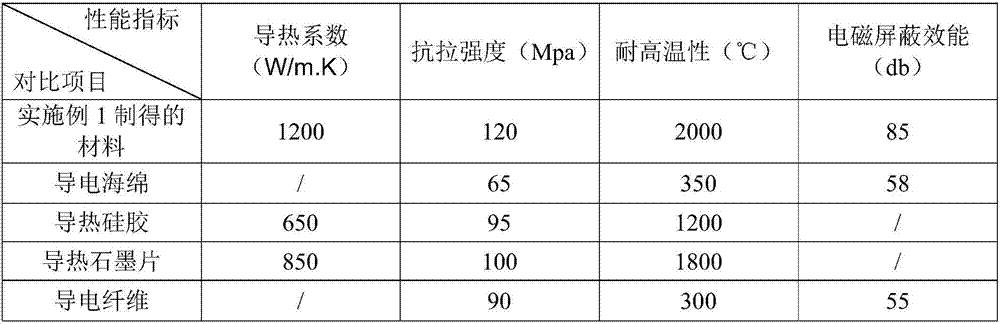

Examples

Embodiment 1

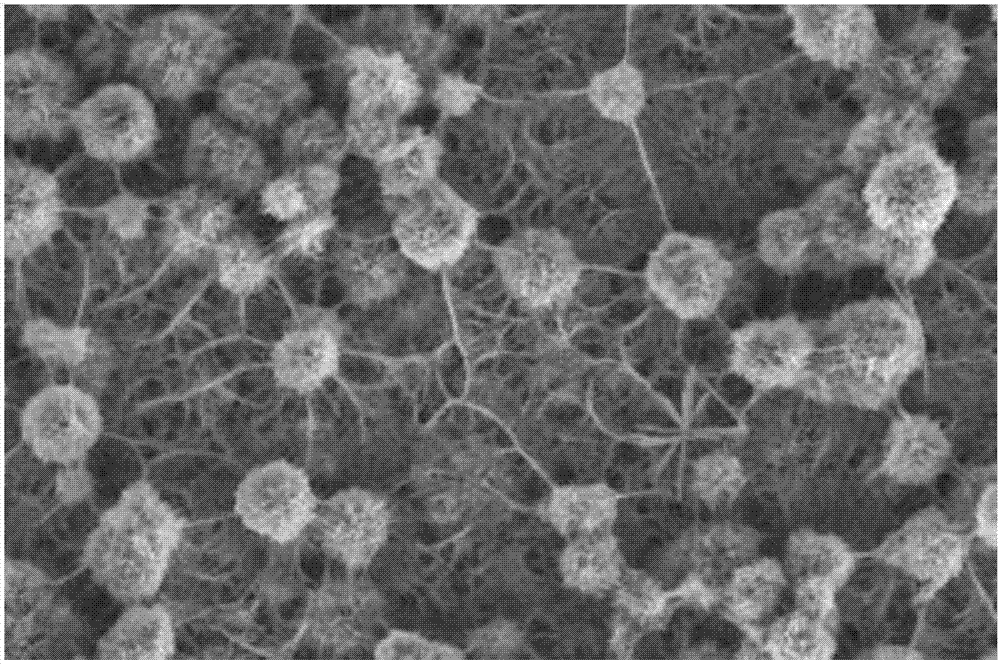

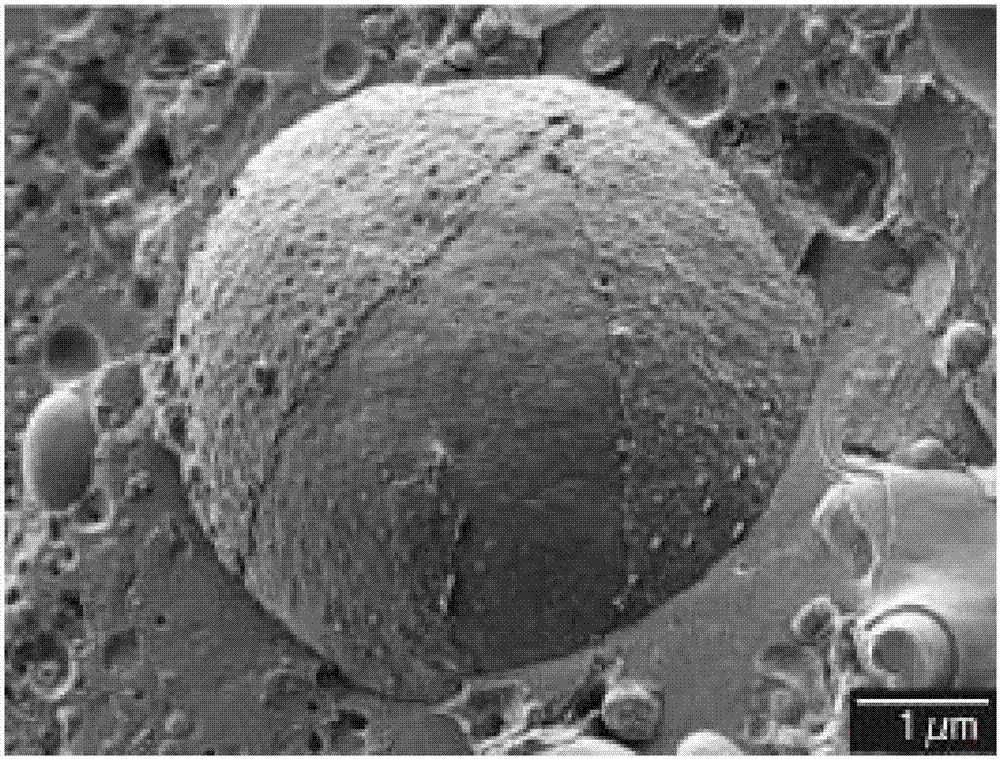

[0027] A preparation method of a three-dimensional structure microporous material is carried out according to the following steps:

[0028] Ⅰ Mix the spherical graphite powder with a particle size of 1nm and the spherical nickel powder with a particle size of 0.1nm at a mass ratio of 5:1 and then use a ball mill for ball milling. The ball milling speed is 5000 rpm and the ball milling time is 5 hours. The surface of the graphite powder is coated with a layer of nickel powder with a thickness of 0.1 μm to obtain a magnetic microsphere graphite powder; the prepared magnetic microsphere graphite powder is dissolved in ethylene glycol with a concentration of 1% to make a magnetic microsphere Spherical graphite powder solution;

[0029] ⅡThrough the conventional chemical plating method, a nickel layer with a thickness of 0.1 μm is plated on the surface of carbon nanotubes with a length of 1 nm and a diameter of 0.5 nm to prepare magnetically conductive carbon nanotubes; the prepare...

Embodiment 2

[0039] A method for preparing a three-dimensional microporous material, the steps of which are similar to those of the method for preparing a three-dimensional microporous material in Example 1, except that:

[0040] 1. In step I, the particle size of the spherical graphite powder is 70nm, the particle size of the spherical nickel powder is 30nm, the mass ratio of the spherical graphite powder to the spherical nickel powder is 7:3, the ball milling speed is 7000 rpm, and the ball milling time is 7 hours, the surface of the graphite powder is coated with a layer of nickel powder with a thickness of 0.5 μm;

[0041] 2. In step II, the carbon nanotubes have a length of 2.5 nm and a diameter of 2.5 nm, and the surface of the carbon nanotubes is coated with a nickel layer with a thickness of 0.5 μm;

[0042] 3. In step Ⅲ, the polymer microporous matrix material adopts a polyurethane film with a thickness of 2.5 μm, a pore diameter of 5 μm, a porosity of 70%, and a pore spacing of 2...

Embodiment 3

[0051] A method for preparing a three-dimensional microporous material, the steps of which are similar to those of the method for preparing a three-dimensional microporous material in Example 1, except that:

[0052] 1. In step I, the particle size of the spherical graphite powder is 0.1 μm, the particle size of the spherical nickel powder is 50 nm, the mass ratio of the spherical graphite powder to the spherical nickel powder is 9:5, the ball milling speed is 9000 rpm, and the ball milling time is After 10 hours, the surface of the graphite powder is coated with a layer of nickel powder with a thickness of 1.0 μm; the organic solvent is isopropanol with a concentration of 10%;

[0053] 2. In step II, the carbon nanotubes have a length of 5 nm and a diameter of 5 nm, and the surface of the carbon nanotubes is coated with an iron layer with a thickness of 1 μm; the organic solvent is isopropanol with a concentration of 10%;

[0054] 3. In step III, the macromolecular microporou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com