Method for preparing high-quality energetic crystal material fine particles

A crystalline material, fine particle technology, applied in offensive equipment, explosives processing equipment, explosives, etc., can solve the problems of wide particle size distribution, irregular particle shape, waste of raw materials, etc., and achieve reduced shock wave sensitivity, narrow particle size distribution, and particle shape. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: RDX ultrasonic dissolution crystallization

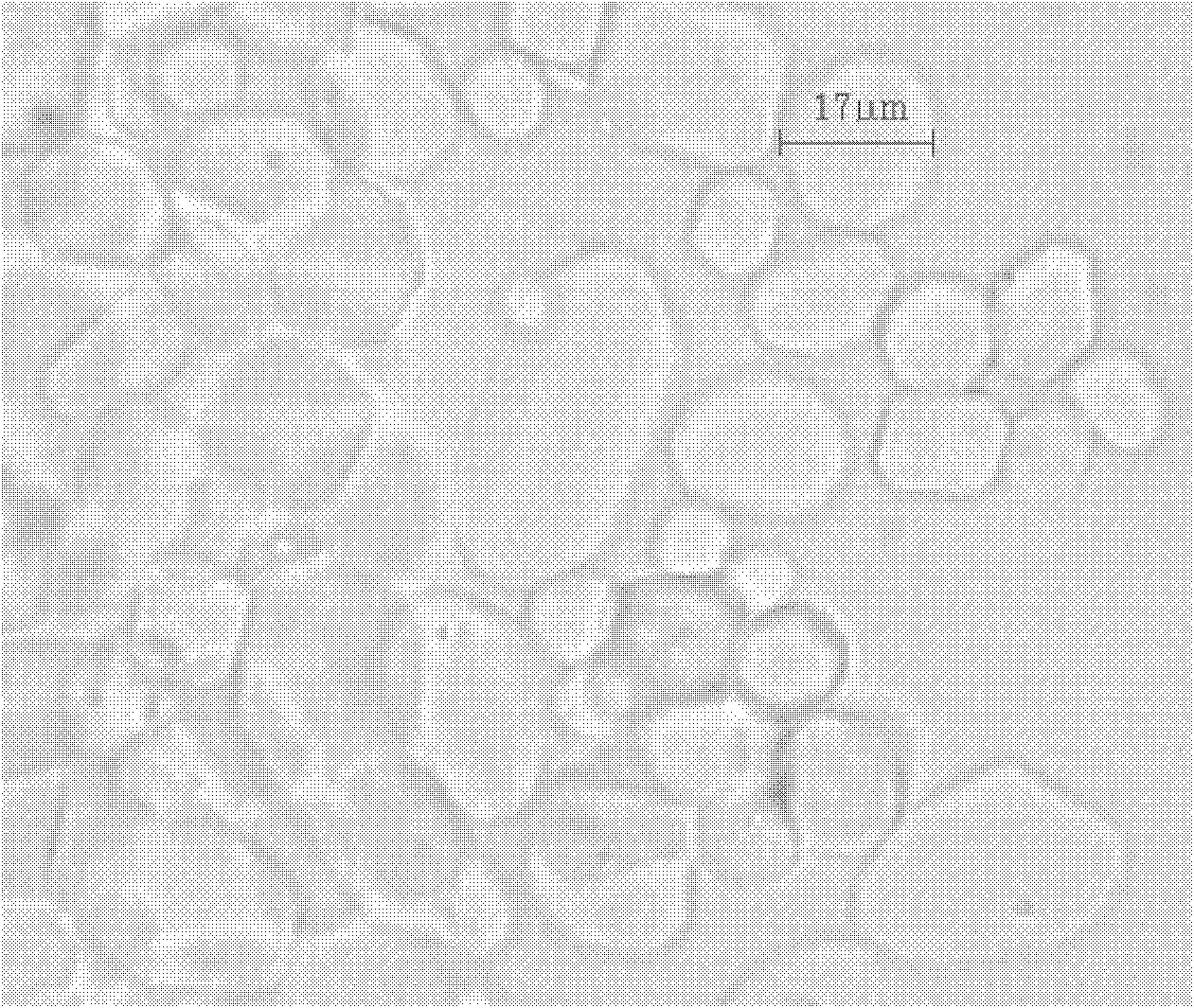

[0015] At room temperature, add 100g of DMSO into the ultrasonic crystallizer, and add 35g of ordinary RDX while stirring at room temperature of 30°C. After it is completely dissolved, start the ultrasonic field, the frequency of the ultrasonic field is 40kHz, and the power density of the ultrasonic field is 0.5W cm -3 , then quickly add 300g ethanol, continue ultrasonication, stir for 1 hour, filter, wash, and dry to obtain 30g high-quality RDX (see attached figure 1 ), crystal density 1.7980g cm -3 , density distribution 1.7976g cm -3 to 1.7982g·cm -3 , the average particle size is 20 μm, D10=10 μm, D90=30 μm, and the particle size distribution is a normal distribution.

Embodiment 2

[0016] Embodiment 2: CL-20 ultrasonic dissolution crystallization

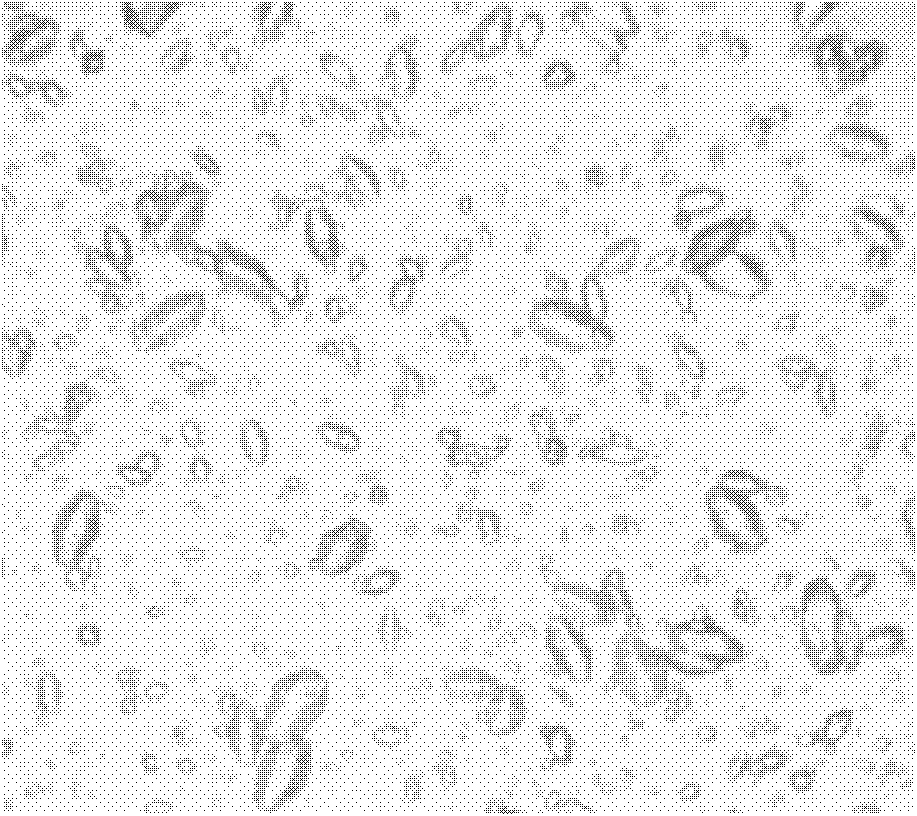

[0017] At room temperature, add 30g of ethyl acetate into the ultrasonic crystallizer, and add 13g of ordinary CL-20 while stirring at room temperature at 30°C. After it is completely dissolved, start the ultrasonic field, the frequency of the ultrasonic field is 20kHz, and the power density of the ultrasonic field is 1W cm -3 , and then quickly add 60g of n-heptane, continue ultrasonication, stir for 1 hour, filter, wash, and dry to obtain 11g of high-quality CL-20 (see attached figure 2 ), crystal density 2.0355g cm -3 , density distribution 2.0351g cm -3 to 2.0366g·cm -3 , the average particle size is 30 μm, D10=10 μm, D90=50 μm, and the particle size distribution is a normal distribution.

Embodiment 3

[0018] Embodiment 3: HMX ultrasonic dissolution crystallization

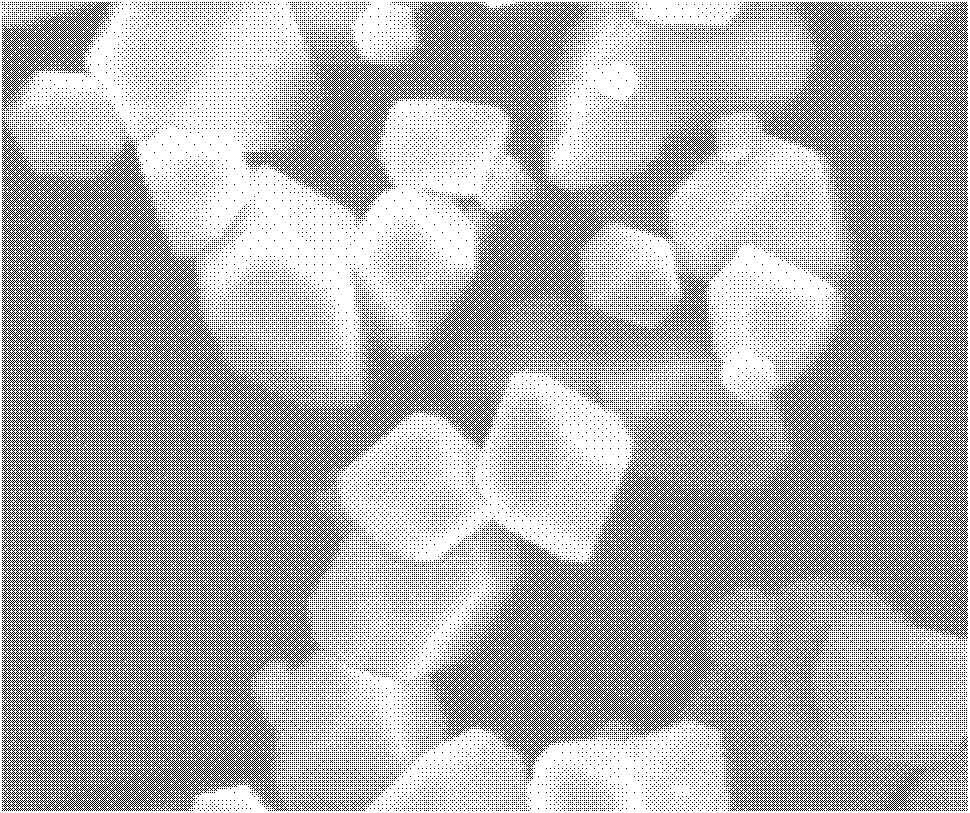

[0019] At room temperature, add 50g of dimethyl sulfoxide into the ultrasonic crystallizer, and add 15g of ordinary HMX while stirring at 20°C to 50°C. After it is completely dissolved, start the ultrasonic field. The frequency of the ultrasonic field is 20kHz to 120kHz. Density greater than 1×10 -3 W·cm -3 , then quickly add 30g to 100g of water, continue ultrasonication, stir for 1 hour, filter, wash, and dry to obtain 14.5g of high-quality HMX fine particle product (see attached image 3 ), crystal density 1.9018g cm -3 , density distribution 1.9010g cm -3 to 1.9021g·cm -3 , the average particle size is 10 μm to 30 μm, and the particle size distribution is a normal distribution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com