Periodically poled Ti-diffusion near-stoichiometry lithium niobate slab waveguide and preparation method

A near-stoichiometric and periodic polarization technology, applied in the field of optical waveguides, can solve the problems that cannot meet the requirements of miniaturization and integration of optical devices, and achieve the effects of less crystal defects, high efficiency and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

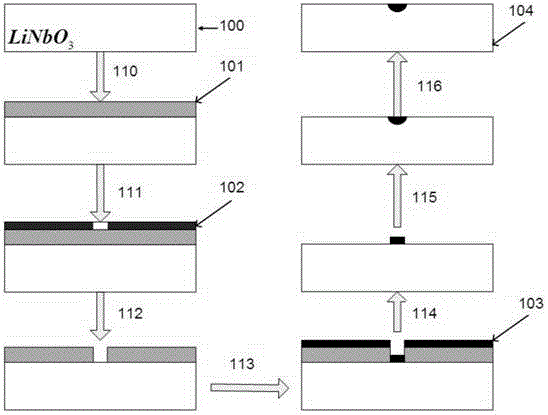

[0035] (1) Sample preparation. The invention chooses optical grade Z-cut 0.5mm thick lithium niobate wafers of the same composition as the starting material. Use a precision cutting machine to cut the wafer into 15mm (length) × 10mm (width) samples;

[0036] (2) Lithography. First, put the cleaned sample on the hot plate and bake for 10 minutes at a temperature of 85°C. Then, use a homogenizer to coat a layer of SPR6112B photoresist on the sample, and set the rotation speed of the homogenizer to 3000r / min and the time to be 1min. After that, the sample after spin-coated photoresist was baked for 10 minutes at 85°C. Next, carry out exposure treatment: After the photoresist in the exposed part is dissolved, it is quickly cleaned with pure deionized water. Then use a high-purity high-pressure nitrogen gun to blow dry the sample. Put the sample and the mask on the operating table of the lithography machine, adjust the position, and expose for 40s. The selected mask is a strip wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com