A watertight load-bearing connector for zero-buoyancy optical cable

An optical fiber connector, zero buoyancy technology, applied in the direction of light guide, optics, instruments, etc., can solve the problems of increasing processing difficulty and processing cost, increasing underwater resistance and noise, reducing shell strength, etc., achieving low processing cost and difficulty, Ensure two-way transmission and reduce overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] A watertight load-bearing connector for zero-buoyancy optical cable of the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments:

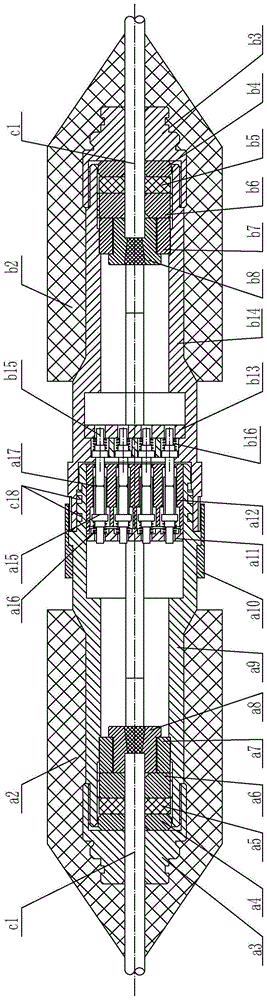

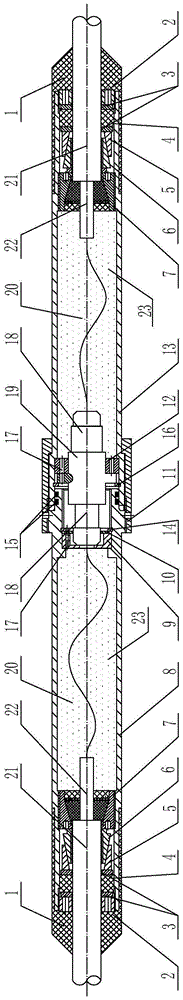

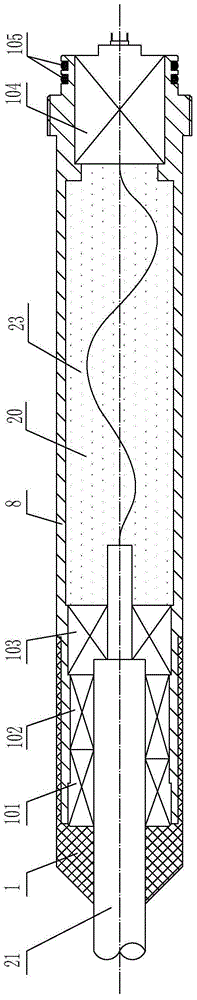

[0034] Such as figure 2 , image 3 and Figure 4 As shown, the zero-buoyancy optical cable watertight bearing connector of the present invention includes a plug and a socket, and the plug includes a plug housing 8, a sealing boot 1 assembled on the left end of the plug housing 8, two O-rings 105 arranged on the right end of the plug housing 8 and The sealing assembly 101, the lock cable assembly 102, the load-bearing assembly 103 and the plug docking assembly 104 located inside the plug housing 8, the socket includes a socket housing 13, a locking nut 11, a sealing boot 1 assembled on the socket housing 13 and a socket housing 13 inside the sealing assembly 101 , the lock cable assembly 102 , the bearing assembly 103 and the socket docking assembly 106 .

[0035] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com