Multi-core optical fiber with gradually-changed core spacing and preparation method of multi-core optical fiber

A multi-core optical fiber, multi-fiber technology, applied in multi-core optical fiber, glass optical fiber, cladding optical fiber, etc., can solve the problems of high control accuracy, difficult preparation, and poor quality of optical fiber coating, and achieves low Loss coupling, ease of operation, improved coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

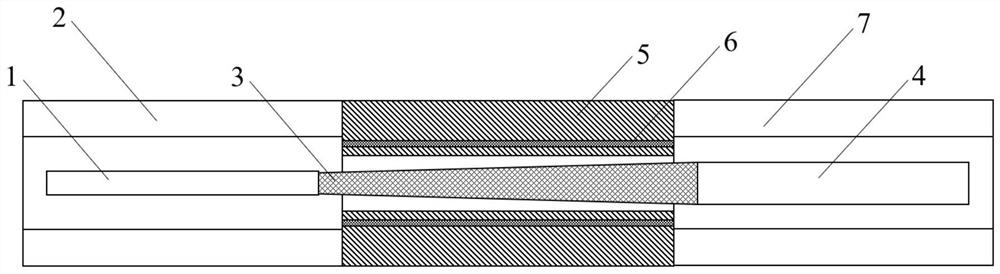

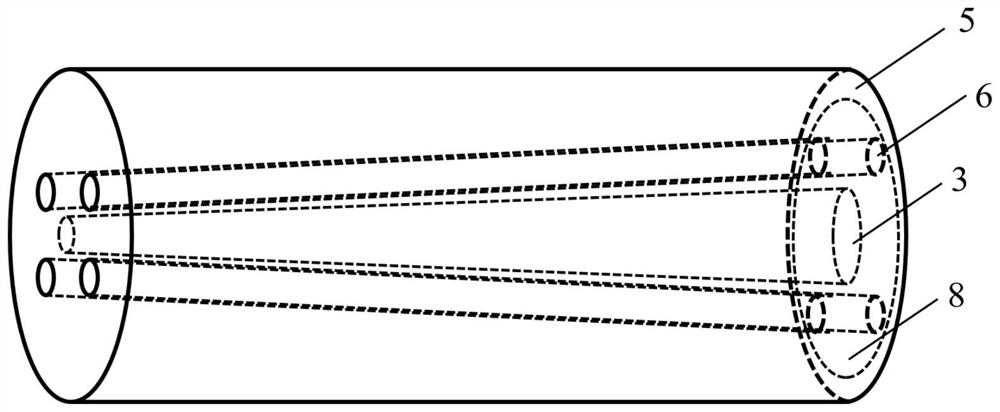

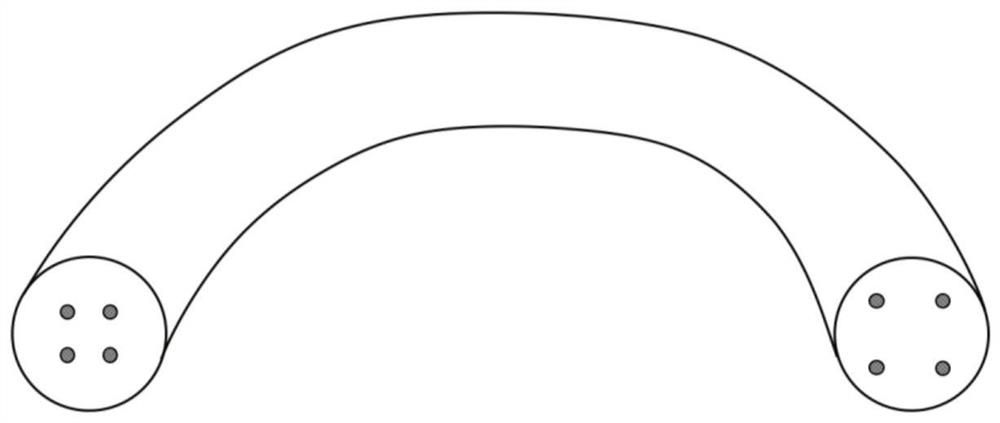

[0038] Such as Figure 1-Figure 3 As shown, it is a schematic diagram of a graded-core-spacing optical fiber provided by an embodiment of the present invention. The graded-core-spacing fiber mainly includes: a cladding layer 5 and a core layer 8 located inside the cladding layer. The outer circumference of the core layer layer has an axial Ring-shaped distribution through holes, an optical fiber core 6 is arranged in the axial ring-shaped distribution through holes, a through hole is arranged in the center of the core layer, and a tapered glass rod 3 is placed in the through hole. The length of the tapered glass rod is The axial length of the core layer is consistent with that of the core layer, and is used to cause the core layer to deform to different degrees, so as to obtain a multi-core optical fiber in which the distance between the cores gradually changes along the axial direction of the core layer and the cladding diameter remains unchanged.

[0039] Wherein, the throug...

Embodiment 2

[0045] This embodiment provides a method for preparing the core-spacing graded multi-core fiber in Embodiment 1, comprising the following steps:

[0046]Step 1: Carry out circular grinding on a plurality of optical fiber preforms, insert them into the axial annular distribution through holes of the quartz rods with axial annular distribution through holes, and heat and melt, so that the plurality of optical fiber preforms and the quartz rods Melting and shrinking into one body; wherein, the outer circumference formed from the axial ring-shaped distribution of through holes is the boundary, the core layer is inward to the center of the quartz rod, and the cladding is outward to the outer circumference of the quartz rod.

[0047] Specifically, the optical fiber preform is prepared by the MCVD process, and the outer diameter of the optical fiber preform prepared by this process is between 13 mm and 15 mm. Clamp each optical fiber preform into the chuck of the cylindrical grinder,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com