A coupling packaged silicon photonic chip

A silicon photonics and chip technology, applied in the optical field, can solve the problems of high electrical interconnection requirements, high cost, and low coupling efficiency of laser chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

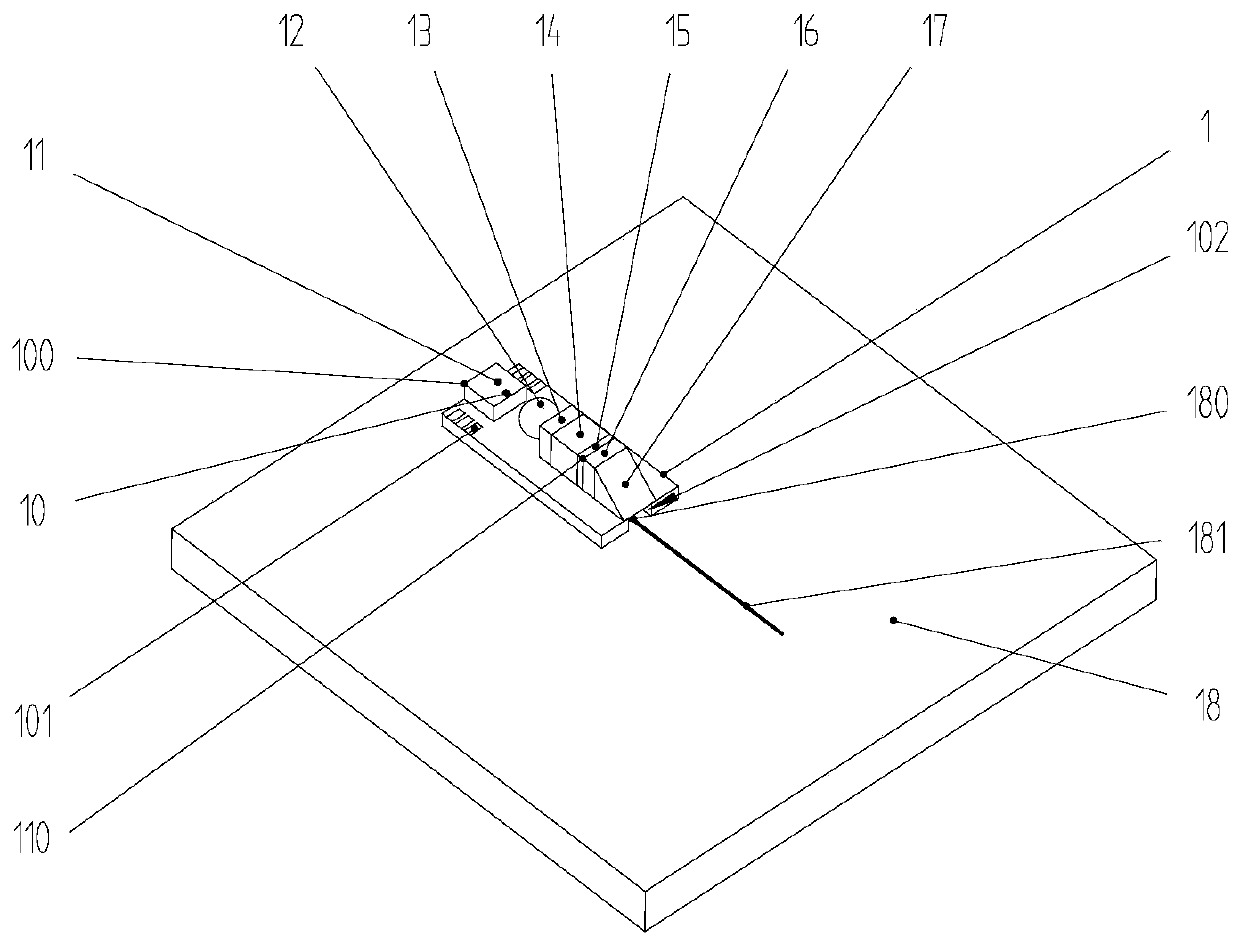

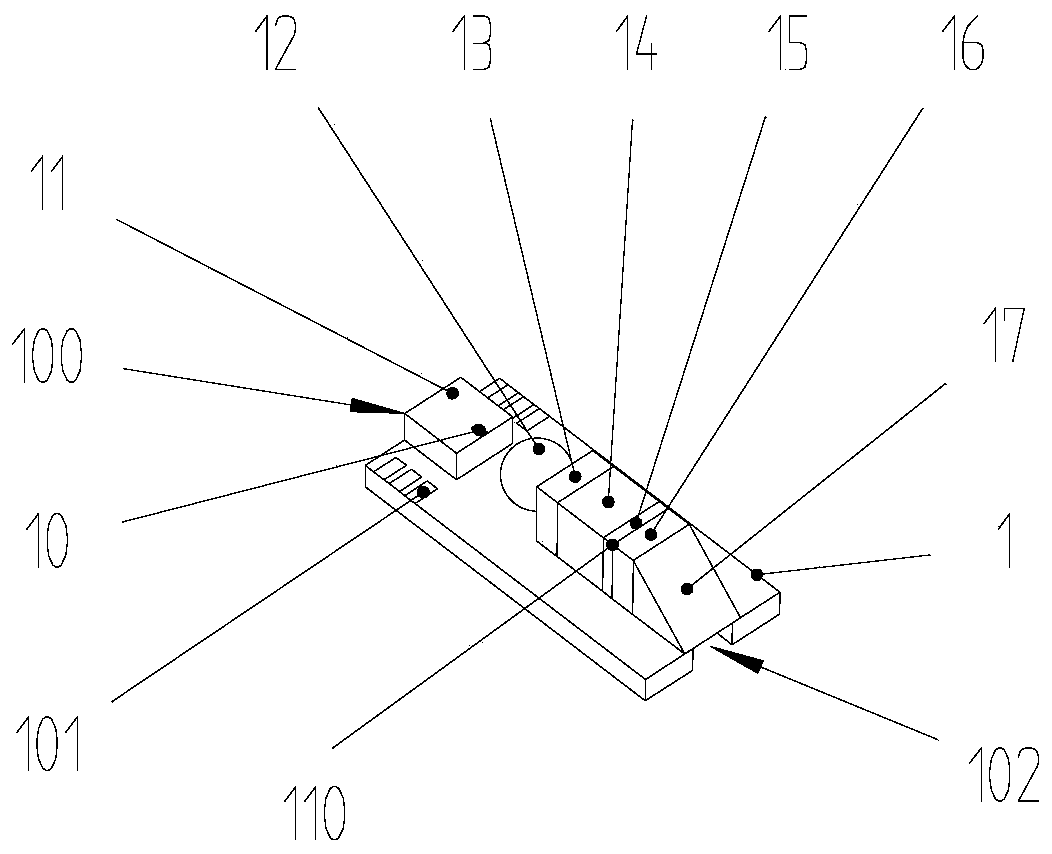

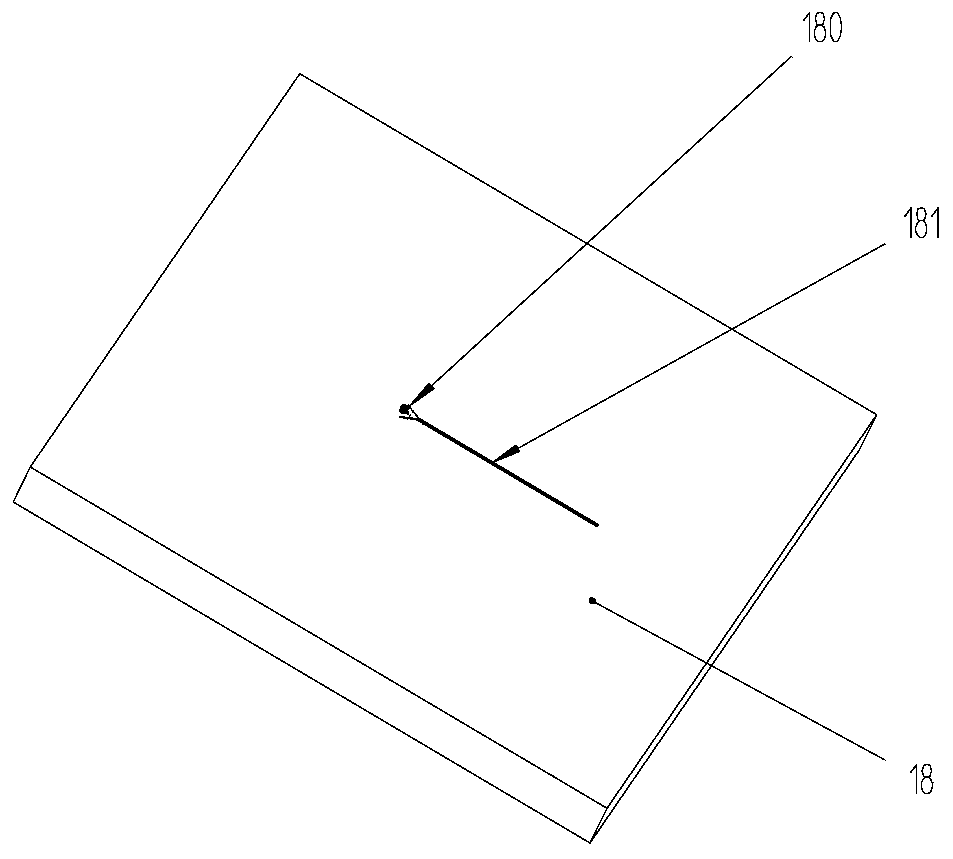

[0026] A coupling and packaging silicon photonic chip, including a substrate 1, a laser chip sub-board 100, a micro-optical module 110, and a silicon photonic chip 18; the laser chip sub-board 100 and the micro-optical module 110 are respectively connected to the substrate 1 , the end of the substrate 1 close to the micro-optical module 110 is provided with a groove 102 for transmitting laser light; the laser chip sub-board 100 is used to emit laser light waves, and the micro-optical module 110 is used The light wave is converted into a TE wave and transmitted to the groove 102; the substrate 1 is connected to the silicon photonic chip 18, and the optical coupling grating 180 of the silicon photonic chip 18 is arranged in the groove 102 in the TE wave transmission direction place.

[0027] In this embodiment, the laser chip sub-board 100 includes a laser chip 10 and a heat sink 11 , and the laser chip 10 is bonded to the heat sink 11 through AuSn eutectic bonding.

[0028] In...

Embodiment 2

[0038] A coupling and packaging silicon photonic chip, including a substrate 1, a laser chip sub-board 100, a micro-optical module 110, and a silicon photonic chip 18; the laser chip sub-board 100 and the micro-optical module 110 are respectively connected to the substrate 1 , the end of the substrate 1 close to the micro-optical module 110 is provided with a groove 102 for transmitting laser light; the laser chip sub-board 100 is used to emit laser light waves, and the micro-optical module 110 is used The light wave is converted into a TE wave and transmitted to the groove 102; the substrate 1 is connected to the silicon photonic chip 18, and the optical coupling grating 180 of the silicon photonic chip 18 is arranged in the groove 102 in the TE wave transmission direction place.

[0039] In this embodiment, the laser chip sub-board 100 includes a laser chip 10 and a heat sink 11 , and the laser chip 10 is bonded to the heat sink 11 through AuSn eutectic bonding.

[0040] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com