Asymmetric waveguide optical fiber end face coupler with two unequal-height arms based on mode evolution

An asymmetric waveguide and fiber end face technology, which is applied in the coupling of optical waveguides, optical waveguides and optical guides, instruments, etc., can solve the problem that the coupling structure cannot be well realized in the height direction, and it is difficult to achieve polarization insensitivity and coupling efficiency. problems such as rise, to achieve the effect of large tolerance, compact structure, and enlarged mold spot size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

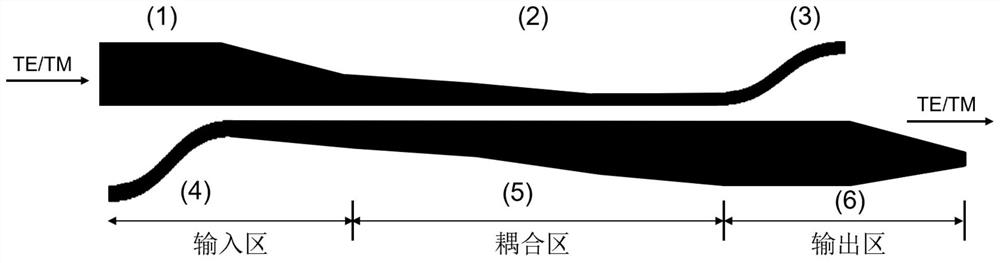

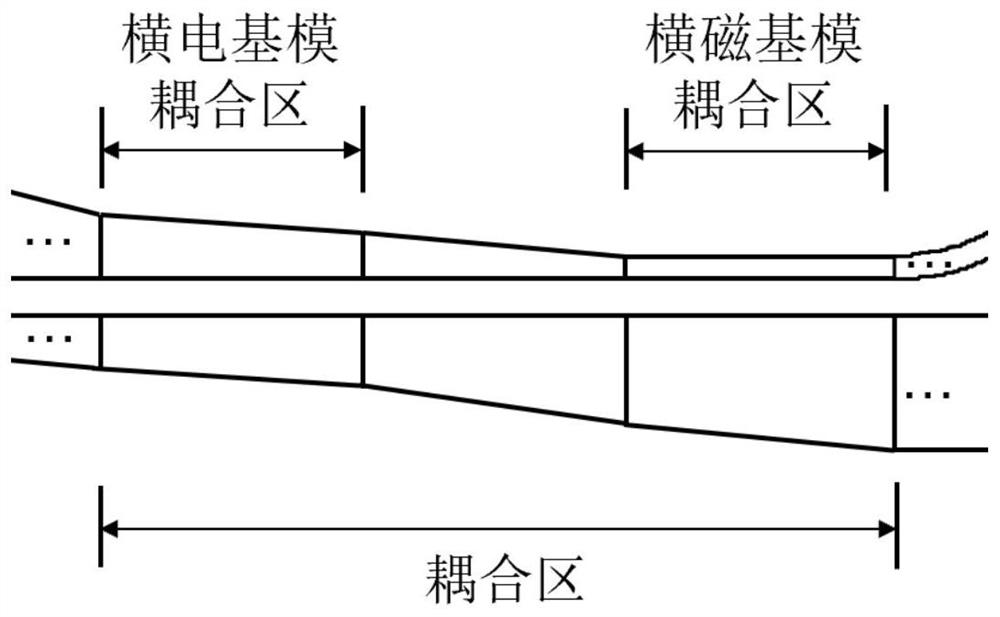

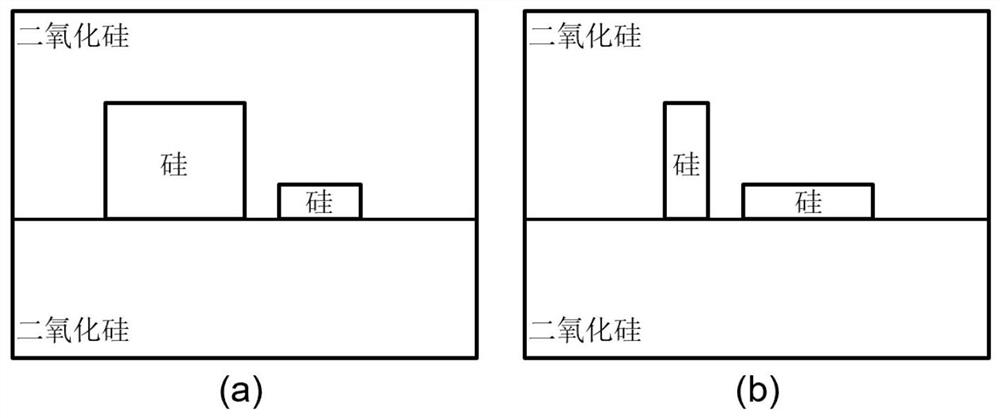

[0060] The silicon nanowire optical waveguide based on silicon-on-insulator (SOI) material is selected: the core layer is silicon material, the thickness of the high-arm waveguide is 220nm, and the refractive index is 3.5068; the thickness of the short-arm waveguide is 150nm, the refractive index is 3.5068, and the lower cladding , the upper cladding material is SiO 2 , with a thickness of 2 μm and a refractive index of 1.444. Considering that the central wavelength is 1310nm and the number of modes is 2, including the fundamental transverse electric mode and the transverse magnetic fundamental mode, the device structure diagram is as follows figure 1 shown.

[0061] For the high-arm input wide straight waveguide 1, the width is 0.38 μm and the length is 10 μm; the beginning and end widths of the short-arm input S-shaped narrow curved waveguide 4 are both 0.18 μm to meet most current technological requirements. The short-arm input S-shaped narrow curved waveguide 4 has a len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com