Patents

Literature

44results about How to "Same output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pholiota nameko cultivation material prepared by adopting edible mushroom waste compost and preparation method thereof

InactiveCN102701821AIncrease incomeReduce manufacturing costBio-organic fraction processingOrganic fertiliser preparationAdditive ingredientEdible mushroom

The invention belongs to the technical field of edible mushroom cultivation, and particularly relates to a pholiota nameko cultivation material prepared by adopting an edible mushroom waste compost and a preparation method thereof. The cultivation material has the following ingredients in proportion: 60-90 percent of waste mushroom packet, 5-15 percent of corncob, and 4-10 percent of wheat bran. The preparation method comprises the following steps of: smashing, burdening, fermenting and bagging the waste mushroom packet. The fermentation can be spontaneous fermentation or heating fermentation; and the spontaneous fermentation comprises building heaps, turning heaps and mixing. According to the pholiota nameko cultivation material prepared by adopting the waste compost, the production cost can be saved, the income of farmers is improved, the resources can be effectively utilized, and the environment is protected. The preparation method is simple and easy to implement, the survival rate of bacterial strains is high, and the cultivation yield is the same as the yield of good compost.

Owner:LIAONING SANYOU AGRI BIOTECH

Application of siraitia grosvenorii fruit residues in cultivation of black fungi

The invention discloses an application of siraitia grosvenorii fruit residues in cultivation of black fungi. Siraitia grosvenorii fruit residue powder is mixed with weed tree sawdust, cottonseed hulls, bran, gypsum powder and lime to prepare compost for cultivating the black fungi. The application has the advantages as follows: utilization and resource recovery of waste are realized, and high yield and high quality of the black fungi can be achieved.

Owner:桂林健成生物科技开发有限公司 +1

Application of siraitia grosvenorii fruit residues in cultivation of schizophyllumcommuneh

The invention discloses an application of siraitia grosvenorii fruit residues in cultivation of schizophyllumcommuneh. Siraitia grosvenorii fruit residue powder is mixed with cottonseed hull, weed tree sawdust, bran, gypsum powder and calcium carbonate to prepare compost for cultivating schizophyllumcommuneh. According to the application, one novel cultivation raw material for cultivating the schizophyllumcommuneh is provided, high yield and high quality of the schizophyllumcommuneh can be achieved, and further, utilization and resource recovery of waste are realized.

Owner:桂林健成生物科技开发有限公司 +1

Application of siraitia grosvenorii fruit residues in cultivation of clitocybe maxima

The invention discloses an application of siraitia grosvenorii fruit residues in cultivation of clitocybe maxima. Siraitia grosvenorii fruit residue powder is mixed with weed tree sawdust, bagasse or corncob, wheat bran, gypsum powder and lime powder to prepare compost for cultivating the clitocybe maxima. According to the application, one novel cultivation raw material for cultivating the clitocybe maxima is provided, high yield and high quality of the clitocybe maxima can be achieved, and further, utilization and resource recovery of waste are realized.

Owner:桂林健成生物科技开发有限公司 +1

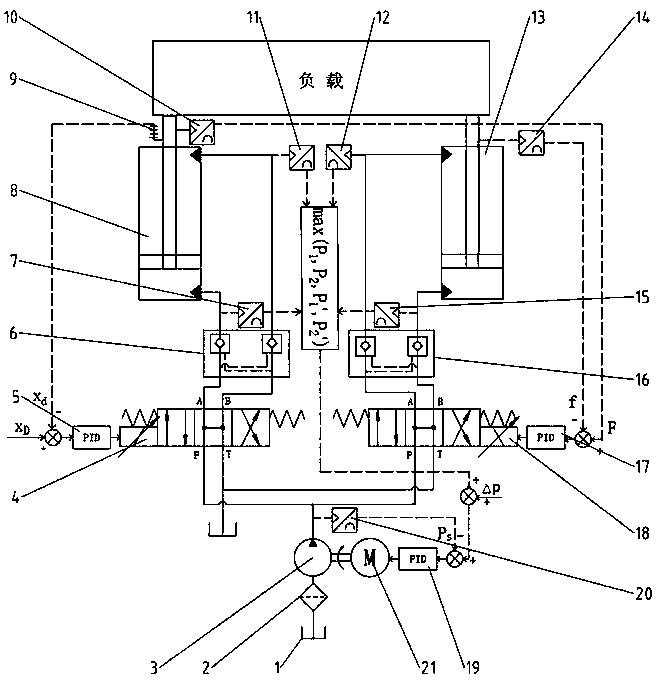

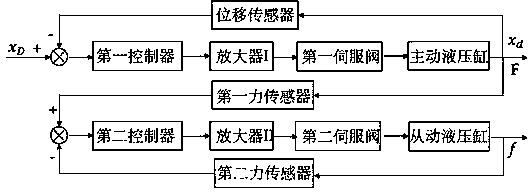

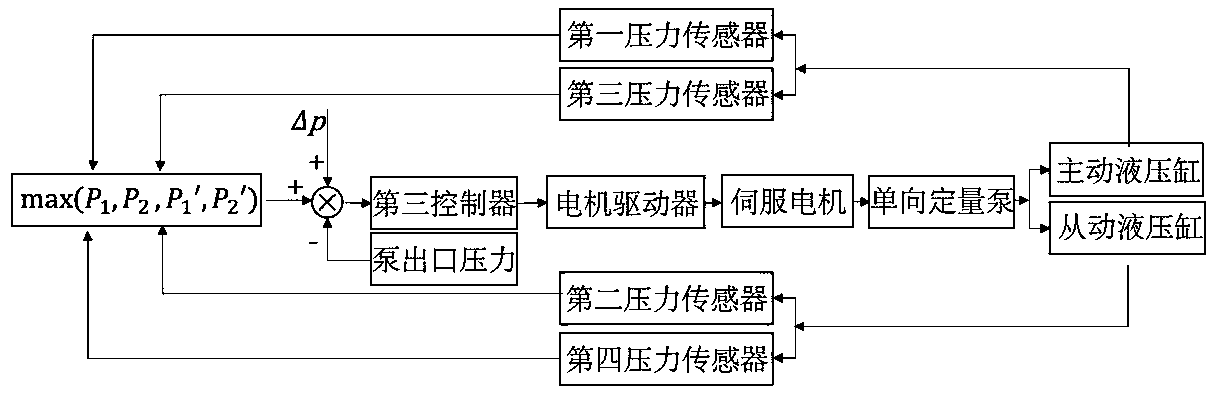

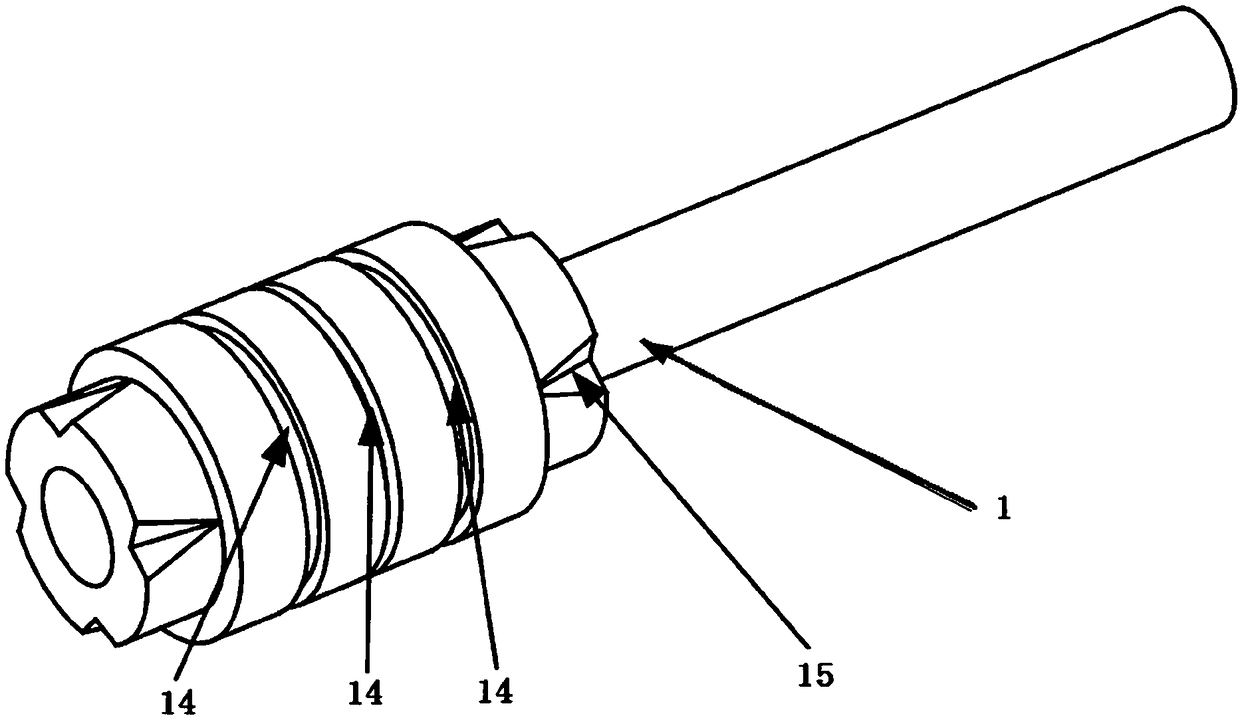

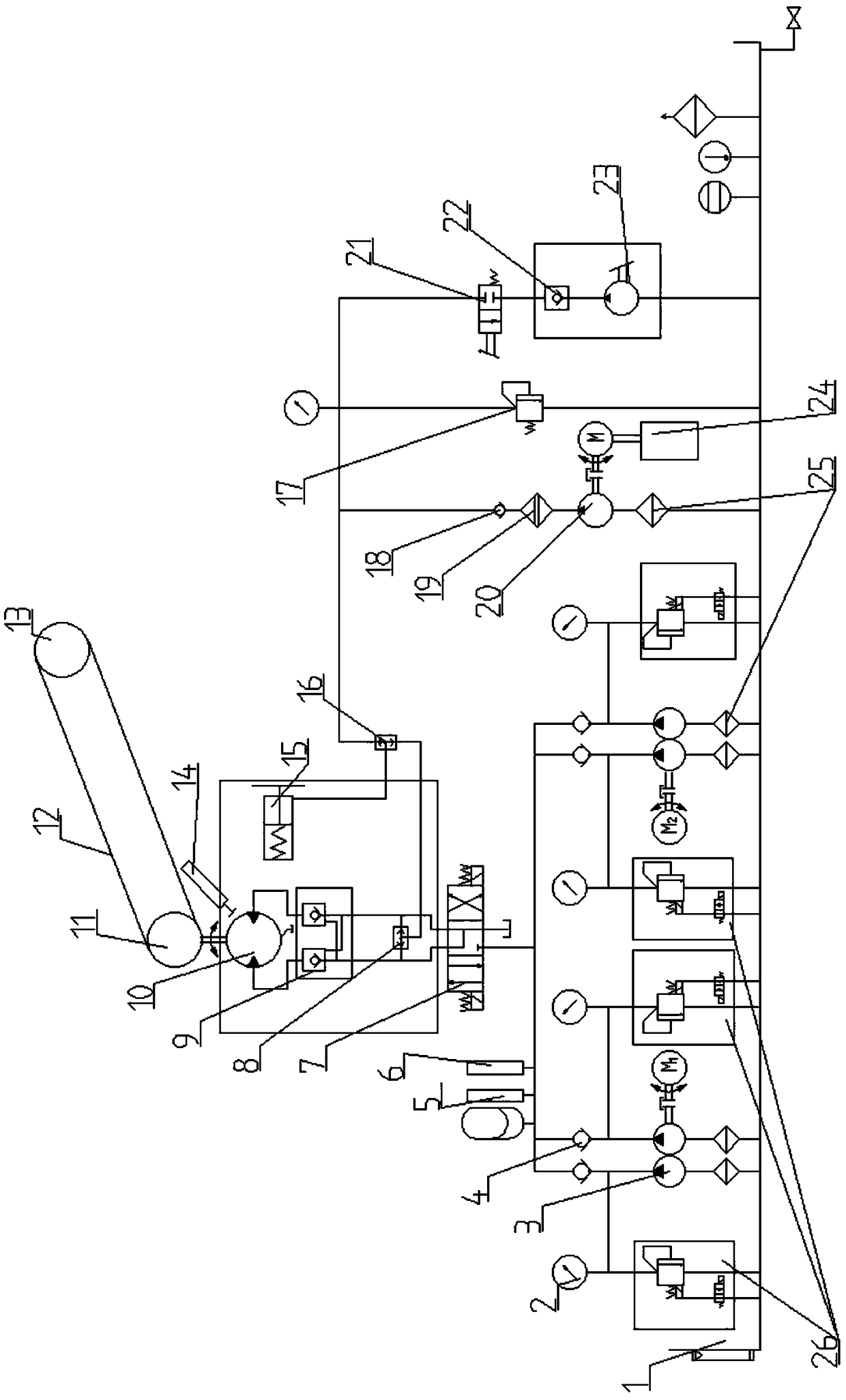

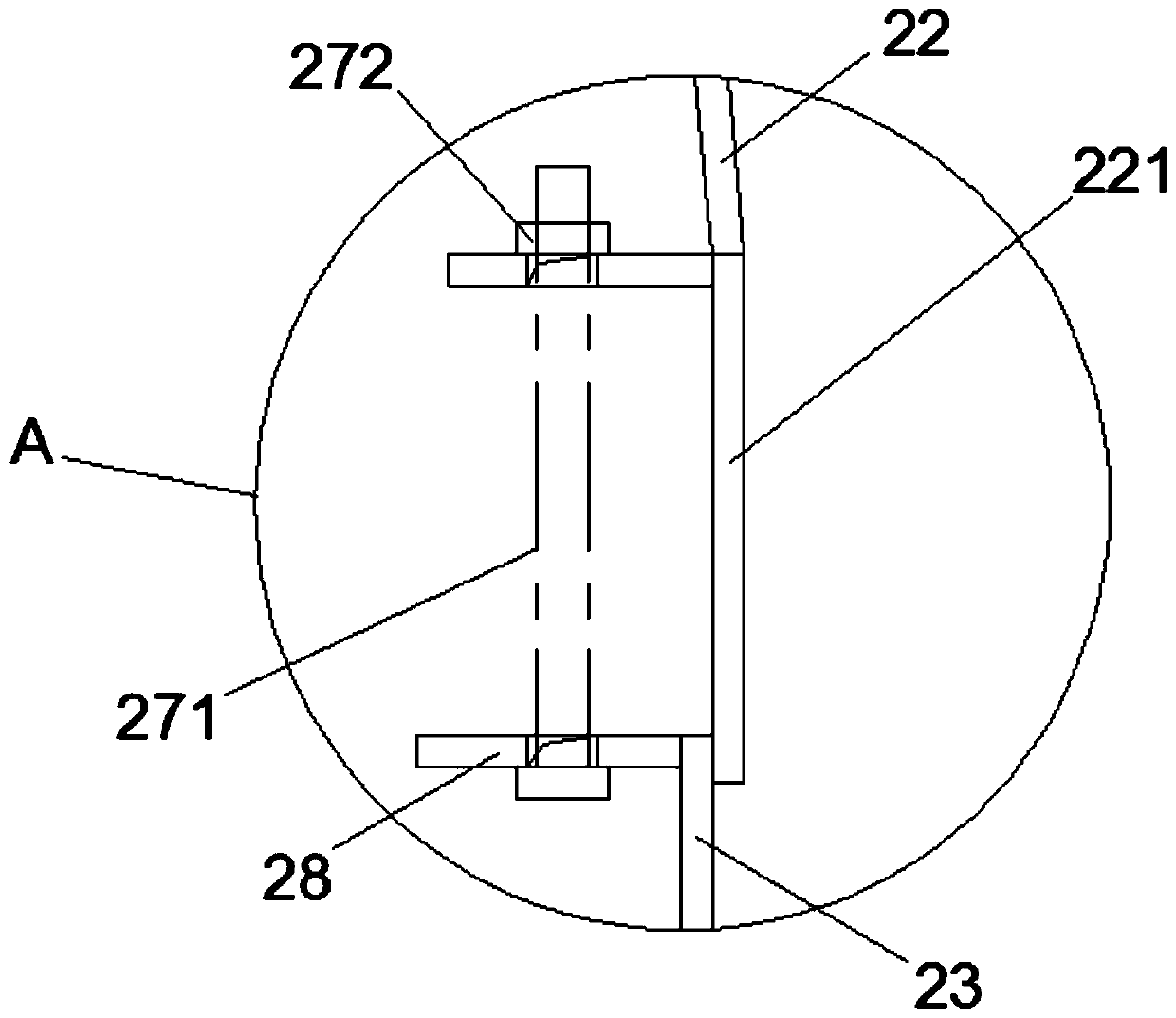

Load-sensitive double-hydraulic-cylinder synchronous system and control method thereof

ActiveCN111577687ASame outputSimple structureFluid-pressure actuator testingServomotor componentsHydraulic cylinderEngineering

The invention belongs to the technical field of hydraulic engineering, and particularly relates to a load-sensitive double-hydraulic-cylinder synchronous system and a control method thereof. The synchronous system mainly involves two synchronous drive hydraulic cylinders, a synchronous controller unit and a load sensitive unit, wherein a force instruction of the driven hydraulic cylinder is takenfrom a feedback signal of a force sensor arranged between a driving hydraulic cylinder and the load, and the output force of the driven hydraulic cylinder is adjusted in real time to ensure that the output force of the driven hydraulic cylinder is the same as the output force of the driving hydraulic cylinder so that synchronous driving of the ''driving'' hydraulic cylinder and the ''driven" hydraulic cylinder can be realized; the load sensitive unit ensures that the power supply of the system is matched with the large power demand in the "driving" hydraulic cylinder and the "driven" hydrauliccylinder; and when the "driving" hydraulic cylinder and the "driven" hydraulic cylinder are in an asynchronous working condition, the valve opening pressure difference of a servo valve on the hydraulic cylinder with large power is reduced, the valve opening pressure difference of a servo valve on the hydraulic cylinder with small power is increased, and at the moment, flow output by a pump flowsto the hydraulic cylinder with the small power more. The load-sensitive double-hydraulic-cylinder synchronous system has the advantages that the synchronization speed is fast, the synchronization precision is high, the reliability is high, the energy is saved, and the like.

Owner:TAIYUAN UNIV OF TECH

Application of siraitia grosvenorii fruit residues in cultivation of Tricholoma lobayense Heim

The invention discloses an application of siraitia grosvenorii fruit residues in cultivation of Tricholoma lobayense Heim. Siraitia grosvenorii fruit residue powder is mixed with bagasse or corncob, bran, lime powder, calcium superphosphate and gypsum to prepare compost for cultivating the Tricholoma lobayense Heim. According to the application, one novel cultivation raw material for cultivating the Tricholoma lobayense Heim is provided, high yield and high quality of the Tricholoma lobayense Heim can be achieved, and further, utilization and resource recovery of waste are realized.

Owner:桂林健成生物科技开发有限公司 +1

Application of siraitia grosvenorii fruit residues in cultivation of abalone mushrooms

The invention discloses an application of siraitia grosvenorii fruit residues in cultivation of abalone mushrooms. Siraitia grosvenorii fruit residue powder is mixed with cottonseed hulls, bagasse or corncob, bran, gypsum powder and lime to prepare compost for cultivating the abalone mushrooms. According to the application, one novel cultivation raw material for cultivating the abalone mushrooms is provided, high yield and high quality of the abalone mushrooms can be achieved, and further, utilization and resource recovery of waste are realized.

Owner:桂林健成生物科技开发有限公司 +1

Application of siraitia grosvenorii fruit residues in cultivation of tremella aurantialba

The invention discloses an application of siraitia grosvenorii fruit residues in cultivation of tremella aurantialba. Siraitia grosvenorii fruit residue powder is mixed with cottonseed hulls, weed tree sawdust, bran, corn flour, gypsum powder and calcium carbonate to prepare compost for cultivating the tremella aurantialba. According to the application, one novel cultivation raw material for cultivating the tremella aurantialba is provided, high yield and high quality of the tremella aurantialba can be achieved, and further, utilization and resource recovery of waste are realized.

Owner:桂林健成生物科技开发有限公司 +1

Application of siraitia grosvenorii fruit residues in cultivation of auricularia polytricha

InactiveCN104892261ARealize resourcesSame outputEnergy inputFertilizer mixturesAgaricResource recovery

The invention discloses an application of siraitia grosvenorii fruit residues in cultivation of auricularia polytricha. Siraitia grosvenorii fruit residue powder is mixed with cottonseed hulls, weed tree sawdust, bran, lime powder and gypsum powder to prepare compost for cultivating the auricularia polytricha. According to the application, one novel cultivation raw material for cultivating the auricularia polytricha is provided, high yield and high quality of the auricularia polytricha can be achieved, and further, utilization and resource recovery of waste are realized.

Owner:桂林健成生物科技开发有限公司 +1

Application of siraitia grosvenorii fruit residues in cultivation of oudemansiella radicata

The invention discloses an application of siraitia grosvenorii fruit residues in cultivation of oudemansiella radicata. Siraitia grosvenorii fruit residue powder is mixed with cottonseed hulls, bran, gypsum powder and calcium carbonate to prepare compost for cultivating the oudemansiella radicata. According to the application, one novel cultivation raw material for cultivating the oudemansiella radicata is provided, high yield and high quality of the oudemansiella radicata can be achieved, and further, utilization and resource recovery of waste are realized.

Owner:桂林健成生物科技开发有限公司 +1

Application of momordica grosvenori pomace to cultivating pleurotus nebrodensis

The invention discloses application of momordica grosvenori pomace to cultivating pleurotus nebrodensis. Momordica grosvenori pomace powder is mixed with cottonseed hulls, bran, corn flour, land plaster and calcium carbonate so as to prepare composts for cultivating the pleurotus nebrodensis. The new cultivating raw materials for cultivating the pleurotus nebrodensis are provided, and the high yield and the high quality of the pleurotus nebrodensis can be achieved; in addition, waste can be used, and waste recycling is achieved.

Owner:桂林健成生物科技开发有限公司 +1

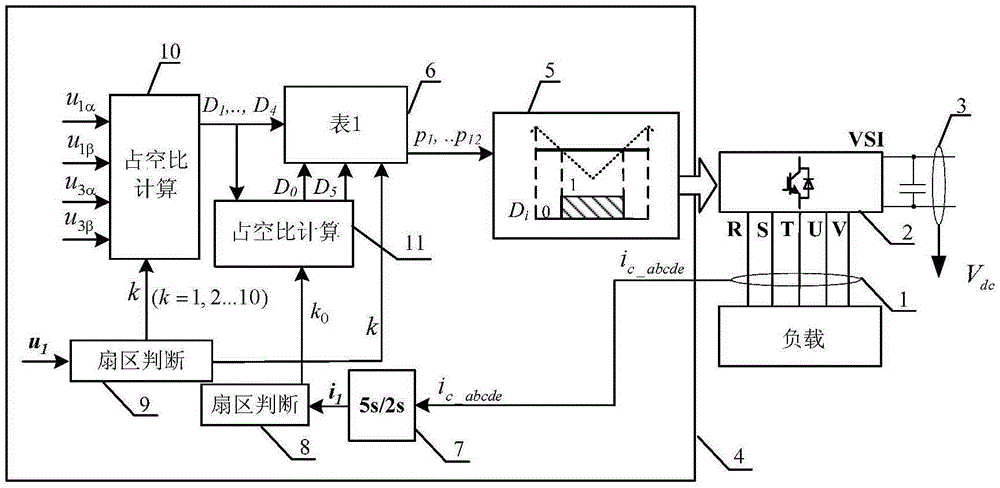

Five-phase inverter space vector modulation system and method with optimal switching loss

ActiveCN105375808ASame outputExcellent lossAC motor controlEfficient power electronics conversionPhase currentsVoltage vector

The invention discloses a five-phase inverter space vector modulation method with an optimal switching loss. The five-phase inverter space vector modulation method comprises the following steps: collecting a direct current voltage of a five-phase inverter; calculating duty ratios of four space voltage vectors according to a voltage sector signal, a first frequency voltage setting and a second frequency voltage setting; collecting a phase current of the five-phase inverter, and converting the phase current into current signals under a two-phase static coordinate system; calculating the duty ratios of a first zero vector and a second zero vector according to a current sector signal and the duty ratios of the four space voltage vectors; and judging in which sector the current voltage is located, and calculating drive signals of five bridge arm switch tubes according to the duty ratio of the first zero vector, the duty ratios of the four space voltage vectors and a switching sequence table corresponding to the sector number. According to the method, the optimal efficiency of the inverter is achieved from the angle of a control strategy on the basis of not changing hardware of the inverter. The invention further discloses a five-phase inverter space vector modulation system with the optimal switching loss.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Application of siraitia grosvenorii pomace in straw mushroom cultivation

The invention discloses an application of siraitia grosvenorii pomace in straw mushroom cultivation. According to the application, the siraitia grosvenorii pomace powder is matched with waste cotton residue, gypsum powder and lime powder to form a culture material for straw mushroom cultivation. The invention provides a new culture raw material for straw mushroom cultivation; besides, high yield and high quality of straw mushrooms can be realized; in addition, waste utilization and waste recycling are realized.

Owner:桂林健成生物科技开发有限公司 +1

Application of momordica grosvenori pomace to tremella cultivation

The invention discloses application of momordica grosvenori pomace to tremella cultivation. A culture medium for tremella cultivation is prepared from momordica grosvenori pomace powder, cottonseed hull, bran, soybean meal, saccharose, gypsum powder and calcium superphosphate. The novel culture medium, provided by the invention, for tremella cultivation has the advantages that the yield and the quality of tremella can be high, and waste utilization and waste recycling are realized.

Owner:桂林健成生物科技开发有限公司 +1

Application of siraitia grosvenorii fruit residues in cultivation of enoki mushrooms

The invention discloses an application of siraitia grosvenorii fruit residues in cultivation of enoki mushrooms. Siraitia grosvenorii fruit residue powder is mixed with cottonseed hulls, bran, corn flour, gypsum powder and calcium carbonate to prepare compost for cultivating the enoki mushrooms. According to the application, one novel cultivation raw material for cultivating the enoki mushrooms is provided, high yield and high quality of the enoki mushrooms can be achieved, and further, utilization and resource recovery of waste are realized.

Owner:桂林健成生物科技开发有限公司 +1

Application of siraitia grosvenorii fruit residues in cultivation of agrocybe cylindracea

InactiveCN104892251ARealize resourcesSame outputFertilizer mixturesAgrocybe rivulosaSiraitia Grosvenorii Fruit

The invention discloses an application of siraitia grosvenorii fruit residues in cultivation of agrocybe cylindracea. Siraitia grosvenorii fruit residue powder is mixed with cottonseed hulls, wheat bran, gypsum powder and calcium carbonate to prepare compost for cultivating the agrocybe cylindracea. According to the application, one novel cultivation raw material for cultivating the agrocybe cylindracea is provided, high yield and high quality of the agrocybe cylindracea can be achieved, and further, utilization and resource recovery of waste are realized.

Owner:桂林健成生物科技开发有限公司 +1

Application of momordica grosvenori pomace to pleurotus geesteranus cultivation

The invention discloses application of momordica grosvenori pomace to pleurotus geesteranus cultivation. A culture medium for tremella cultivation is prepared from momordica grosvenori pomace powder, cottonseed hull, bran, gypsum and calcium carbonate. The novel culture medium, provided by the invention, for tremella cultivation has the advantages that the yield and the quality of pleurotus geesteranus can be high, and waste utilizatio and waste recycling are realized.

Owner:桂林健成生物科技开发有限公司 +1

Application of siraitia grosvenorii fruit residues in cultivation of white beech mushrooms

The invention discloses an application of siraitia grosvenorii fruit residues in cultivation of white beech mushrooms. Siraitia grosvenorii fruit residue powder is mixed with cottonseed hulls, bran, corn flour, gypsum powder and calcium carbonate to prepare compost for cultivating the white beech mushrooms. According to the application, one novel cultivation raw material for cultivating the white beech mushrooms is provided, high yield and high quality of the white beech mushrooms can be achieved, and further, utilization and resource recovery of waste are realized.

Owner:桂林健成生物科技开发有限公司 +1

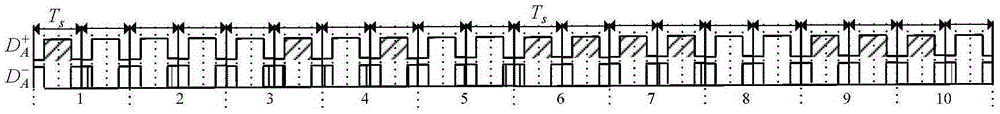

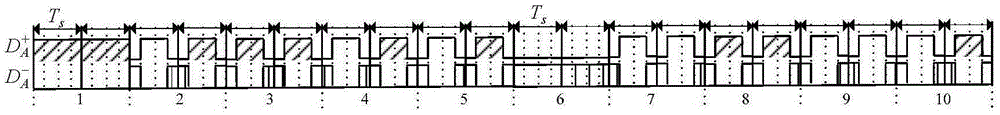

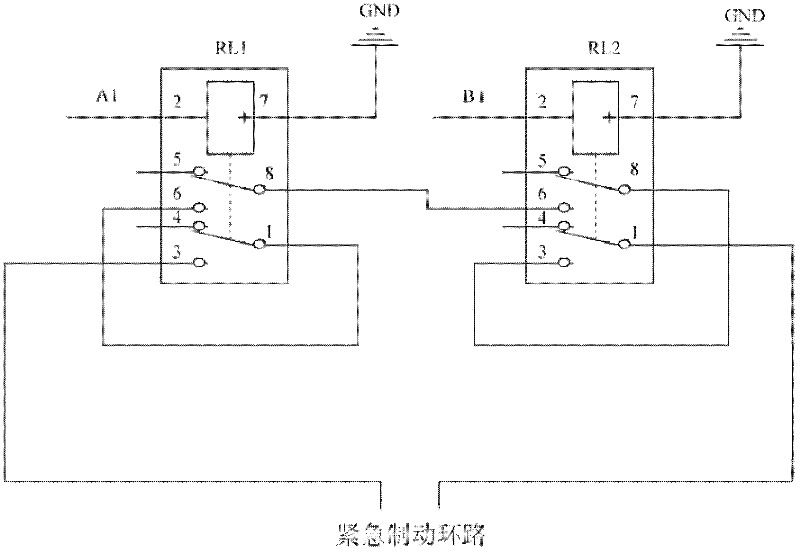

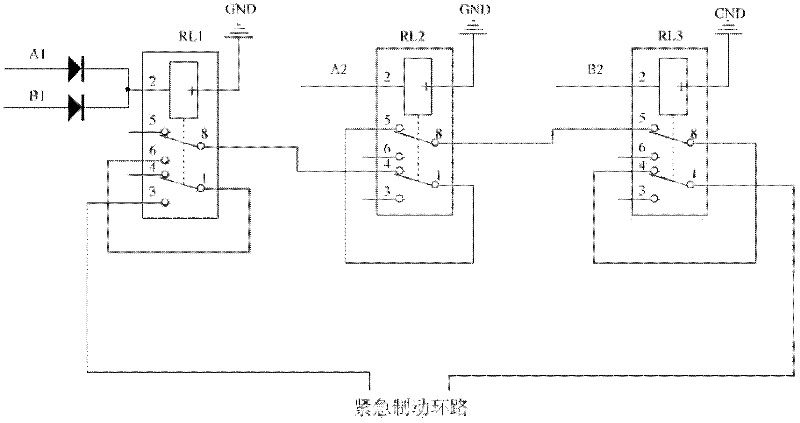

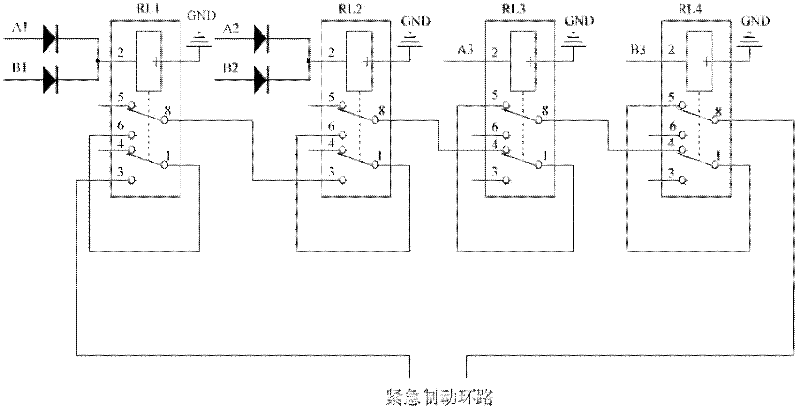

Control circuit for emergency brake loop

The invention discloses a control circuit for an emergency brake loop, relating to the technical field of train control. The control circuit comprises at least one normally opening relay and two normally closed relays, which are connected in series in an emergency brake loop, wherein the at least one normally opening relay is simultaneously controlled by two host machines, and the two normally closed relays are respectively controlled by the two host machines. According to the control circuit for the emergency brake loop, the normally opening relay controlled simultaneously by the two host machines is arranged in series in the emergency brake loop, so that the two host machines output same signals, and the system can normally operate without using a switch device after one of the two host machines cannot work.

Owner:TRAFFIC CONTROL TECH CO LTD

Application of siraitia grosvenori pomace in cultivating coriolus versicolor

The invention discloses the application of siraitia grosvenori pomace in cultivating coriolus versicolor. According to the application, siraitia grosvenori pomace powder is combined with cotton seed hulls, weed tree sawdust, bran, land plaster and calcium carbonate, so that cultivation compost for cultivating the coriolus versicolor is produced out. By means of the novel cultivation compost for cultivating the coriolus versicolor, the high yield and the high quality of the coriolus versicolor can be achieved, waste materials are utilized, and the reclamation of wastes is achieved.

Owner:桂林健成生物科技开发有限公司 +1

Application of siraitia grosvenorii fruit residues in cultivation of oyster mushrooms

The invention discloses an application of siraitia grosvenorii fruit residues in cultivation of oyster mushrooms. Siraitia grosvenorii fruit residue powder is mixed with cottonseed hulls, straw, bran, lime, phosphatic fertilizer and gypsum to prepare compost for cultivating the oyster mushrooms. The application has the advantages as follows: one novel cultivation raw material for cultivating the oyster mushrooms is provided, high yield and high quality of the oyster mushrooms can be achieved, and further, utilization and resource recovery of waste are realized.

Owner:桂林健成生物科技开发有限公司 +1

Application of momordica grosvenori pomace to hericium erinaceus cultivation

The invention discloses application of momordica grosvenori pomace to hericium erinaceus cultivation. A culture medium for tremella cultivation is prepared from momordica grosvenori pomace powder, cottonseed hull, bran and gypsum powder. The application has the advantages that waste utilization and waste recycling are realized, and the yield and the quality of hericium erinaceus can be high.

Owner:桂林健成生物科技开发有限公司 +1

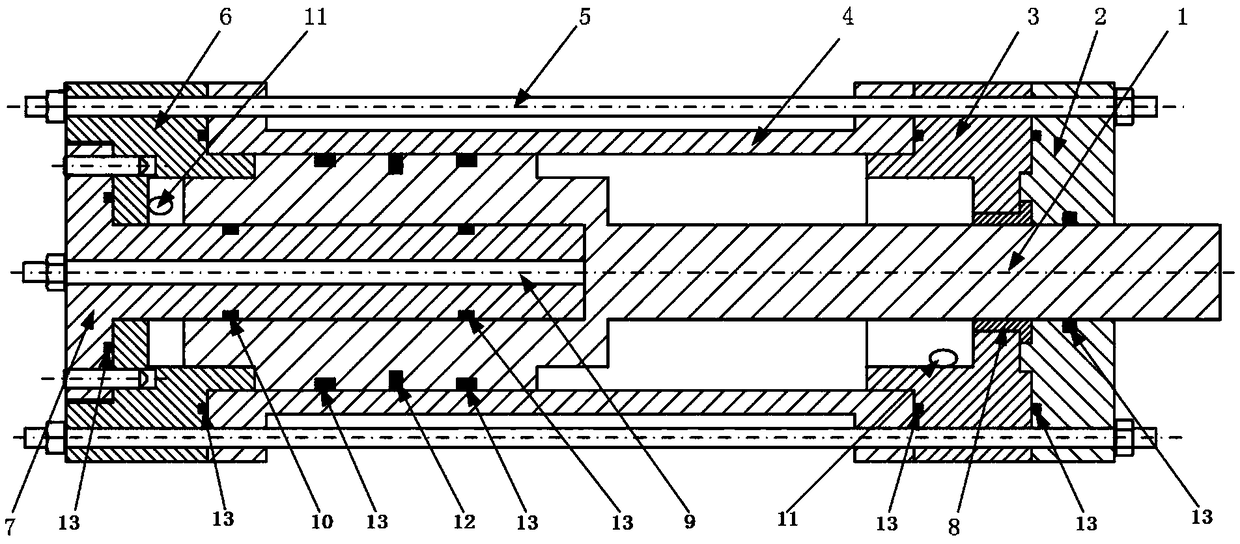

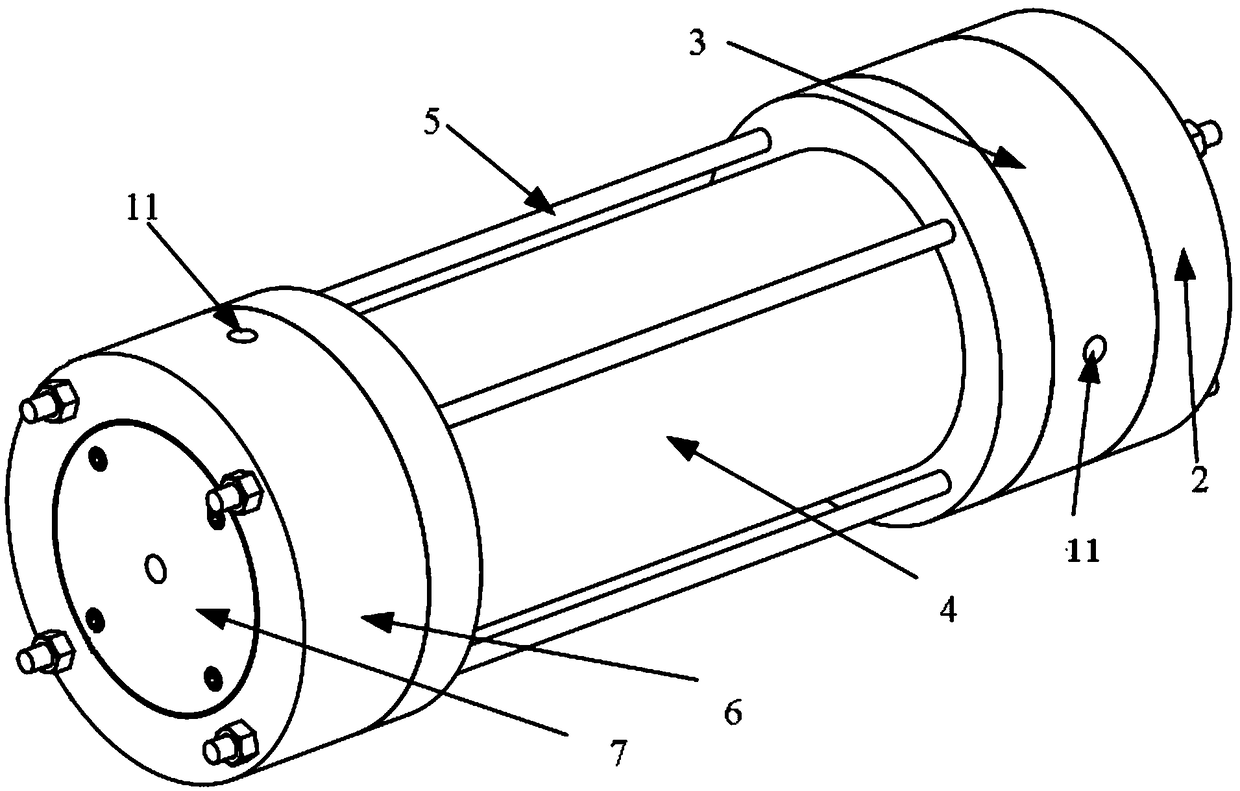

Easy-to-control single rod type piston cylinder based on equivalent acting surface

ActiveCN108869448AConsistent performanceSymmetrical outputFluid-pressure actuatorsHydraulic cylinderCylinder head

The invention discloses an easy-to-control single rod type piston cylinder based on an equivalent acting surface. The easy-to-control single rod type piston cylinder comprises a cylinder cover, a cylinder head, a cylinder barrel, a cylinder bottom, a piston rod and a guide rod, wherein the cylinder cover and the cylinder head are arranged at one end of the cylinder barrel in sequence in a sealingmanner; the cylinder cover is located at the outer side of the cylinder head; the cylinder bottom is arranged at the other end of the cylinder barrel in the sealing manner; the piston rod comprises apiston head and a connection rod, which are connected; the piston head is located in the cylinder barrel; the connection penetrates out of the cylinder head and the cylinder cover; a cylindrical holeis formed in the middle of the piston head; one end of the guide rod is embedded into the cylindrical hole and the other end of the guide rod is in sealed connection with the cylinder bottom; the diameter of one end, which is embedded with the cylindrical hole, of the guide rod is equal to the diameter of the connection rod; an oil hole is formed in each of the cylinder head and the cylinder bottom. According to the easy-to-control single rod type piston cylinder based on the equivalent acting surface, two chambers of the piston cylinder have an equal effective acting area, so that the performance of a piston on positive and negative routes is consistent and the flow of an oil inlet and an oil outlet is symmetrical; the flow is symmetrical in two movement directions so that output and input properties of the single rod type piston cylinder are the same, and the hydraulic cylinder is easier to detect and control.

Owner:YANSHAN UNIV

Double-mode driven brake hydraulic control system of belt conveyor

ActiveCN109335471ASolve the problem of drive power imbalanceSame outputConveyorsServomotor componentsGear pumpDrive motor

The invention relates to a double-mode driven brake hydraulic control system of a belt conveyor. The double-mode driven brake hydraulic control system of the belt conveyor comprises a hydraulic station connected with a hydraulic motor and a PLC connected with a drive motor. The hydraulic station comprises an oil tank, a power oil path and an electro-hydraulic directional valve. One end of the power oil path is connected with the electro-hydraulic directional valve, and the other end of the power oil path is connected with the oil tank. Two oil outlets of the electro-hydraulic directional valveare connected with the hydraulic motor. A first shuttle valve is connected between the two oil outlets of the electro-hydraulic directional valve. A middle oil port of the first shuttle valve is connected with a second shuttle valve. A middle oil outlet of the second shuttle valve is connected with a brake oil cylinder of a hydraulic brake. The other oil port of the second shuttle valve is connected with a gear pump which is connected with a brake motor. The brake motor is connected with am variable frequency inverter which is connected with the PLC. The problem of power unbalance of two-motor driving is solved, the hydraulic system can adjust output torque and rotation speed automatically, and it is ensured that drive units are the same in output force and rotation speed; effective braking can be achieved; and the hydraulic system can absorb part of impact loads.

Owner:SHANDONG UNIV OF SCI & TECH

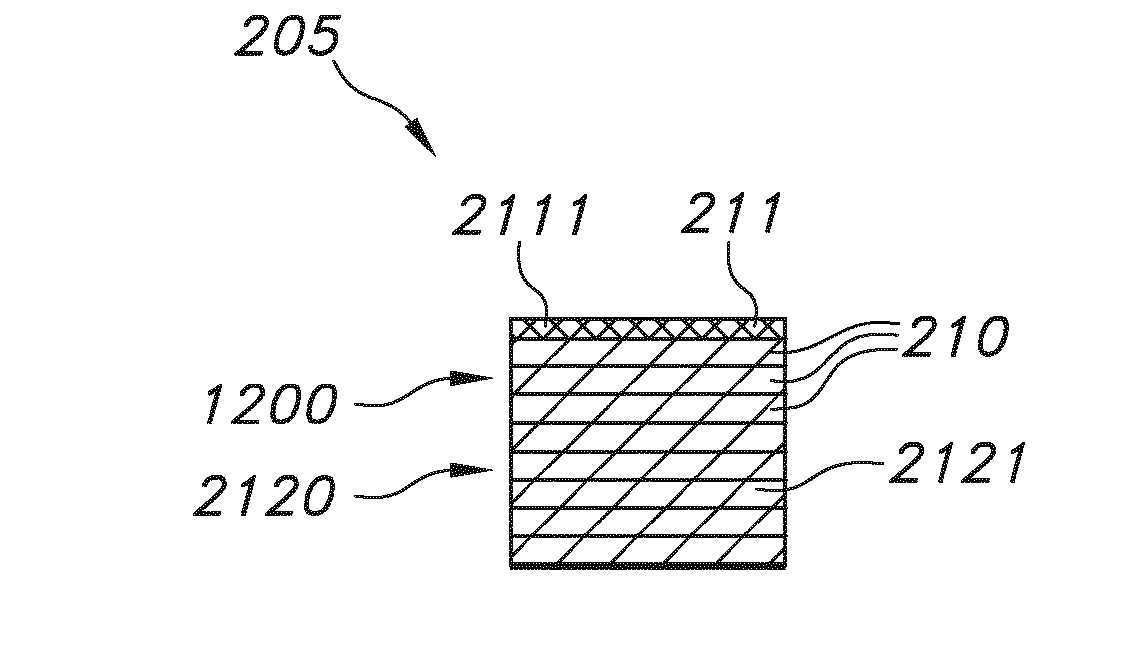

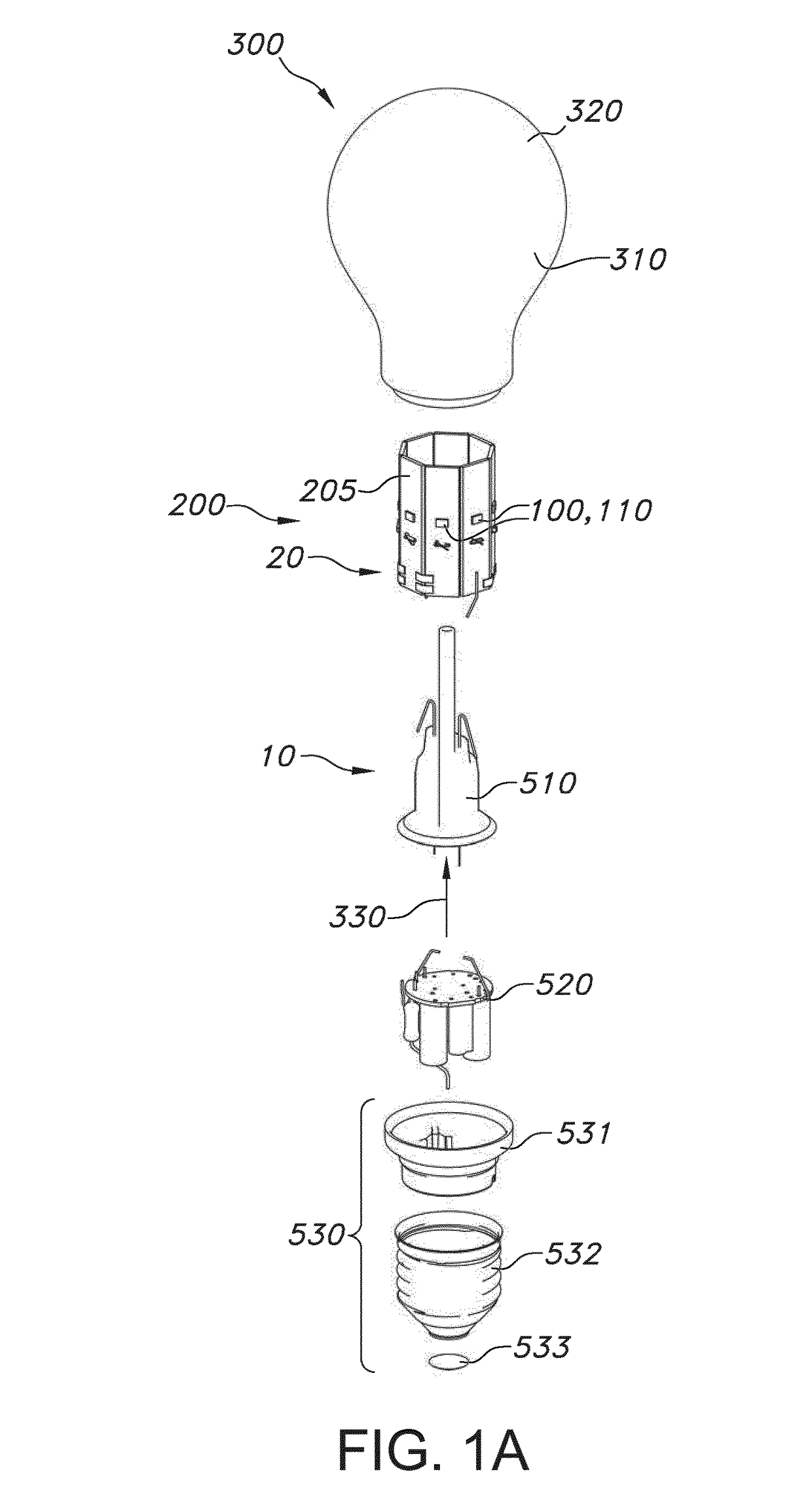

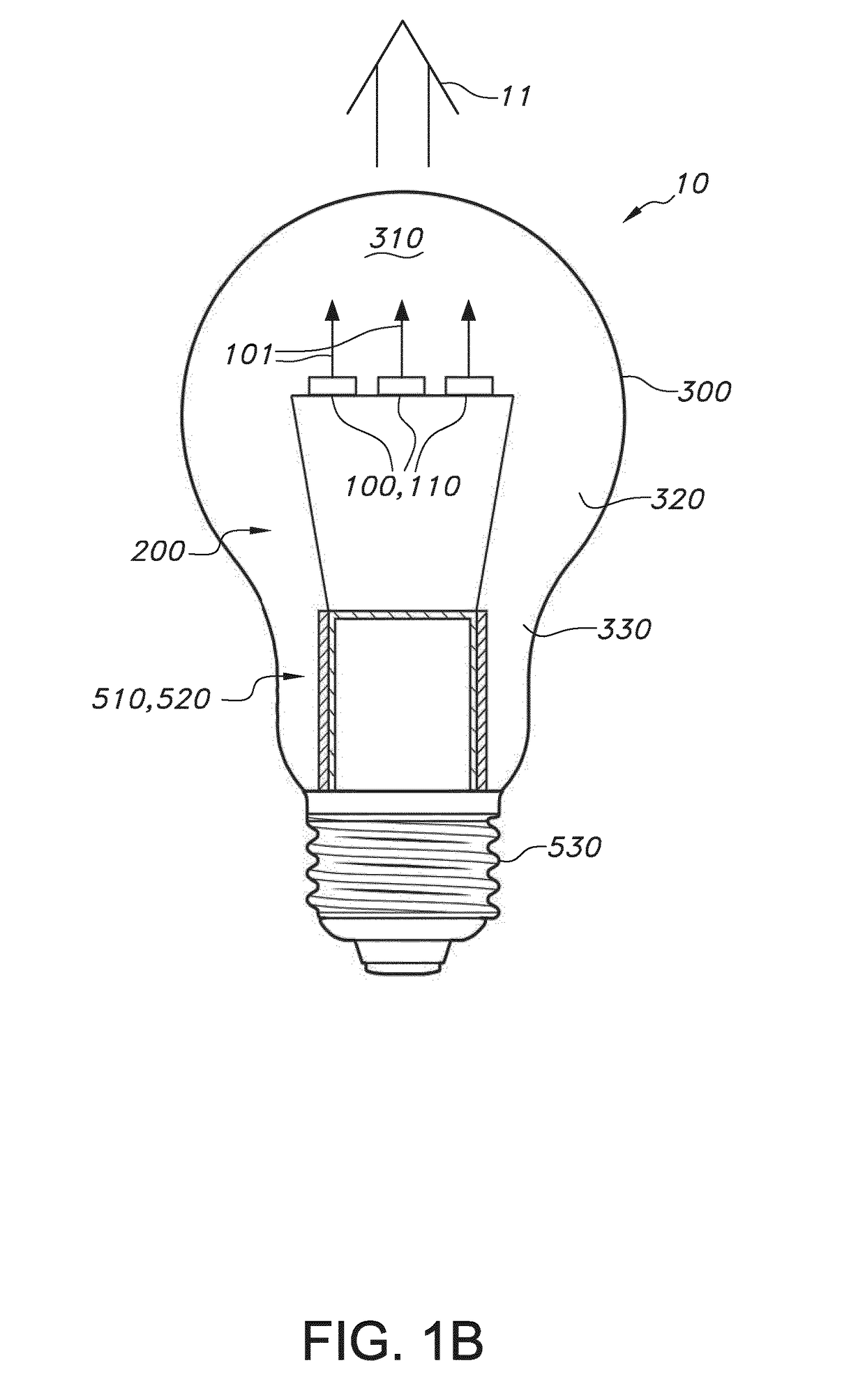

Barrier layer delaying oxygen depletion in sealed gas-filled LED lamps

InactiveUS20180255642A1Reduce oxidation rateThermal oxidation can be delayed and reducedFinal product manufactureLighting heating/cooling arrangementsEngineeringCopper

The invention provides a lighting unit (10) comprising (a) a lighting device (100), (b) a support (200), and (c) an envelope (300), wherein: —the lighting device (100) is configured to provide lighting device light (101); wherein the lighting device (100) comprises a light source (110); —the support (200) is configured to support the light source (110); wherein the 5 support (200) comprises a laminate of layers, wherein the laminate of layers comprises an electrically conductive first layer, an electrically non-conducive second layer), and a third layer, wherein the first layer comprises copper, wherein the second layer comprises an epoxy-based material, and wherein the third layer comprises an oxygen barrier material; —the envelope (300) is configured to provide a sealed space (310) enclosing the 10 light source (110) and at least part of the support (200); wherein the envelope (300) comprises an envelope part (320) transmissive for the lighting device light (101), and wherein the sealed space (310) comprise a filling gas (330) comprising a thermally conductive gas, wherein the filling gas (330) at least comprises oxygen (O2).

Owner:SIGNIFY HLDG BV

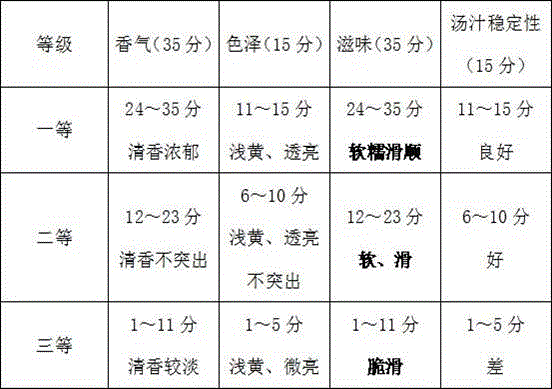

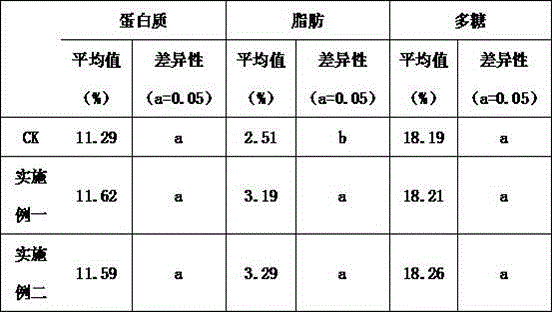

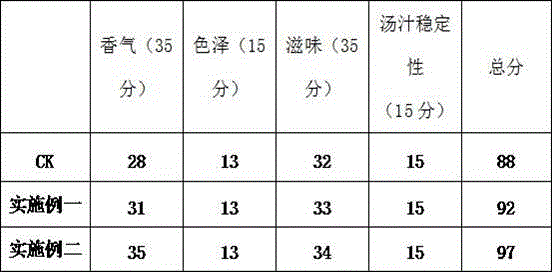

High-quality tremella cultivation medium and preparation method thereof

ActiveCN106831188ALow costImprove tasteCalcareous fertilisersBio-organic fraction processingGypsumPalm fiber

The invention discloses a high-quality tremella cultivation medium and a preparation method thereof. The cultivation medium comprises, by weight, 20-70 parts of olive branches, 20-60 parts of palm fibers, 10-40 parts of lotus seed hulls, 9-20 parts of palm meal, 5-10 parts of yeast protein and 1-2 parts of gypsum powder. According to the cultivation medium, the natural olive branches and the palm fibers serve as main carbon source substrates cultivating tremella and can completely replace cotton seed hulls, the yield of the tremella cultivated by the aid of the olive branches and the palm fibers is as same as that of the tremella cultivated by the aid of the cotton seed hulls, cost is can be reduced, the taste of the tremella can be improved, pesticide residue is completely eradicated, the yeast protein and fermented palm meal serve as main nitrogen sources cultivating the tremella are high in quality and environmentally friendly, cost is reduced, and the taste of the tremella is softer and lubricant.

Owner:FUJIAN XIANGYUN BIOTECH DEV CO LTD

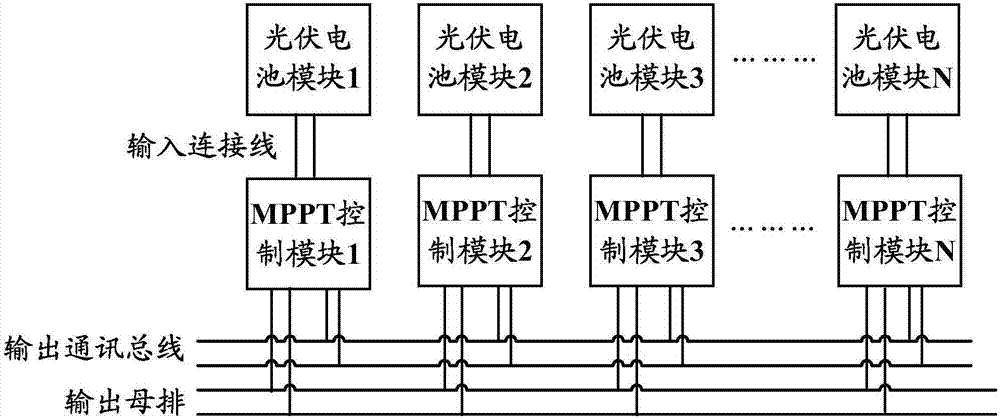

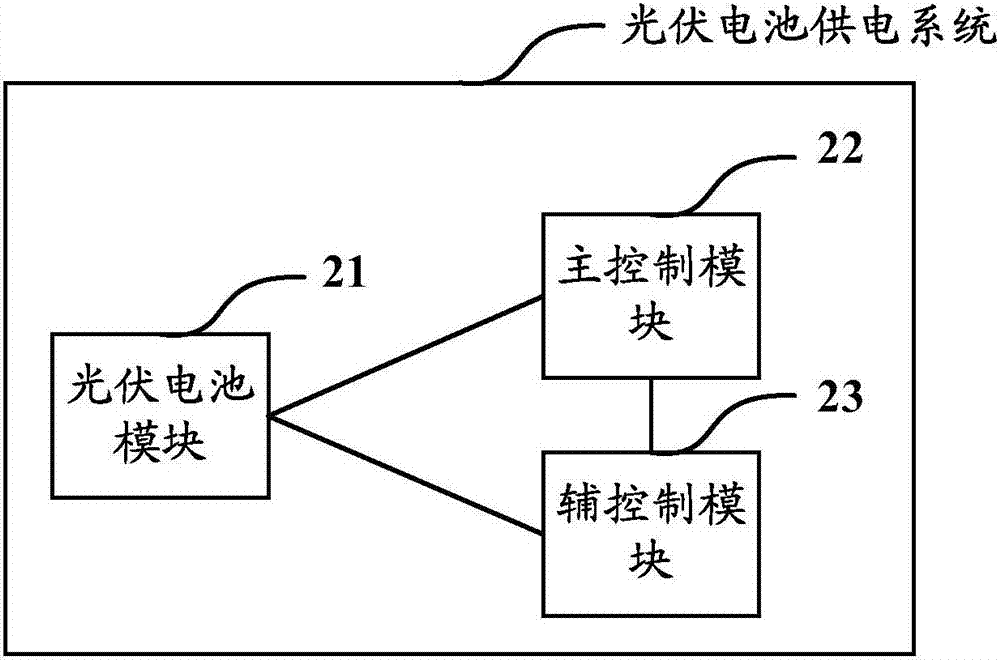

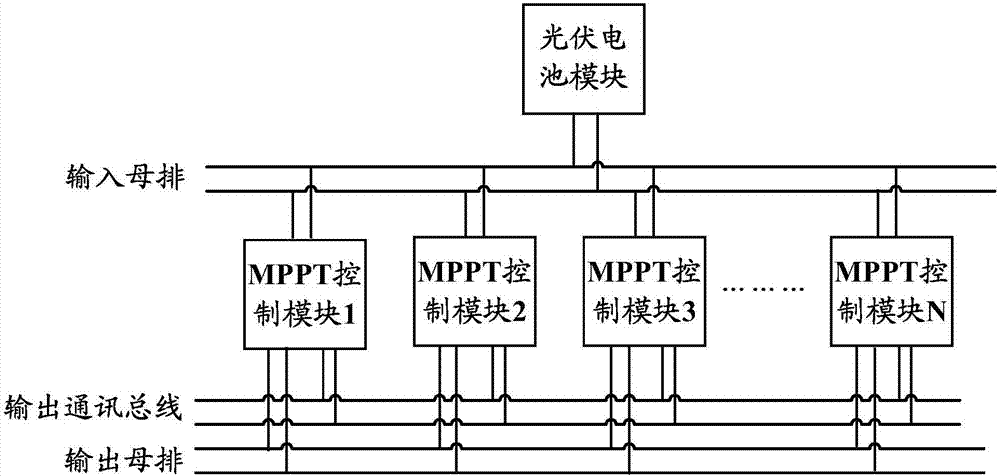

Photovoltaic battery power supply system, and MPPT control method and device

InactiveCN107887901AImprove power supply efficiencySame outputDc source parallel operationPhotovoltaic energy generationEngineeringUtilization rate

The invention discloses a photovoltaic battery power supply system, and an MPPT control method and device. The photovoltaic battery power supply system is composed of a photovoltaic battery module, amain control module and at least one auxiliary control module. Compared with the prior art, the photovoltaic battery power supply system is characterized by only comprising one photovoltaic battery module, so that the main control module and the at least one auxiliary control module are connected in parallel at an input stage; and thus the inputs of the main control module and the at least one auxiliary control module are identical, so that consistency of outputs of the main control module and the at least one auxiliary control module is ensured. Therefore, the number of photovoltaic battery modules is reduced; and the power supply efficiency of the photovoltaic battery power supply system and the utilization rate of the output energy are improved.

Owner:EMERSON NETWORK POWER CO LTD

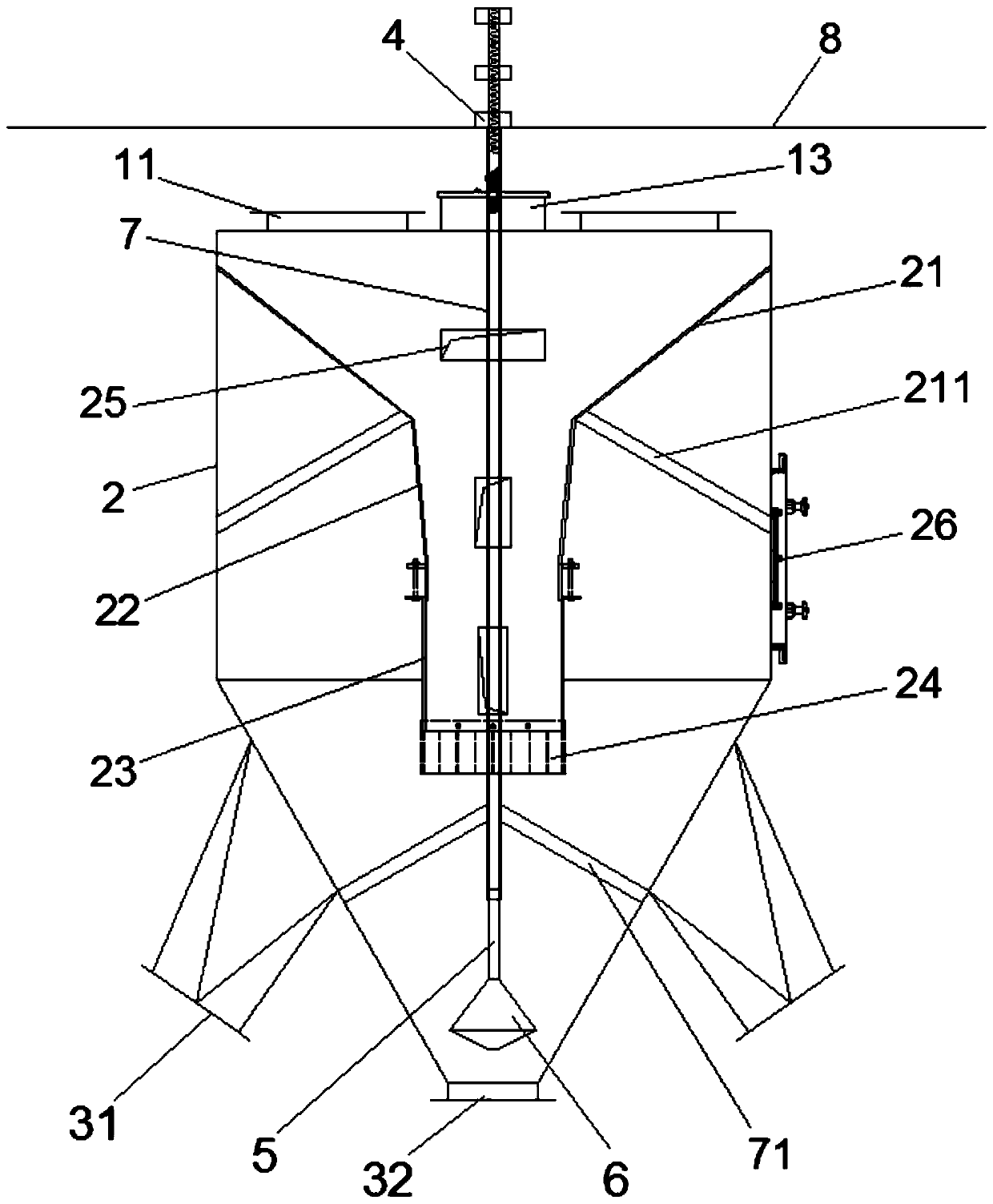

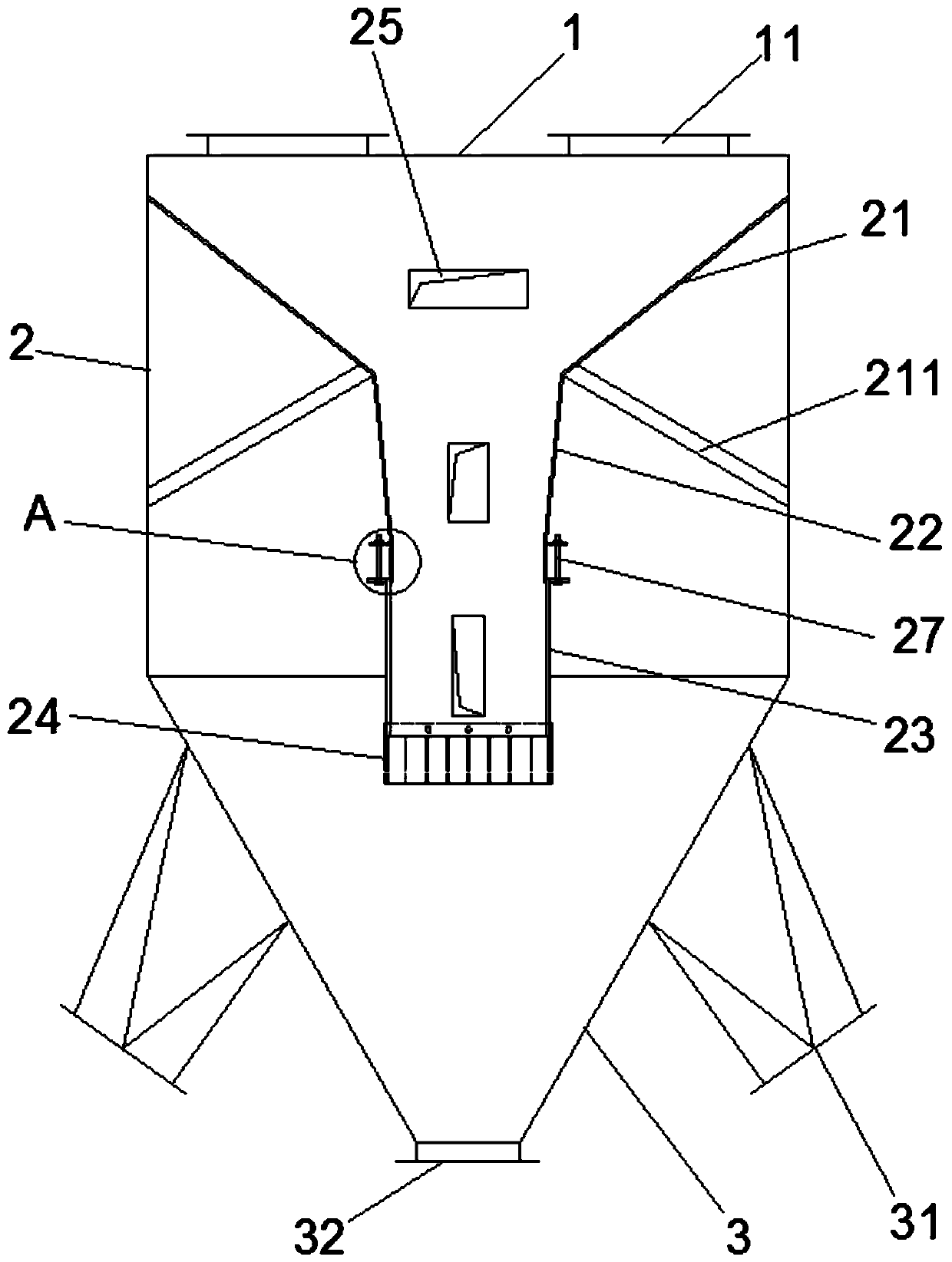

Silo top distributor

The invention discloses a silo top distributor and belongs to the field of grain and oil. The silo top distributor structurally comprises a shell, an adjusting device, a plurality of feeding inlets and a plurality of discharging outlets; the discharging outlets face towards inlets of corresponding storage bins and comprise the center discharging outlet and the multiple side discharging outlets; the shell comprises an upper cover plate, a middle box body and a lower conical hopper which are coaxially connected in sequence, and the small opening end of the lower conical hopper is the center discharging outlet; the side discharging outlets are uniformly arranged in the positions, close to the large opening end, of the lower conical hopper in the circumferential direction; and the adjusting device is used for achieving flow adjusting of the center discharging outlet. According to the silo top distributor, by directly utilizing the adjusting device, uniform overflowing operation of all thedischarging outlets is achieved, the device structure is simplified, and the investment cost is reduced; and meanwhile, the distributor is of a one-spot or multi-spot feeding structure, it is ensuredthat the discharging outlets are much the same in output through the various structures, the bin deflection phenomenon in a traditional scheme is reduced, the interior utilization rate of the storagebins is increased, the practicality of the storage bins is ensured, and the grading phenomenon in the material warehousing process is reduced.

Owner:GSS SYST SUZHOU

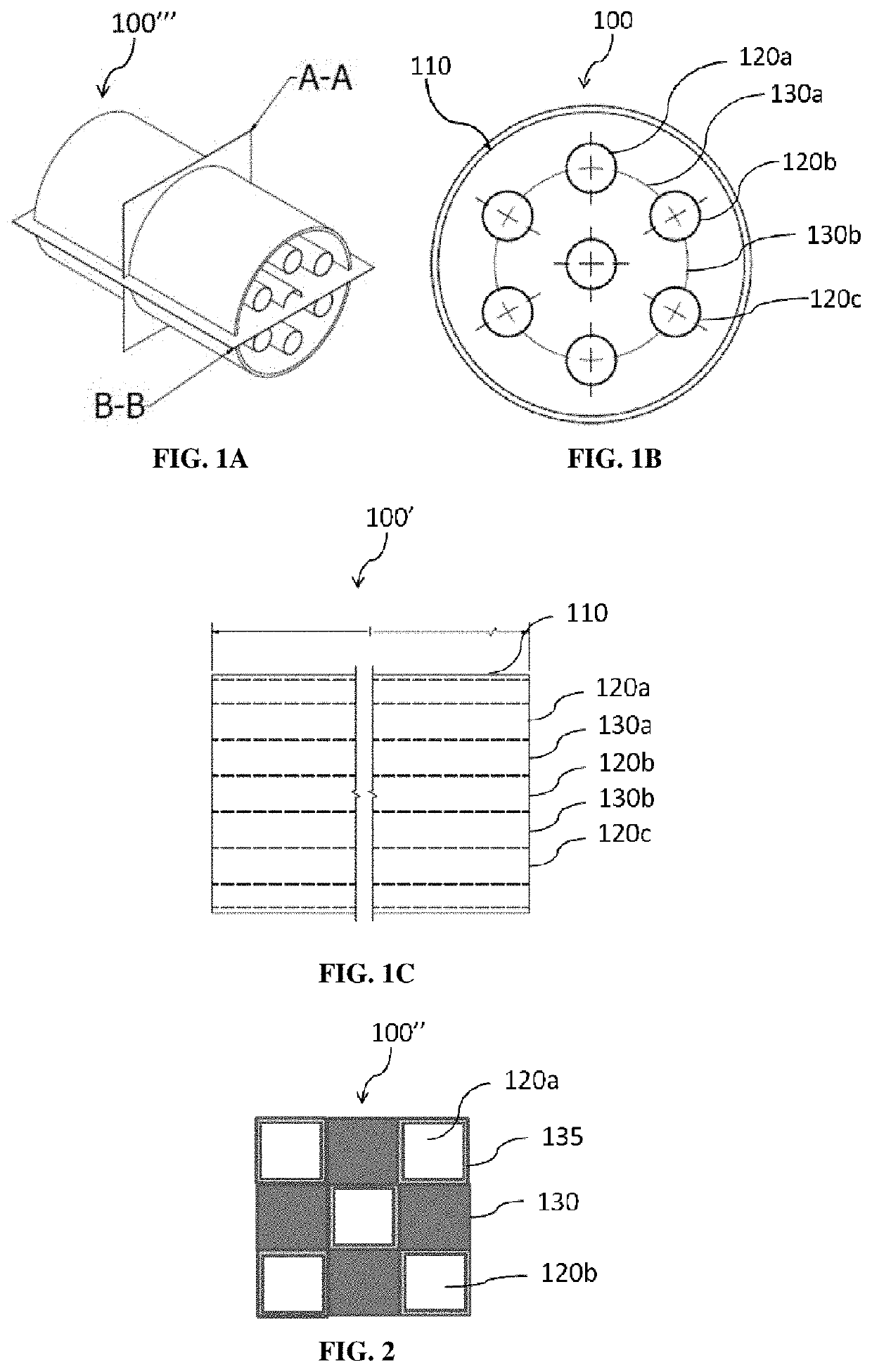

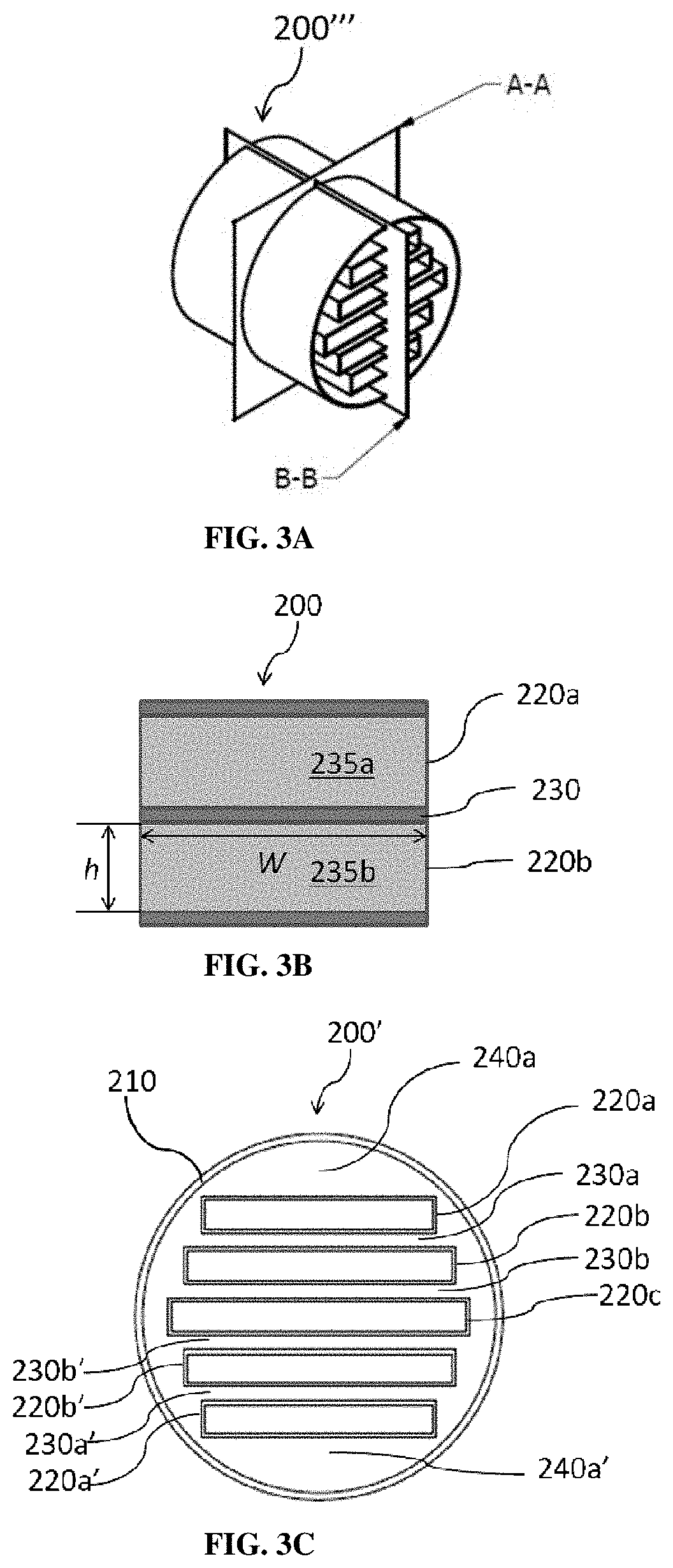

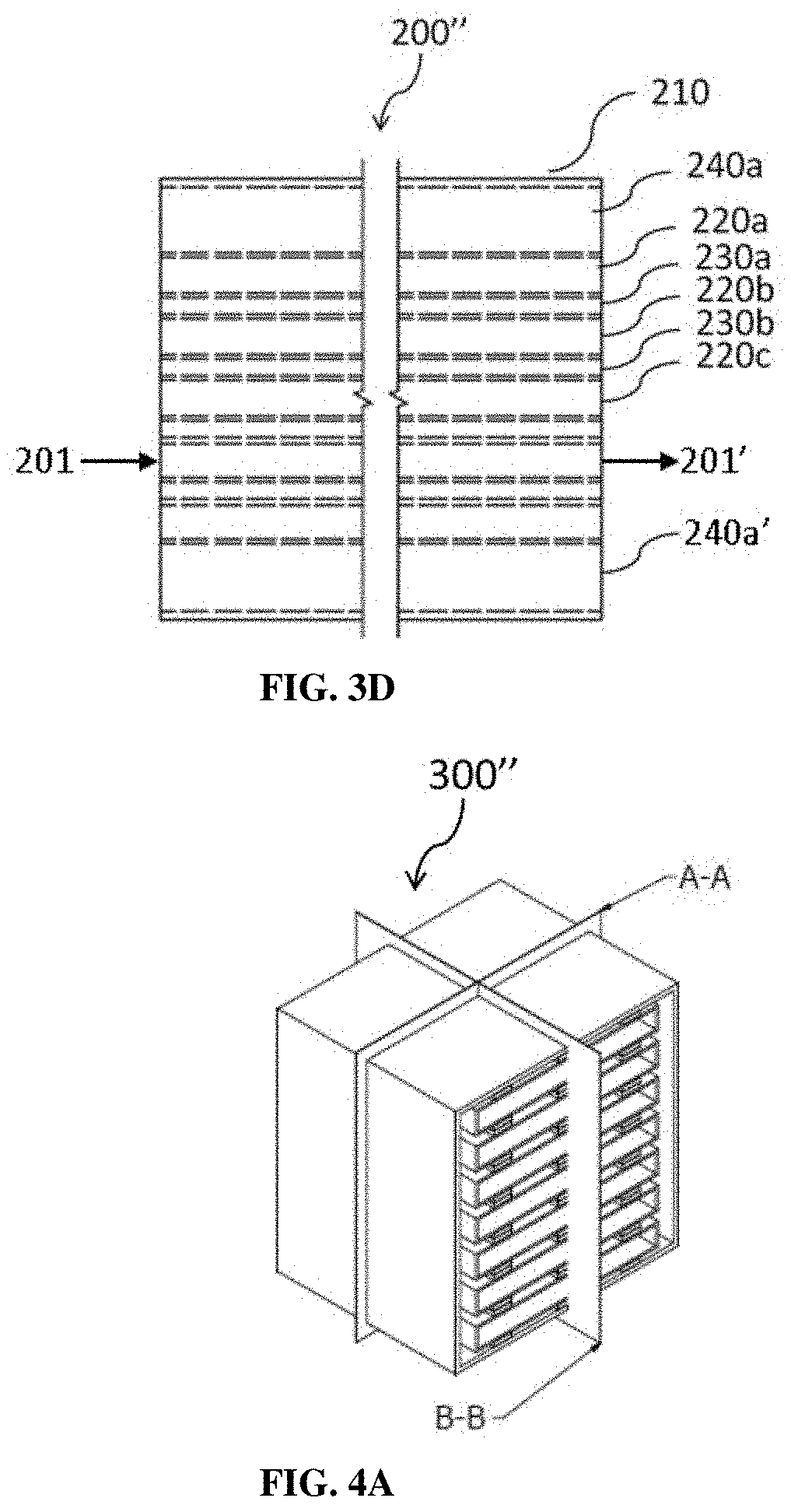

Channel reactors

ActiveUS10544371B2Small shell volumeSame outputHydrocarbon from carbon oxidesCatalyst regeneration/reactivationPtru catalystChemical reaction

Described is an industrial scale chemical reactor or reactor containing a shell having an inner wall, and at least one channel inside the shell. The shell has a circular, square, or rectangular cross-sectional area. All of the internal dimensions of the channel are greater than 10 mm, and optionally less than 50 mm. The channel has a rectangular cross-sectional area, and contains a catalyst bed containing catalyst particles and / or pieces containing catalyst particles packed inside the channel. The reactor has improved shell volume utilization, catalyst loading capacities, heat exchange efficiency, process intensification, or combinations thereof, compared to currently existing reactors. Exothermic reactions, such as the Fischer-Tropsch synthesis can be performed inside the channels of the reactor. Also described are methods of making the reactor.

Owner:INSTREETCARICRON

Oudemansiella radicata culture material using the root of sprouted beans and corn cob as carbon sources

The invention relates to an Oudemansiella radicata culture material using the root of sprouted beans and corn cob as carbon sources, wherein the Oudemansiella radicata culture material is prepared from the following components by weight: 40-45 parts of corn cob debris, 40-45 parts of the root of sprouted beans, 13-16 parts of bran, 0.8-1.2 parts of sugar and 0.8-1.2 parts of calcium carbonate through the existing technology. According to the present invention, the yield and the quality of the Oudemansiella radicata cultivated by using the crop waste as the carbon source are almost the same as the yield and the quality of the Oudemansiella radicata cultivated by using sawdust and cottonseed hull as the carbon source while the production cost is substantially reduced.

Owner:桂林宏泰养殖农民专业合作社

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com