Silo top distributor

A technology of feeder and outlet, which is applied in the field of feeder on the top of the warehouse, can solve the problems of unfavorable influence of the warehouse equipment, reduce work efficiency, and difficult to distribute materials evenly, so as to improve the efficiency of follow-up maintenance and installation, and the structure is simple , the effect of slowing down the partial position phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

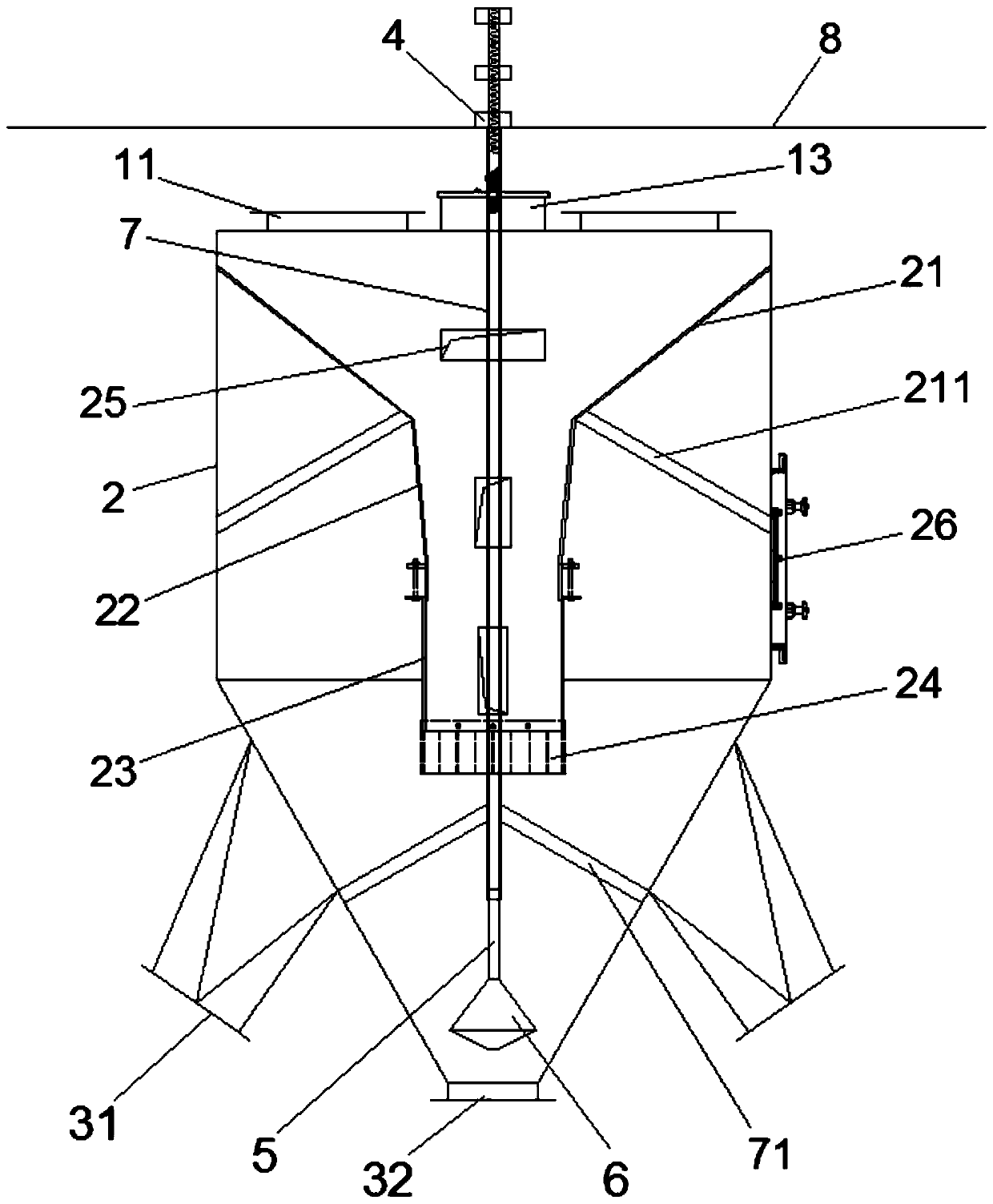

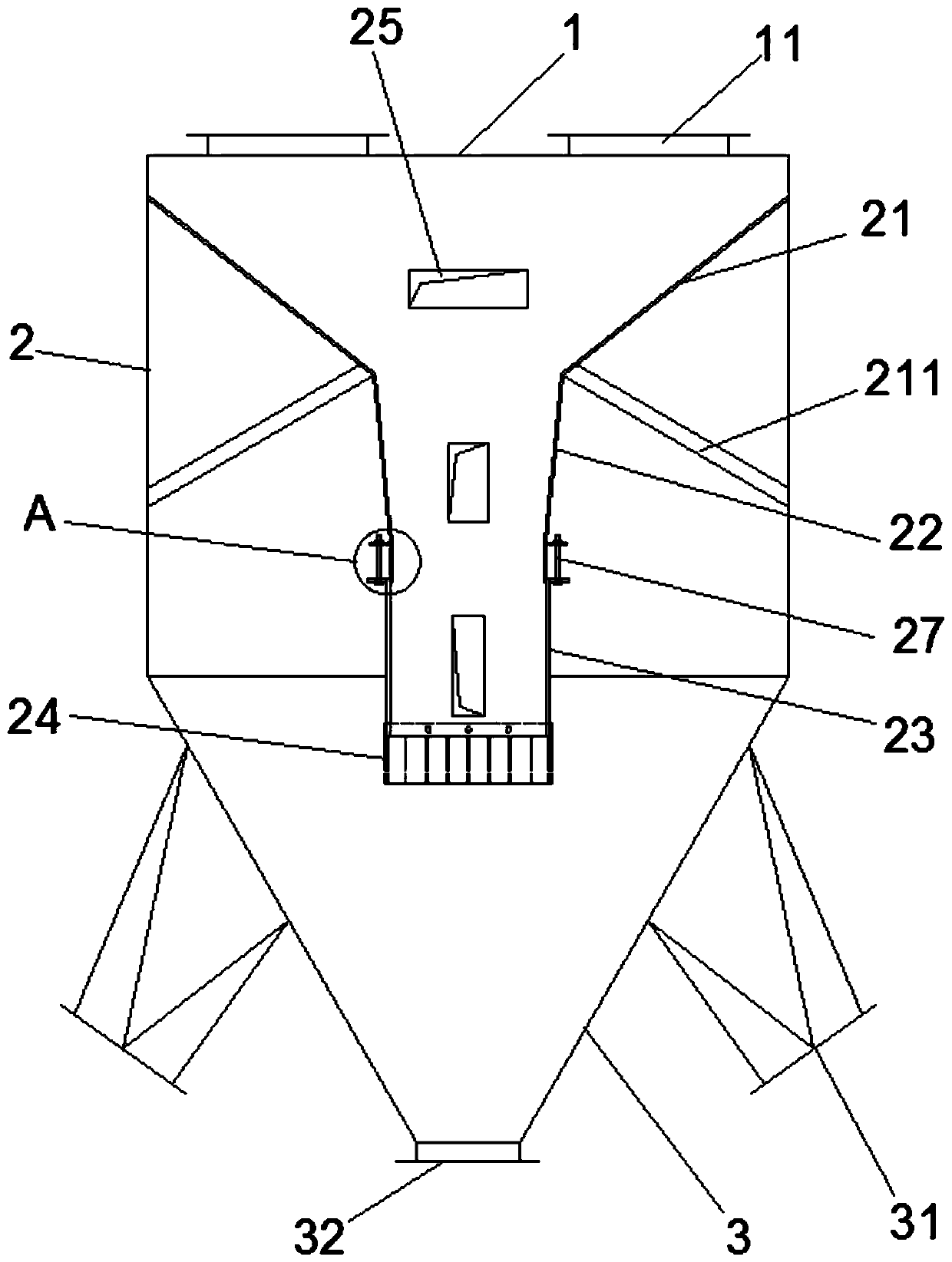

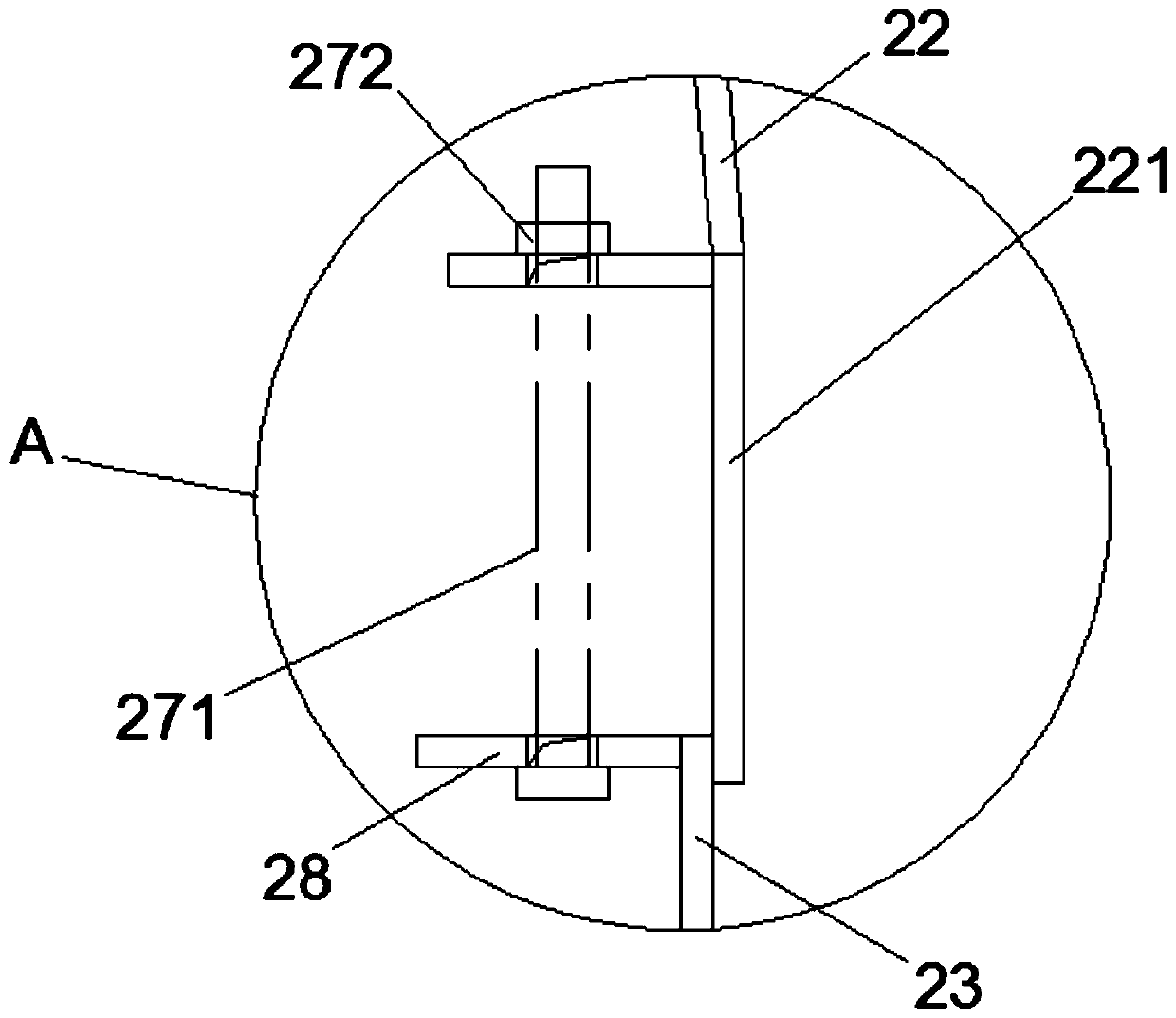

[0039] The shell structure of the dispenser includes an upper cover plate 1 , a middle box body 2 and a lower cone 3 that are coaxially connected in sequence. The upper cover 1, the middle box 2 and the lower cone 3 are connected by connecting flanges, that is, the shell structure is set as a split structure, which facilitates the subsequent transportation and storage of the structure, and facilitates the subsequent maintenance and replacement of each structure. The production cost is reduced, and the flange connection method is simple and easy to implement, ensuring the connection / disassembly efficiency. like figure 2 As shown, the middle box 2 is a cylindrical structure, the lower cone 3 is an inverted conical structure, and the structure of the upper cover plate 1 is as follows Figure 4 Shown is a circular structure that matches the end fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com