Patterned substrate for controlling gallium nitride nucleating growth position and preparation method thereof

A graphic substrate, gallium nitride technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as epitaxial growth defects of LED chips, and achieve the effects of reducing crystal defects, improving chip brightness, and improving crystal quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] see Figure 2 to Figure 5 , as shown in the figure, the present invention provides a method for preparing a graphics substrate for controlling the nucleation position of gallium nitride growth, and the method at least includes the following steps:

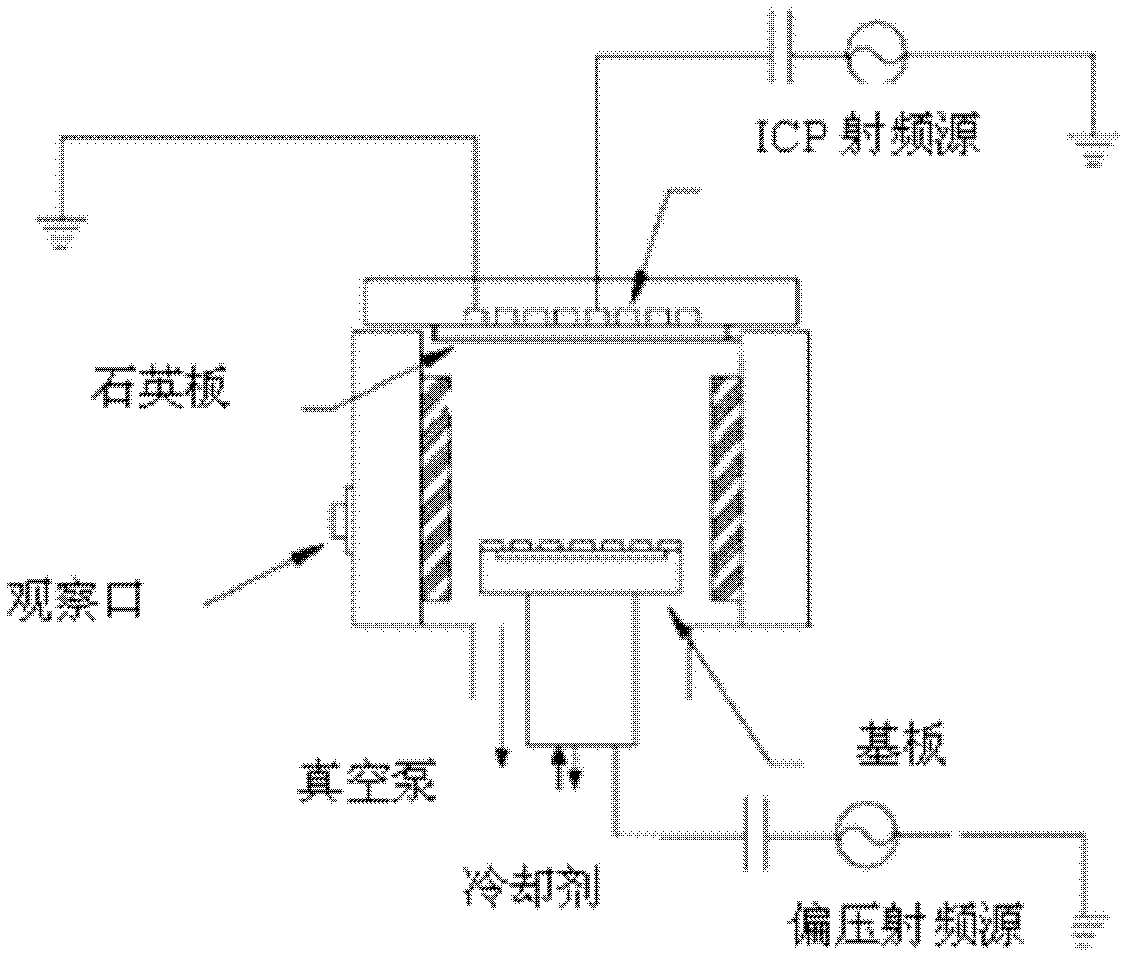

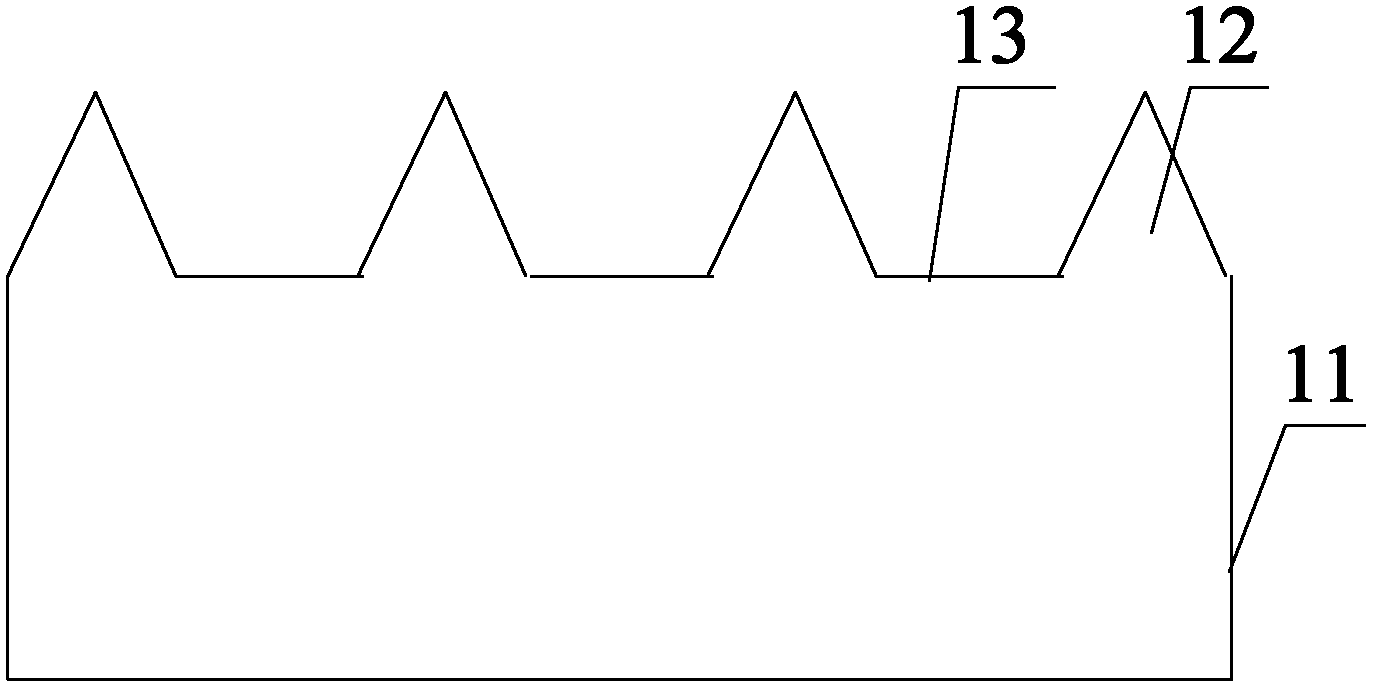

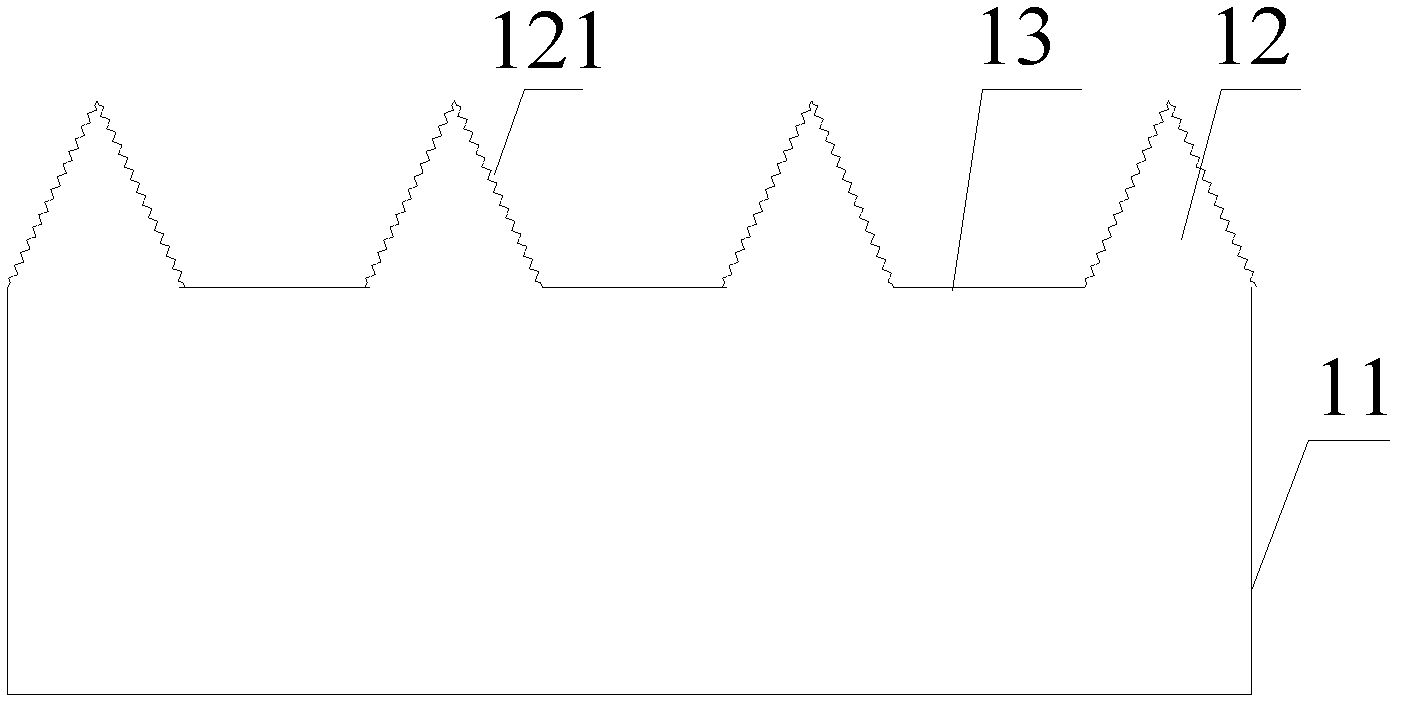

[0028] see figure 2 , as shown in the figure, at first step 1) is performed, a semiconductor substrate 11 is provided, and the semiconductor substrate 11 is etched for the first time to form a plurality of raised microstructures 12 on its surface, and each raised There are gap platforms 13 between the microstructures. In this embodiment, the semiconductor substrate 11 is a sapphire substrate, and the first etching is carried out in ICP etching equipment. In the specific implementation process, the surface is made of periodically arranged photoresist The patterned sapphire substrate is loaded into the ICP etching equipment, using BCl 3 gas as etchant gas or BCl 3 and Cl 2 The mixed gas is used as the etching gas, and th...

Embodiment 2

[0033] see Figure 2 to Figure 5 , as shown in the figure, the basic implementation steps of the preparation method of the graphic substrate used to control the growth and nucleation position of gallium nitride are as in Example 1, and in the dry etching equipment, the power of the RF radio frequency source is Between 30% and 50% of the rated power, the power of the bias RF source is 50% to 80% of the rated power of the equipment, the etching pressure is 0.2 to 0.5pa, the gas flow is 50 to 150sccm, and the processing time is 5 to 10 minutes .

[0034] see image 3 , as shown in the figure, the structure of the graphics substrate used to control the growth and nucleation position of GaN is as shown in Embodiment 1.

[0035] Through the processing technology of the invention, a high-quality patterned sapphire substrate can be produced, and the light extraction efficiency of the LED chip can be improved. After graphic surface treatment, the brightness can be increased by 10%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com