Method for preparing substrate having monocrystalline film

A technology of single crystal thin film and single crystal substrate, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as economic disadvantages, high material costs and process costs, safety and health issues, and achieve low cost , high smoothness, less crystal defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

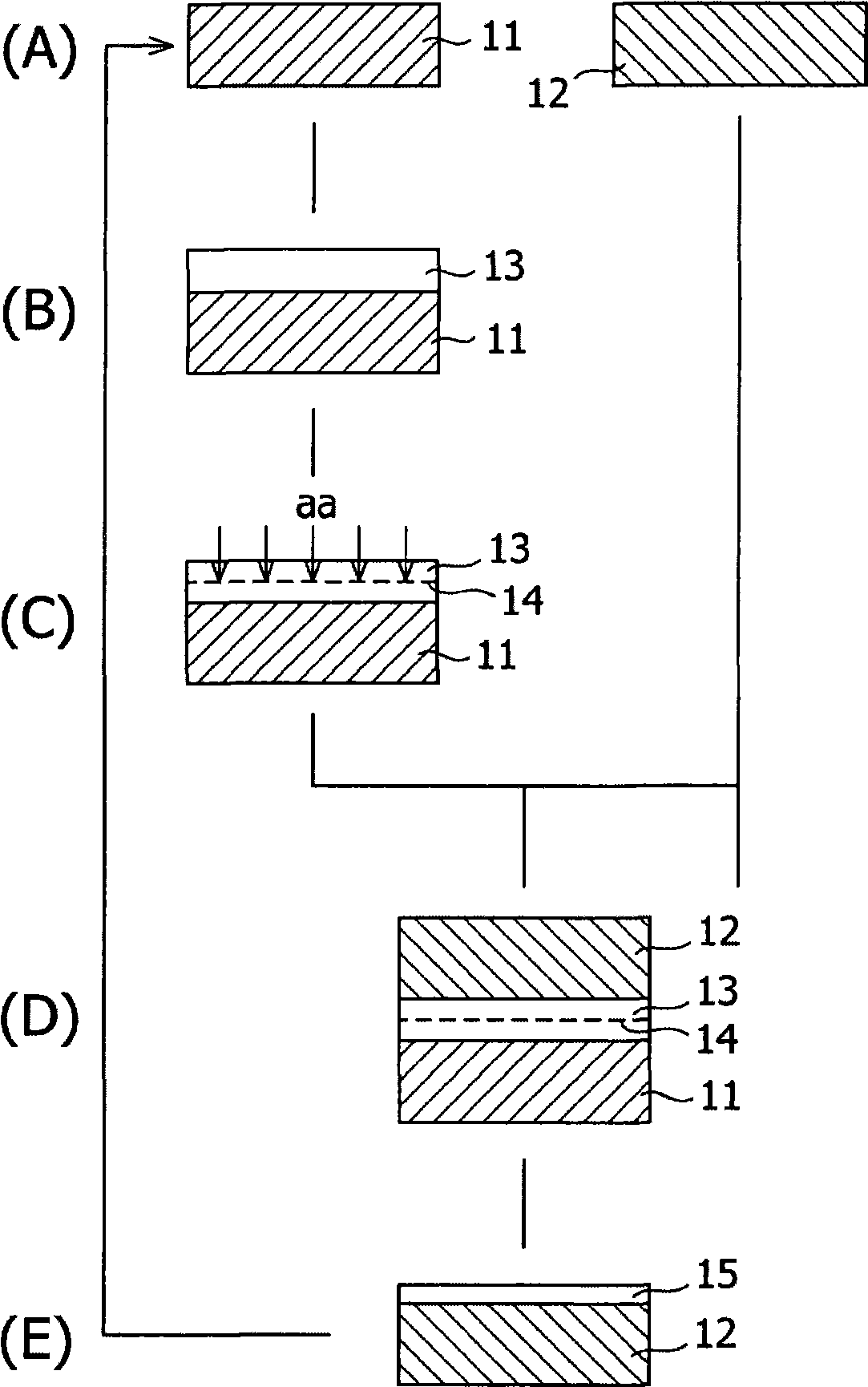

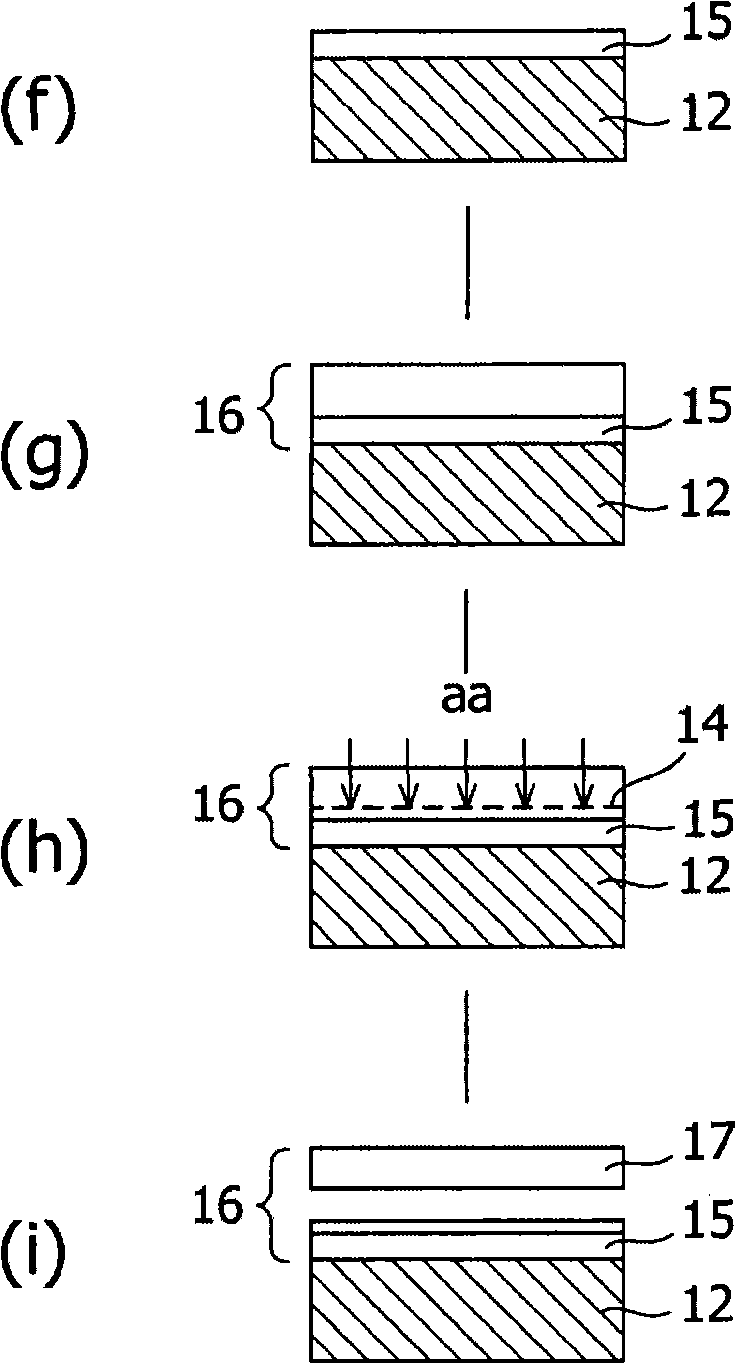

[0060] according to figure 1 The steps shown prepare a substrate with a diamond film.

[0061] exist figure 1 In the step (A), silicon single crystal substrates having a diameter of 6 inches (150 mm) and a thickness of 625 μm were provided as the donor substrate 11 and the handle substrate 12 . The surface roughness (Ra) of the prepared processing substrate 12 was 0.3 nm as measured by using an atomic force microscope (AFM).

[0062] exist figure 1 In the step (B), the donor substrate 11 is placed in a 2.45GHz microwave plasma device, and plasma CVD is carried out under the conditions of 30Torr (4,000Pa) and 850° C. hydrogen. As a result, the diamond layer 13 grew to a thickness of 15 μm.

[0063] exist figure 1 In the step (C), the dosage is 5×10 17 / cm 2 Hydrogen ions were implanted into the diamond layer 13 grown on the donor substrate 11, so that an ion-implanted layer 14 was formed at a depth of 500 nm from the surface.

[0064] exist figure 1 In the step (D), t...

Embodiment 2

[0069] exist figure 1In step (A) of , a synthetic quartz substrate having a diameter of 4 inches (100 mm) and a thickness of 400 μm was provided as a donor substrate 11 . An AlN buffer layer with a thickness of 1 μm was stacked by reactive sputtering on a synthetic quartz substrate. A sapphire substrate having a diameter of 4 inches (100 mm) was provided as the handle substrate 12 . The surface roughness (Ra) of the processed substrate 12 was 0.38 nm as measured by using an atomic force microscope (AFM).

[0070] exist figure 1 In step (B) of , by the HVPE (Hydride Vapor Phase Epitaxy) method, using ammonia water and gallium chloride, in the presence of hydrogen gas as a carrier gas, at 1,050°C under atmospheric pressure, on the donor substrate 11 A GaN single crystal layer 13 with a thickness of 8 μm was grown on the surface of the buffer layer.

[0071] exist figure 1 In the step (C), the dosage is 9×10 16 / cm 2 Hydrogen ions were implanted into the GaN single crystal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com