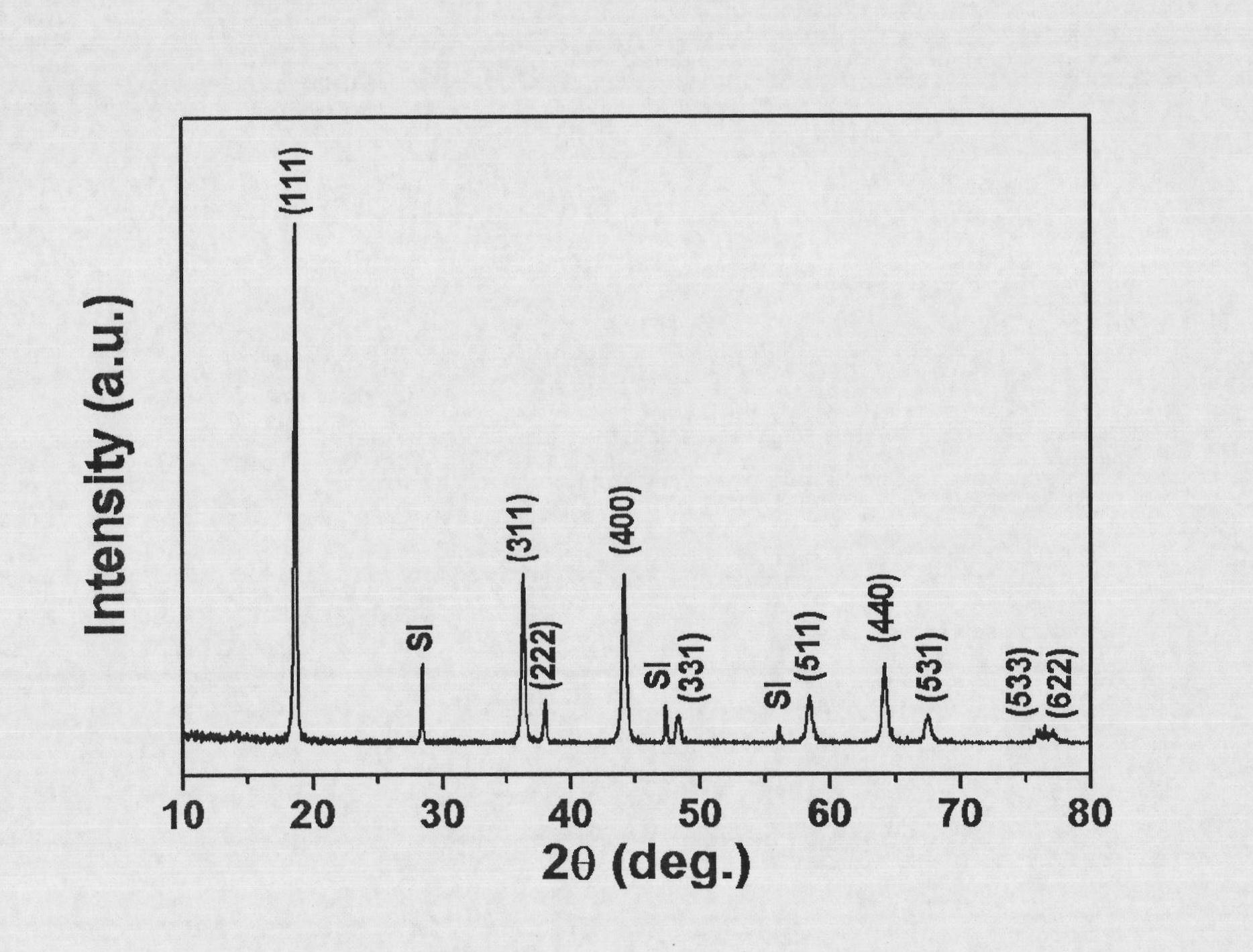

Preparation method of spinel type lithium manganate with high crystallinity used in lithium ion battery

A lithium ion battery, lithium manganate technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problem of reducing battery high temperature cycle performance, cycle performance and high current working performance, Jahn-Teller structure deformation, sacrificing battery energy Density and other issues, to achieve the effect of improving cycle performance, easy large-scale production, and achieving large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

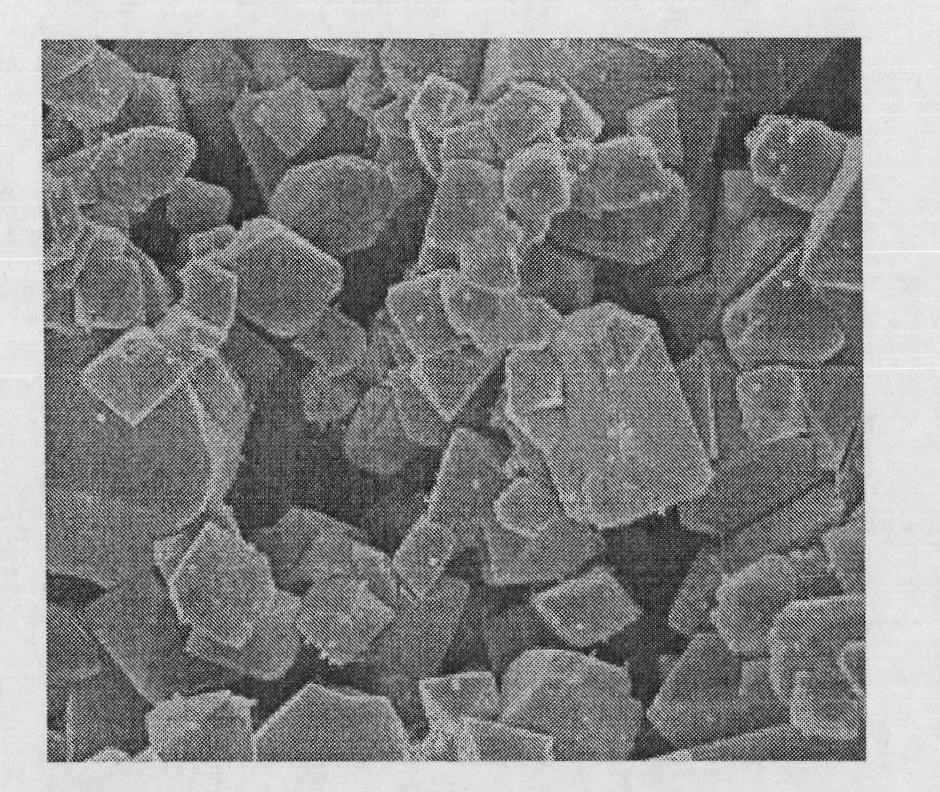

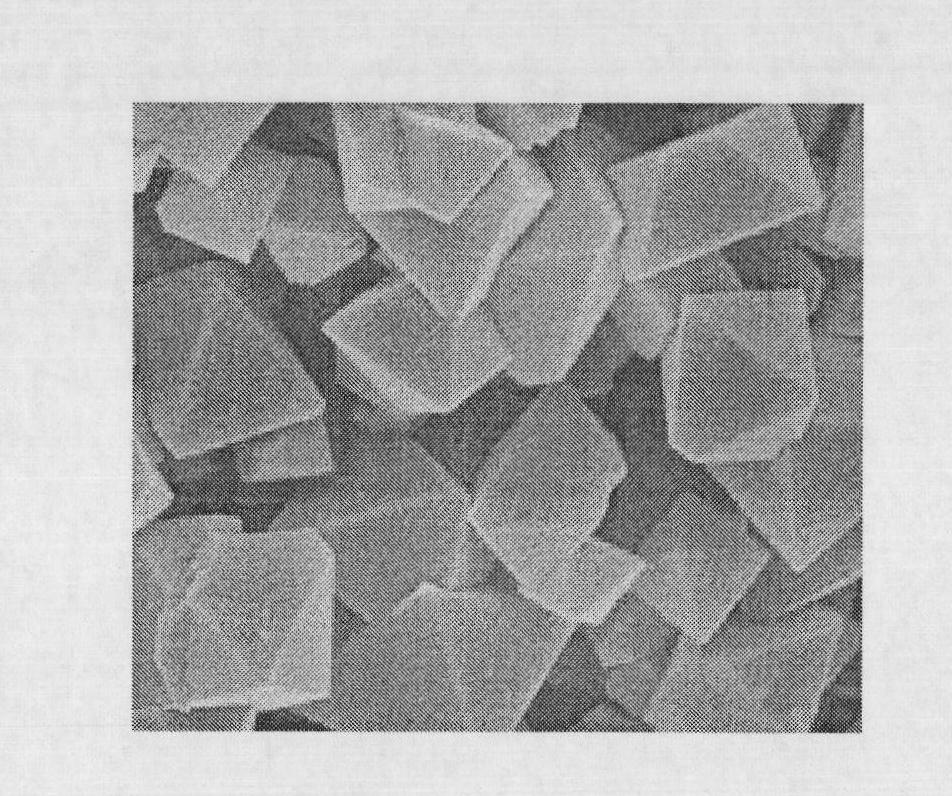

[0032] Embodiment 1 A kind of preparation method for the high crystalline spinel type lithium manganate of lithium ion battery, comprises the following steps:

[0033] (1) Raw material selection: select battery-grade electrolytic manganese oxide with a particle size of 3-25um; battery-grade lithium-containing compounds with an average particle size of ≤8um, with an impurity content of ≤0.5%;

[0034] Wherein: the manganese oxide is trimanganese tetraoxide, and the lithium-containing compound is lithium carbonate.

[0035] (2) After uniformly mixing manganese oxide and lithium-containing compound at a manganese / lithium molar ratio of 1:0.56, ball milling and pressing into block mixture;

[0036] (3) Put the mixture obtained in step (2) into a continuous sintering furnace, and heat it at a constant temperature at 760° C. for 18 hours in an oxygen-containing atmosphere with an oxygen concentration of 30%; After cooling for 20 hours, the product Li can be obtained through classif...

Embodiment 2

[0037] Embodiment 2 A kind of preparation method for the high crystalline spinel type lithium manganate of lithium ion battery, comprises the following steps:

[0038] (1) Raw material selection: select battery-grade electrolytic manganese oxide with a particle size of 3-25um; battery-grade lithium-containing compounds with an average particle size of ≤8um, with an impurity content of ≤0.5%;

[0039] Wherein: manganese oxide is manganese trioxide; lithium-containing compound is lithium carbonate.

[0040] (2) After uniformly mixing manganese oxide and lithium-containing compound at a manganese / lithium molar ratio of 1:0.58, ball milling and pressing into block mixture;

[0041] (3) Put the mixture obtained in step (2) into a continuous sintering furnace, and heat it at a constant temperature at 730° C. for 24 hours in an oxygen-containing atmosphere with an oxygen concentration of 100%; After cooling for 30 hours, the product Li can be obtained through classification inspecti...

Embodiment 3

[0042] Embodiment 3 A kind of preparation method for the high crystalline spinel type lithium manganate of lithium ion battery, comprises the following steps:

[0043] (1) Raw material selection: select battery-grade electrolytic manganese oxide with a particle size of 3-25um; battery-grade lithium-containing compounds with an average particle size of ≤8um, with an impurity content of ≤0.5%;

[0044] Wherein: the manganese oxide is manganese dioxide, and the lithium-containing compound is lithium hydroxide.

[0045] (2) After uniformly mixing manganese oxide and lithium-containing compound at a manganese / lithium molar ratio of 1:0.57, ball milling and pressing into a block mixture;

[0046](3) Put the mixture obtained in step (2) into a continuous sintering furnace, and heat it at a constant temperature at 810°C for 12h in an oxygen-containing atmosphere with an oxygen concentration of 60%; After cooling for 10 hours, the product Li can be obtained through classification insp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com