Perovskite solar cell with black phosphorus being hole transfer layer and preparation method thereof

A hole transport layer, solar cell technology, applied in the field of solar cells, can solve the problems of high cost, limited long-term use of perovskite cells, poor stability, etc., to reduce crystal defects, excellent chemical stability, low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

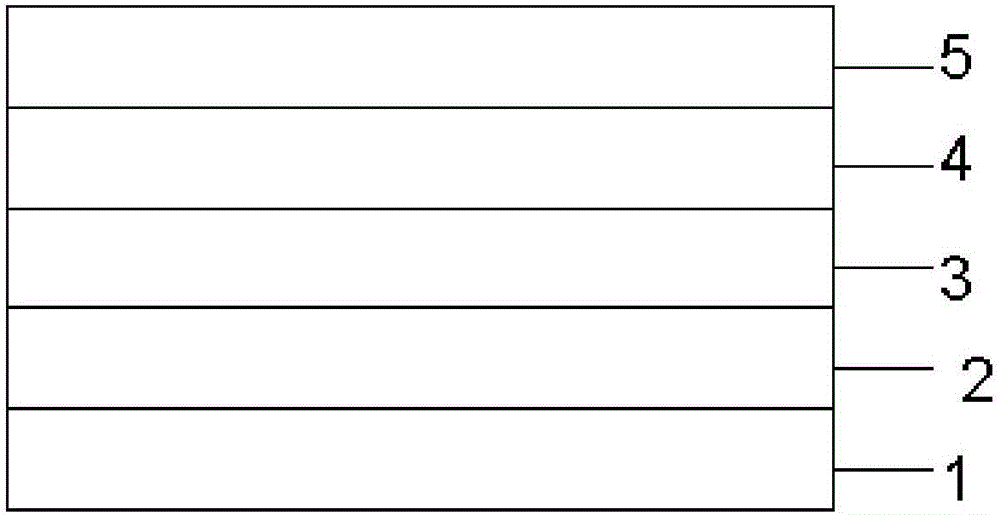

[0015] The structure of the perovskite solar cell is: a transparent conductive electrode and an electron transport layer stacked on the electrode in sequence, a perovskite structure light absorption layer, a black phosphorus nanoparticle hole transport layer and a positive electrode. Among them, the transparent conductive electrode is indium tin oxide, the electron transport layer is ZnO, the light-absorbing layer of perovskite structure is CH3NH3PbI3 layer, and the positive electrode is gold electrode layer or silver electrode layer.

Embodiment 2

[0017] The manufacturing method of the perovskite solar cell structure is as follows: step 1, sequentially form an electron transport layer and a perovskite structure light-absorbing layer on the transparent conductive electrode by conventional deposition, sputtering or spin coating; step 2, in the case of isolating the air Next, get black phosphorus and grind, and the black phosphorus after grinding is dispersed in organic solvent (organic solvent comprises N-methylpyrrolidone (NMP), dimethylformamide (DMF), dimethyl sulfoxide (DMSO) , acetone, tetrahydrofuran, absolute ethanol, methanol, isopropanol, chloroform and dichloromethane) to obtain a dispersion with a concentration of 0.6 to 1.2 mg / mL; the dispersion was first Perform probe-type ultrasonication at a power of 1000-1400W for 2-4 hours, and then perform water-bath ultrasonication at a power of 200-400W for 8-12 hours; after the ultrasonication is completed, centrifuge and collect the supernatant; step 3, the collected ...

Embodiment 3

[0019] The manufacturing method of the perovskite solar cell structure is as follows: step 1, sequentially form an electron transport layer and a perovskite structure light-absorbing layer on the transparent conductive electrode by conventional deposition, sputtering or spin coating; step 2, in the case of isolating the air Next, get black phosphorus and grind, and the black phosphorus after grinding is dispersed in organic solvent (organic solvent comprises N-methylpyrrolidone (NMP), dimethylformamide (DMF), dimethyl sulfoxide (DMSO) , acetone, tetrahydrofuran, absolute ethanol, methanol, isopropanol, chloroform and dichloromethane) to obtain a dispersion with a concentration of 0.6 to 1.2 mg / mL; the dispersion was first Perform probe-type ultrasonication at a power of 1000-1400W for 2-4 hours, and then perform water-bath ultrasonication at a power of 200-400W for 8-12 hours; after the ultrasonication is completed, centrifuge and collect the supernatant; Add titanium disulfid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com