Method of chemical gas phase precipitation for growing carbon doped silicon germanium alloy buffer layer and germanium film

A technology of chemical vapor deposition and buffer layer, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., which can solve the complex process, high cost, and high requirements for precise control of reaction gas source flow, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

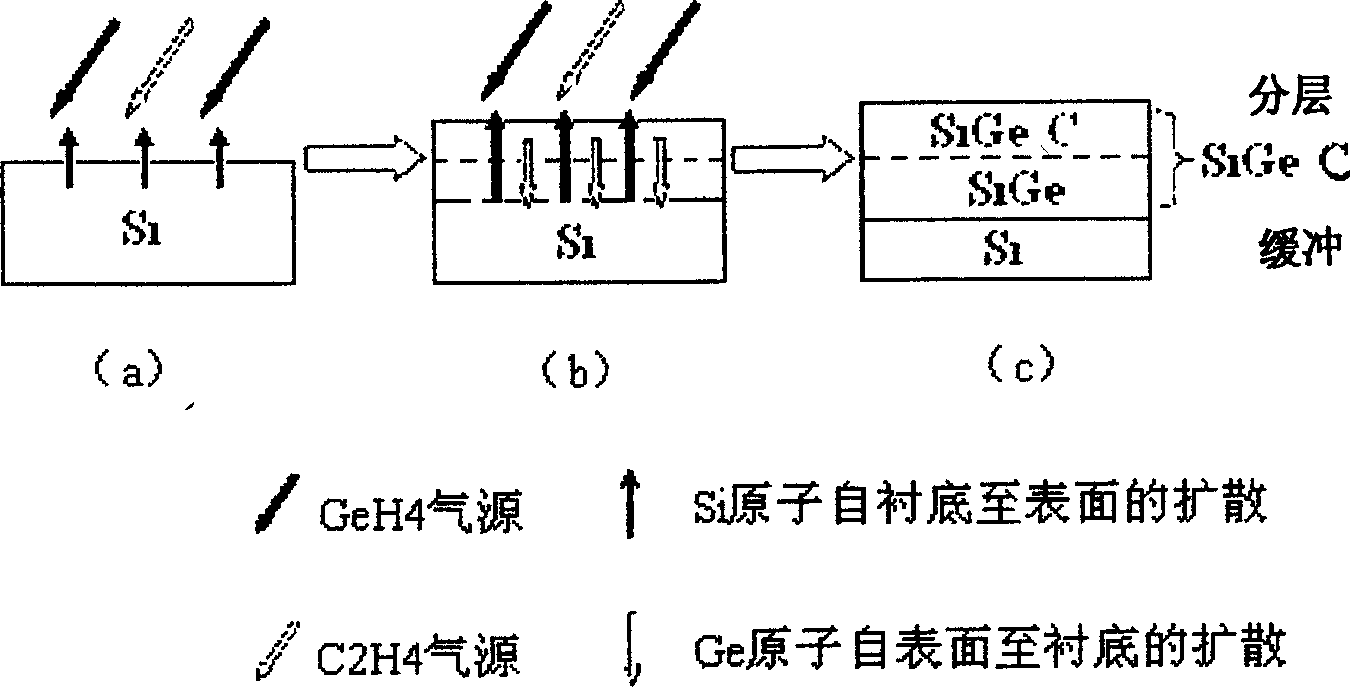

[0016] figure 1 In, for Si 1-x Ge x The growth process of the :C buffer layer is described as follows: on the sample surface, Si and reaction gas source (GeH 4 、C 2 h 4 ) react to form Si 1-x Ge x :C film, the higher growth temperature causes the Si atoms in the substrate to diffuse to the surface, thus maintaining the Si on the surface of the sample 1-x Ge x : The progress of C thin film epitaxial growth (such as figure 1 (a) shown); at the same time, Si 1-x Ge x : Metal Ge atoms in the C epitaxial layer diffuse toward the substrate to fill the vacancies left by the diffusion of Si to the surface, so the CVD epitaxial Si 1-x Ge x : Form Si under C thin film 1-x Ge x layer (eg figure 1 (b) shown). As a result of the above growth process, Si with Ge composition gradient is obtained on the Si substrate. 1-x Ge x :C buffer layer (such as figure 1 (c) shown).

[0017] The present invention adopts CVD method, growth uses germane (GeH 4 ) as germanium source, eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com