Y-shaped perforating and fuse inserting device for firework pasting assembly

A technology for grouping pots and fireworks, which is applied in the direction of pyrotechnics, offensive equipment, weapon types, etc. It can solve the problems that single-hole continuous m-shaped arrangement of lead wires cannot be realized, and achieve the effect of simple structure and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

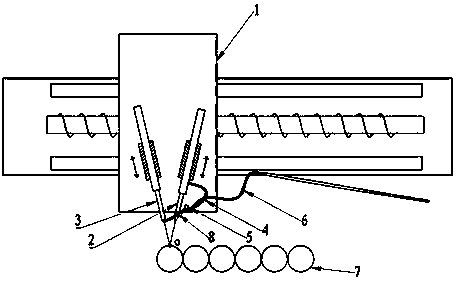

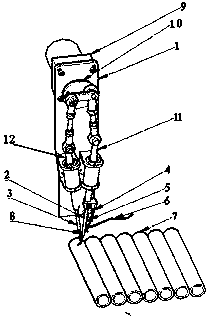

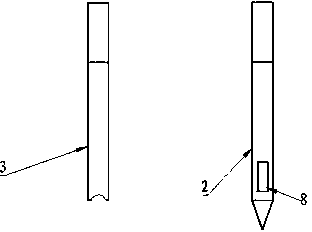

[0023] See figure 1 with figure 2 , Reflecting a specific structure of the present invention, 1 device platform is fixed on a base that can move left and right, 9 power equipment, 10 power transmission devices and 5 thimble are respectively installed on the 1 device platform, 11 movable rods 1 and 12 movable The rod 2 is installed on the 10 transmission device. At the lower end of the 11 movable rod 1 are fixed 2 punching traction needles and 4 anti-backflow springs, and the lower end of the 12 movable rod is fixed with 3 insertion pins, 2 punching traction needles and 3 insertion needles. Arranged in a non-closed y shape. The 6-lead wire passes through the gap between the 2 punching traction needle and the 4 anti-backflow spring and then passes through the 8 piercing hole, and the 6-lead wire after passing through the 8 piercing hole appears on the downward trajectory of the 3 insertion needle. 9 power equipment, 10 transmission device, 11 movable rod 1 and 12 movable rod 2 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com