Diamine compound and preparation method thereof, liquid crystal alignment agent, liquid crystal alignment film, liquid crystal display element

A technology of liquid crystal alignment agent and amine compound, applied in the field of new structure diamine compound and its preparation, can solve the problems of inability to solve the problem of friction method, reduced process efficiency, insufficient environmental affinity, etc., to ensure safety and economy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

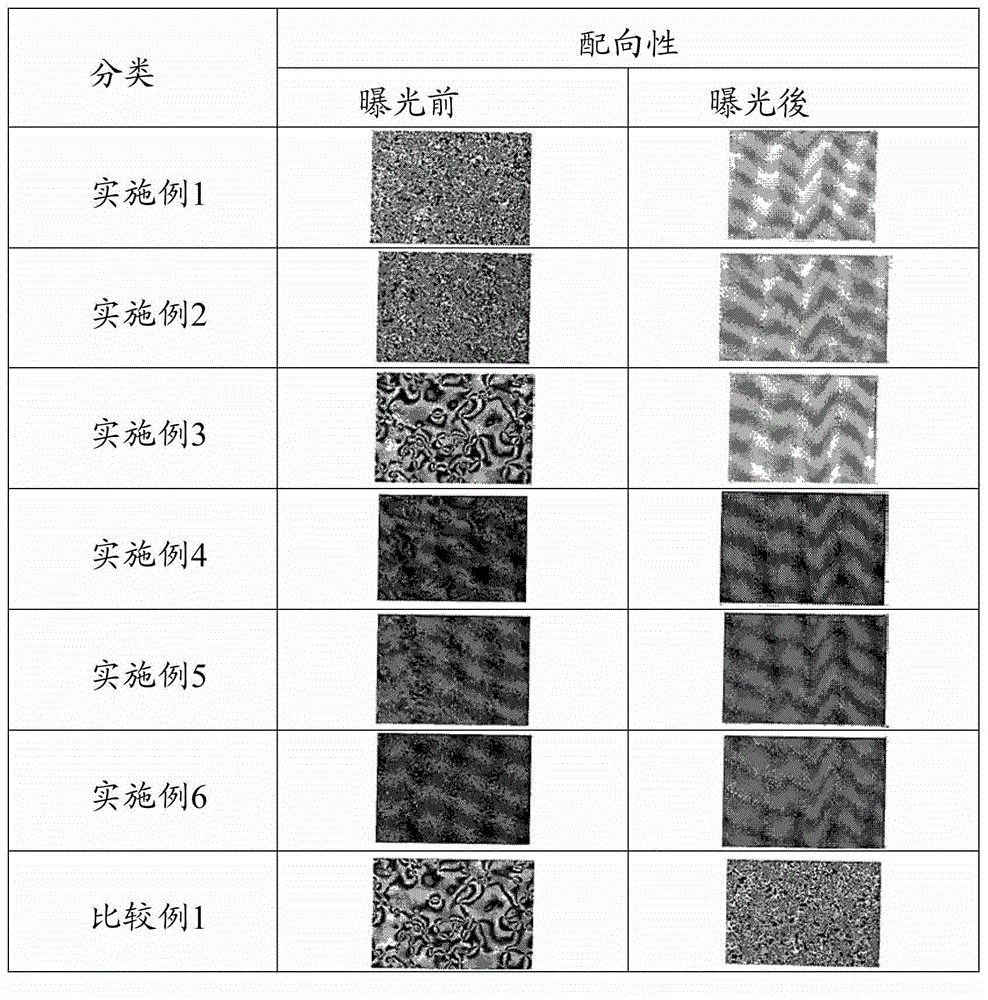

Examples

preparation example Construction

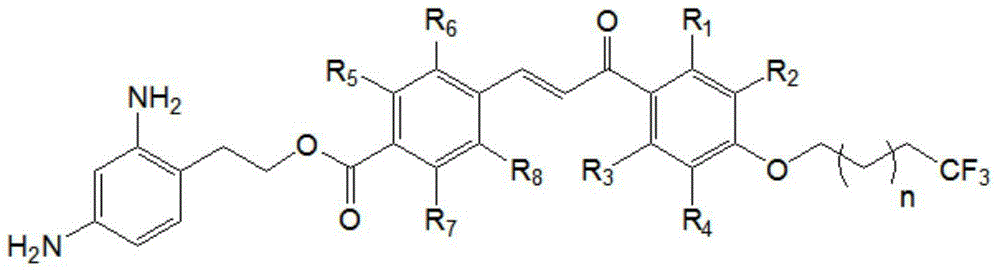

[0067] The preparation method of the diamine compound represented by the chemical formula 10 comprises the following steps:

[0068] reacting the compound represented by the following Chemical Formula 6 with the compound represented by the following Chemical Formula 8 to prepare the compound represented by the following Chemical Formula 9; and

[0069] removing the protecting group PG of the compound represented by the following chemical formula 9;

[0070] [chemical formula 6]

[0071]

[0072] [chemical formula 8]

[0073]

[0074] [chemical formula 9]

[0075]

[0076] [chemical formula 10]

[0077]

[0078] In chemical formulas 6, 8, 9 and 10, n is an integer from 1 to 20; R 1 to R 8 are the same or different, and independently represent H, CN, NO2, CF3, halogen, an alkyl group with 1 to 10 carbon atoms, or an alkoxy group with 1 to 10 carbon atoms; PG is benzyloxycarbonyl (carbobenzyloxy, Cbz), p-Methoxybenzyl carbonyl (p-Methoxybenzyl carbonyl, Moz), te...

preparation Embodiment 1

[0201] Preparation of Chemical Formula 10 (n=1, R 1 ~R 8 =H, when PG=BOC) compound

[0202] [Reaction Formula Ⅰ]

[0203]

[0204] Dissolve 95.0 g (0.74 mol) of the raw material 4,4,4-trifluorobutan-1-ol (chemical formula 1) in 135 ml (0.97 mol) of triethylamine (TEA) and 1 L of dichloromethane (Methylene Chloride, MC) and cooled to 0°C. To the resulting material was slowly added 63.0 ml (62.0 ml) of methanesulfonyl chloride (MsCl) over 30 minutes. The mixture was stirred at 0°C for 10 minutes and allowed to react at room temperature for 2 hours to prepare 4,4,4-trifluorobutyl methanesulfonate (4,4,4-trifluorobutyl methanesulfonate) (Chemical Formula 2 ).

[0205] The compound of chemical formula 2 was detected by NMR, and the results were as follows.

[0206] 1 H NMR (400MHz, CDCl 3 ) δ4.30 (t, 2H), 3.04 (s, 3H), 2.28 (m, 2H), 2.05 (m, 2H)

[0207] [Reaction Formula Ⅱ]

[0208]

[0209] Next, 75.9g (0.56mol) of 4-hydroxyacetophenone (4-hydroxyacetophe...

preparation Embodiment 2

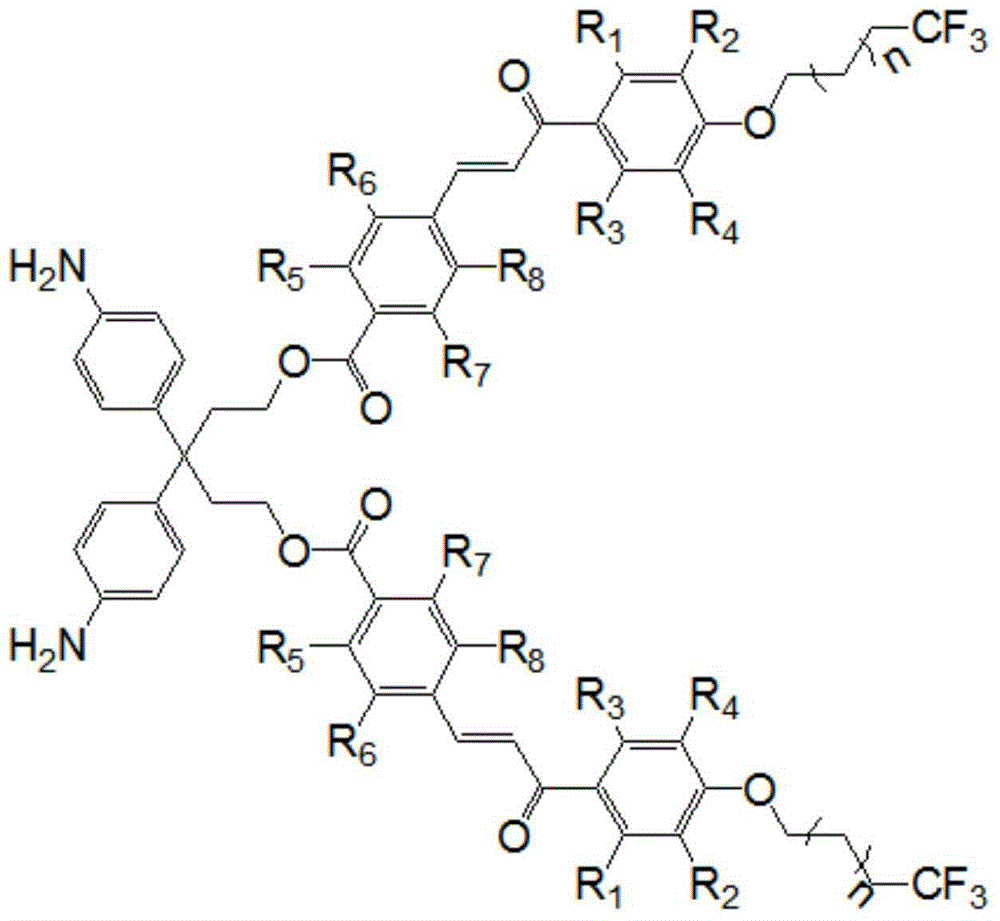

[0228] Preparation of the compound of chemical formula 23 (n=1, R1~R8=H, PG=BOC)

[0229] [Reaction Formula Ⅵ]

[0230]

[0231] 95.0 (0.74mol) of the raw material 4,4,4-trifluorobutan-1-ol (chemical formula 1) was dissolved in 135ml (0.97mol) of triethylamine and 1L of dichloromethane, and within 30 minutes At 0°C, 63.0ml (0.81mol) of methanesulfonyl chloride (methanesulfonyl chloride, MsCl) was slowly added. The mixture was stirred at 0°C for 10 minutes, and reacted at room temperature for 2 hours to prepare 4,4,4-trifluorobutyl methanesulfonate (Chemical Formula 2).

[0232] The compound of chemical formula 2 was detected by NMR, and the results were as follows.

[0233] 1 H NMR (400MHz, CDCl 3 ) δ4.30 (t, 2H), 3.04 (s, 3H), 2.28 (m, 2H), 2.05 (m, 2H)

[0234] [Reaction formula VII]

[0235]

[0236] Dissolve 72.5g (0.53mol) of 4-hydroxyacetophenone (4-hydroxyacetophenone) (chemical formula 3) in 700mL of DMF, and make it with 152g (0.64mol) of methanesulfonic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com