Multi-layer pipe arranging and storing device for mechanical modular workover operation

A modularization and workover technology, applied in the direction of drilling pipes, casings, drilling equipment, etc., can solve the problems of small number of storage pipes, large floor area, and inability to align the mechanism vertically, so as to improve work efficiency and reduce land occupation The effect of large area and convenient access to tube work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] This part will describe the specific embodiments of the present invention in detail, and the preferred embodiments of the present invention are shown in the accompanying drawings. Each technical feature and overall technical solution of the invention should not be construed as limiting the protection scope of the invention.

[0038] In the description of the present invention, unless otherwise clearly defined, words such as setting should be understood in a broad sense, and those skilled in the art can reasonably determine the specific meanings of the above words in the present invention in combination with the specific content of the technical solution.

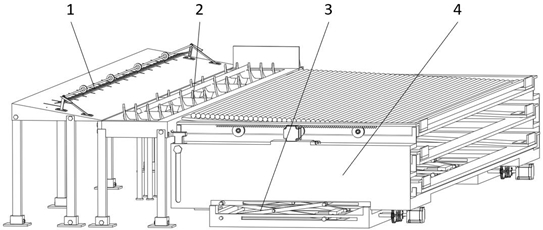

[0039] Among them, see figure 1 As shown, the present invention proposes a multi-layer pipe arrangement and storage device for mechanical modular well workover operations, including a single-layer pipe pulling module 1 , an alignment module 2 , a fork lift module 3 and a multi-layer tubing storage module 4 .

[0040]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com