Self-arrangement cable winding and unwinding device for mechanical and electrical installation

A technology for rewinding, unwinding and installation, which is applied in the direction of transportation and packaging, conveying filamentous materials, thin material processing, etc. Ingenious, easy to operate, easy to get the effect of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

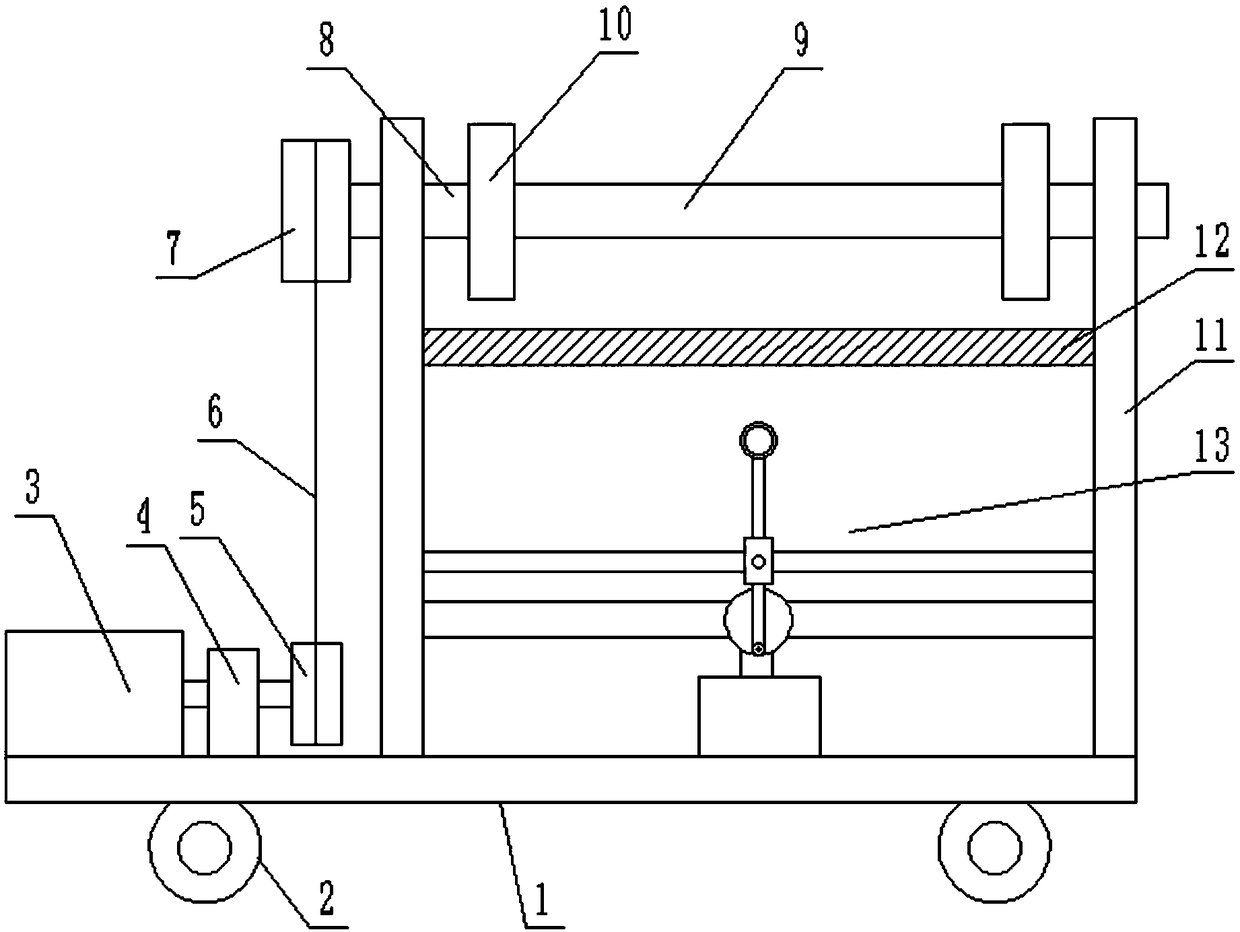

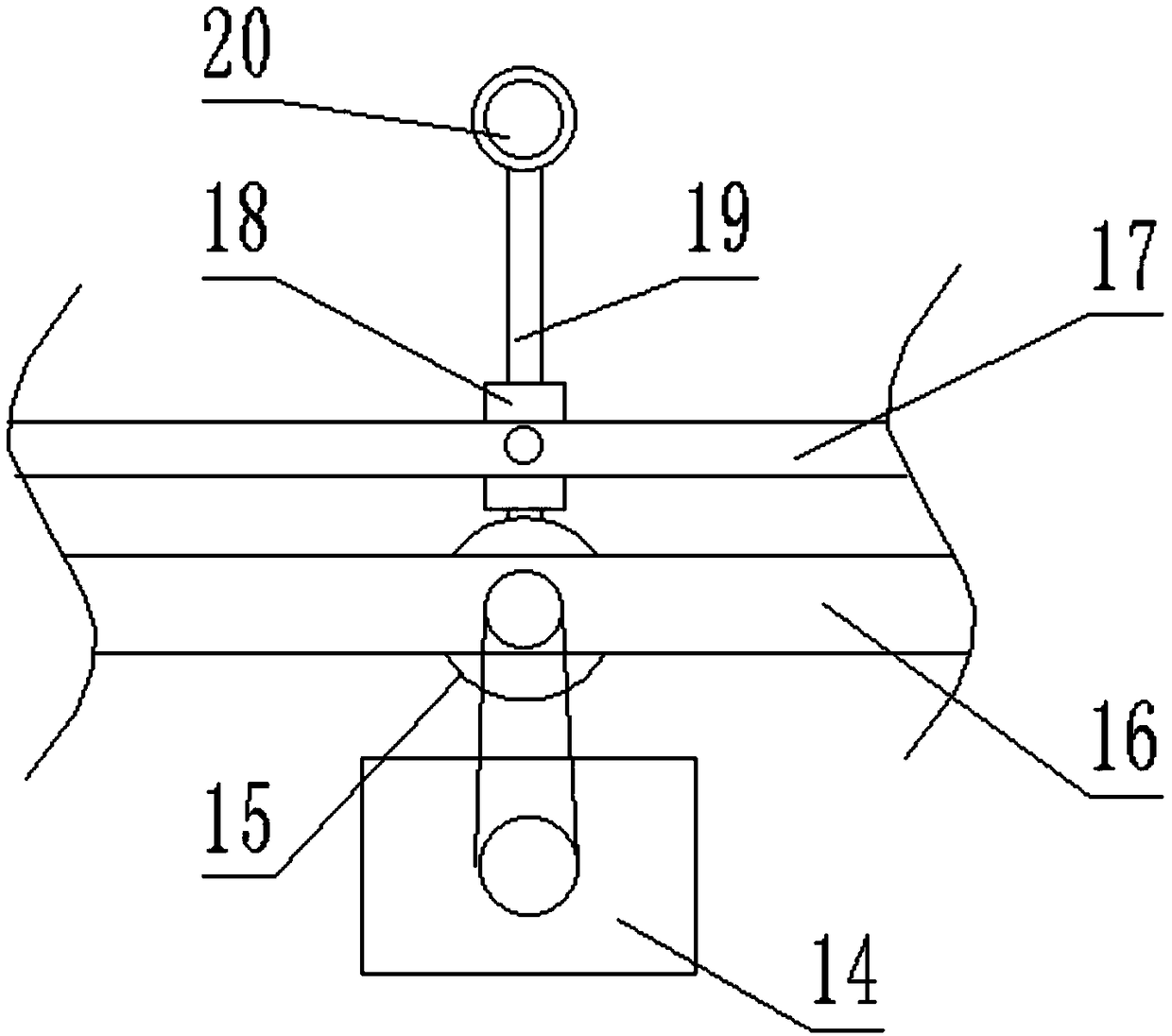

[0022] see Figure 1-2 , a self-arranging cable rewinding and unwinding device for electromechanical installation, comprising a vehicle frame 1, a support 11, a bidirectional motor 3 and a rewinding and unwinding roller 9, the support 11 is located above the vehicle frame 1, and the support 11 is arranged in parallel with each other And form vertical boards perpendicular to each other with the vehicle frame 1, the two ends of the rewinding and unwinding roller 9 are provided with a rotating shaft 8 that is clamped and installed with it, and the rotating shaft 8 is inserted on the support 11 and is connected with the support 11 in rotation. A guide 13 is provided below the rewinding and unwinding roller 9; the guide 13 includes an adjustment motor 14 fixed on the upper plane of the vehicle frame 1, a first cross bar 16 and a second cross bar 17 arranged in sequence above the adjustment motor 14, The output shaft of the adjustment motor 14 is arranged along the horizontal direct...

Embodiment 2

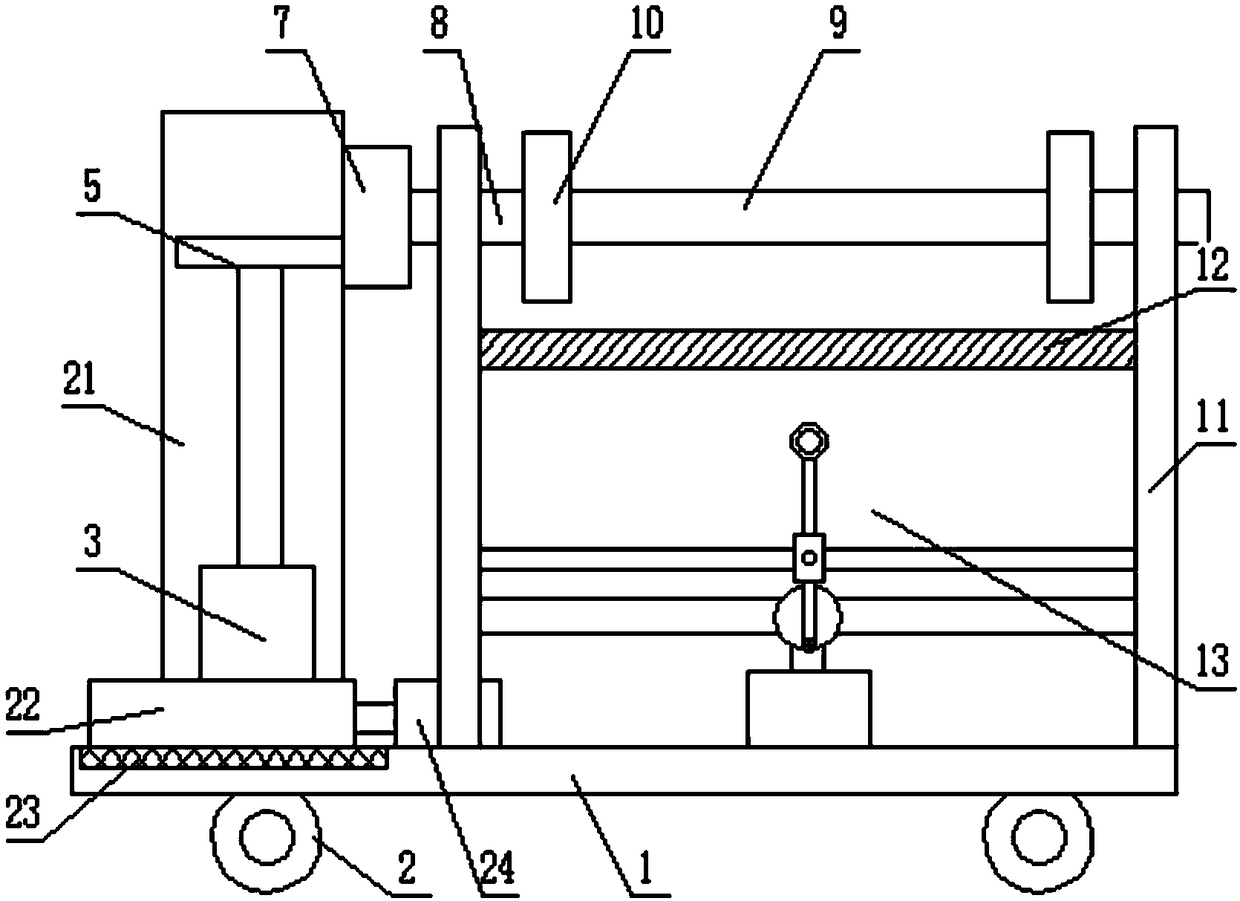

[0030] Such as image 3 As mentioned above, the difference from Embodiment 1 is that the bidirectional motor 3 is located in a motor box 21, and the output shaft of the bidirectional motor 3 is arranged vertically, and the driving wheel 5 is fixed on the top of the output shaft of the bidirectional motor 3 , an opening is provided on the side of the motor case 21, and the side opening of the motor case 21 is larger than the size of the driven wheel 7, a chute 23 is provided on the top surface of the vehicle frame 1, and a sliding base that is slidably connected to it is provided in the chute 23 22, the motor box 21 is fixed on the upper plane of the sliding base 22, and a hydraulic cylinder 24 is also provided on the top surface of the vehicle frame 1, and the output end of the hydraulic cylinder 24 is provided with a telescopic rod fixedly connected to the side of the motor box 21; When performing rewinding and unwinding work, the hydraulic cylinder 24 drives the motor box 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com