Four-color bulk terminal crimping machine

A terminal crimping machine and terminal technology, applied in the direction of electrical components, circuits, connections, etc., can solve the problems of low crimping qualification rate, complicated operation method, and large labor dependence, and achieve high crimping qualification rate and application environment. Friendly, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

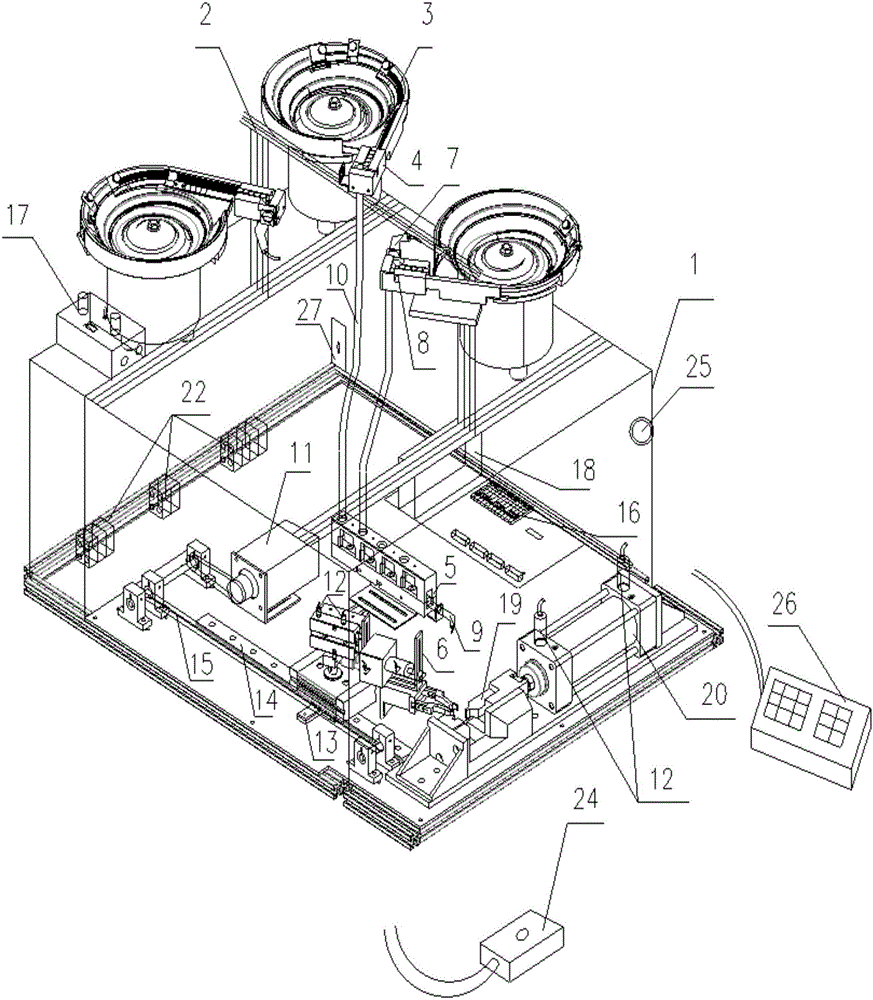

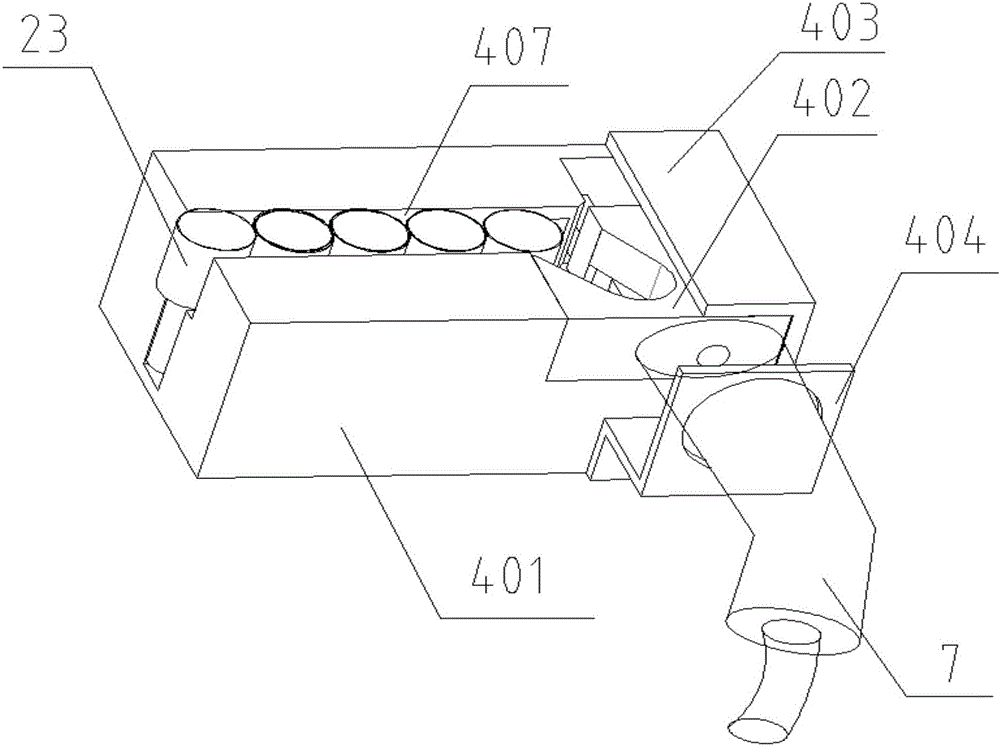

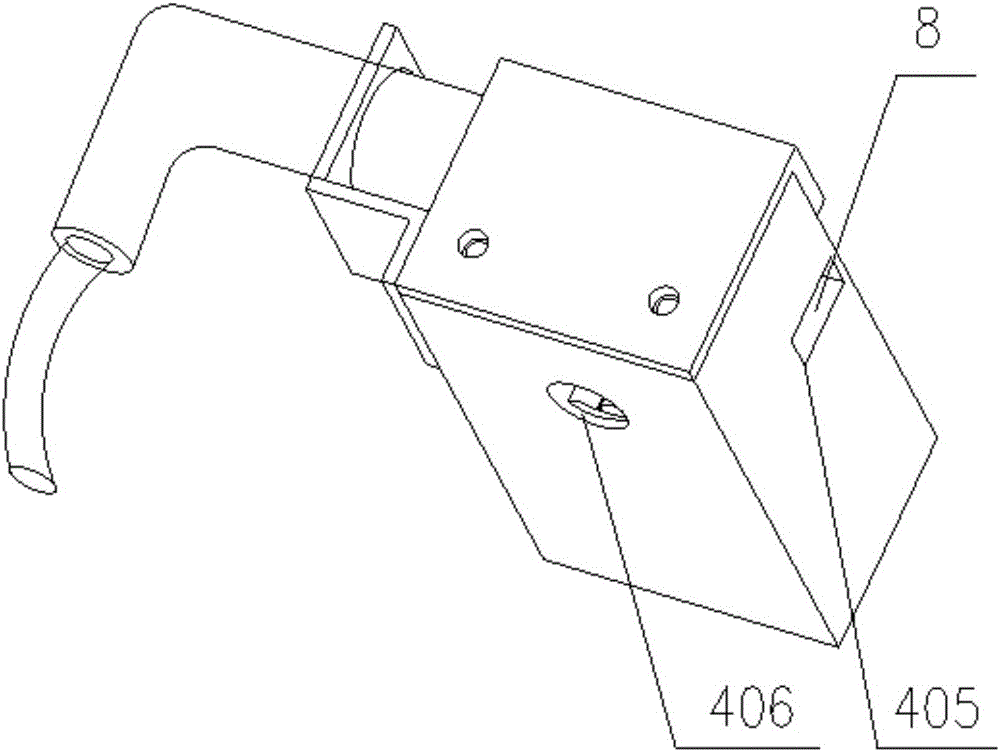

[0018]The main structure of the four-color bulk terminal crimping machine involved in this embodiment includes a protective cover 1, a bracket 2, a vibrating plate 3, an escapement 4, a positioner 5, a manipulator 6, an escapement cylinder 7, and an escapement sensor 8 , Positioning cylinder 9, transmission pipe 10, motor 11, solenoid valve 12, pulley 13, guide rail 14, synchronous belt 15, single-chip microcomputer 16, vibrating disc controller 17, power supply 25 transformer 18, mechanical pliers 19, mechanical pliers cylinder 20, Position sensor 21, relay 22, terminal 23, control pedal 24, power supply 25, terminal machine controller 26, air source 27, electric wire (not shown in the accompanying drawing) and pipeline (not shown in the accompanying drawing); Terminal 23 is a grenade shape structure, the radius of the head cylinder is greater than the radius of the bottom cylinder; four vibrating plates 3 are fixedly arranged on the upper part of the transparent protective co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com