Patents

Literature

160results about How to "Avoid human contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

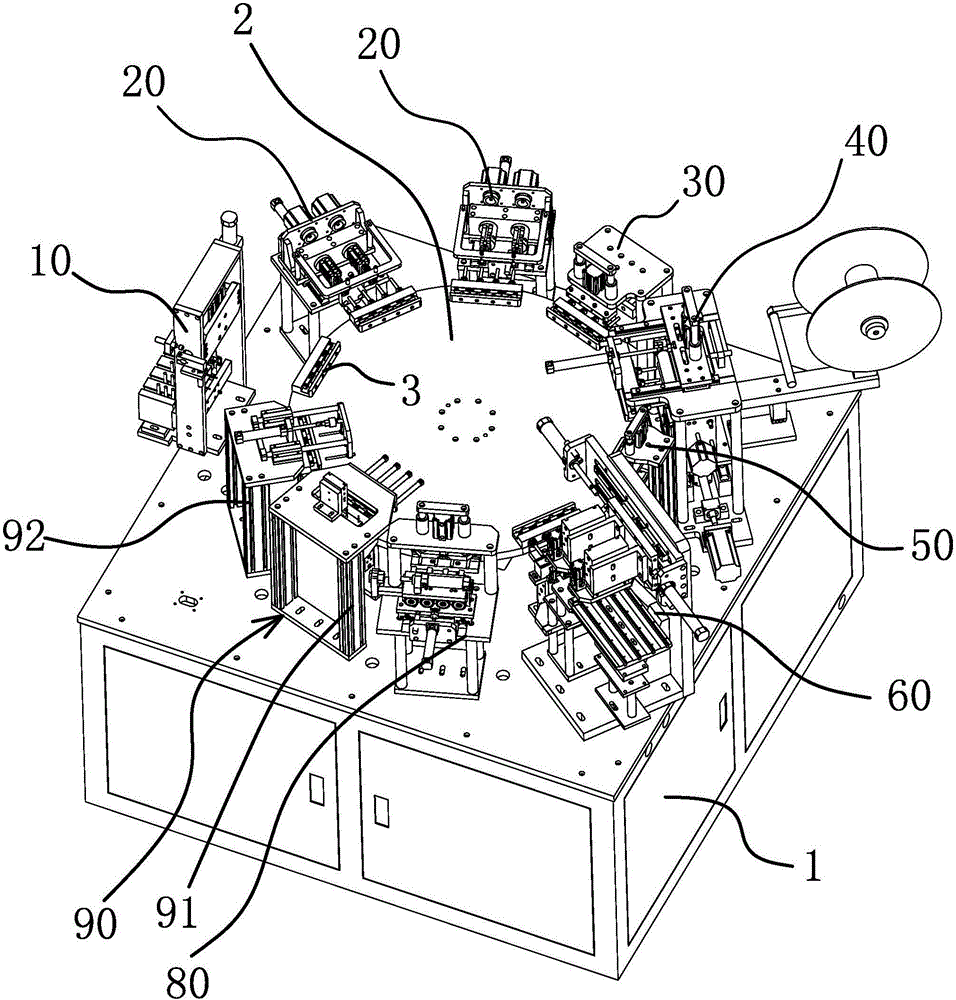

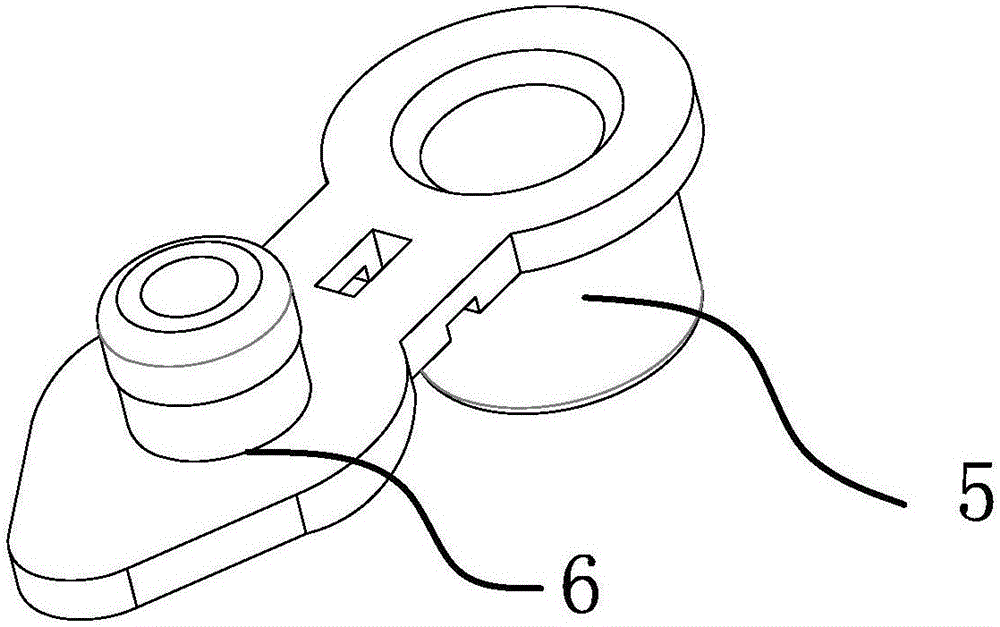

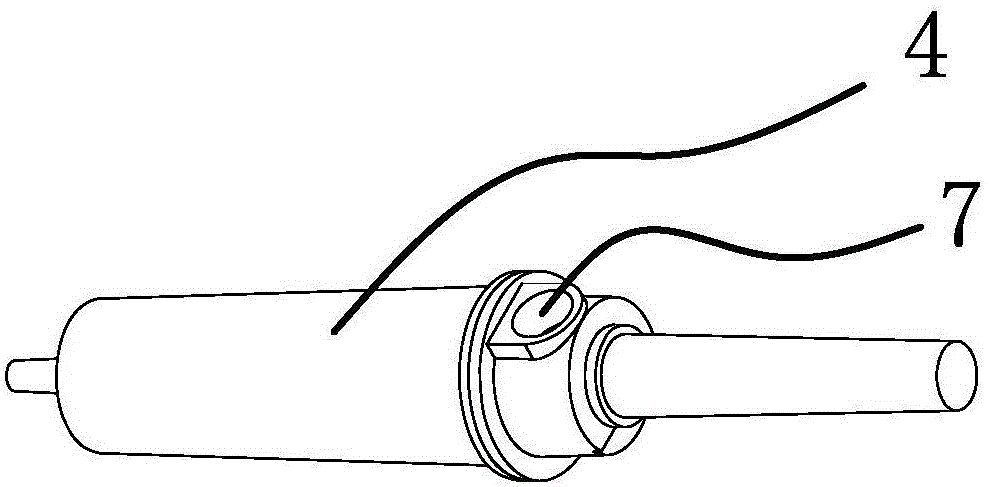

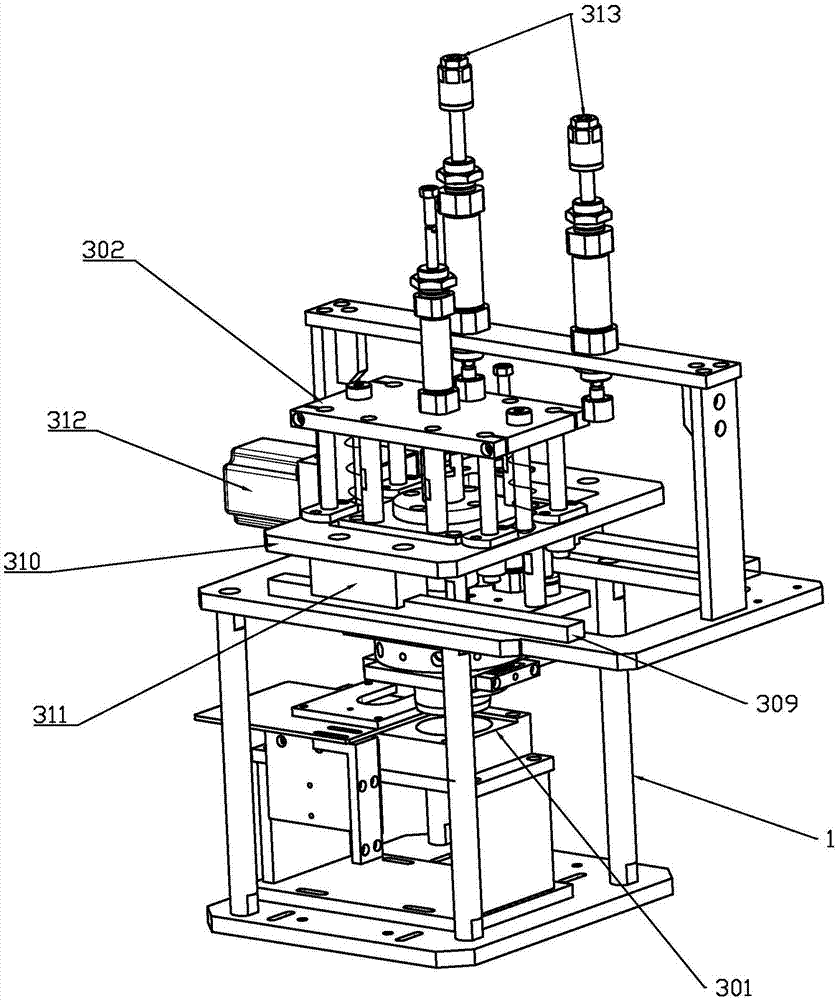

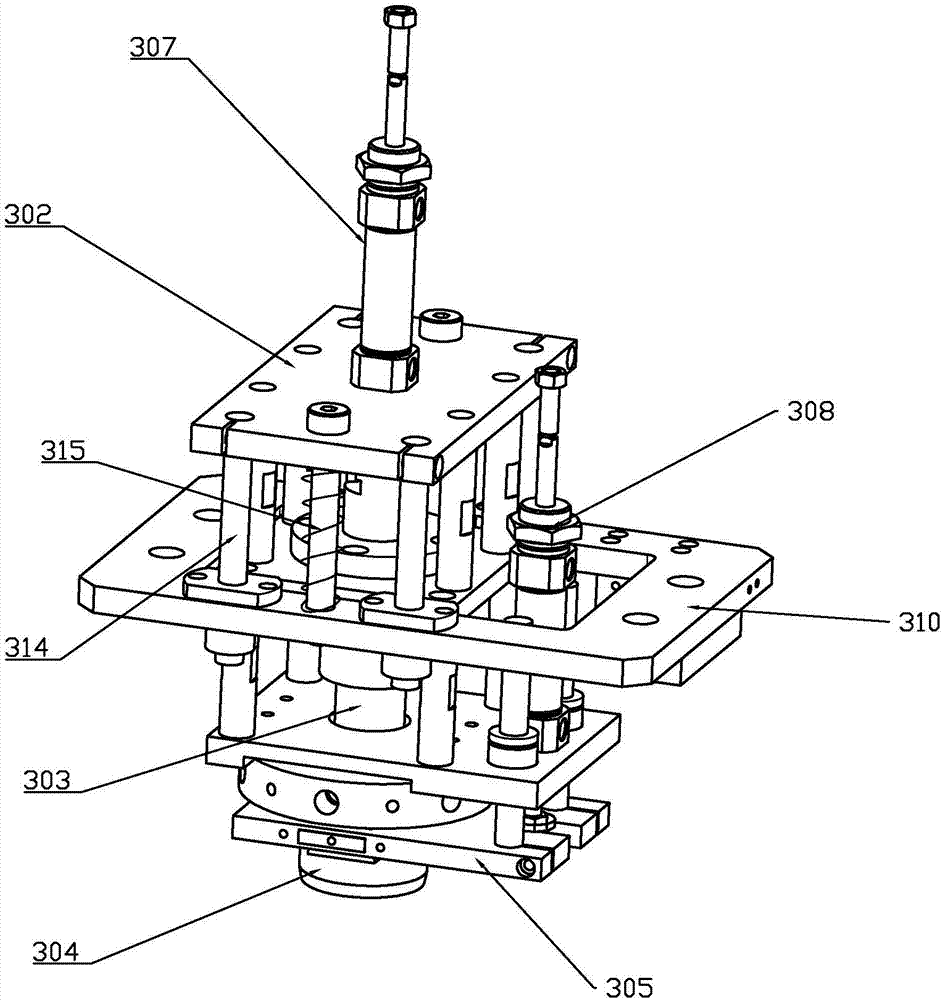

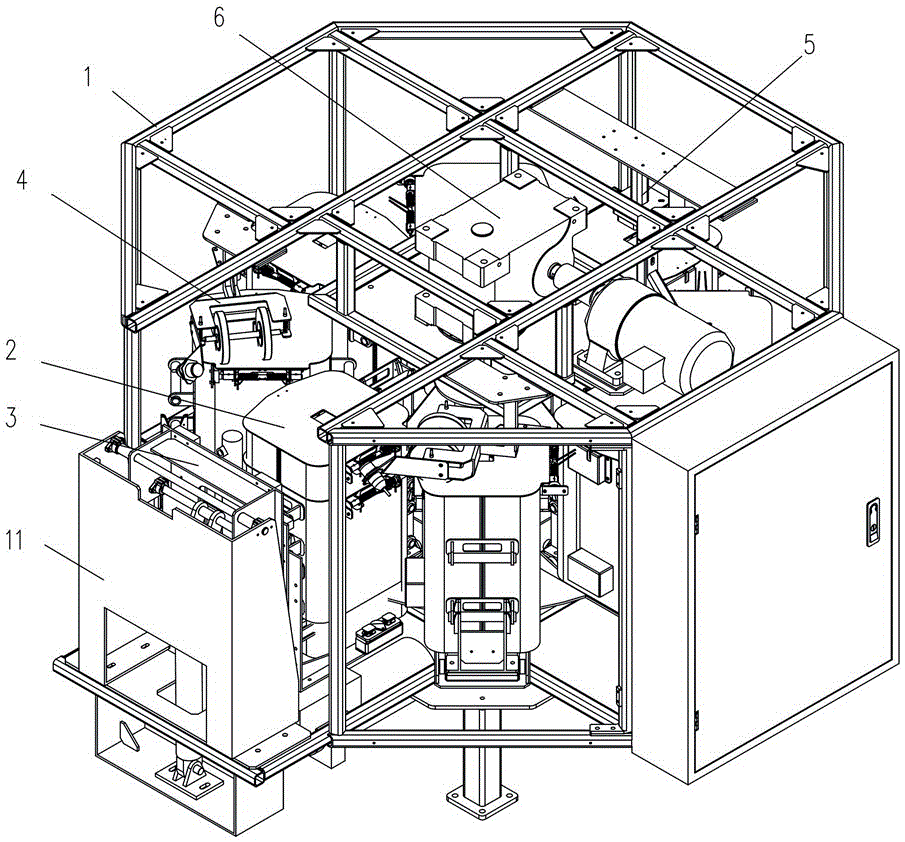

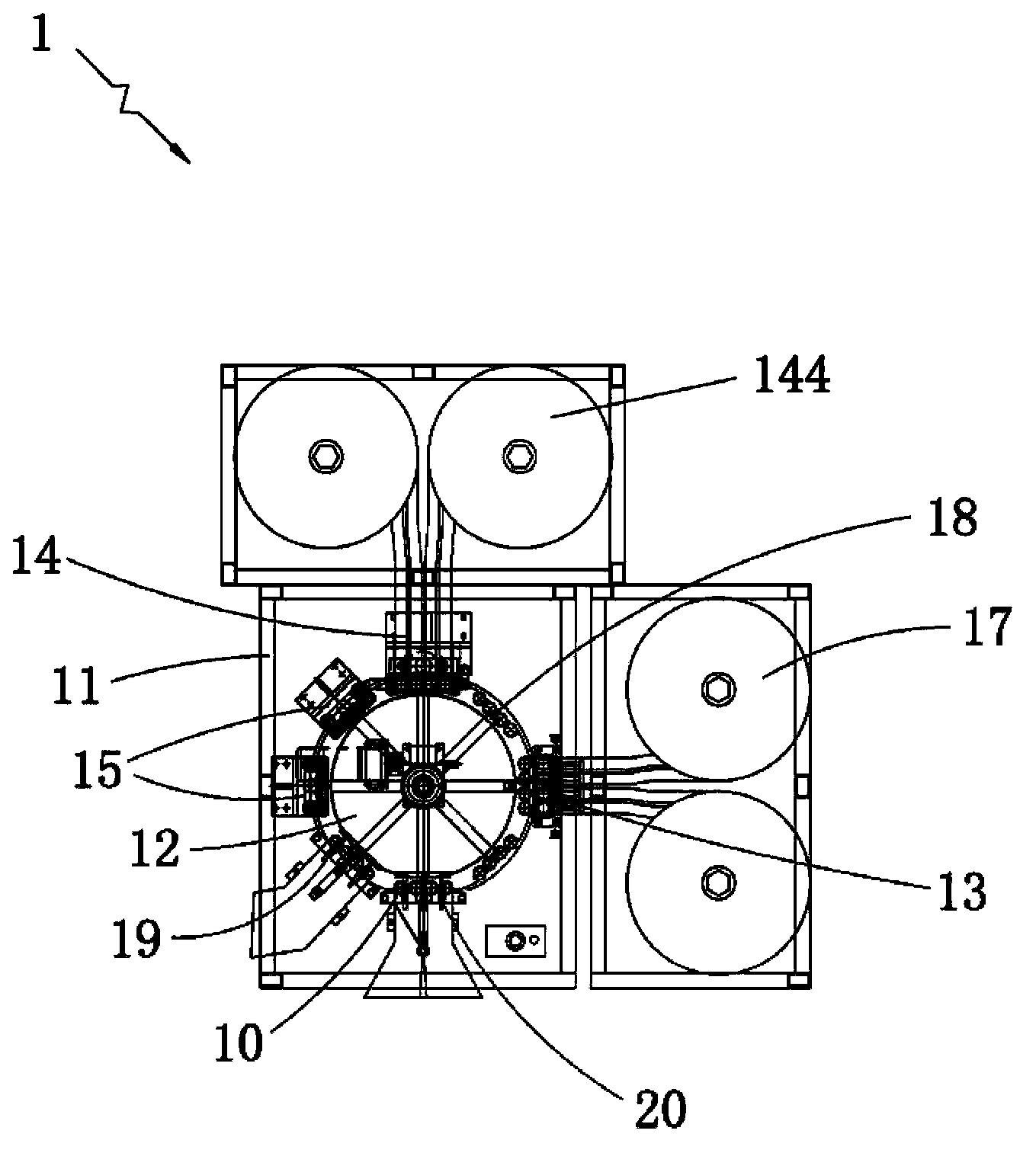

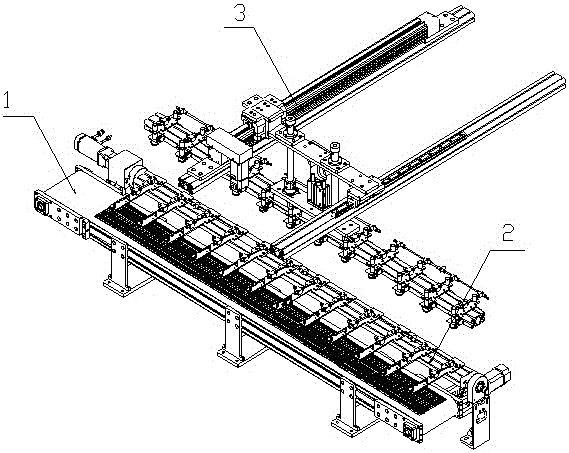

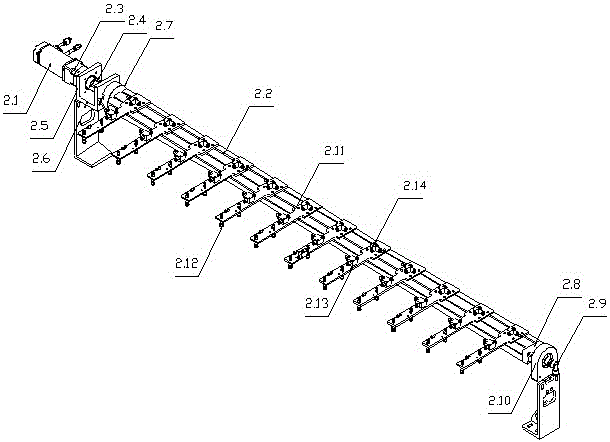

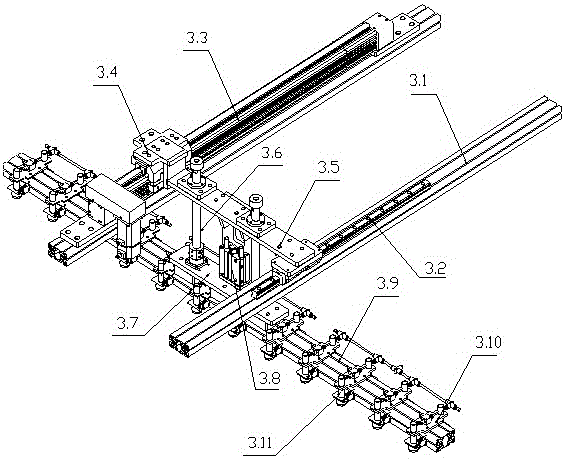

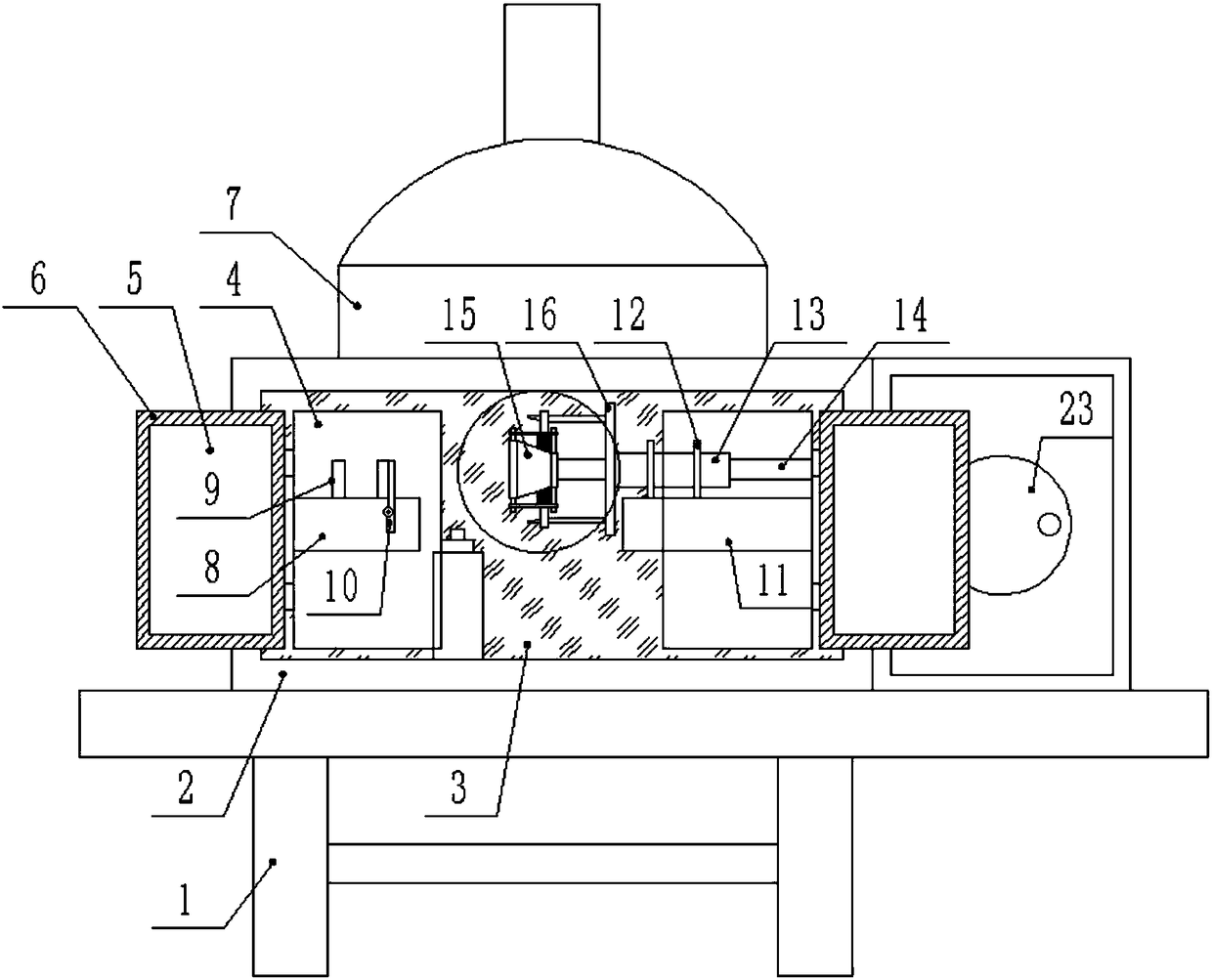

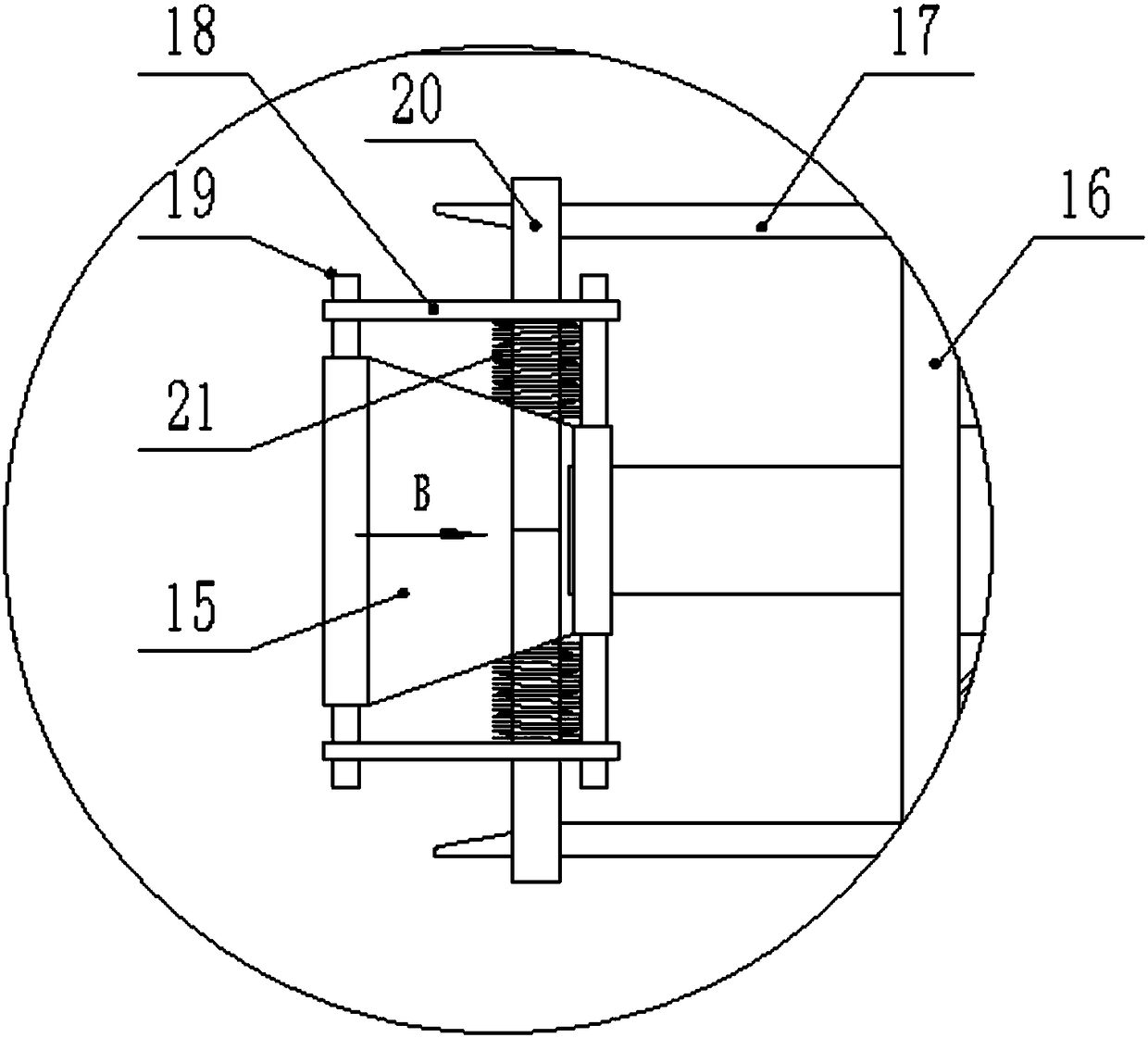

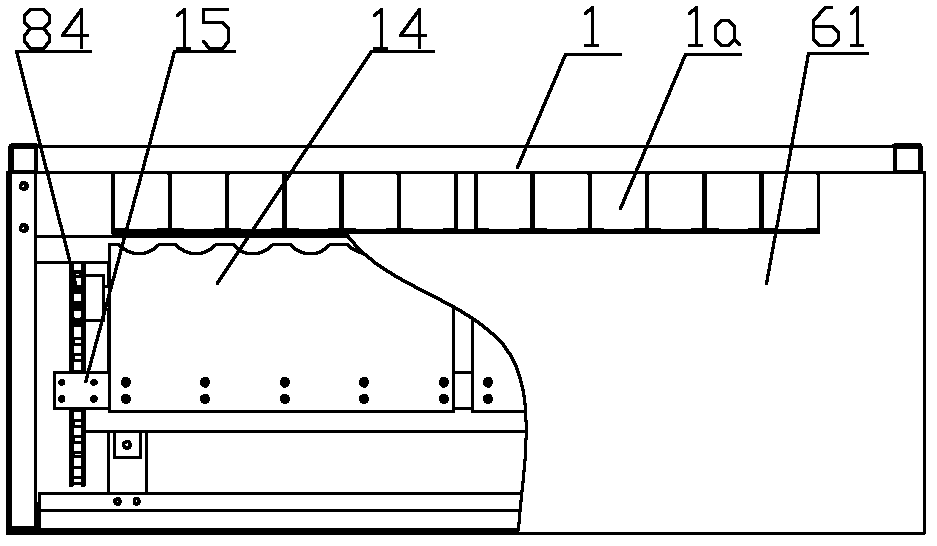

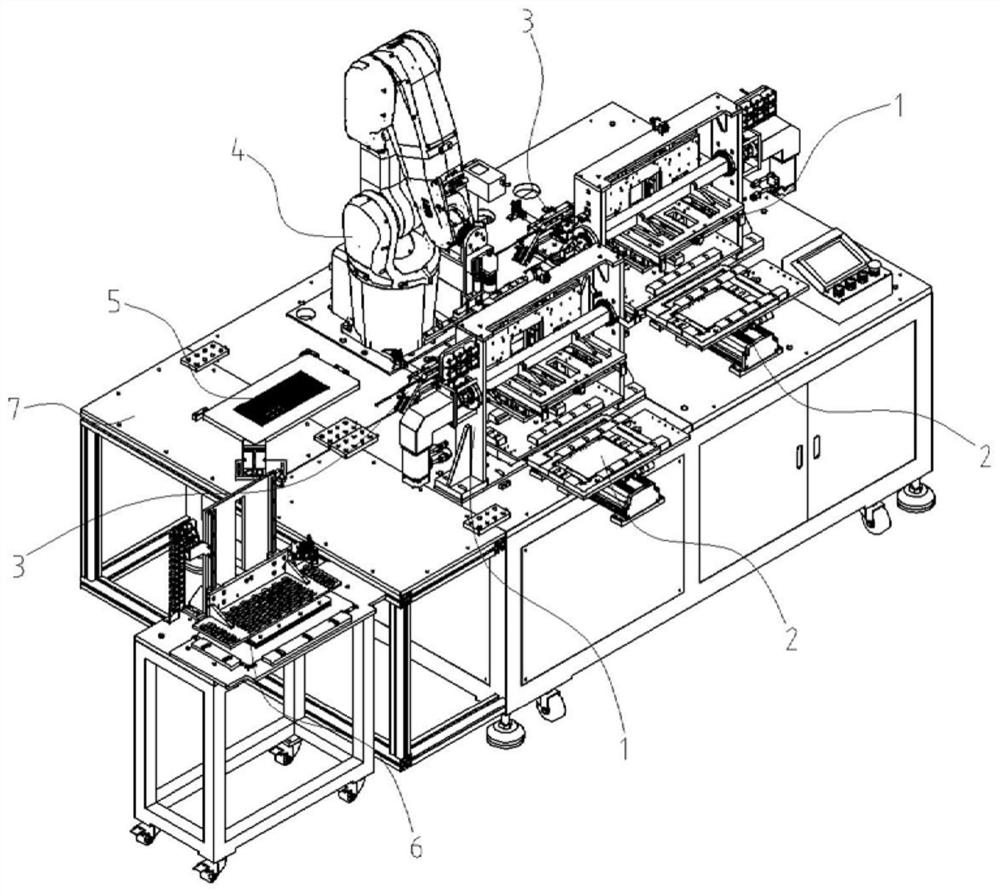

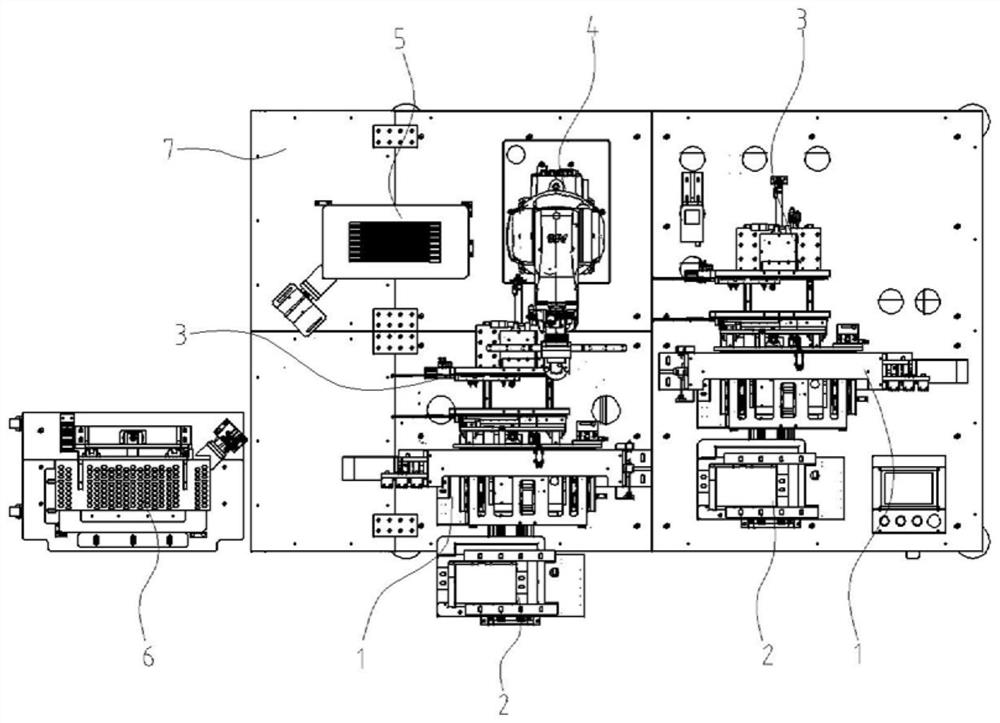

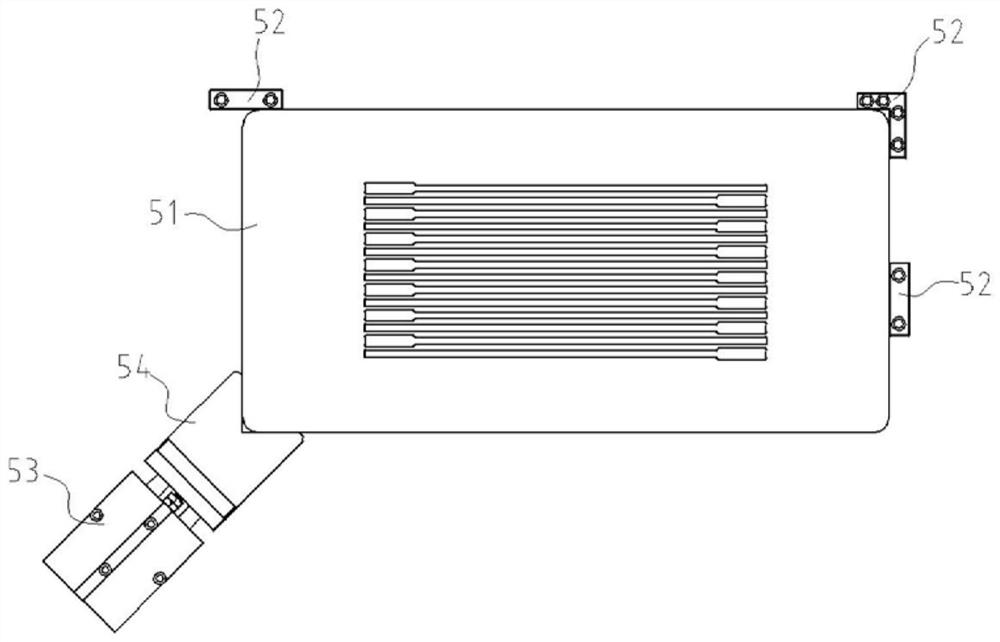

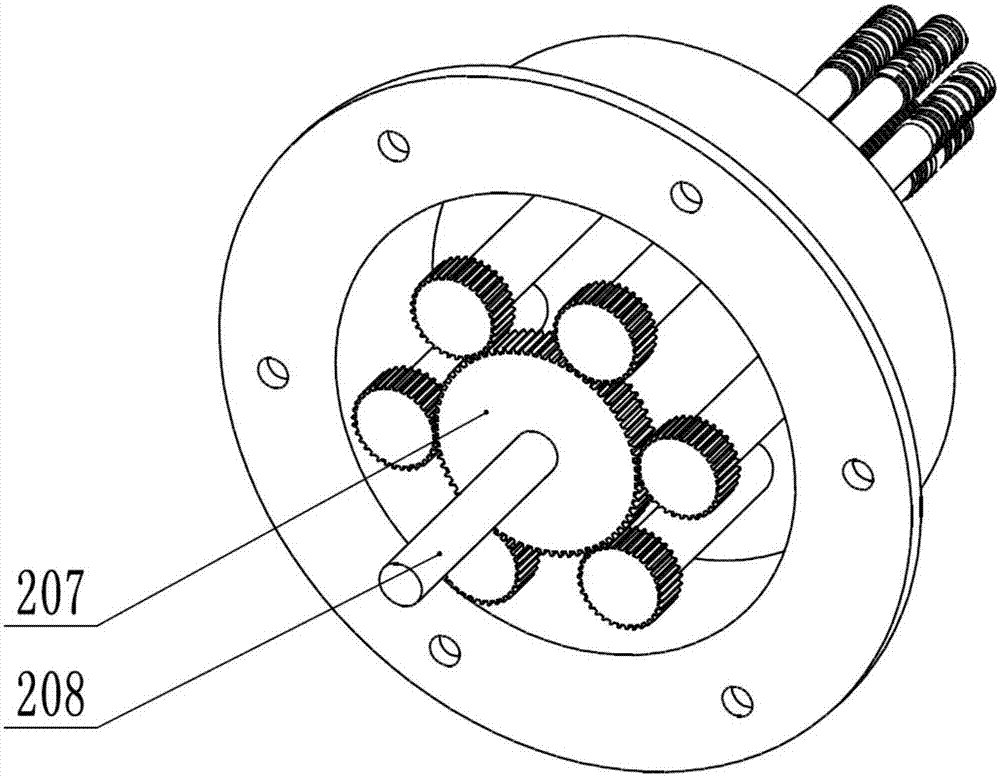

Assembling device of plastic needle assembly of infusion apparatus

ActiveCN105108492AAutomate assemblyIncrease productivityAssembly machinesMetal working apparatusPunchingAssembly machine

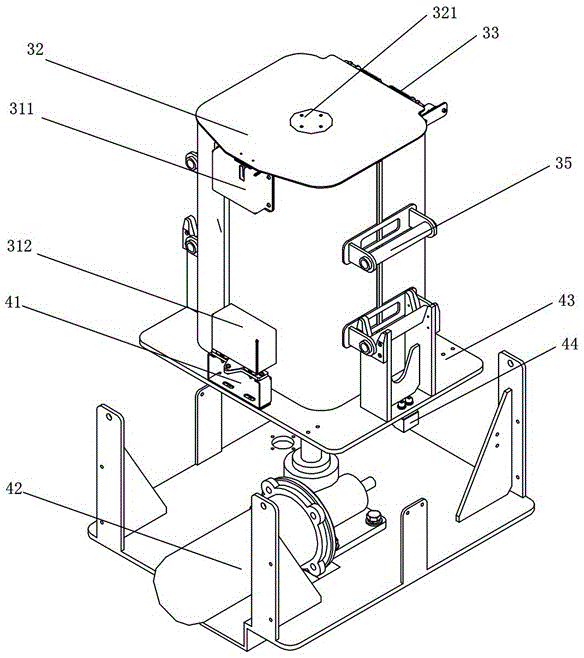

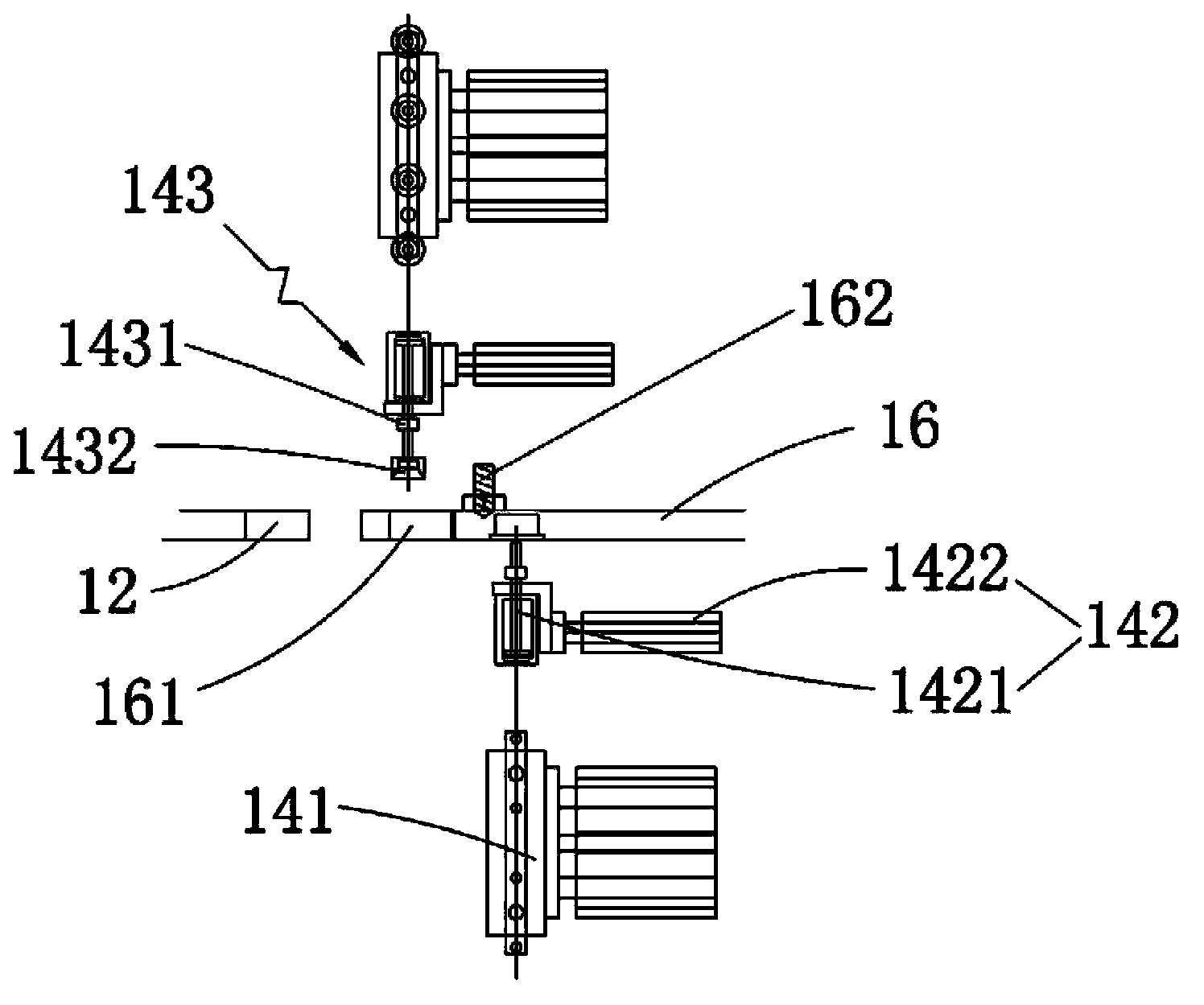

The invention provides an assembling device of a plastic needle assembly of an infusion apparatus, and belongs to the technical field of infusion apparatus assembling machines. The technical problem that a plastic needle assembly cannot be automatically assembled in the prior art, so that efficiency is low is solved. The assembling device comprises a machine frame. The machine frame is provided with an index plate which can rotate around the axis of the index plate relative to the machine frame in the horizontal direction. A clamp for positioning a plastic needle body is fixed to the edge of the index plate. An upper film station fixed to the machine frame and used for assembling a filter film on an exhaust hole in the plastic needle body is arranged on the periphery of the index plate. The upper film station comprises an upper film support. A film punching assembly is fixed to the middle of the upper film station. A feeding tray used for conveying filer film paper is fixed to the rear portion of the upper film support. According to the assembling device, automatic plastic needle assembling can be achieved, and therefore production efficiency is improved; meanwhile, manual contact is avoided, and the hygiene level is improved.

Owner:浙江东美智能设备有限公司

Coating for Improved Carbon Nanotube Conductivity

ActiveUS20110059317A1Great fiber fiber contactSuperior electrical propertySynthetic resin layered productsNon-conductive material with dispersed conductive materialCarbon nanotubePolymer coating

We discovered that the use of certain dopants or dopant moieties in polymeric coating formulations, that when applied over carbon nanotubes, unexpectedly decrease the measured electrical resistance of the coated carbon nanotubes (CNTs), when measured through the coating, even though the polymer coatings themselves do not have bulk conductivity. CNT compositions with enhanced electrical conductivity and methods of making such compositions are described. The CNTs are preferably coated with a dopant or dopant moiety having a HOMO energy of −7.0 eV or lower.

Owner:BATTELLE MEMORIAL INST

Intelligent sample collecting device

ActiveCN105752470ARisks Affecting Mass AccuracyHigh security for collection and transferLidsNon-removalbe lids/coversLocking mechanismEngineering

The invention discloses an intelligent sample collecting device which comprises a machine frame. The machine frame is provided with a feed inlet. A rotatable rotating disc mechanism and multiple sample storage barrels used for collecting samples are arranged in a collecting cavity formed by the machine frame. The sample storage barrels are hung on the rotating disc mechanism. Each sample storage barrel is provided with a hinged barrel cover and an induction locking mechanism used for locking the barrel cover. The hinged position of the barrel cover is provided with an elastic part so that the barrel cover can bounce upwards to be opened when not locked. The feed inlet is provided with a liftable weighing mechanism. The weighing mechanism is provided with an induction unlocking assembly matched with the induction locking mechanism. When the rotating disc mechanism drives the sample storage barrels to rotate to the position below the feed inlet, the weighing mechanism raises to lift up the sample storage barrels, so that the induction locking mechanism induces an unlocking signal of the induction unlocking assembly to open the barrel covers for sample connection and weighing operation. The intelligent sample collecting device has the advantages that the structure is simple and compact, the intelligence degree is high, sample collection and transfer safety is high, sample collection quality precision is high, working efficiency is high, and the production cost is low.

Owner:HUNAN SUNDY SCI & TECH DEV

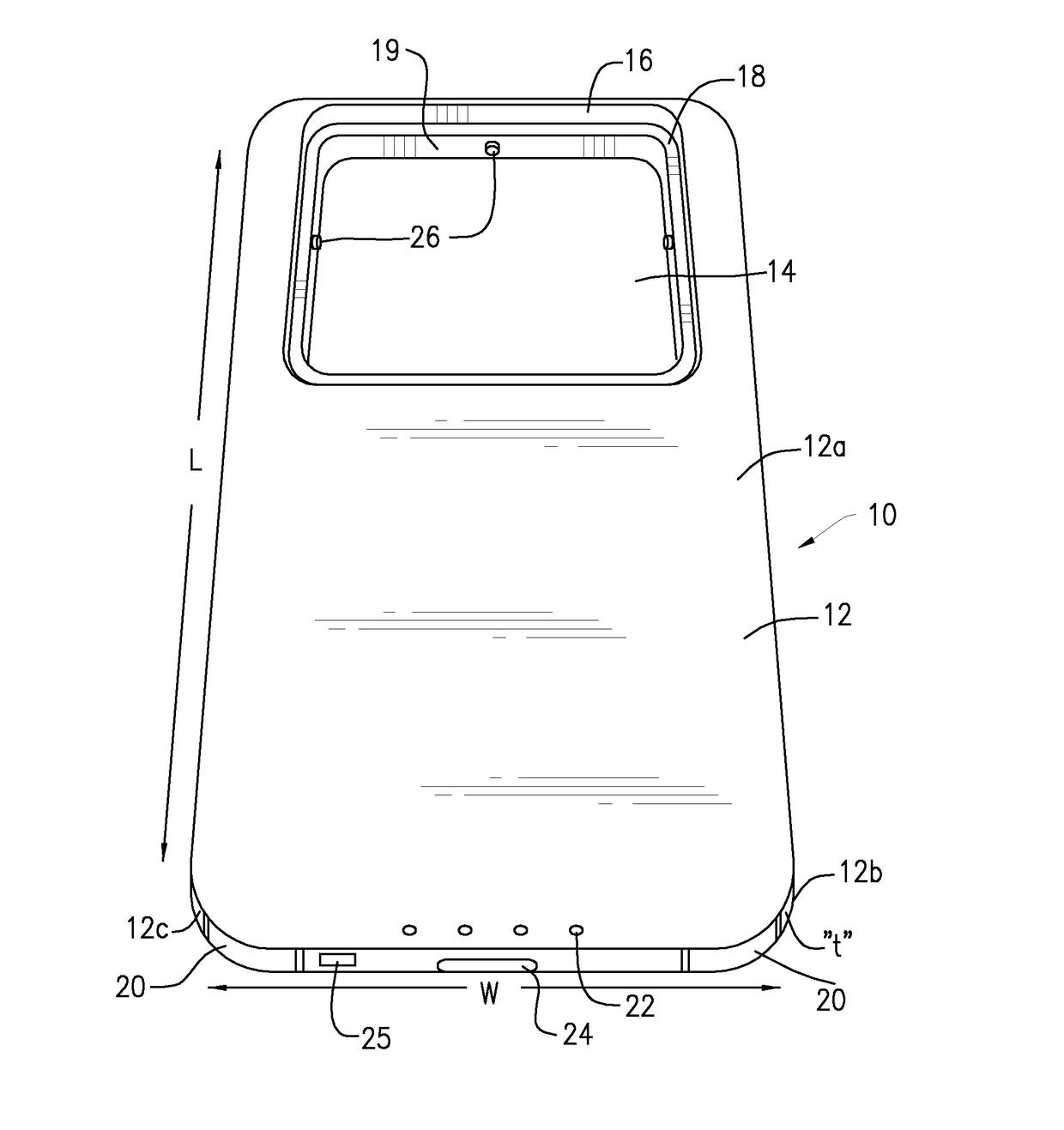

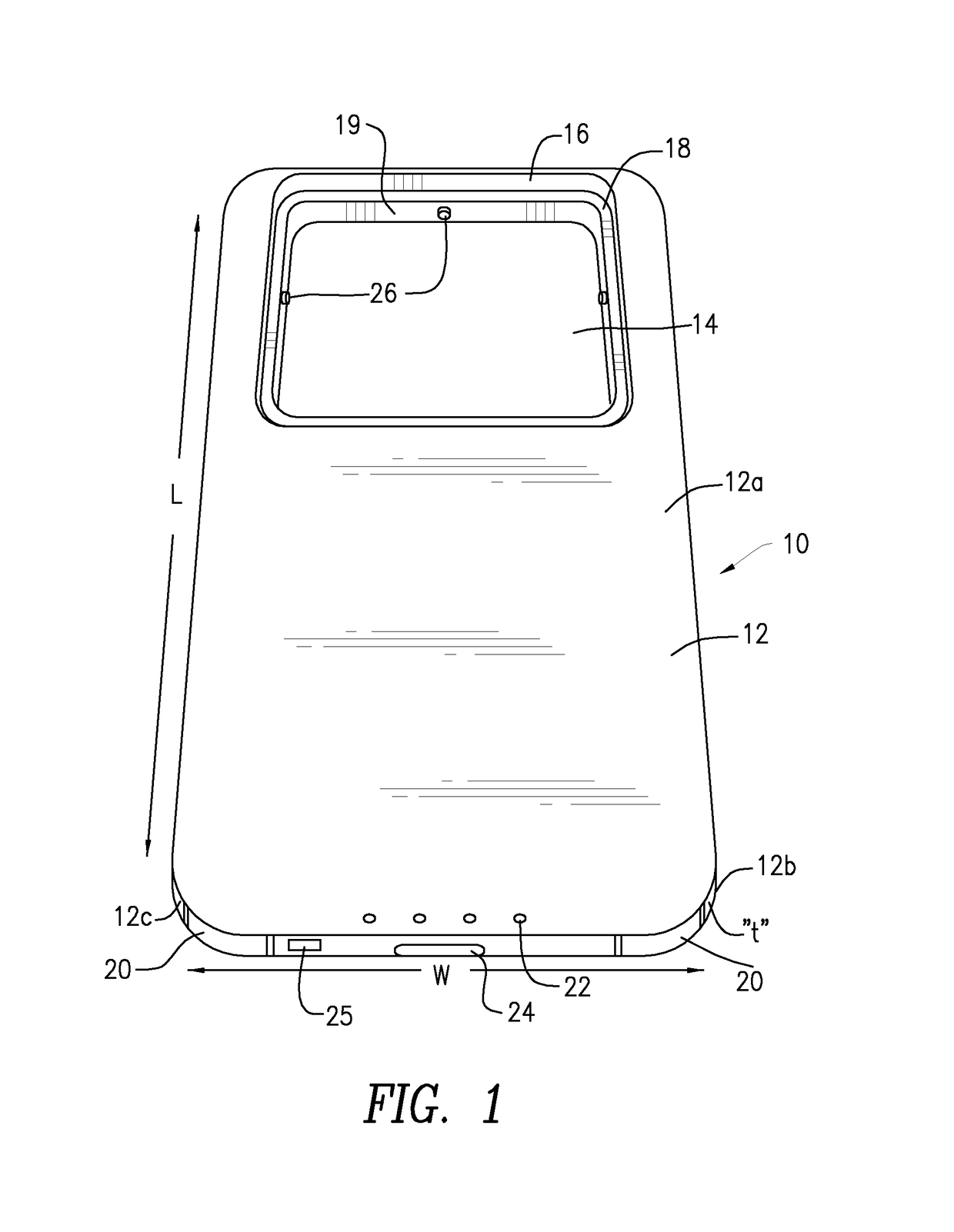

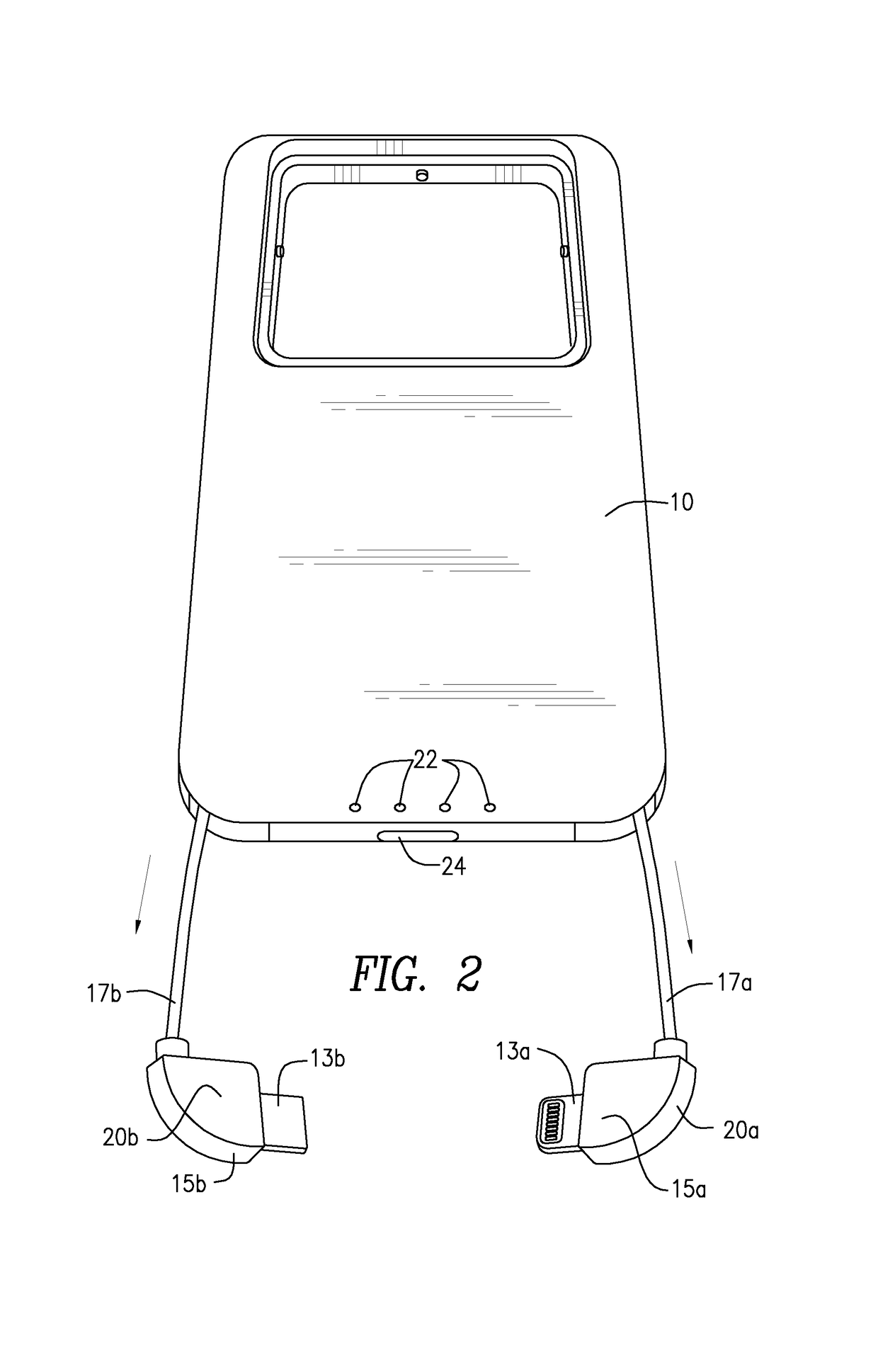

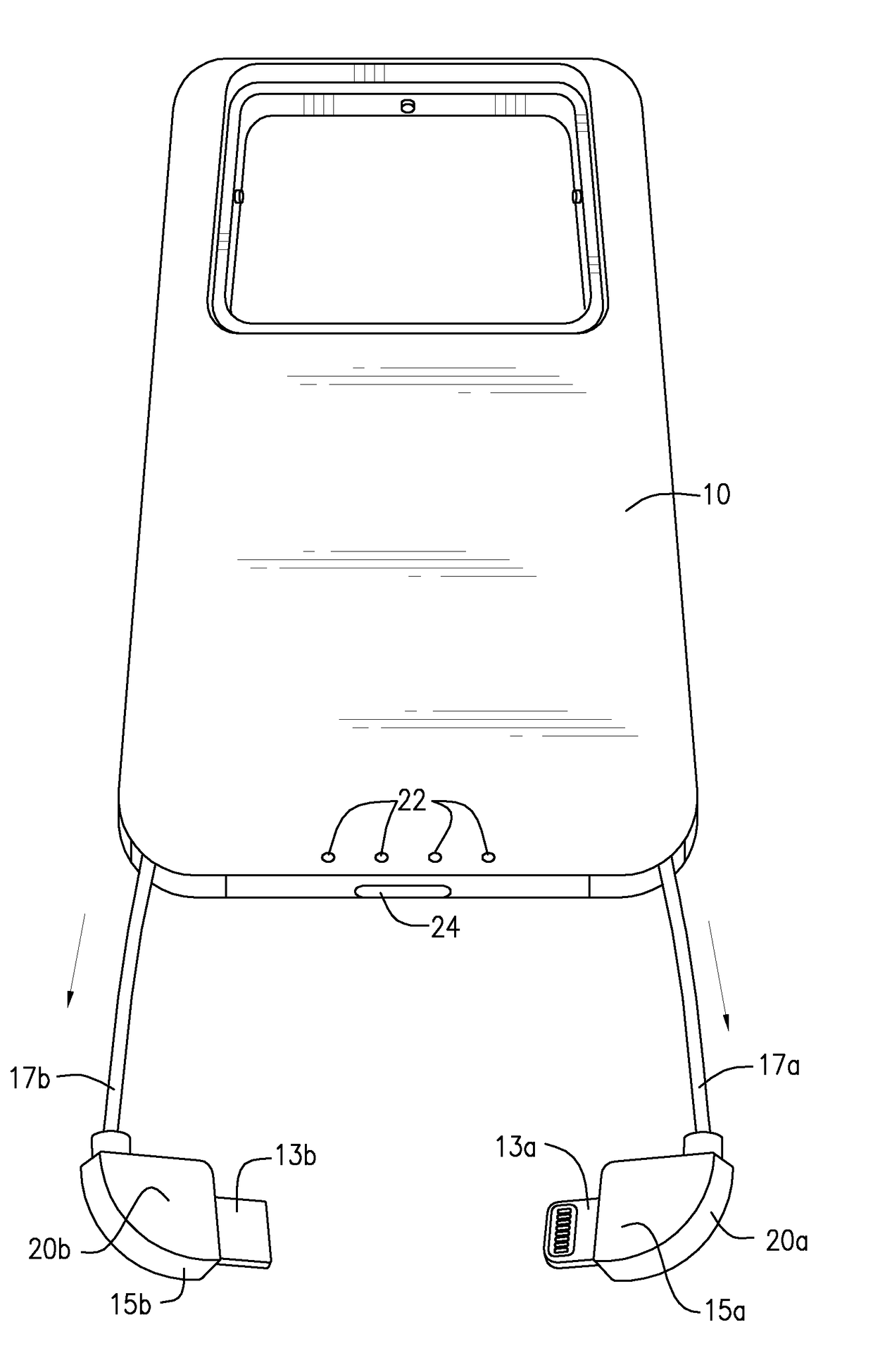

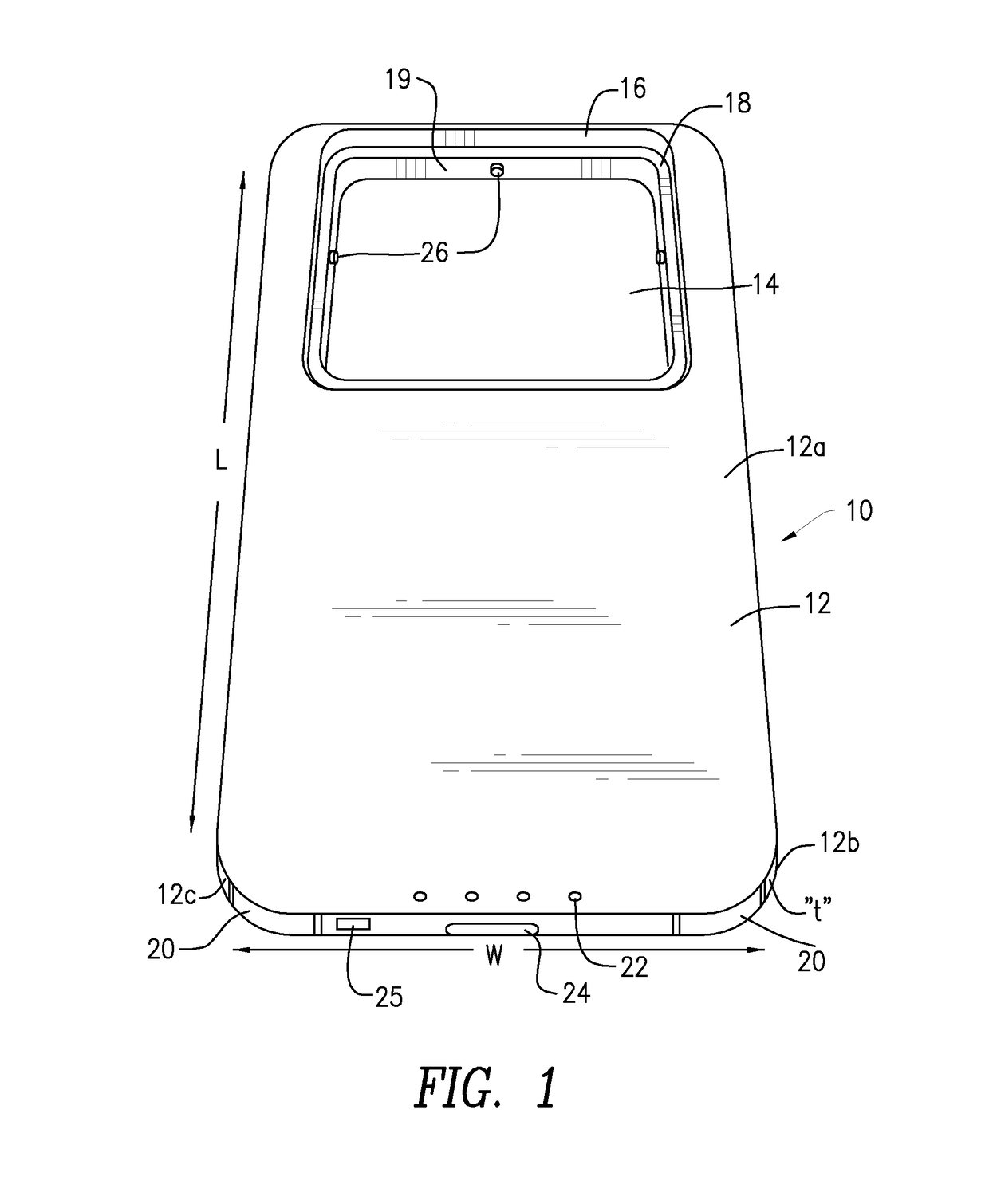

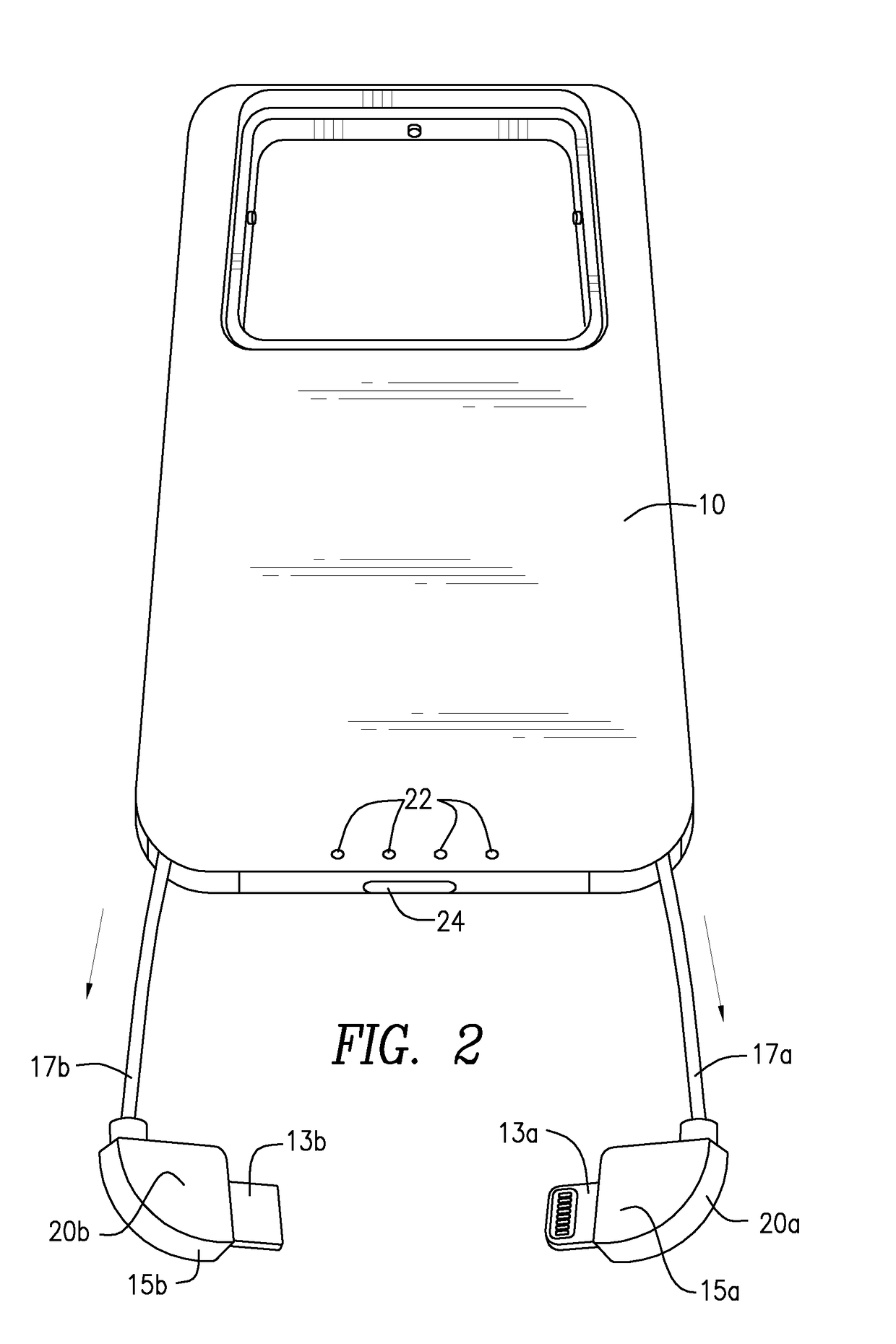

Universal phone battery chargers for mobile cellphones and like devices

ActiveUS9977462B2Easy to holdAvoid human contactCircuit monitoring/indicationDigital data processing detailsRechargeable cellComputer module

A universal charging accessory for mobile devices. The accessory has a generally flat and thin body configured to lie flat against the flat rear side of the mobile device and includes an internal rechargeable battery, two charging plugs that are configured to be electronically coupled to the charging plug of the mobile device, with the charging plugs being retrievably stowed inside the body of the accessory and to be withdrawn as needed to charge the mobile device. The accessory has a window formed in the body of the charging accessory which receives, interchangeably, a plug-in module that can be inserted into an AC socket to charge the internal battery as well as the cellphone battery.

Owner:SORIASKY YEOSHUA

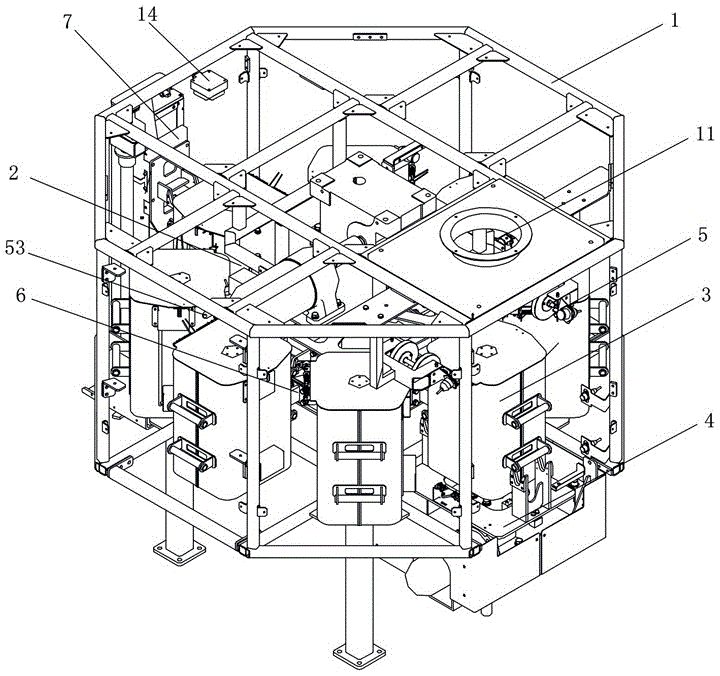

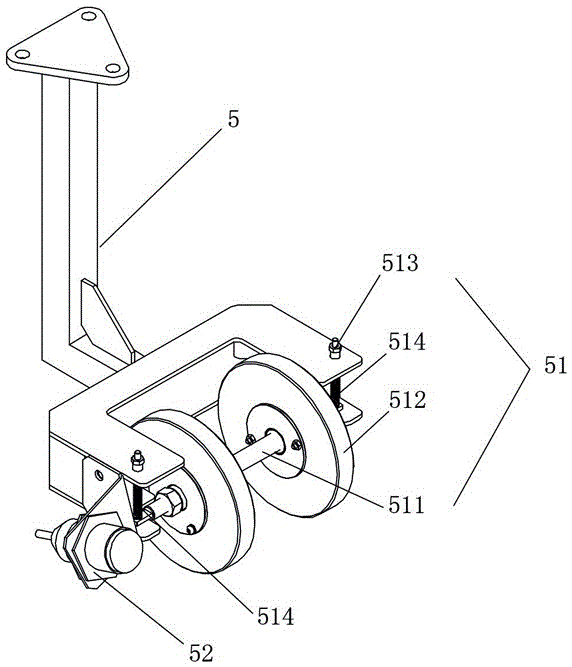

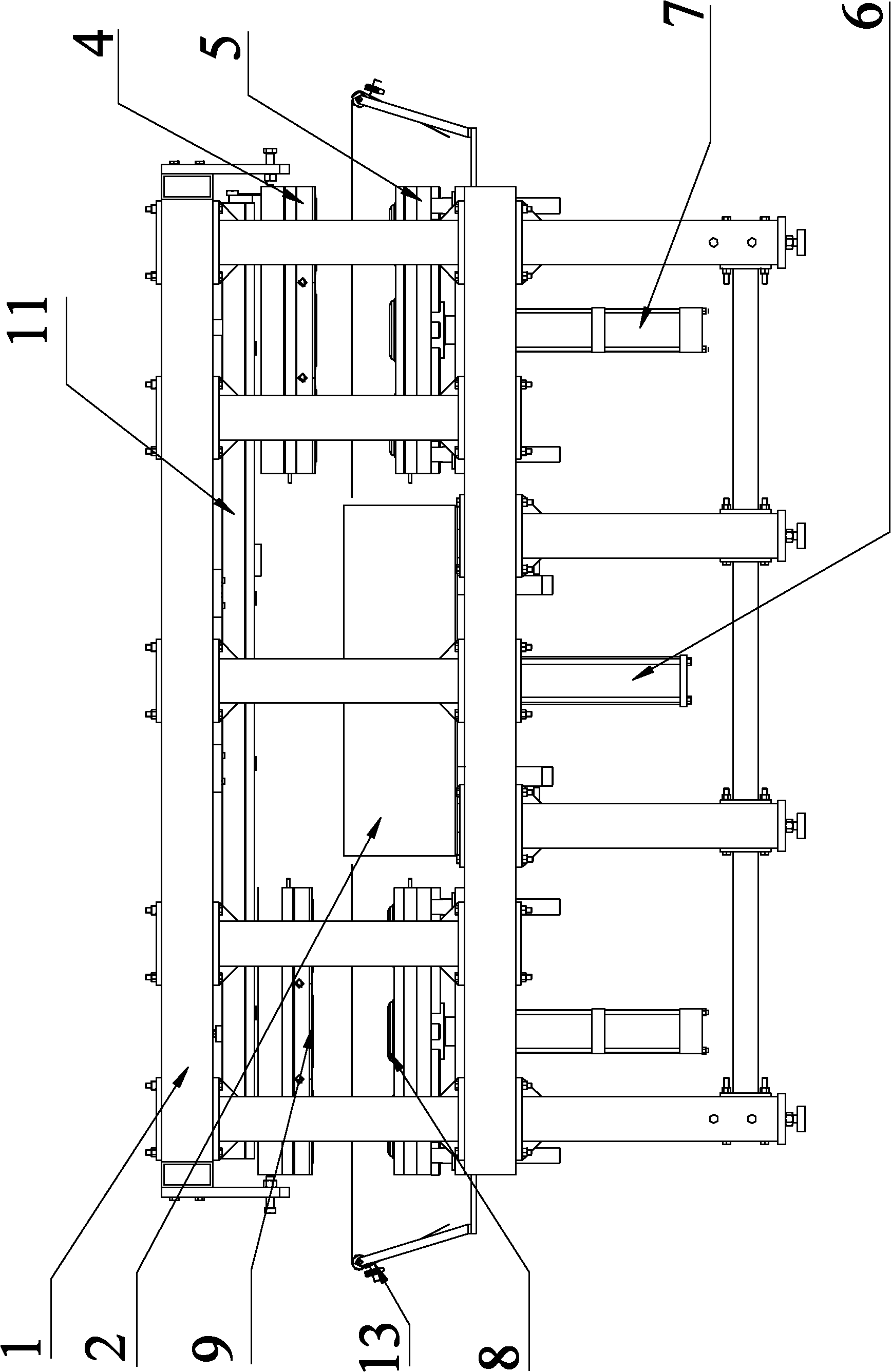

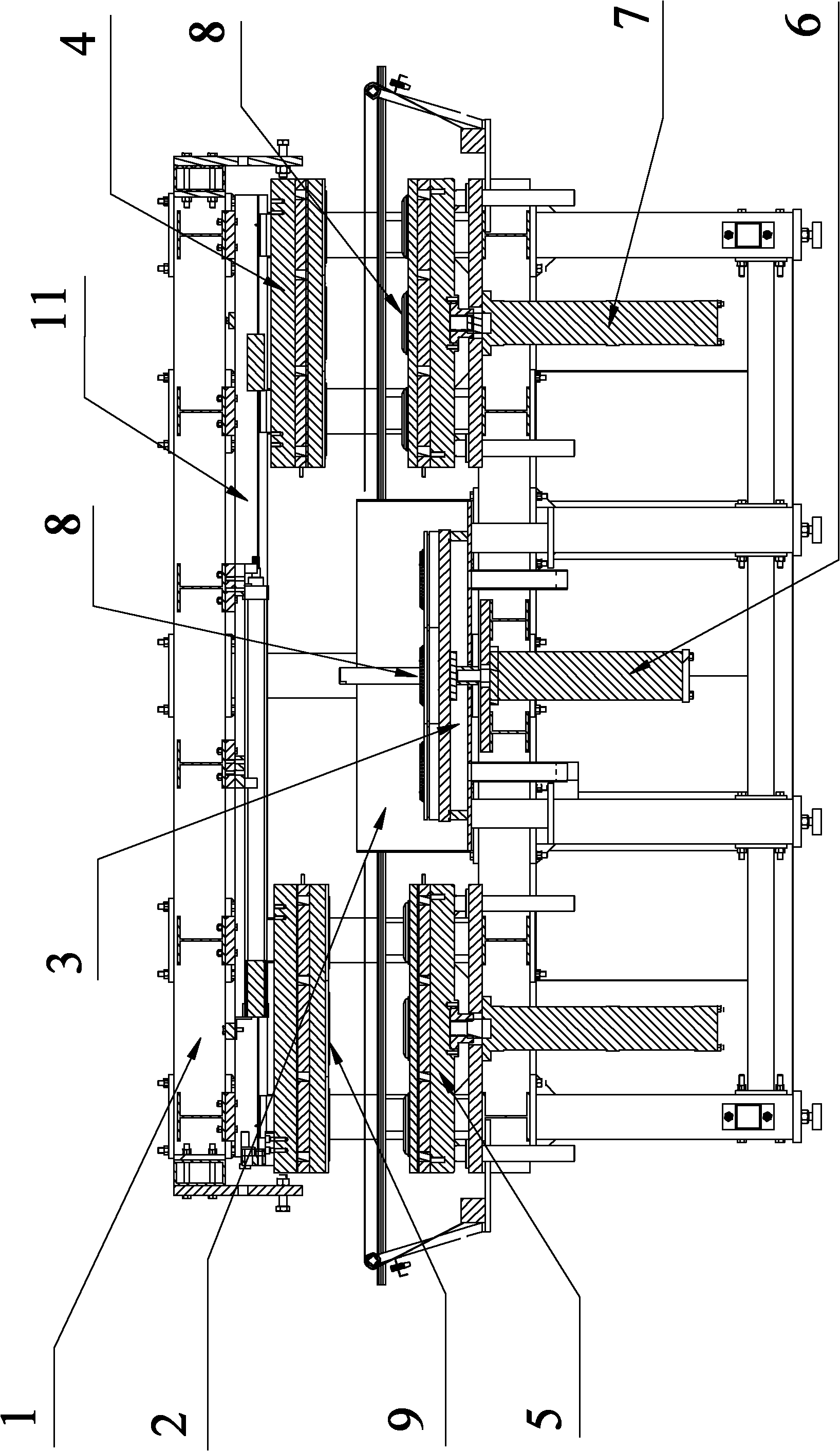

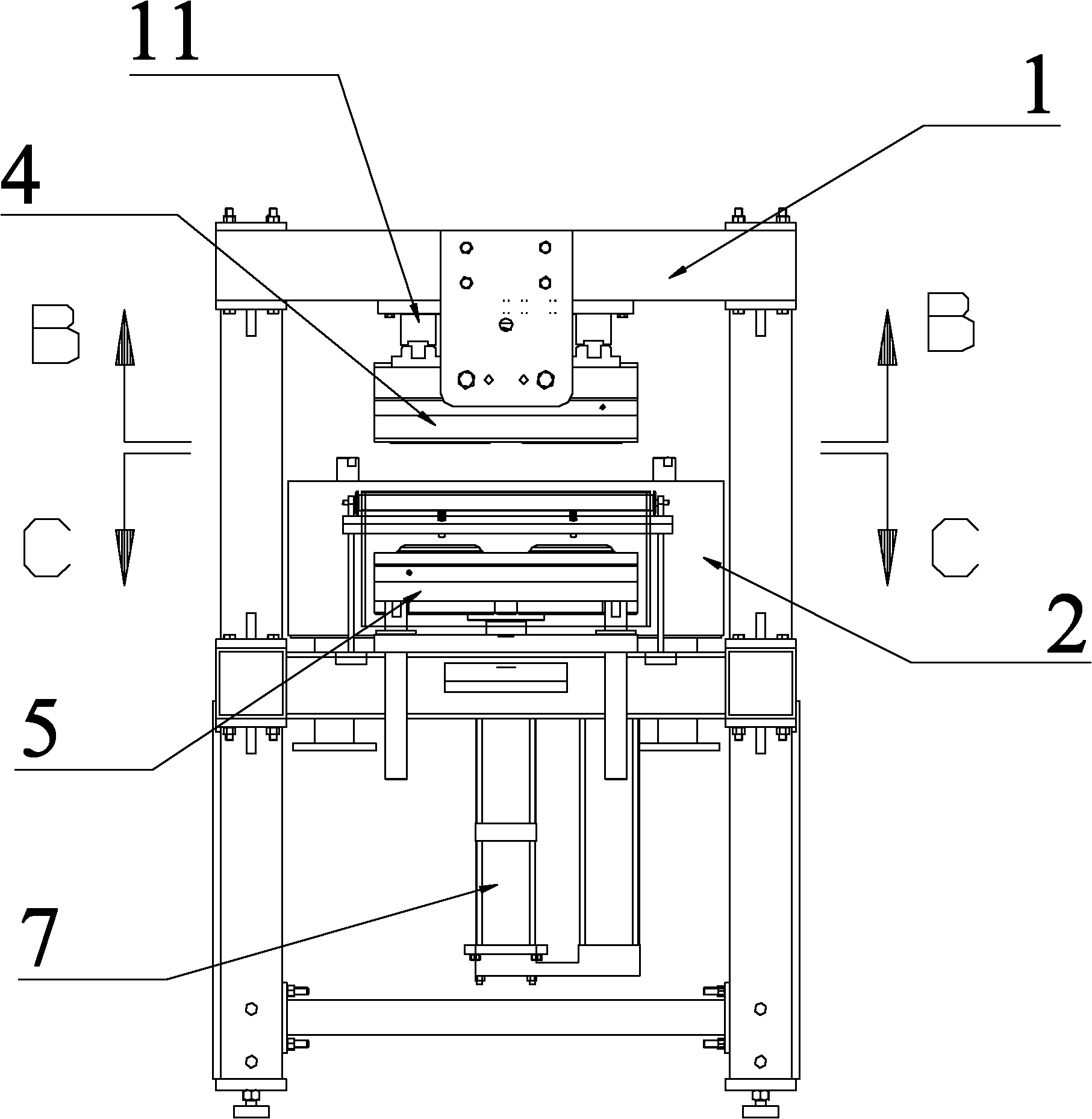

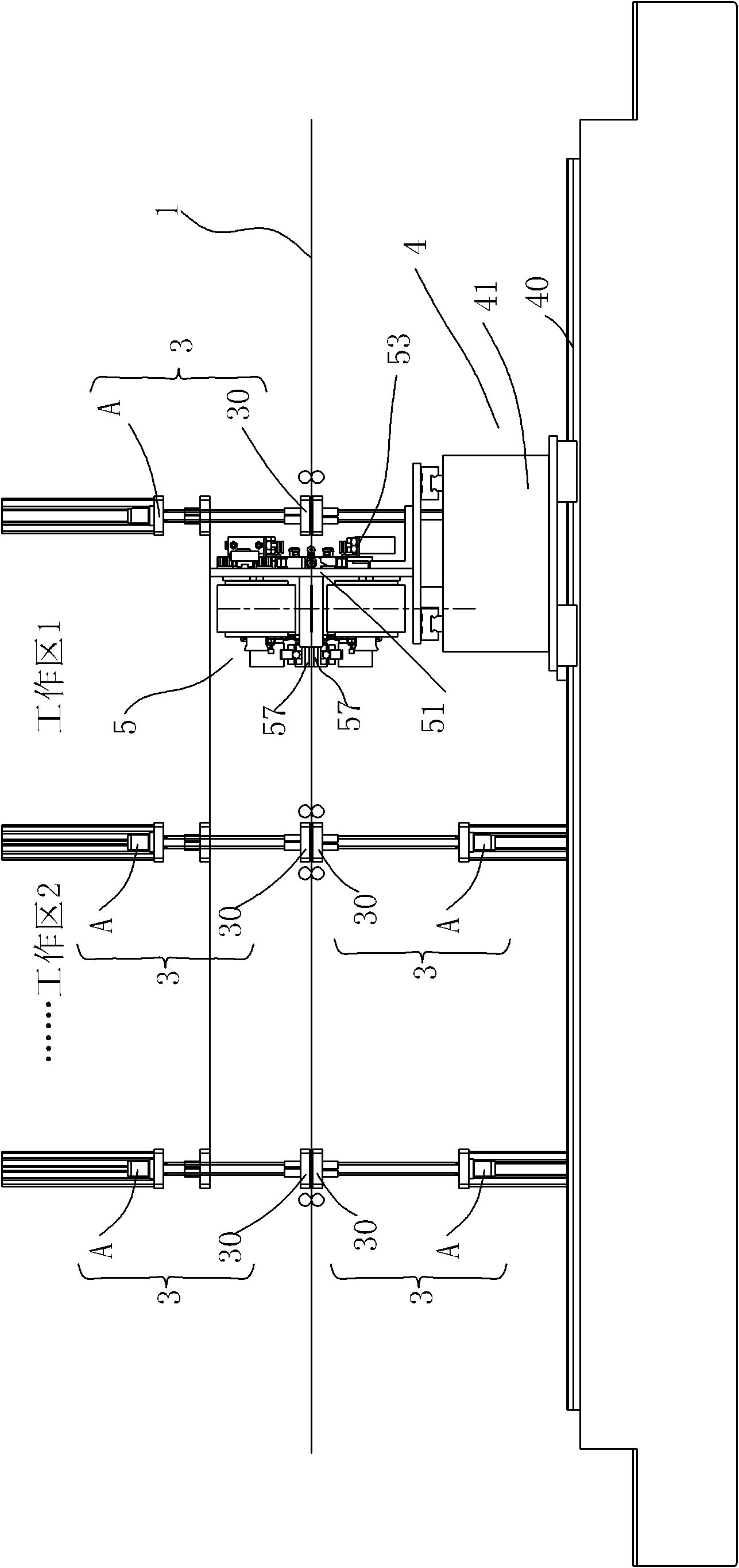

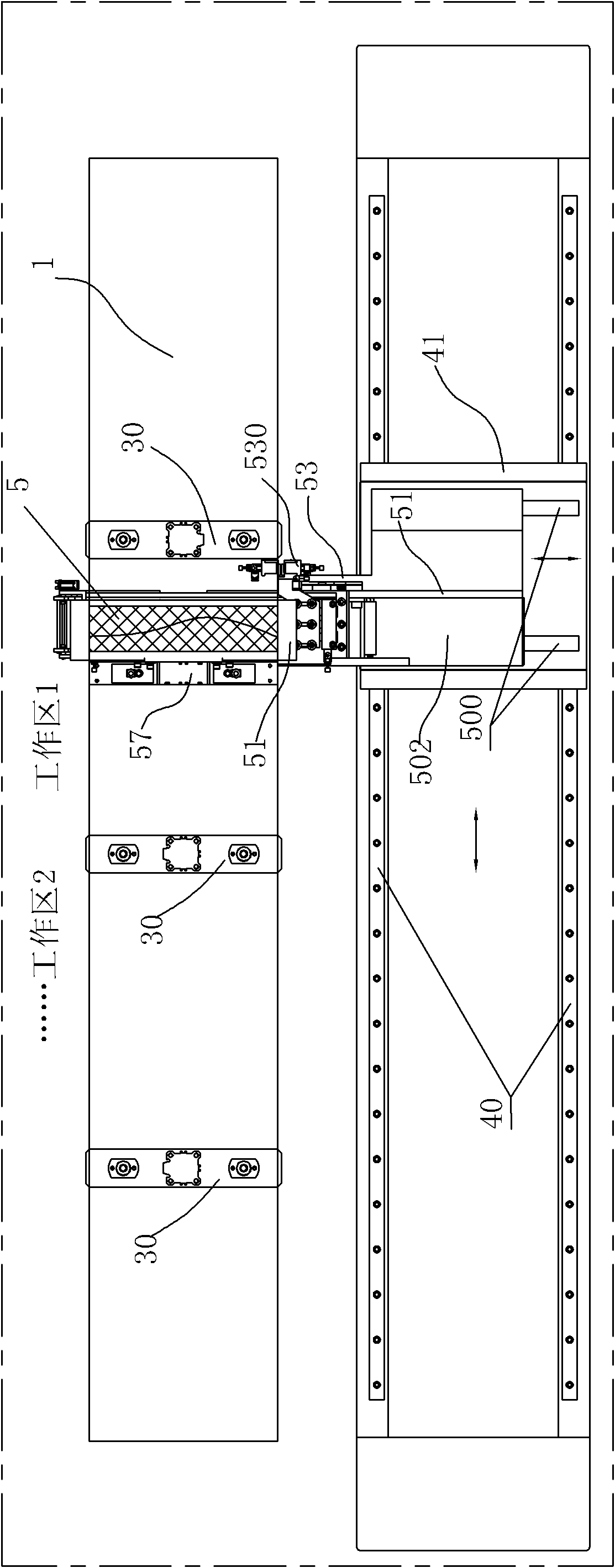

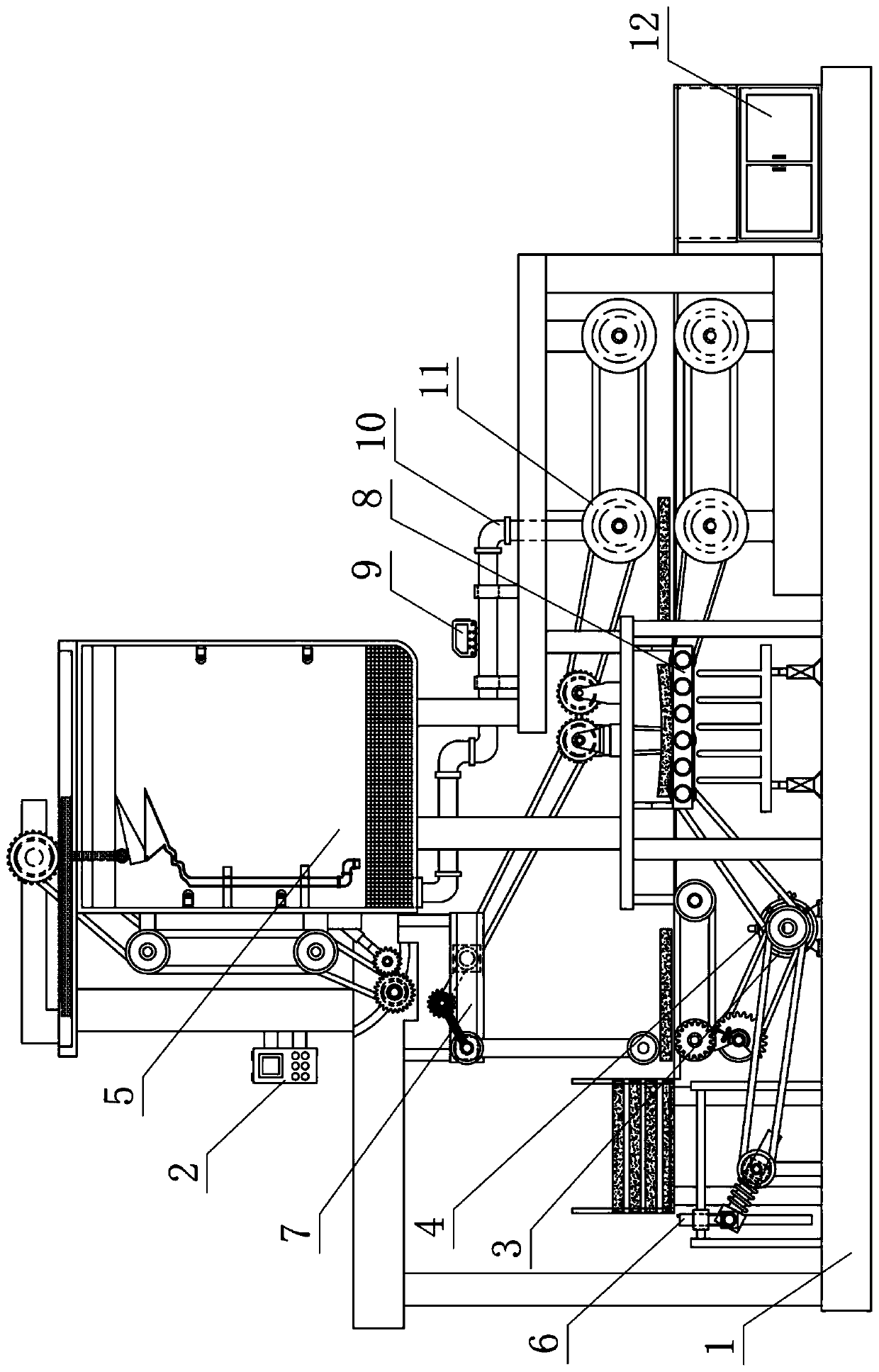

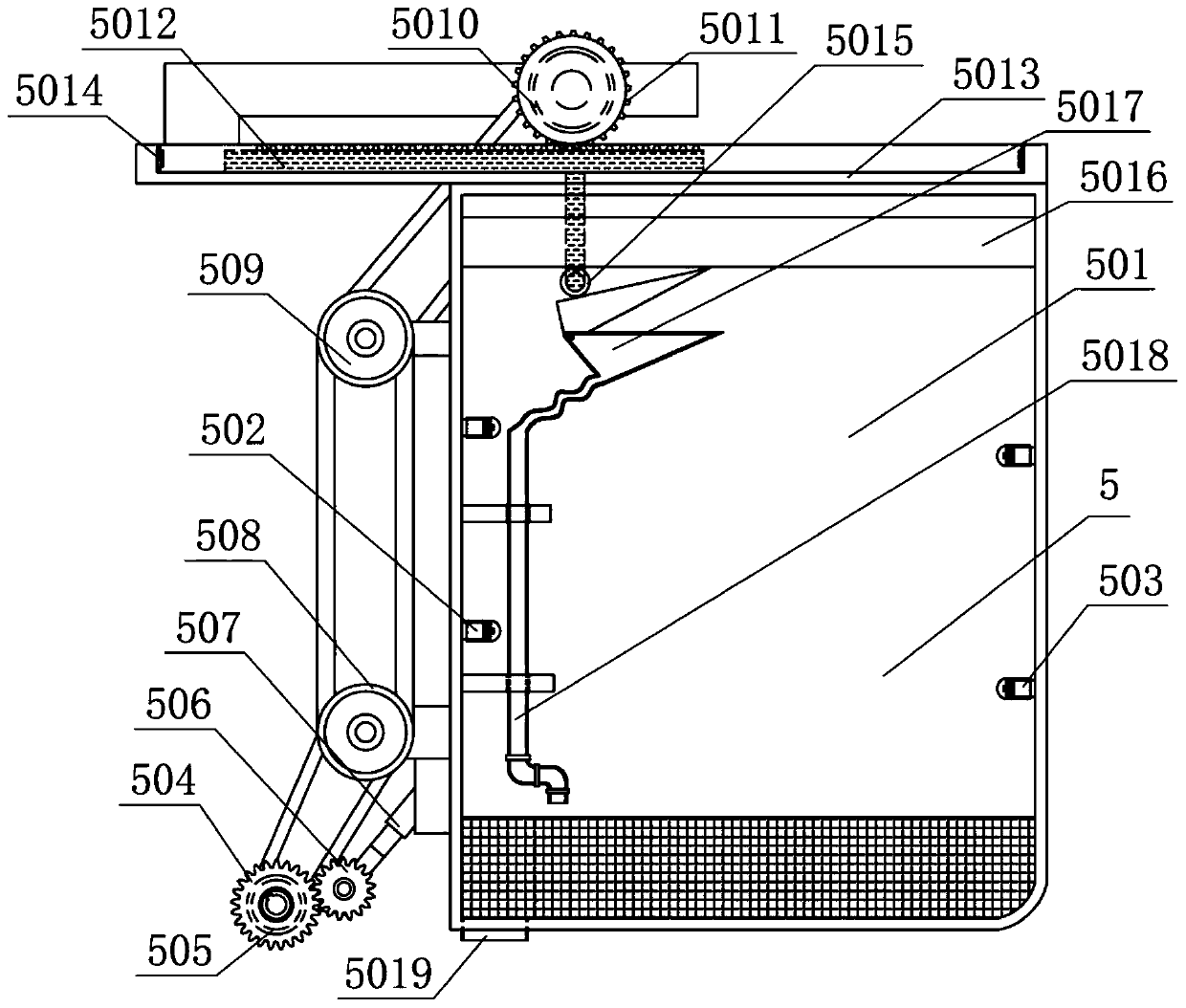

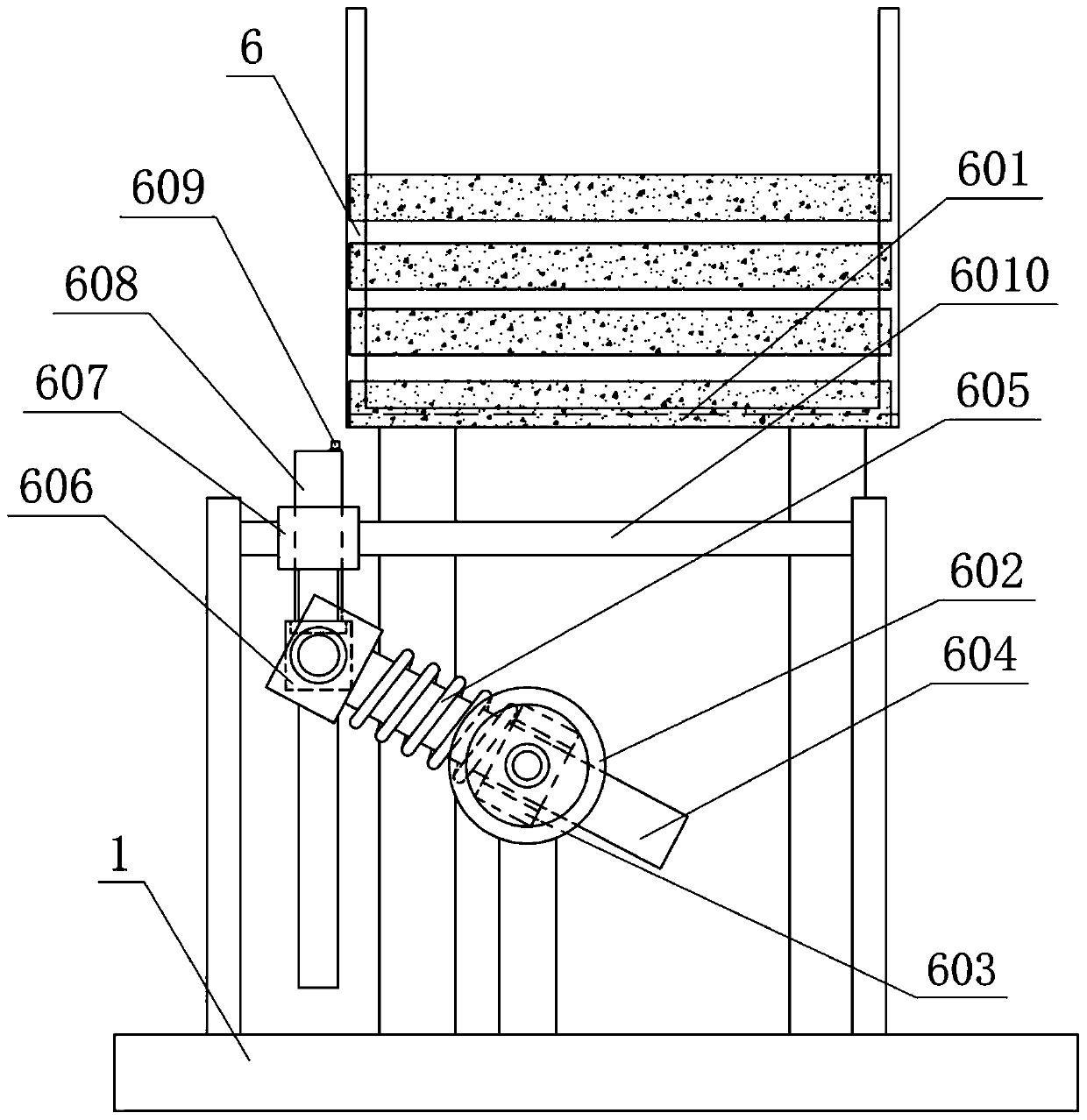

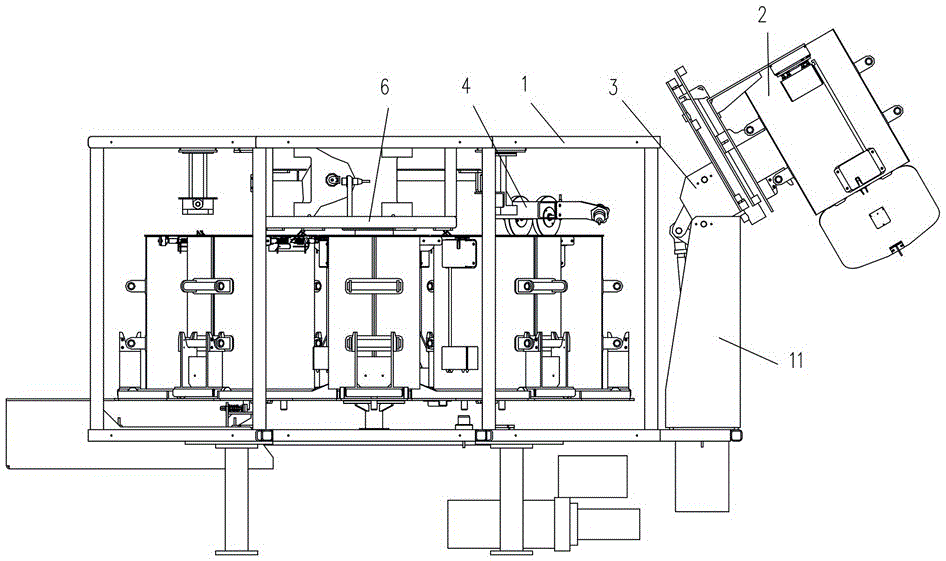

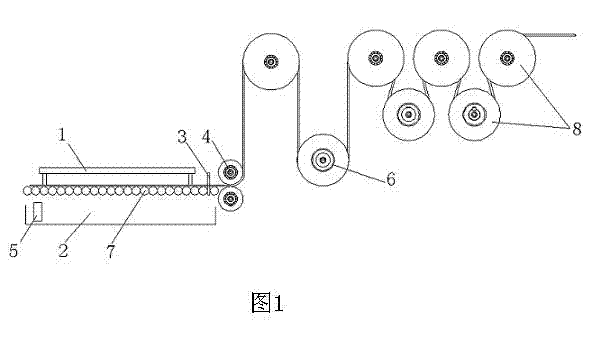

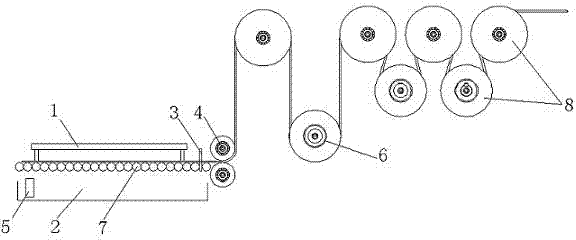

Production equipment of paper pulp molding product and method for producing molding product by applying same

ActiveCN102465477AEasy maintenanceExtended service lifeTextiles and paperMechanical engineeringHot press

The invention relates to a piece of production equipment of a paper pulp molding product and a method for producing the molding product by applying the same. The production equipment comprises a rack (1), a pulp groove (2), a male die wet-green molding prepressing mechanism (3), a female die moving mechanism (4) and a finalizing and drying mechanism (5), wherein the male die wet-green molding prepressing mechanism (3), the female die moving mechanism (4) and the finalizing and drying mechanism (5) are arranged in the pump groove (2), wherein the downside of the wet-green molding prepressing mechanism (3) is connected with an air cylinder (6), and the downside of the finalizing and drying mechanism (5) is connected with a pressure cylinder (7); and the equipment further comprises an automatic receiving box (13). The method for producing the molding product comprises the steps of : (1) pump injection; (2) transferring of the wet-green; (3) hot-press forming; (4) transferring of the molding product, wherein after the hot-press forming is finished, the pressure cylinder drives the finalizing and drying mechanism to move downward, meanwhile, the automatic receiving box is moved under the female die moving mechanism to receive the molding product; and (5) repetition of the steps.

Owner:SHANDONG TRALIN PAPER

Beverage bottle dewatering and arranging production line

ActiveCN106184934AShort drying distanceSmall space for wind actionPackaging protectionPackaging bottlesWind drivenSprayer

The invention relates to a beverage bottle dewatering and arranging production line. The beverage bottle dewatering and arranging production line comprises a bottom plate, wherein a transferring tray is mounted at the rear side of the bottom plate, a wind-driven dewatering device is mounted in the middle of the bottom plate, a conveying bridge plate used for conveying beverage bottles is mounted between the wind-driven dewatering device and the transferring tray, and a beverage bottle arranging device is mounted at the front side of the bottom plate; and the transferring tray comprises a motor I vertically arranged, a turntable is mounted on a shaft of the motor I, the outer side of the turntable tilts downwards, the upper end surface of the turntable is uniformly fixedly connected with partition boards used for separating the beverage bottles, the periphery of the turntable is encircled by one circle of fence, and the right side part of the fence is provided with an opening. The beverage bottle dewatering and arranging production line has the advantages that washed beverage bottles are blown dry by air sprayers mounted on side baffles, and the blow-drying distance is shorter than that of an air blower; and due to the blocking of a surrounding space by the side baffles, a wind acting space is small, so that air pressure is higher, and the blow-drying efficiency is obviously improved.

Owner:安庆市佳美饮料有限公司

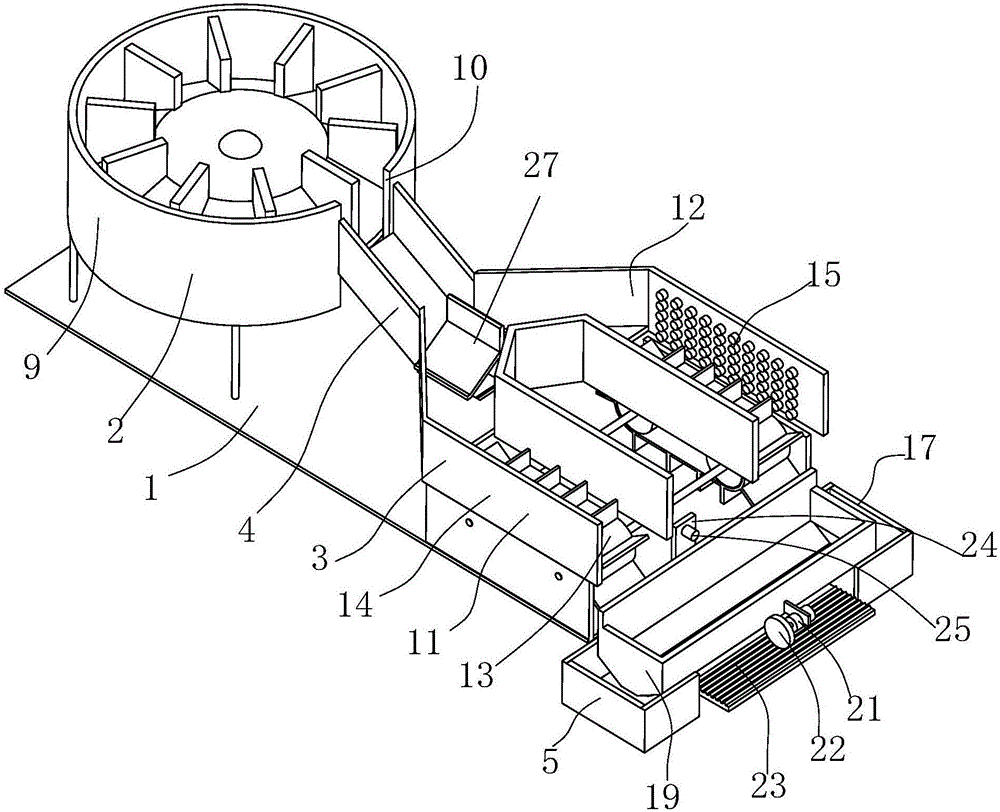

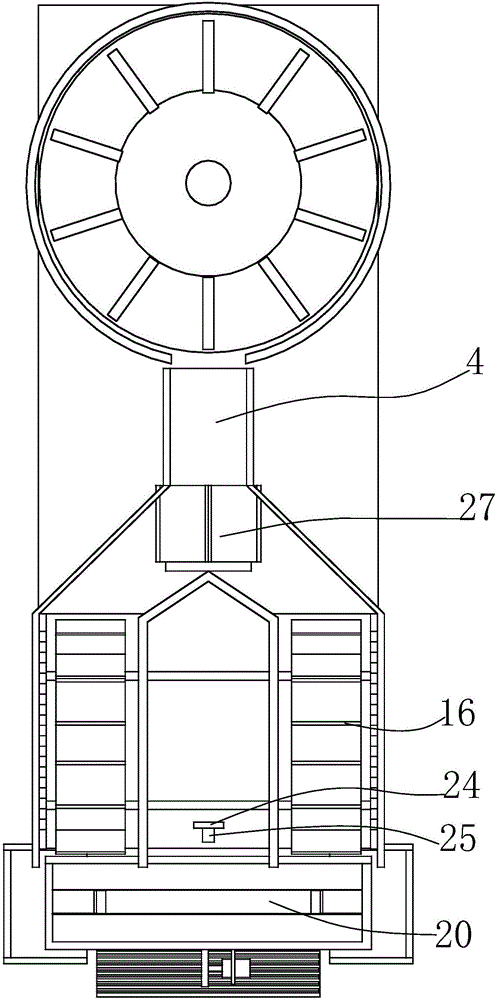

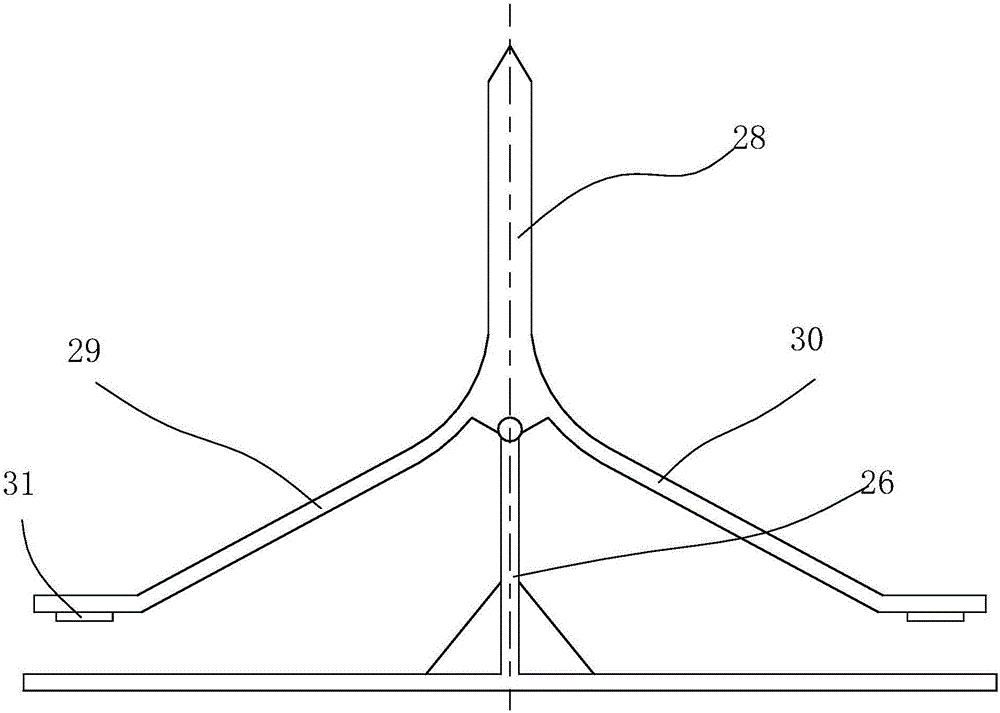

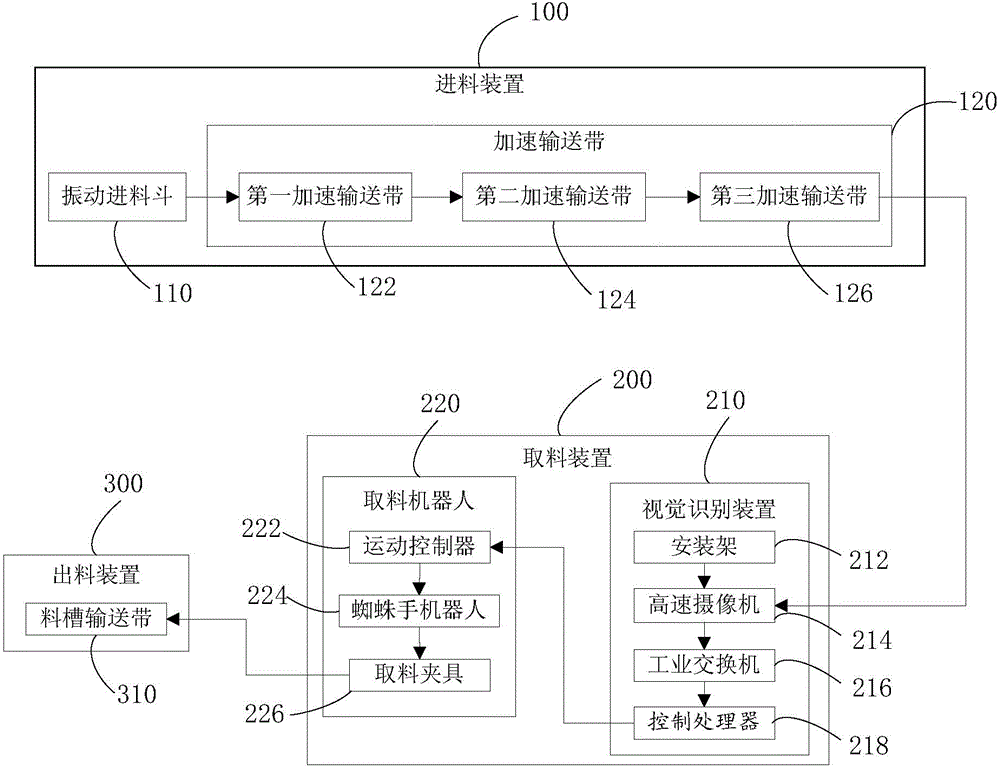

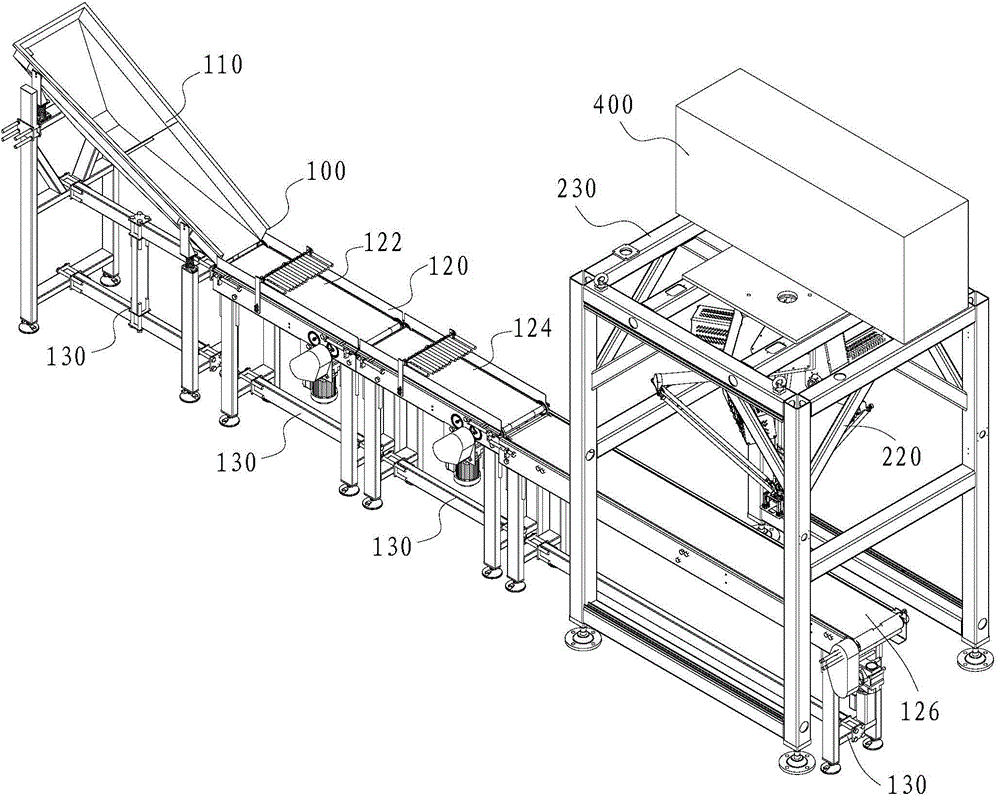

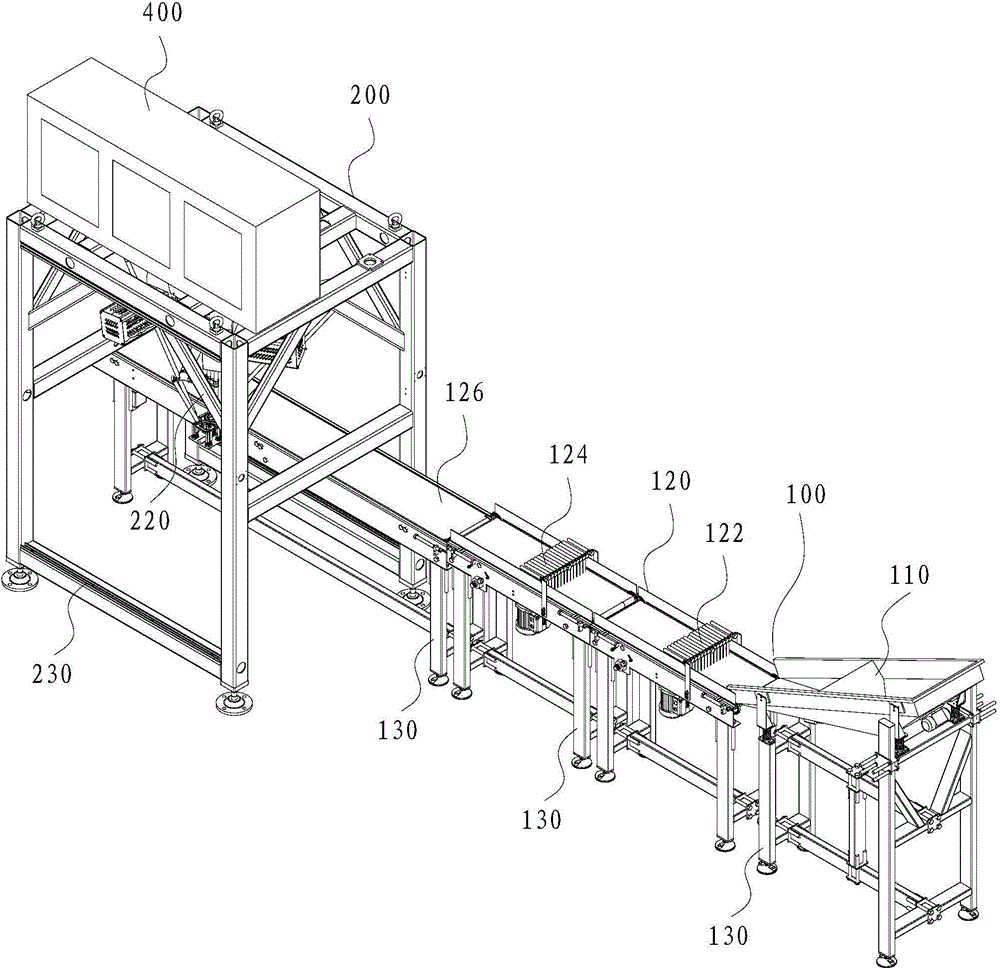

Feeding system and method for block-shaped food

ActiveCN104890936AEnsure food hygiene and safetyGuaranteed quantityPackaging automatic controlEngineeringRobot

The invention provides a feeding system and method for block-shaped food. The feeding system comprises a feeding device, a reclaiming device and a discharging device which are arranged in sequence. The feeding device comprises a vibration feed hopper and an acceleration conveying belt connected with the vibration feed hopper. The reclaiming device comprises a rack arranged at the end of the acceleration conveying belt in a covering mode, a visual identity device arranged above the rack and above the acceleration conveying belt and a reclaiming robot arranged inside the rack. The reclaiming robot is in communicating connection with the visual identity device. The discharging device comprises a trough conveying belt. The end of the trough belt is arranged inside the rack and is arranged below the reclaiming robot. According to the technical scheme provided by the feeding system and method for the block-shaped food, the problems that manually feeding cost for the block-shaped food is high, the efficiency is low, the quality is bad, and the sanitation is bad in the traditional technology in the traditional technology are solved.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

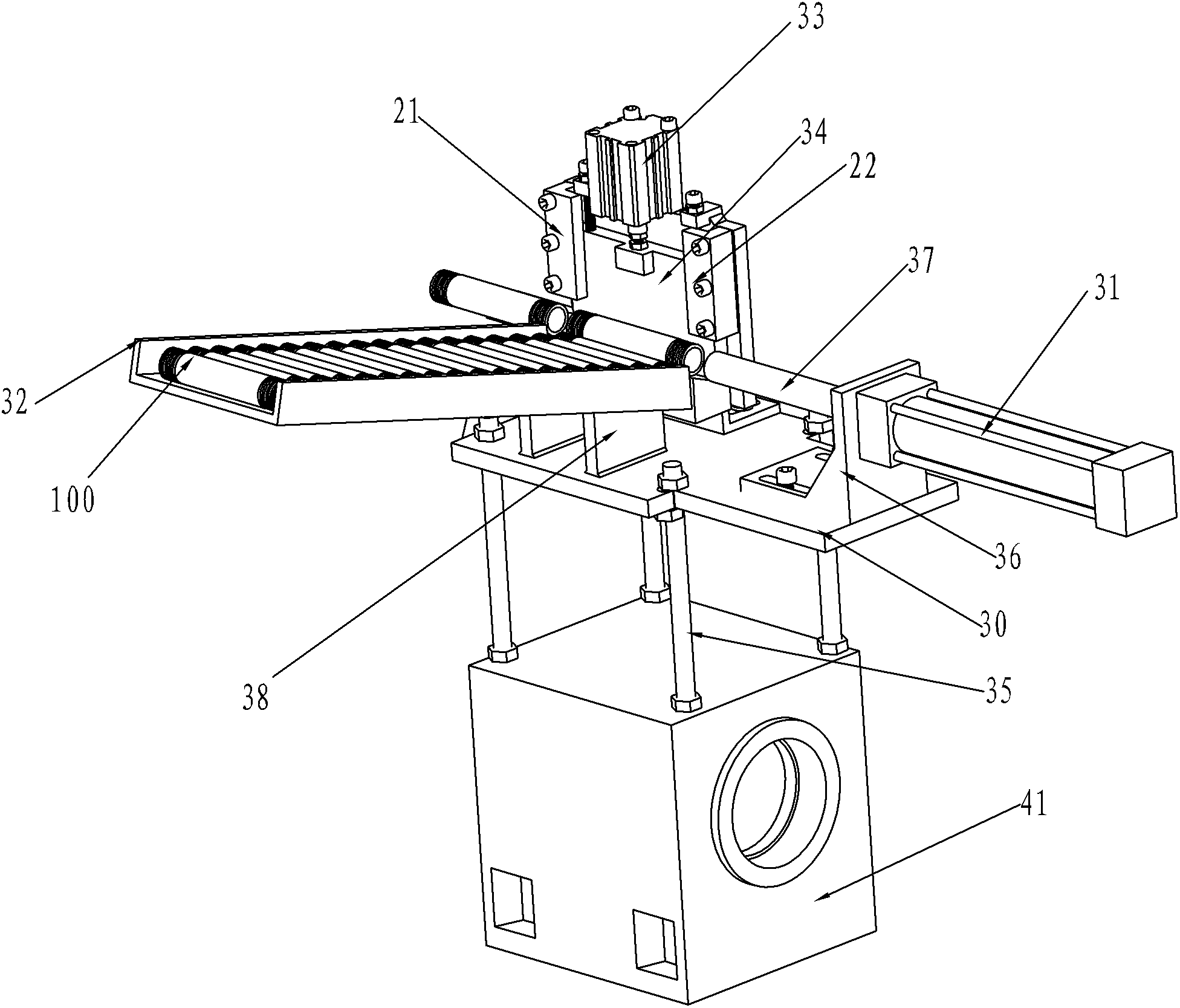

Assembly machine for draining pump valve body

InactiveCN107443074AReduce labor intensityImprove labor healthAssembly machinesFatigue damageEngineering

The invention discloses an assembly machine for a draining pump valve body, which comprises a disc cutter, a mounting platform, and a sealing ring mounting station; the sealing ring mounting station comprises a sealing ring presetting plate, a floating frame, an opening mechanism, a scraping mechanism, a first moving mechanism and a second moving mechanism; the opening mechanism comprises a central spindle provided with an external conical surface at the bottom, a third driving part driving the central spindle to move up and down, and an opening strut arranged below the central spindle; a center hole is formed in the top of the opening strut, and an internal conical surface is formed in the center hole; the opening strut is divided into a plurality of sections in the manner of central symmetry; the scraping mechanism comprises a scraping plate and a fourth driving part driving the scraping plate to move up and down. The assembly machine can automatically finish mounting of a sealing ring in a valve body assembly, do not need manual participation in a mounting process, effectively avoid fatigue damage to hands of workers, prevent grease pollution and corrosion to skin of the hands of workers, and improve the working health conditions of the workers; meanwhile, the assembly efficiency and the success rate are greatly improved, and the reduction of production cost is facilitated.

Owner:JIANGMEN HUILANG IND ROBOT CO LTD

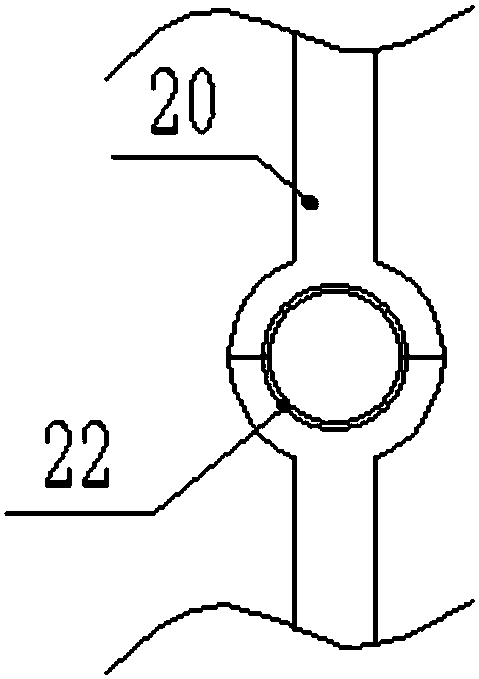

Automatic feeding device

InactiveCN102601669AAvoid human contactReduce labor intensityMetal working apparatusEngineeringMechanical engineering

The invention discloses an automatic feeding device. A feeding cylinder fixing seat is mounted on the top of a feeding support plate, a feeding cylinder is fixed onto the feeding cylinder fixing seat, a piston rod of the feeding cylinder is connected with a push rod, a material groove is obliquely fixed onto the feeding support plate, a slider fixing seat is fixed onto the feeding support plate, a slider seat is fixed onto the slider fixing seat, a carrying cylinder is fixed to the top of the slider fixing seat, the lower end of a piston of the carrying cylinder is connected with the top of a slider, a left slider pressure plate and a right slider pressure plate are respectively fixed to the left side and the right side of the slider seat and press on two sides of the slider, the slider can be driven by the carrying cylinder to vertically slide among the left slider pressure plate, the right slider pressure plate and the slider seat, a receiving table is disposed on the lower portion of the slider and positioned at an outlet of the lower end of the material groove, and the position of the push rod corresponds to that of the receiving table. The automatic feeding device automatic feeds materials, manual feeding is omitted, labor intensity of workers is reduced, work efficiency is improved, and health and safety of operators are guaranteed.

Owner:莱州市山普管件制造有限公司

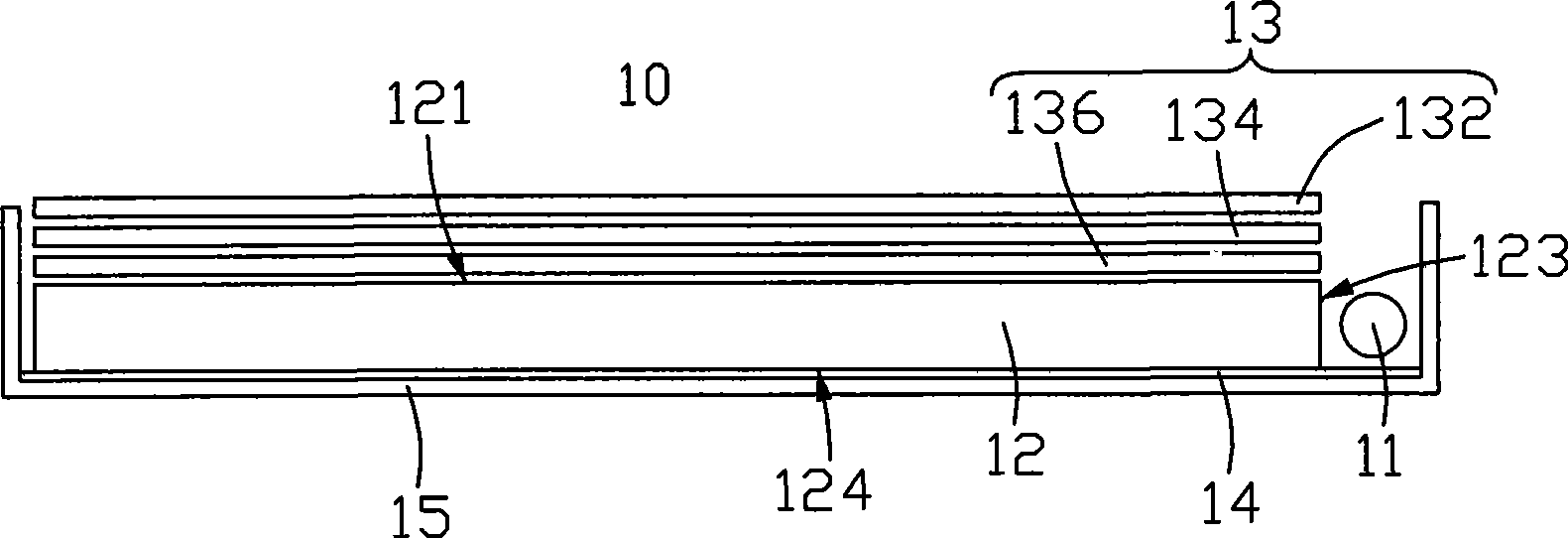

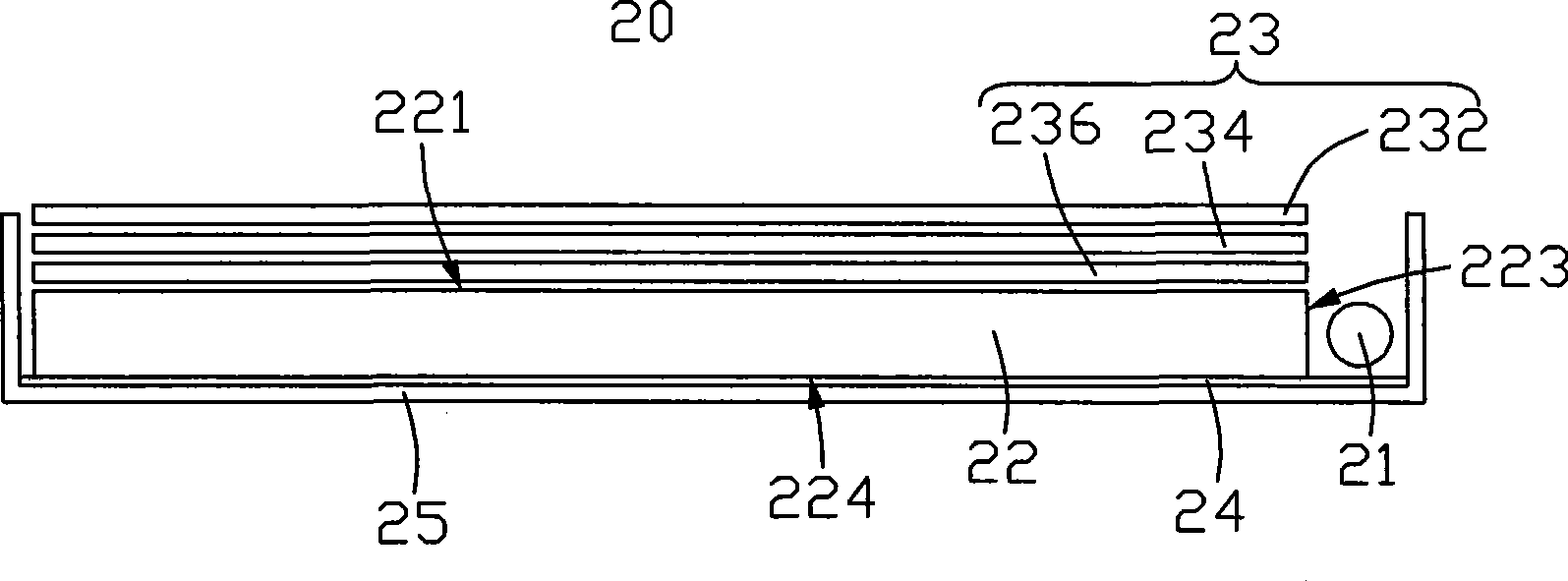

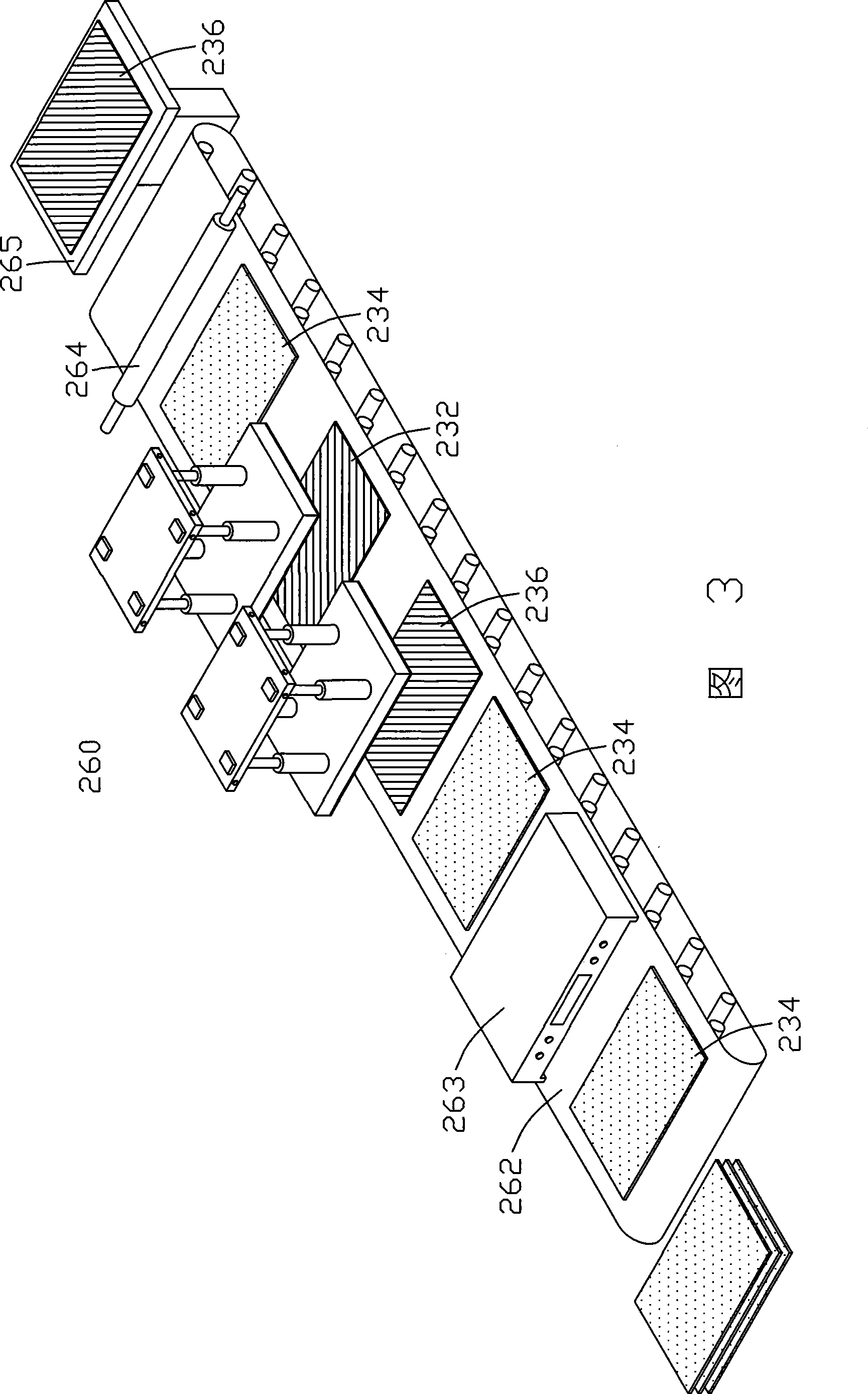

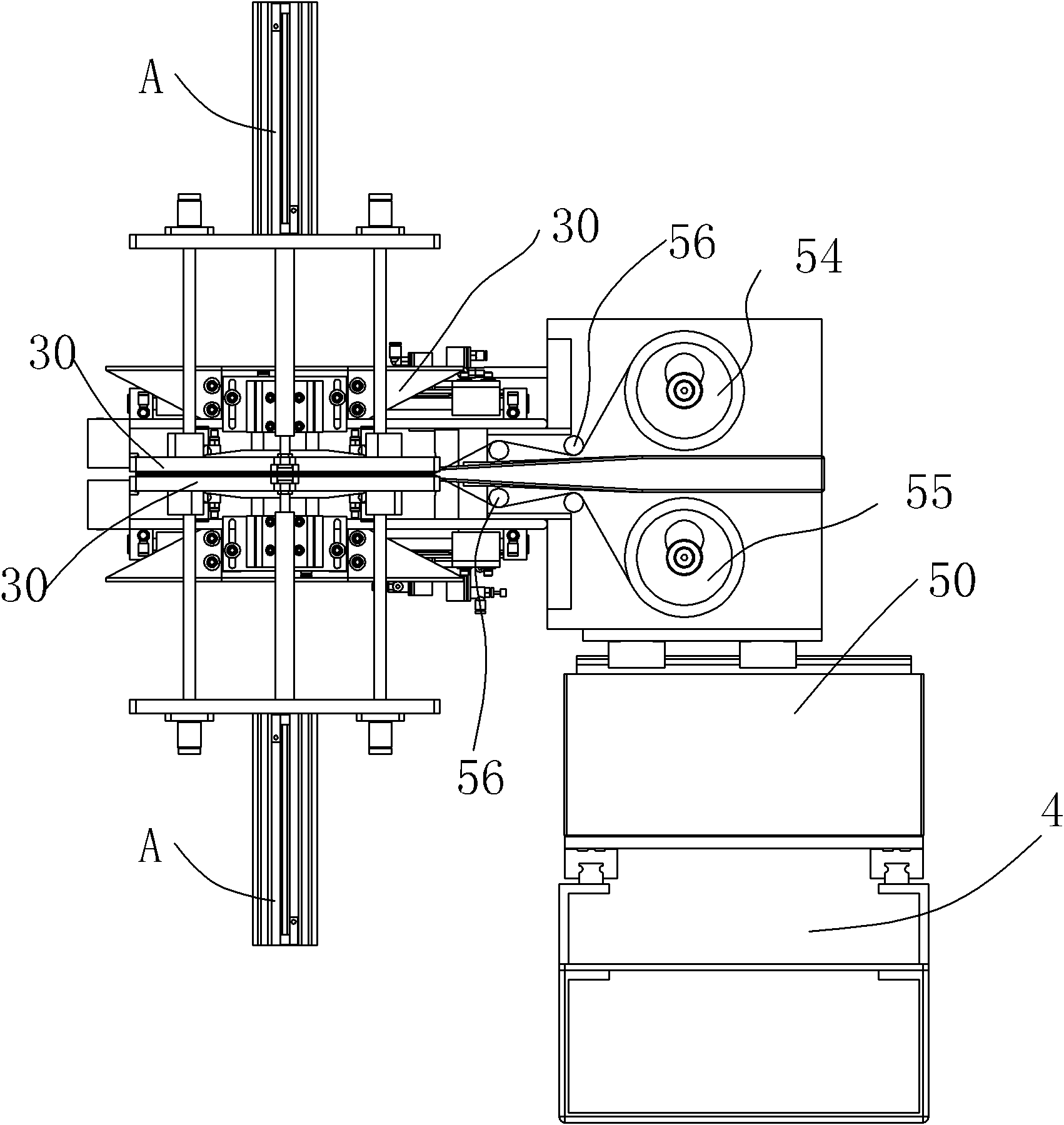

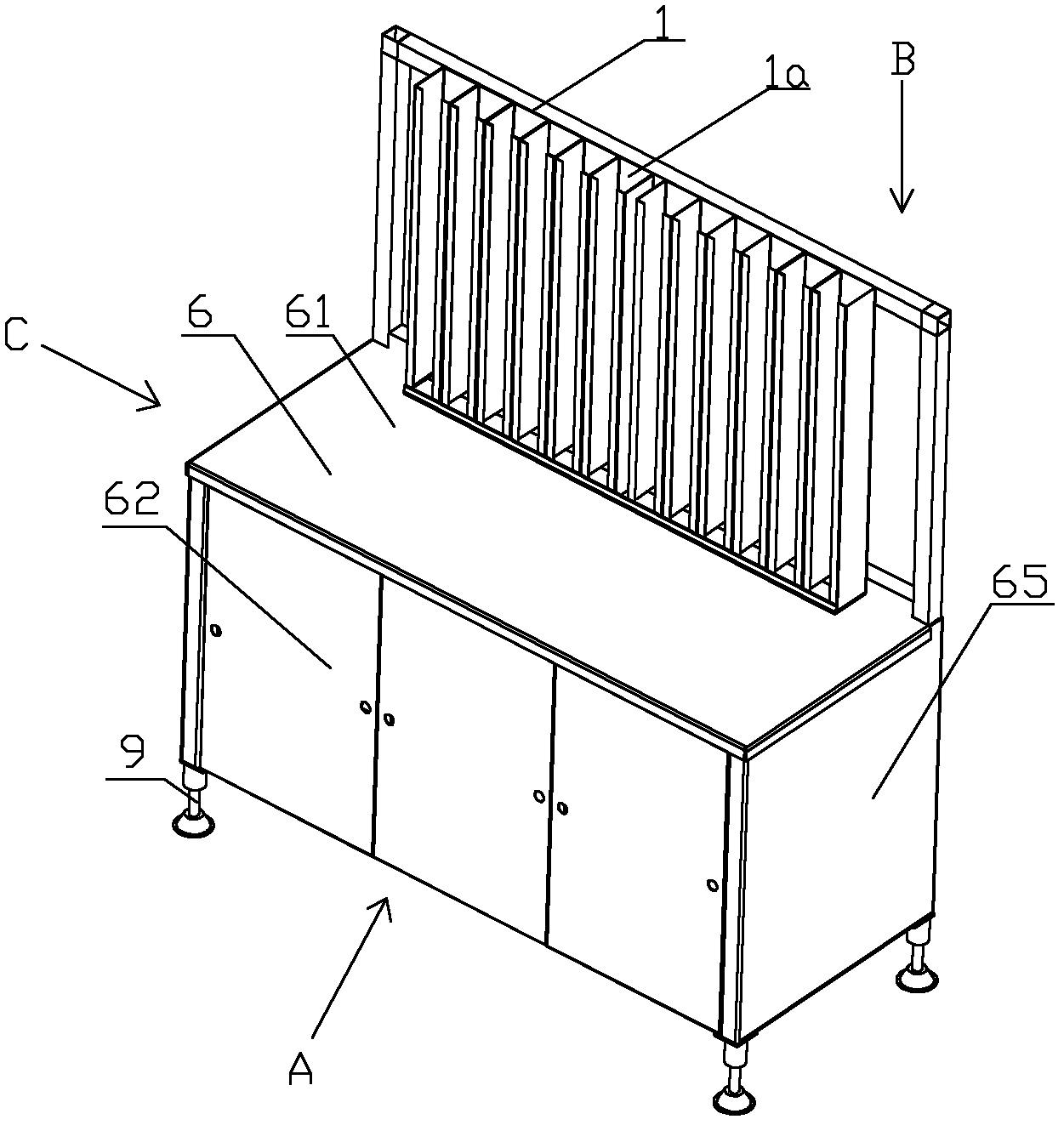

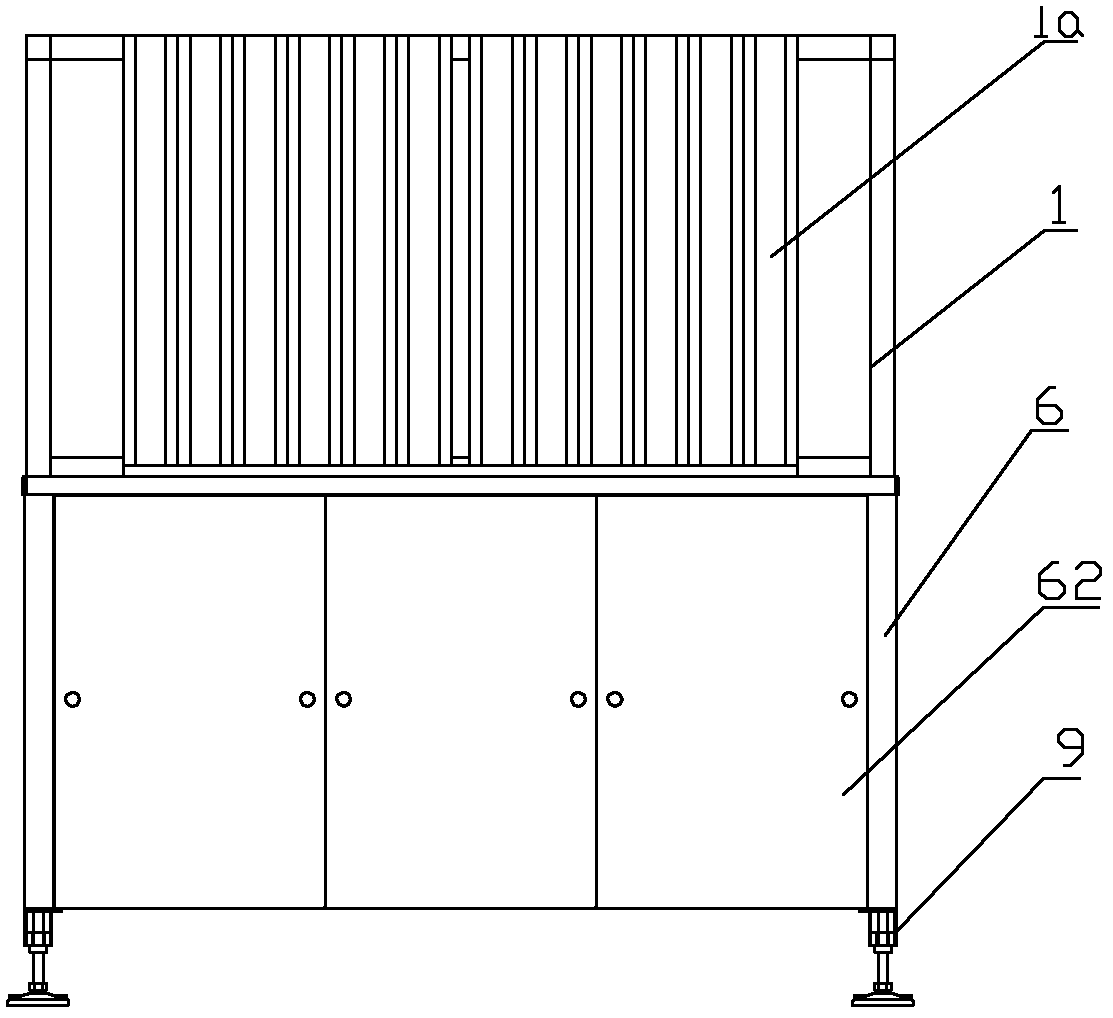

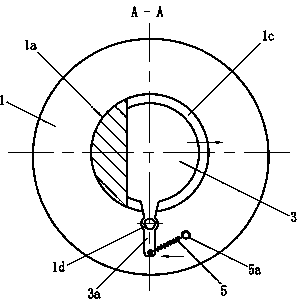

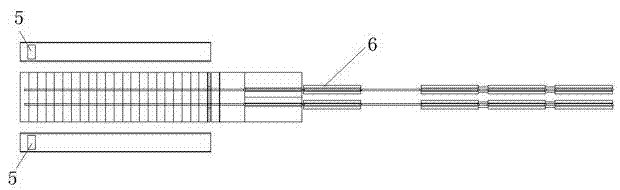

Optical film auto-assembling system and optical film auto-assembling method

ActiveCN101382696AAvoid human contactImprove assembly qualityLamination ancillary operationsLaminationEngineeringAssembly systems

The invention relates to an optical mask automatic assembly system and an optical mask automatic assembly method. The optical mask automatic assembly system comprises a transmission device, an automatic dyestripping device and a modularity device; the transmission device can transmit an optical mask to go through dyestripping along a preset direction, the automatic dyestripping device carries out automatic dyestripping treatment over the optical mask passing through and the modularity device can carry out modularity assembly to the dyestripped optical mask and other optical mask to go through modularity.

Owner:INNOCOM TECH SHENZHEN +1

Automatic tape splicing machine for lithium battery pole piece

The invention provides an automatic tape splicing machine for a lithium battery pole piece. The automatic tape splicing machine is full-automatic, fully enclosed and highly efficient, and can effectively ensure the clean standard of a working area. The machine includes a pole piece tape requiring threading or a pole piece tape in a transmission process; a pole piece tape transmission working area is equipped with a fracture tape detection device which can automatically detect fracture of the pole piece tape; the pole piece tape transmission working area is also equipped with multiple groups of spaced pole piece clamp devices opposite to each other up and down, which can automatically clamp and hold the fractured pole piece tape on an upper side and a lower side thereof at a same time; one side of the pole piece tape is provided with a fracture positioning device, which can be parallel to the pole piece and automatically move to the fracture of the pole piece tape according to a signal detected by the fracture tape detection device; and the fracture positioning device is mounted with a tape splicing device, which can move with the fracture positioning device and automatically draw the fracture pole piece tape and automatically adhere the tape.

Owner:ZHUHAI HIGRAND ELECTRONICS TECH

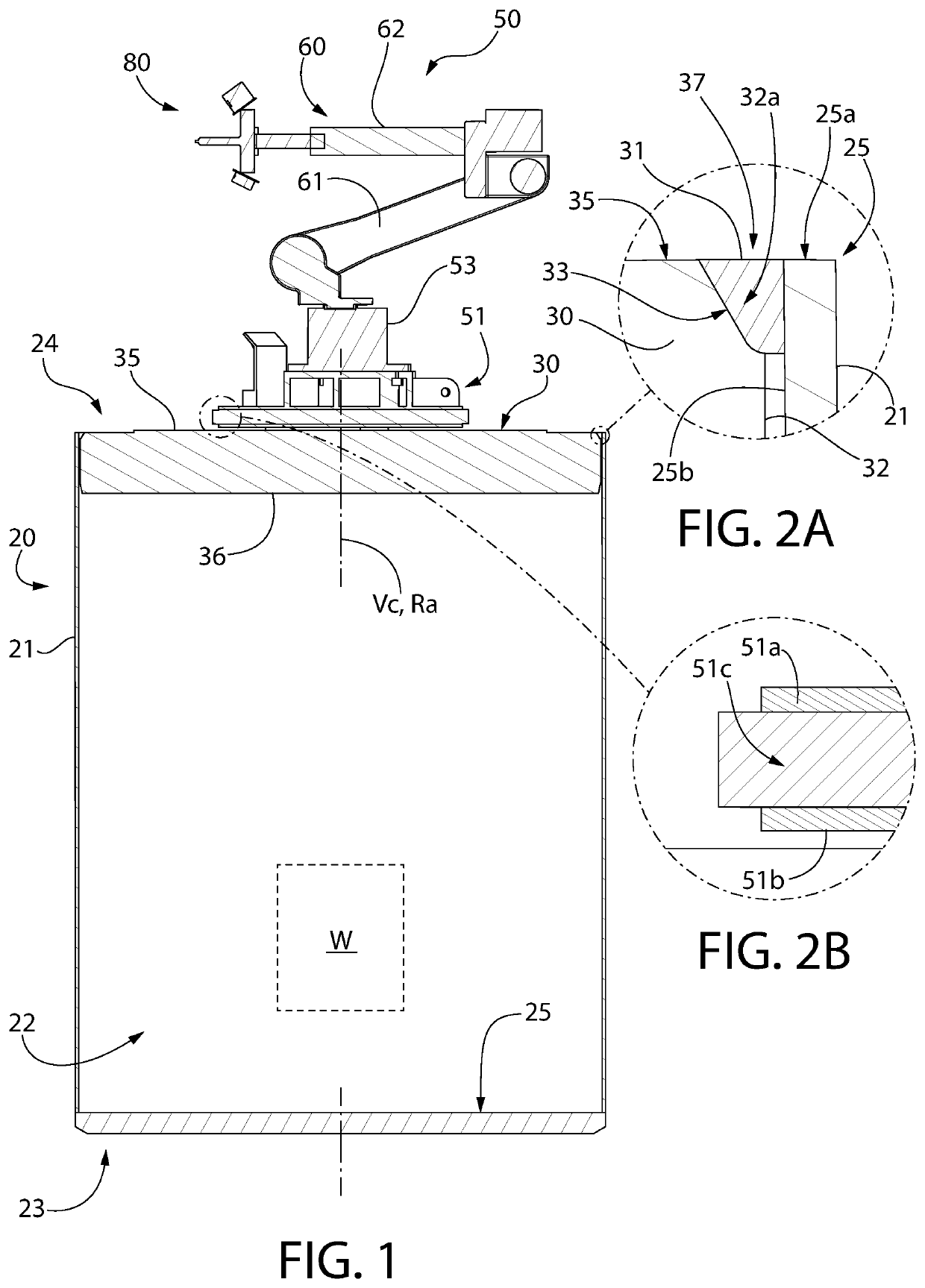

Universal phone battery chargers for mobile cellphones and like devices

ActiveUS20180074550A1Easy to holdAvoid human contactCircuit monitoring/indicationDigital data processing detailsElectricityComputer module

A universal charging accessory for mobile devices. The accessory has a generally flat and thin body configured to lie flat against the flat rear side of the mobile device and includes an internal rechargeable battery, two charging plugs that are configured to be electronically coupled to the charging plug of the mobile device, with the charging plugs being retrievably stowed inside the body of the accessory and to be withdrawn as needed to charge the mobile device. The accessory has a window formed in the body of the charging accessory which receives, interchangeably, a plug-in module that can be inserted into an AC socket to charge the internal battery as well as the cellphone battery.

Owner:ROLAX CORP

Paperboard printing device

ActiveCN111114099AAvoid unclearEndanger life and healthArticle feedersRotary lithographic machinesPaperboardDust control

The invention relates to a printing device, in particular to a paperboard printing device. The paperboard printing device comprises a supporting frame, a control screen, a first motor, a first transmission wheel, a liquefaction mechanism, an automatic adding mechanism, a dust removing mechanism, a flattening mechanism, a flow regulator, a liquid delivery pipe, a printing mechanism and a storage bin; and the control screen is arranged on the middle-top part of the left end of the supporting frame, and the first motor is arranged on the middle-left part of the bottom end in the supporting frame.The paperboard printing device achieves the effects that industrial alcohol volatile in a fountain solution is liquefied and collected, manual contact and consequently damage to human health are avoided, meanwhile, the fountain solution required by printing can be quickly supplemented, manual feeding is replaced with automatic feeding through a machine, the situation that the machine idles to waste energy is avoided, and by treating dust of a paperboard and flattening the bending edge, the situation that printing patterns are unclear, the printing quality is reduced, and consequently, the quality of a finished product is poor is avoided.

Owner:宁波津兰纸制品有限公司

Candy and production technique thereof

InactiveCN101310609AShort processing timeSimple preparation processConfectionerySweetmeatsAdditive ingredientHigh fructose

The invention provides a candy and a production manufacturing process thereof, which contains the following components: 10 percent to 30 percent of white sugar, 20 percent to 60 percent of malt syrup, 0 percent to 30 percent of high fructose syrup, 0 percent to 30 percent of concentrated juice, 3 percent to 10 percent of preserved fruit cubes, 0.1 percent of calcium chloride, 1 percent to 15 percent of water, 10 percent to 30 percent of modified starch, 0.2 percent to 5 percent of acidity regulator, 0 percent to 0.01 percent of coloring matter and 0 percent to 0.5 percent of essence. The manufacturing process of the candy comprises five steps, including mixing ingredients, extruding, curing and seasoning, quantitative filling, sealing and parting, cooling and packaging. The production manufacturing process of the candy of the invention is simple, low in energy consumption, sanitary and reliable, good in taste and beautiful in appearance.

Owner:朱先洪

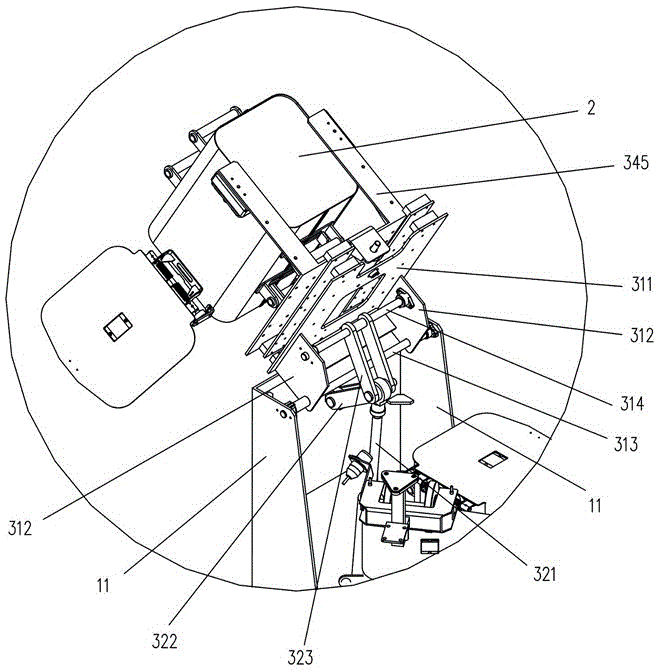

Sample dumping device capable of realizing automatic discharging

ActiveCN106629098ASimple and compact structureHigh degree of intelligenceBottle emptyingLoading/unloadingAutomotive engineering

The invention discloses a sample dumping device capable of realizing automatic discharging. The sample dumping device comprises a machine frame. A rotatable turntable mechanism and a plurality of sample storage barrels are arranged in a collecting cavity formed by the machine frame. The sample storage barrels are used for collecting samples. One or more overturning and discharging mechanisms, which are used for overturning the sample storage barrels from the machine frame to conduct dumping and discharging, are arranged on the side surface of the machine frame. Each overturning and discharging mechanism comprises an overturning frame component, an overturning driving component, a lifting driving component and an extracting component. The overturning frame components are vertically hinged to the machine frame. The extracting components are mounted on the overturning frame components through the lifting driving components. The lifting driving components drive the extracting components to do lifting motion to extract the sample storage barrels in the collecting cavity. The overturning driving components are connected with the overturning frame components to drive the overturning frame components to be overturned from the machine frame and synchronously drive the extracted sample storage barrels to be overturned outwards for dumping and discharging. The sample dumping device has the advantages of being simple and compact in structure, high in intelligent degree, high in sample safety and high in working efficiency, and can be reduced in labor intensity.

Owner:HUNAN SUNDY SCI & TECH DEV

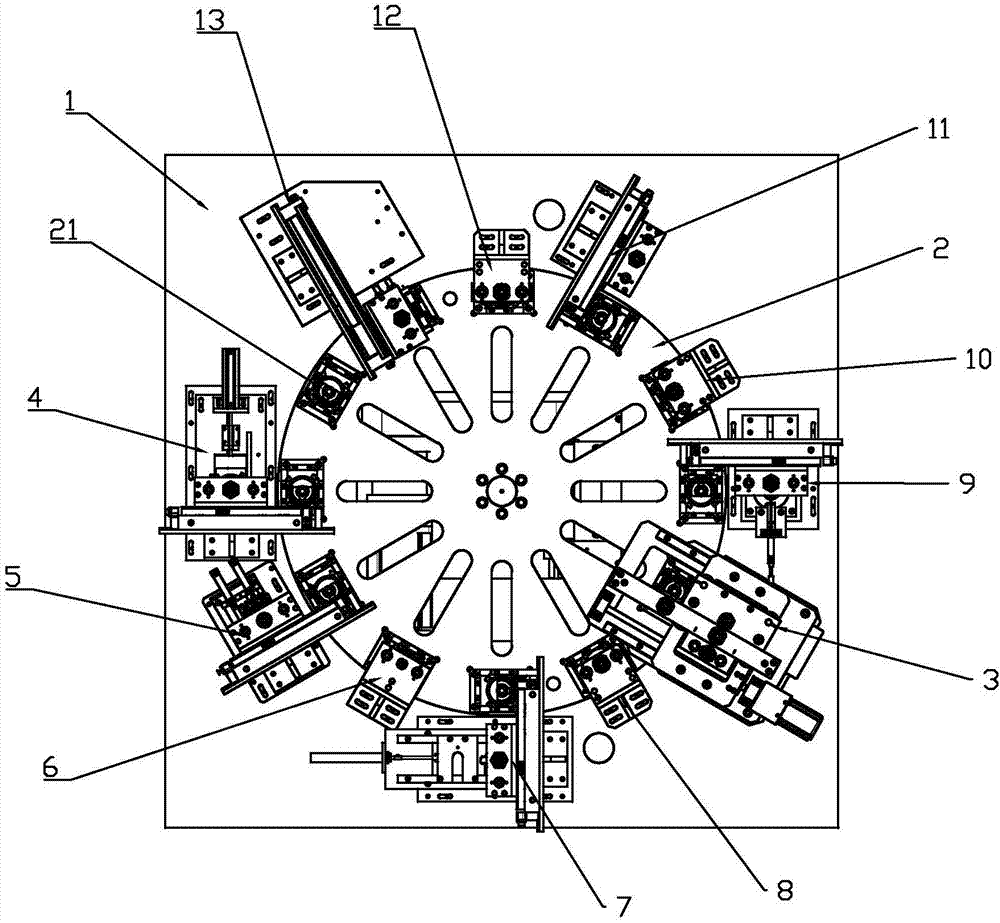

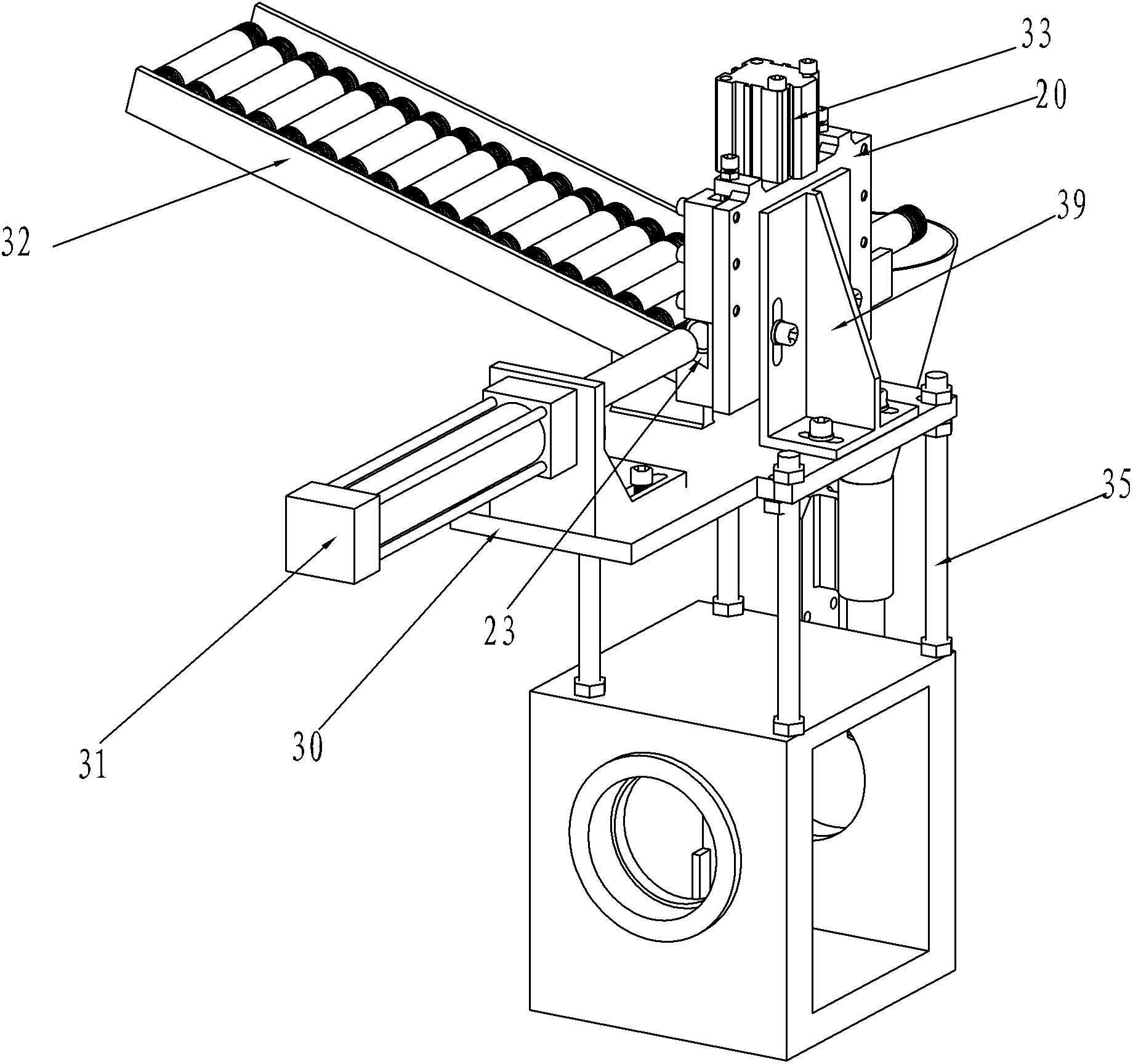

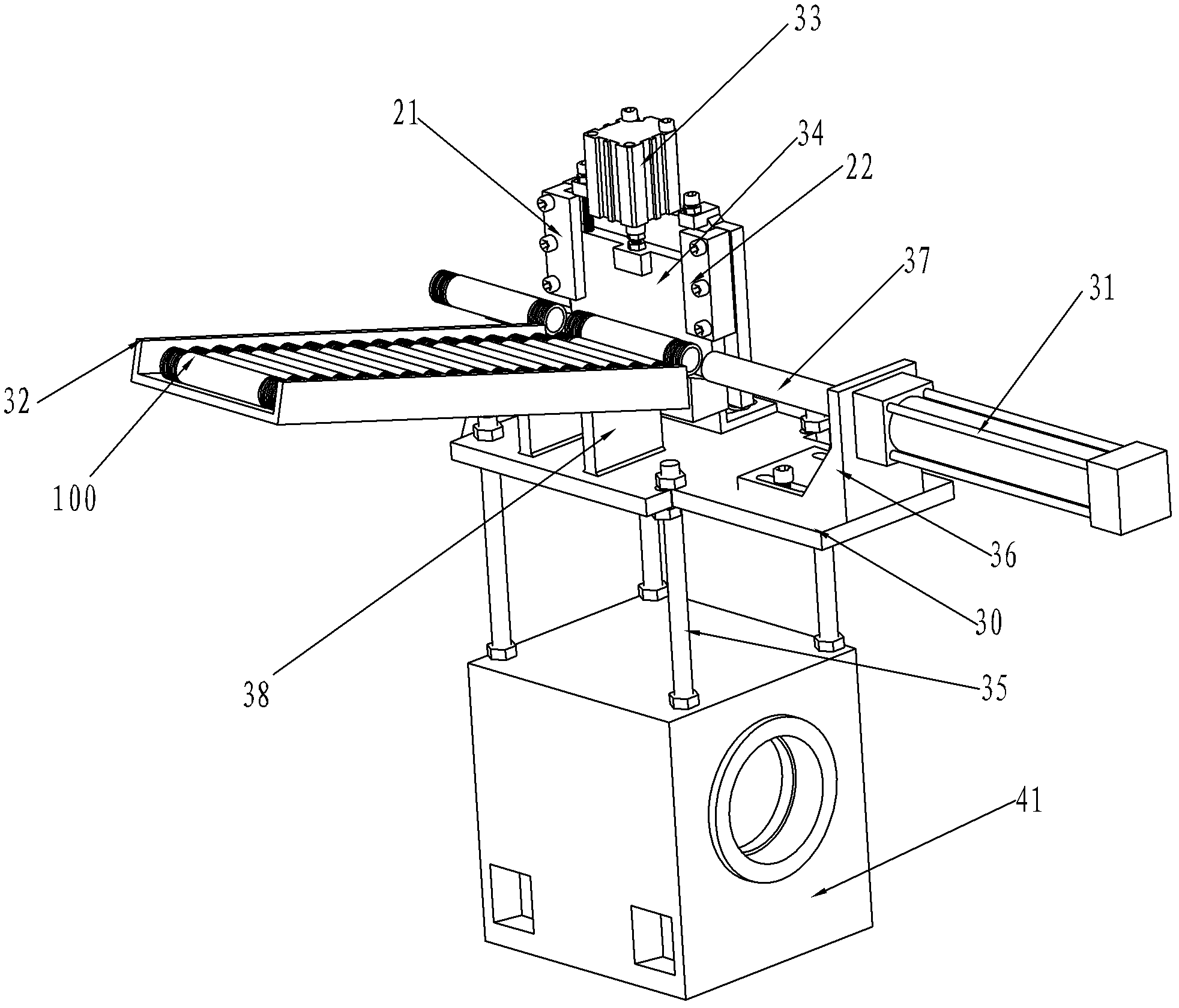

Assembly machine for loading inner plugs in bottle caps

InactiveCN103769846AAvoid human contactThe overall structure is simple and reliableMetal working apparatusMetal-working hand toolsFully automaticBottle cap

The invention provides an assembly machine for loading inner plugs in bottle caps. The assembly machine is used for pressing the inner plugs into the bottle caps. The assembly machine comprises a rack, a rotary disk mechanism, a bottle cap feeding mechanism, an inner plug feeding mechanism and a pressure pad mechanism used for pressing the inner plugs into the bottle caps. The rotary disk mechanism is arranged on the rack, the bottle cap feeding mechanism, the inner plug feeding mechanism and the pressure pad mechanism are respectively arranged on the rack and distributed around the rotary disk mechanism, the inner plug feeding mechanism comprises a feeding mechanism capable of feeding at least two inner plugs, a first air cylinder used for ejecting out the inner plugs and a manipulator for placing the ejected inner plugs in the bottle caps, the feeding mechanism is connected with the first air cylinder, and the manipulator is arranged on the rack. The inner plugs are made to ascend, stretch out, descend, be positioned and move back through the manipulator, and then the inner plugs are smoothly placed in the bottle caps. The inner plug placing method has the advantages of being fast, stable and the like, tests show that the rate of finished products can reach 99.99 percent, a complex mechanical transmission structure is avoided for the structure of the assembly machine, the reliability is improved, and the work process is fully automatic.

Owner:中山市金易自动化设备有限公司

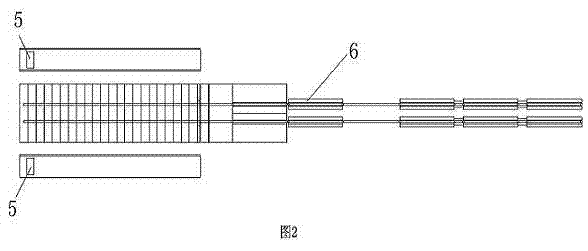

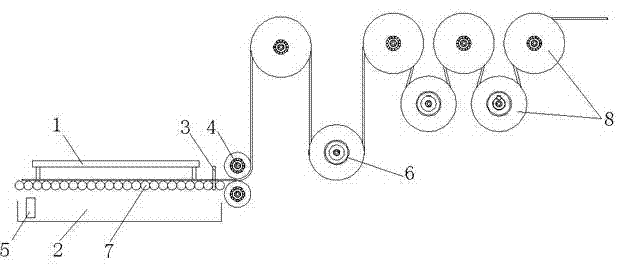

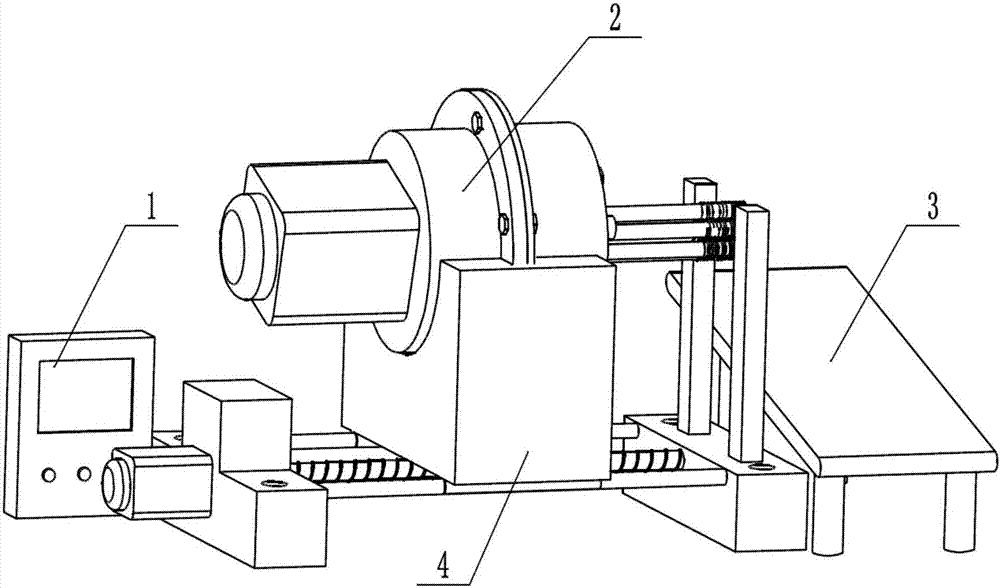

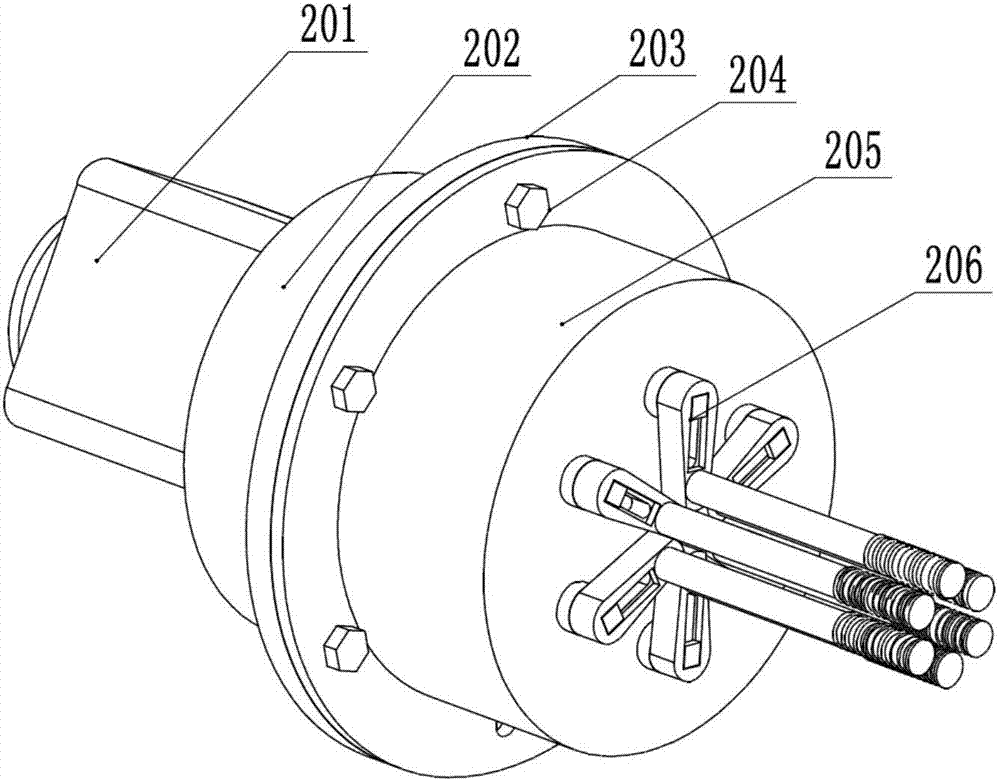

Automatic production line and automatic production method for ultrafiltration membrane

InactiveCN102247762AReduce labor intensityIncrease productivityUltrafiltrationUltrafiltrationEngineering

The invention provides an automatic production line for an ultrafiltration membrane and an automatic production method for processing the ultrafiltration membrane by adopting the production line. The production line comprises an ultrafiltration membrane fiber delivery device which runs through the whole production line as well as an automatic membrane fiber cutoff device and an automatic membranefiber collection device which are sequentially arranged from front to back, wherein the ultrafiltration membrane fiber delivery device comprises a wheel set delivery mechanism, a double-roll pulling device and a rolling type transport platform which are sequentially arranged from front to back and a buffer device which is arranged between the wheel set delivery mechanism and the double-roll pulling device; the buffer device at least comprises a fixed roll and a movable roll which can freely slide up and down within the limited range; and the movable roll is arranged between the fixed roll andthe wheel set delivery mechanism. The automatic production of membrane fibers is realized, the labor intensity of operators is greatly reduced, the production efficiency is improved, the pollution tothe membrane fibers is also reduced, and the fixed-length production and counting of the membrane fibers can be ensured and the waste of the membrane fibers is avoided.

Owner:刘镇江

Cell string automatic unloading mechanism

PendingCN106449497AAvoid human contactQuick flipFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention relates to a cell string automatic unloading mechanism which comprises a conveying mechanism used for conveying a cell string to a preset position, a turning device used for turning a cell string on the conveying device, and a handling device used for putting a cell string on the turning device into a material box. The turning device is disposed between the conveying device and the handling device. After the turning device adsorbs a cell string on the conveying device, the turning device turns the cell string 180 degrees to the handling device on the other side, and the handling device adsorbs the cell string, moves the cell string to a target position and puts the cell string into a material box. Through cooperation of the three devices, automatic unloading of cell strings is realized. The problem that the hand touches cells in the checking process is avoided, cells can be quickly and accurately turned in batches, the efficiency is improved, and cell breakage, pollution and other loss caused by hand touch are prevented effectively.

Owner:JIANGSU ZHONGQIRUICHI IND ROBOT AUTOMATION CO LTD

Portable robotic welder for nuclear waste handling

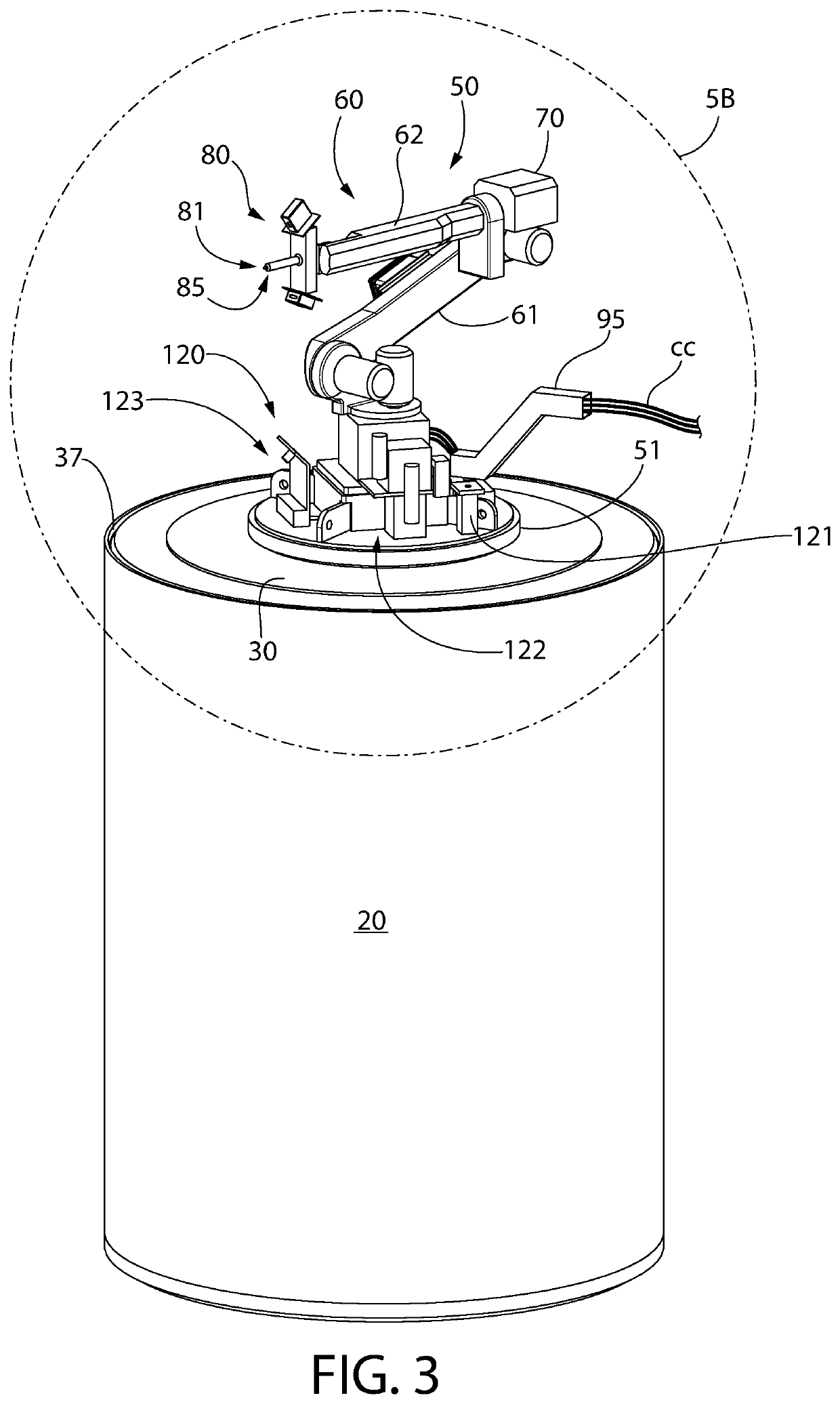

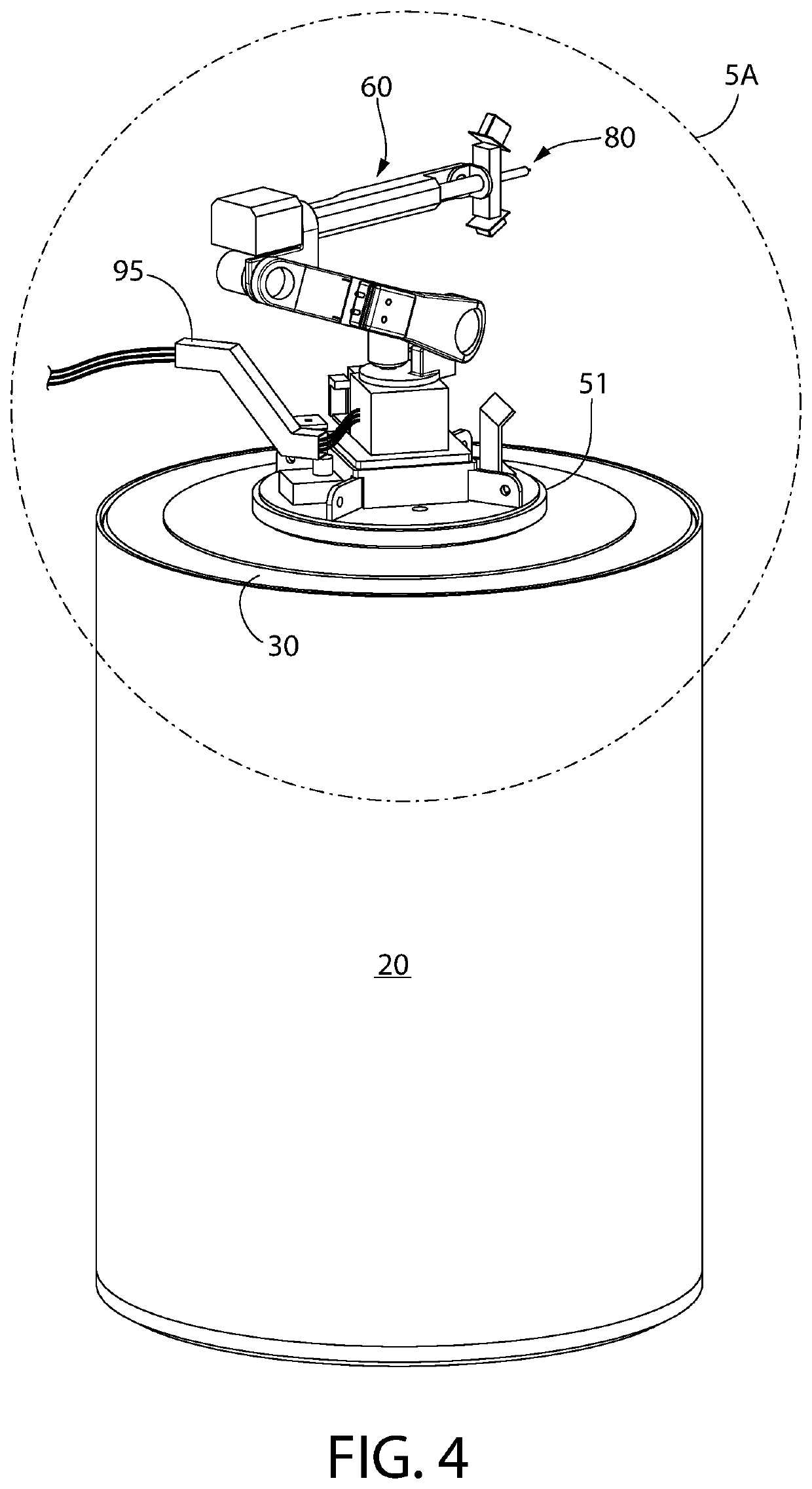

PendingUS20210046569A1High weld deposition rateIncrease deposition ratePortable shielded containersWelding/soldering/cutting articlesRobotic armEngineering

An automated welding system for sealing high level radioactive waste containers in the field at the nuclear plant site. The system includes a programmable portable robotic welder comprising a multi-jointed articulating robotic arm. A welding head operable to form a weld is mounted to the arm. Operation of the robotic welder and ancillary components is controlled by a programmable controller which implements a welding plan. In one embodiment, a circumferentially-extending lid-to-shell hermetic seal weld may be formed by the robotic welder. The weld is completed in multiple welding passes through the weld joint between the lid and shell guided by an automated joint tracking sensor linked to the controller. The highly portable robotic welder is detachably mountable on the lid to perform the welding. An automated pivotable cable-conduit management apparatus keeps electrically conductive wiring and flow tubing out of the path of the rotating robotic arm during welding.

Owner:HOLTEC INT

Horizontal swinging mechanism-based paint film removal device of environmental-friendly enameled wire

InactiveCN108512016AAvoid direct contactAvoid human contactLine/current collector detailsElectrical and Electronics engineeringSmoke

The invention discloses a horizontal swinging mechanism-based paint film removal device of an environmental-friendly enameled wire. The paint film removal device comprises a device body, wherein the device body is provided with a support rack, an operating room is arranged above the support rack, a smoke guide pipe is arranged at the top of the operating room, a left support seat is arranged in the operating room, a right support seat is arranged at a right side of the operating room, a fixed rack is arranged above the right support seat, a fixed cylinder is arranged on the fixed rack, a movable cylinder is arranged in the fixed cylinder, a paint film removal chamber is arranged at a left end part of the movable cylinder, and the device body is provided with a driving cabin. The paint filmremoval device is simple in structure; harmful gas is prevented from overflowing to be absorbed by a human body by sealing a front surface of the device body; the enameled wire is prevented from being in direct contact with a hand during operation of the device body; and the paint film is scrapped by a rubber scraper, the hand is prevented from being brunt after firing just now, unthorough scrapping caused by paint film scrapping after cooling for a long time is prevented, the paint film removal effect is effectively ensured, and the paint film removal device is convenient to use and is highin practicability.

Owner:王鹏 +2

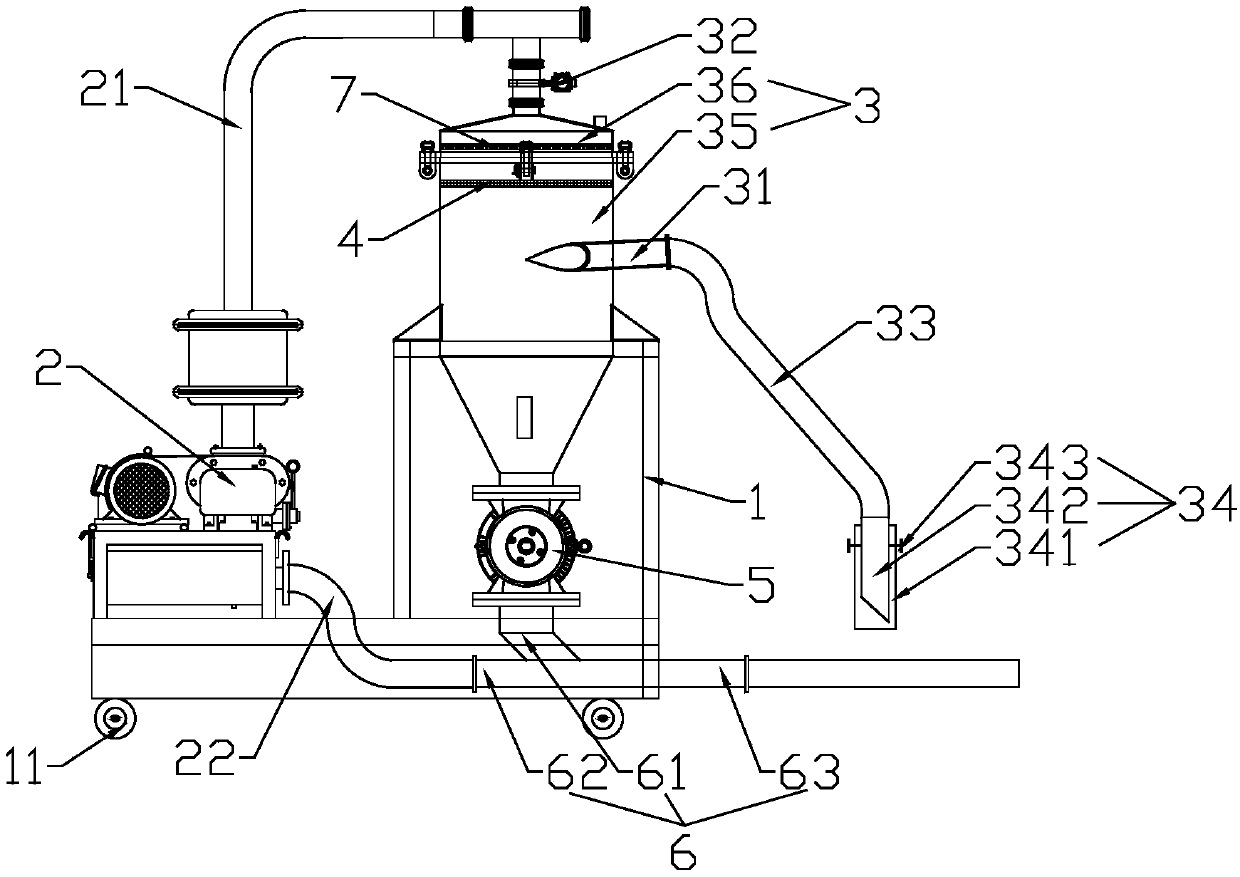

Activated carbon loading and unloading device

PendingCN109896298AEfficient loading and unloading of carbon operationsAvoid human contactBulk conveyorsLoading/unloadingEngineeringVacuum pump

The invention provides an activated carbon loading and unloading device. The device comprises a support, wherein a vacuum pump and a stock bin are arranged on the support, the vacuum pump is connectedwith an air outlet in the top of the stock bin through a first pipeline, the position, close to the top, of the stock bin is provided with a filtering device, a feeding port is formed on the side wall of the stock bin, a discharging port is formed in the bottom of the stock bin, the discharging port of the stock bin is connected with a rotary discharge valve, the rotary discharging valve is connected with a first pipe opening of a three-way pipe, and the vacuum pump is connected with a second pipe opening of the three-way pipe through a second pipeline. According to the device, the vacuum pump and the rotary discharging valve are started, negative pressure is generated in the stock bin, granular active carbon is continuously sucked into the stock bin, after the rotary discharging valve works, activated carbon particles in the stock bin continuously move downwards to complete discharging. The device has the advantages that the structure is simple and compact, the loading and unloadingcarbon operation of the activated carbon can be effectively carried out, the manual contact of activated carbon powder is effectively avoided, and the carbon loading and unloading efficiency is improved.

Owner:SHANGHAI JIAYUAN ENVIRONMENTAL PROTECTION TECH

Automatic sorting machine for bread slices

ActiveCN102293226ARealize automatic arrangementAvoid human contactDough processingElectric machineryStructural engineering

The invention discloses an automatic bread slice arranging machine, which comprises a blanking hopper, a cutting device and a feeding device, wherein the cutting device is arranged below the blanking hopper; the feeding device comprises a motor of which the free end in transmission connection with an eccentric wheel, a rocking handle component of which one end is in transmission connection with an eccentric shaft of the eccentric wheel through a connecting rod pin component and the other end is in transmission connection with a transverse rotating shaft, a right chain wheel component which isin transmission connection with the right end of the rotating shaft, a left chain wheel component which is in transmission connection with the left end of the rotating shaft, and a feeding plate component which is arranged below the cutting device and of which the left and right ends are in transmission connection with the left chain wheel component and the right chain wheel component respectively along the vertical direction. The automatic bread slice arranging machine has high production efficiency, is clean and sanitary and meets the using requirements of the conventional bread processing industry.

Owner:广州浩胜食品机械有限公司

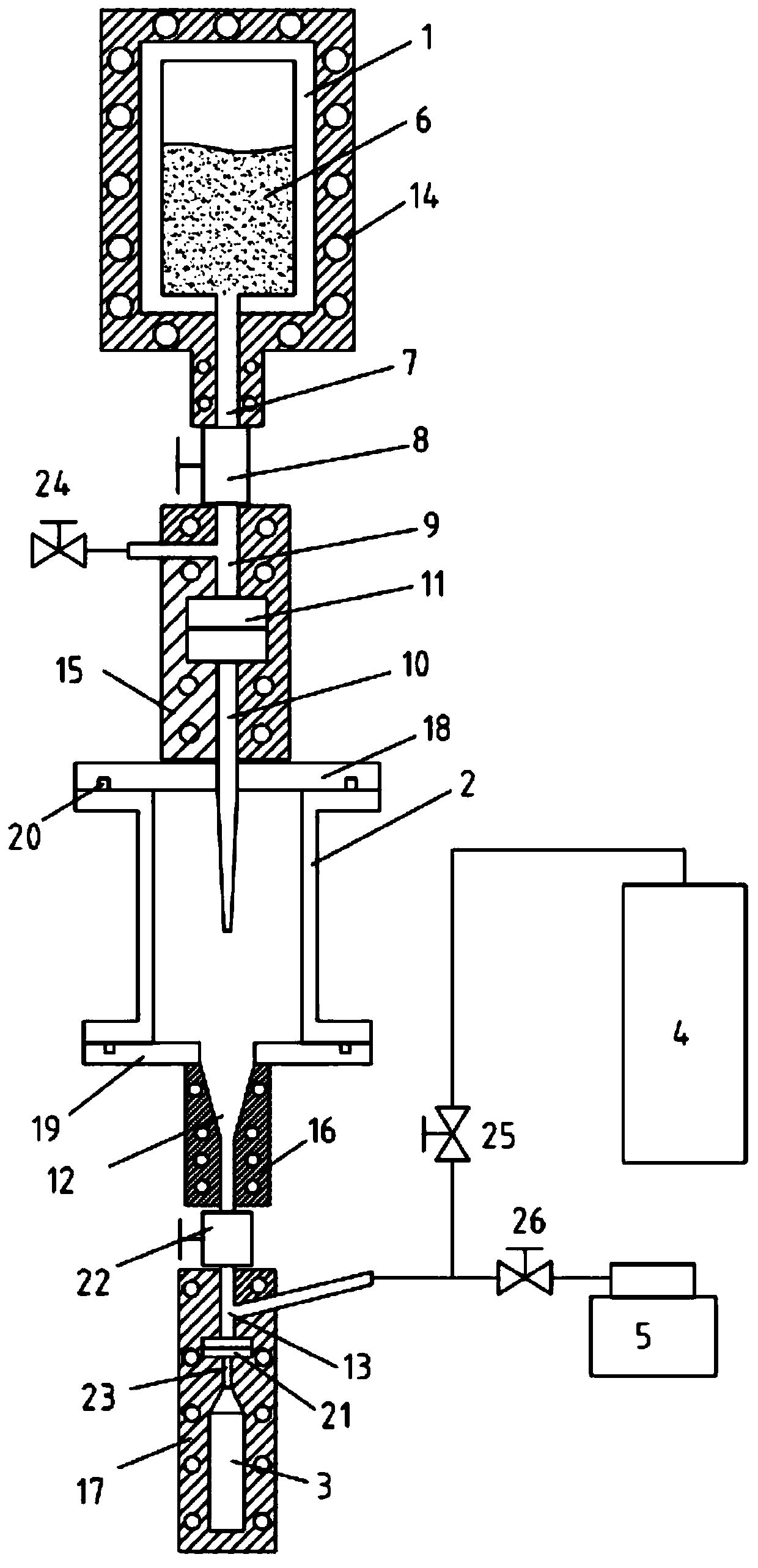

High-temperature heat pipe working medium filling device and method

ActiveCN110411253AReduce the risk of contaminationAvoid human contactIndirect heat exchangersEngineeringContinuous production

The invention discloses a high-temperature heat pipe working medium filling device and method. The device comprises a working medium container, a conical pipe, a quartz container, a packaging pipe anda high-temperature heat pipe which are arranged sequentially from top to bottom, the bottom of the working medium container is in communication with the first end of a first communicating pipeline, the second end of the first communicating pipeline is connected with the first end of the conical pipe, the second end of the conical pipe is arranged in a cavity of the quartz container, the bottom ofthe quartz container is in communication with the first end of a second connecting pipeline, the second end of a second communicating pipeline is in communication with the packaging pipe, the packaging pipe is communicated with the high-temperature heat pipe, the first end of the first communicating pipeline is connected with the second end of the first communicating pipeline through a first valve, and the first end of the second communicating pipeline is connected with the second end of the second communicating pipeline through a second valve. According to the device and method, human contact is avoided, and the risk that the working medium is polluted in the filling process is reduced; the device can realize continuous filling and is suitable for continuous production; and the device issimple in structure and convenient to operate.

Owner:GUILIN UNIV OF ELECTRONIC TECH

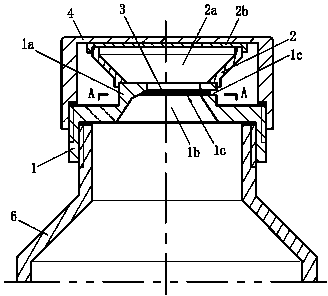

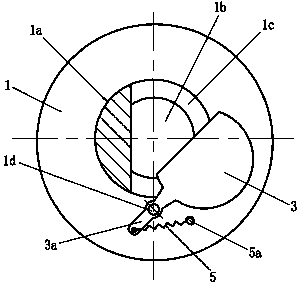

Granular drug taking quantifying device

ActiveCN103979214AAvoid germsEasy to takeSmall article dispensingPharmaceutical drugMechanical engineering

Provided is a granular drug taking quantifying device. The device comprises a base cover (1) capable of being connected with the opening of a granular drug packaging bottle, the surface of the base cover (1) is provided with a boss (1a), and a channel (1b) communicated with a containing cavity of the packaging bottle is formed in the boss; the lower end of a quantifying container (2) is combined with the upper opening wall of the channel (1b) in the base cover, a quantifying cavity (2a) of the quantifying container is communicated with the channel (1b), and the upper end of the quantifying container is provided with a detachable end cap (2b); a partition board (3) capable of opening and closing the channel (1b) is arranged on the surface of the base cover (1); a sealing cover (4) is connected with the base cover (1). The granular drug taking quantifying device has comprehensive functions of quantifying and isolating and sealing after quantifying. Through simple operation, the quantity of the drugs taken each time can be quantified, people can take the quantitative drugs conveniently, human hands are prevented from making contact with the granular drugs in the quantitative operation process, and bacteria are prevented from spreading.

Owner:黄帮华

Ultrafiltration membrane automation protection method

InactiveCN103084071AReduce labor intensityIncrease productivitySemi-permeable membranesUF - UltrafiltrationEngineering

The invention provides an ultrafiltration membrane automation protection method. Membrane filaments are formed and delivered by combining an automatic traction device and an automatic delivery device, and are cut off when the membrane filaments achieve the preset lengths; the membrane filaments after being cut off are collected automatically; and a buffer device capable of adjusting the delivery distance automatically is arranged between the automatic traction device and a membrane filament automatic delivery device for cutting off the operation front ends, so that the cut operation front ends of the membrane filaments keep the tensioning state all the time. According to the invention, the membrane filaments are produced automatically; the labor intensity of operators is lowered greatly; the production efficiency is improved; the pollution to the membrane filaments is also reduced; and the fixed-length production of the membrane filaments, counting can be ensured, and membrane filament waste is prevented.

Owner:刘镇江

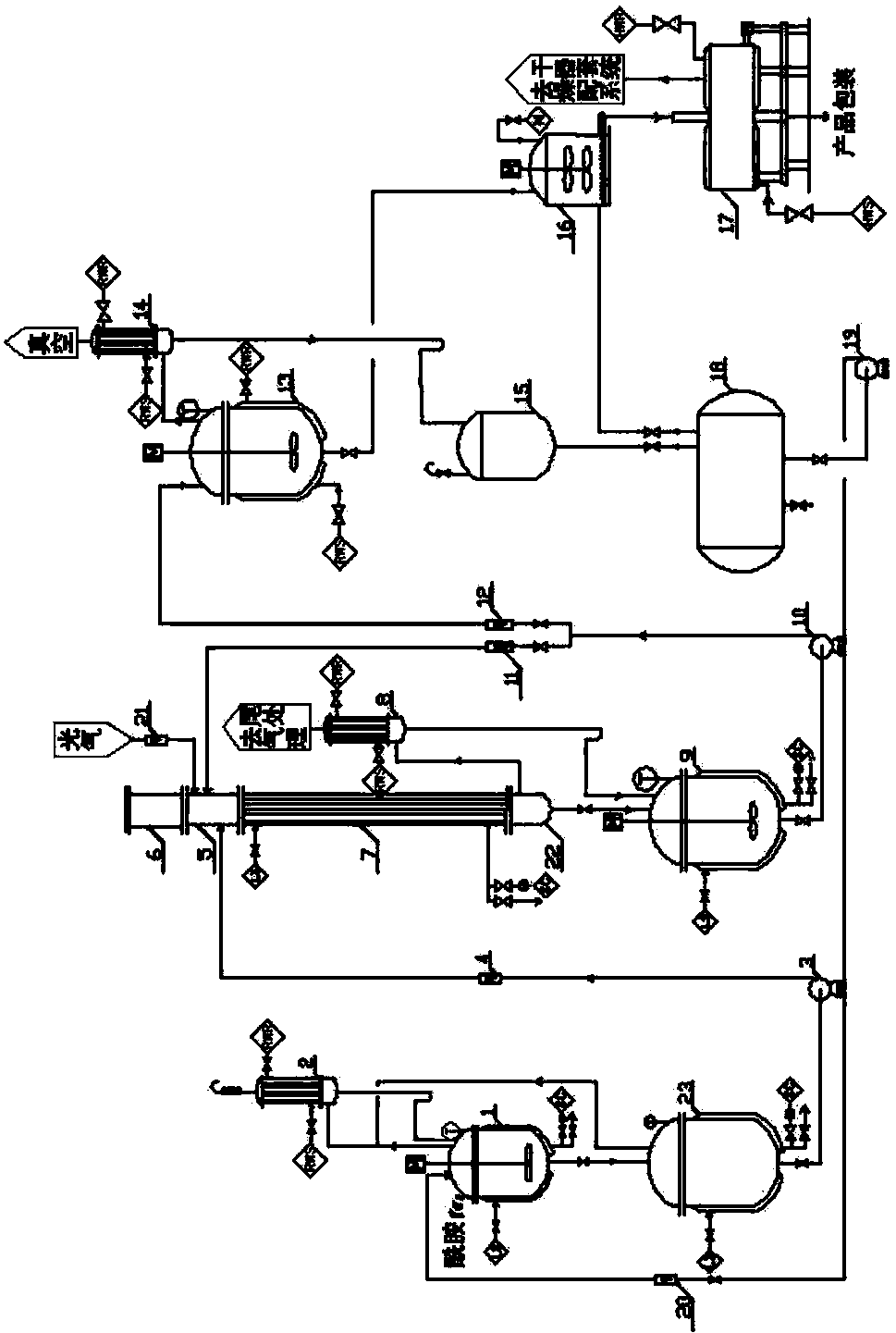

2-cyanophenol preparing method

ActiveCN103664698ALarge specific surface areaIncrease contact areaCarboxylic acid nitrile preparationOrganic compound preparationSolventChemistry

The invention discloses a 2-cyanophenol preparing method which is implemented by steps that salicylamide and phosgene are subjected to continuous reactions by a recycling continuous reaction system under the action of a catalyst dioxane and a solvent toluene. According to the method, a tubular reactor is adopted, the provided heat transfer specific surface area is large, the contact area of phosgene and a liquid-state material is increased, heat is transferred timely to a reactant, reaction temperature control is facilitated, and a fast reaction requirement is met. Transition-state continuous reaction is promoted through enhancement of mass transfer of a gas-liquid heterogeneous material, a forward reaction process is facilitated, and the reaction time is shortened; a material circulation mode of a raw material mixer, the tubular reactor and an insulation kettle is adopted, so that a gas-solid-liquid three-phase reaction formation is converted into a gas-liquid two-phase reaction formation, and a pipe blockage problem and a phosgene flow velocity limit problem are solved simultaneously; and further, automation control is facilitated, manual labor intensity is reduced, manual contact with the materials is avoided, and the productivity is increased effectively.

Owner:宁夏海利科技有限公司

Green and environment-friendly intelligent logistics unmanned distribution method

ActiveCN113112199AImprove experienceImprove the level of management and schedulingForecastingBuying/selling/leasing transactionsTime informationLogistics management

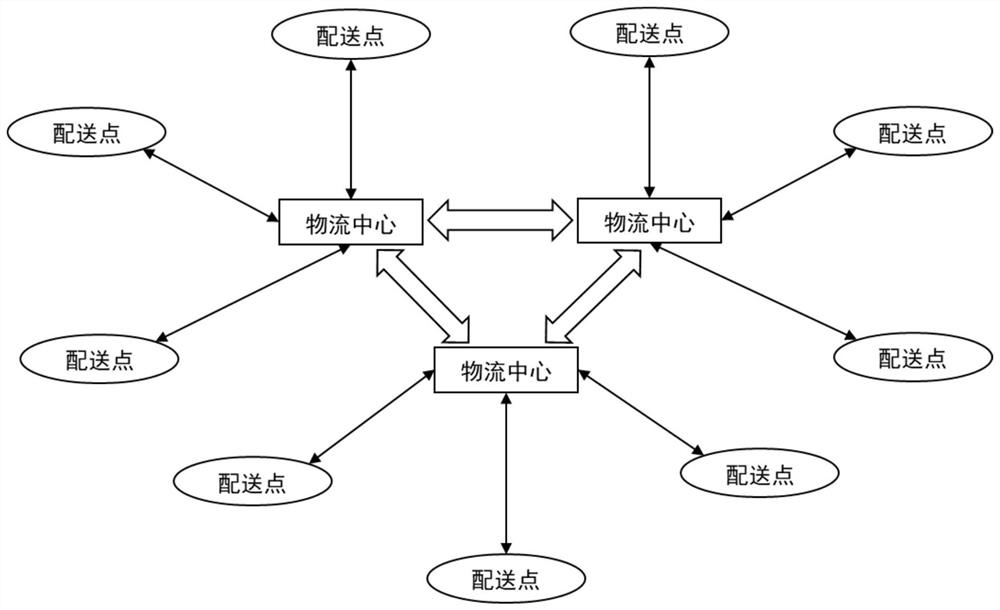

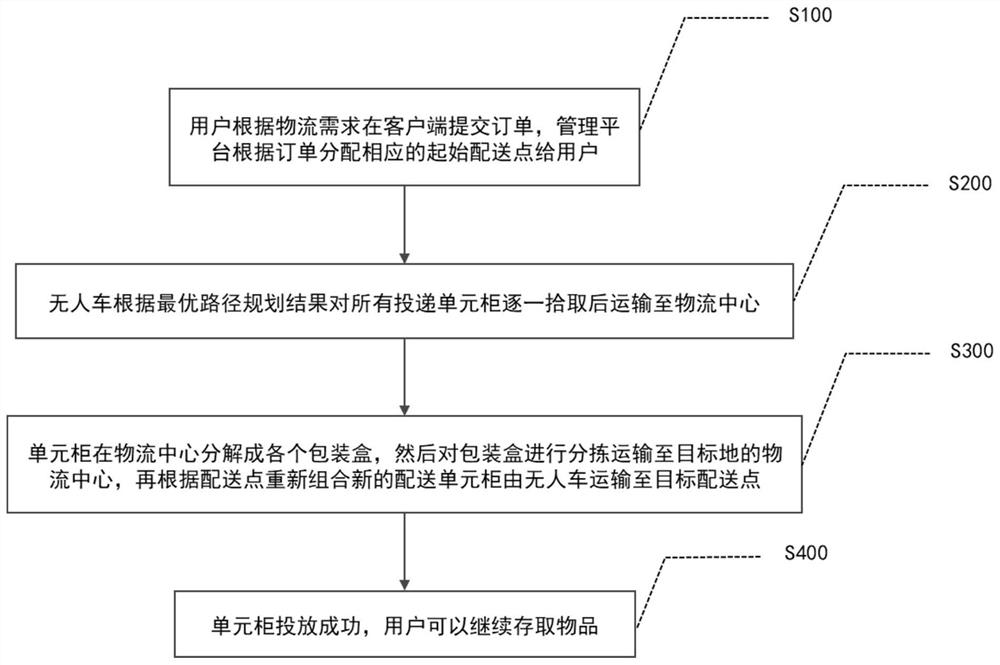

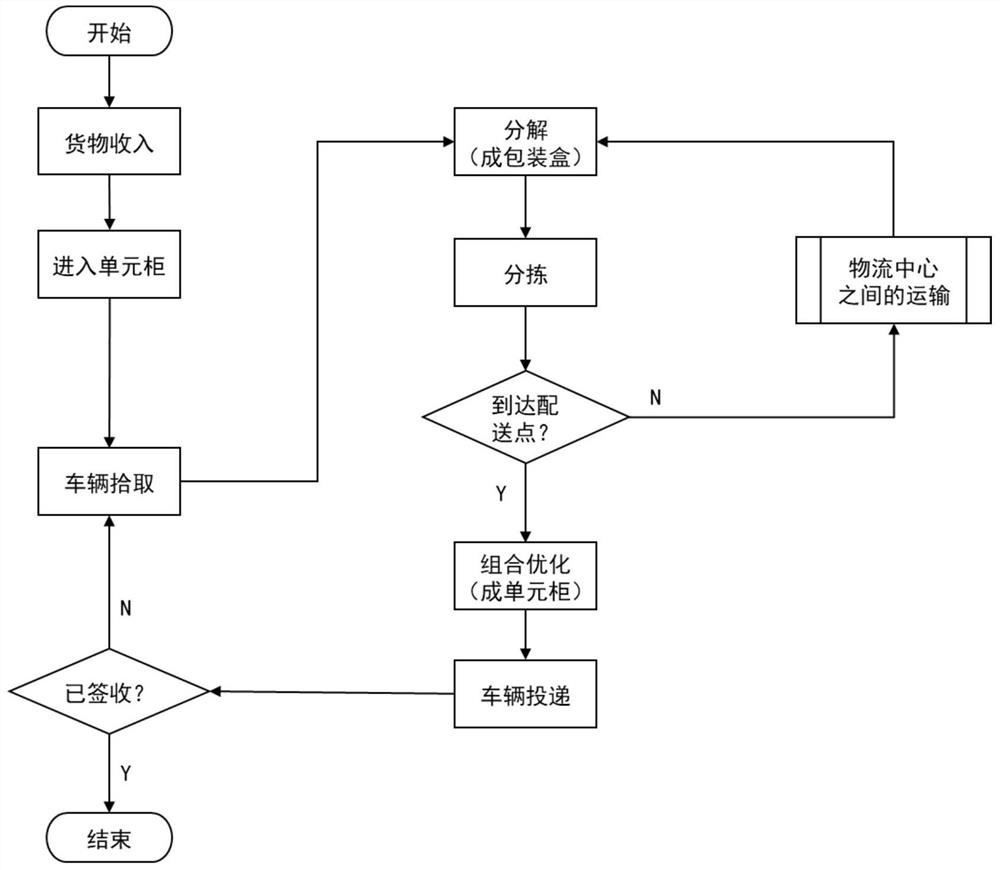

The invention discloses a green and environment-friendly intelligent logistics unmanned distribution method, which comprises the following steps: S100, a user submits an order at a client according to a logistics demand, and a management platform allocates a corresponding initial delivery point to the user according to the order; S200, an unmanned vehicle picks up all the delivery unit cabinets one by one according to the optimal path planning result and then transports the delivery unit cabinets to a logistics center; s300, the unit cabinets are decomposed into packaging boxes in the logistics center, then the packaging boxes are sorted and transported to the logistics center of the destination, new distribution unit cabinets are recombined according to the distribution points, and the new distribution unit cabinets are transported to the target distribution points through the unmanned vehicle; and S400, if the unit cabinets are successfully put, the user can continuously store and take the articles. According to the invention, intelligent logistics modes such as real-time information, path optimization, unmanned vehicle distribution and the like can be adopted for peripheral logistics, so that the labor cost can be effectively saved, the logistics operation efficiency is improved, and the green transformation of express packaging is promoted.

Owner:HEFEI UNIV OF TECH

Automatic assembling equipment of FPC light bars

InactiveCN112355603AAvoid human contactAvoid damageMaterial gluingMetal working apparatusStructural engineeringMaterial transfer

The invention discloses automatic assembling equipment of FPC light bars. The automatic assembling equipment comprises a material placing mechanism used for placing FPC light bars, a material transferring mechanism, a material taking robot, a material taking and attaching mechanism and a positioning jig used for loading iron frames, wherein the material taking robot is used for transferring the FPC light bars from the material placing mechanism to the material transferring mechanism; the material transferring mechanism is used for transferring the FPC light bars to the material taking and attaching mechanism; and the material taking and attaching mechanism is used for attaching the FPC light bars to the iron frames. According to the automatic assembling equipment of FPC light bars, the material placing mechanism, the material transferring mechanism, the material taking robot, the material taking and attaching mechanism and the positioning jig cooperate with each other to automaticallyload and attach the FPC light bars; the manual contact with the FPC light bars is avoided; the risks of damage of LED lights and breakage of the FPC light bars are reduced; the problems that the FPC light bars cannot be tightly attached manually and the falling risks exist are solved; the gluing positions of the FPC light bars are more accurate; and the assembly accuracy of the products can be better met.

Owner:HUIZHOU WAI CHI ELECTRONICS CO LTD

Bearing ring taking-out device for casting

A bearing ring taking-out device for casting comprises a controller, a tight supporting mechanism, a sliding-off plate and a displacement mechanism. The tight supporting mechanism is fixed to the upper end of the displacement mechanism. The sliding-off plate is arranged on the right side of the displacement mechanism. The controller and the tight supporting mechanism are electrically connected with the displacement mechanism. Through the displacement mechanism, stable displacement of the tight supporting mechanism is achieved. The tight supporting mechanism opens a plurality of pull rod mechanisms through meshing of large gears on a tight supporting motor spindle and small gears on the pull rod mechanisms, then radial force is applied to the inner wall of a bearing ring. Friction force is increased through friction stripes at the ends of the pull rod mechanisms, thus the bearing ring can be pull out smoothly, the pull rod mechanisms comprise locating bolts and locating grooves, the rotation radius of the pull rod mechanisms can be adjusted, the universality of the bearing ring taking-out device is improved, and production cost is lowered. Through arrangement of a sliding table, manual contact with the bearing ring under high temperature is avoided, and thus the bearing ring rolls to a fixed area under guiding of a slope of the sliding table.

Owner:ANHUI HAILI PRECISION CASTING CO LTD

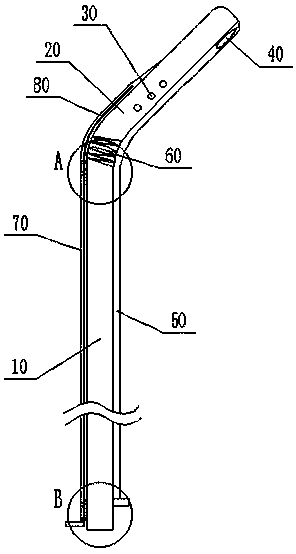

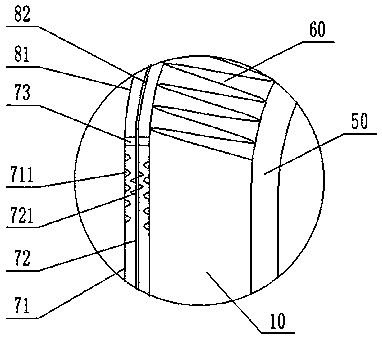

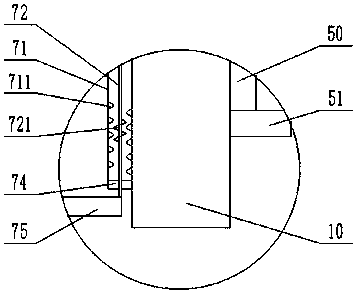

Jejunum nutrition tube

The invention relates to the technical field of medical instruments, in particular to a jejunum nutrition tube. A developing layer is arranged inside the wall of a tube head, a conveying hose is connected with the tube head through a connecting tube, the head end of an expansion tube is connected with a balloon, the balloon is arranged at the head end of the tube head, a sealing plug is arranged at the tail end of the expansion tube, the expansion tube and a transmission flexible shaft are fixedly connected with the outer walls of two sides of the conveying hose, a hard wire with an arc-shapedstructure is arranged in a steering tube, the head of a shaft core in the transmission flexible shaft is fixedly connected with the tail of the hard wire, internal threads are arranged on the inner walls of the head and the tail of a plastic case of the transmission flexible shaft, and external threads matched with the internal threads are arranged on the shaft core. The position of the tube headin a body can be conveniently displayed, allergic rejection of the human body is avoided, the angle of the tube head can be conveniently adjusted by the aid of the transmission flexible shaft, the hard wire with the arc-shaped structure and the soft connecting tube with a corrugated structure, and the pain of a patient cannot be increased due to rotation of the conveying hose.

Owner:孟静

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com