Sample dumping device capable of realizing automatic discharging

An automatic unloading and unloading device technology, applied in packaging, loading/unloading, transportation and packaging, etc., can solve the problem of affecting sample test results and production and operation, the tedious work of manual code reading confirmation, and the uncertainty of the number of storage buckets. and other problems to achieve the effect of shortening the residence time, ensuring authenticity and reliability, reducing labor costs and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

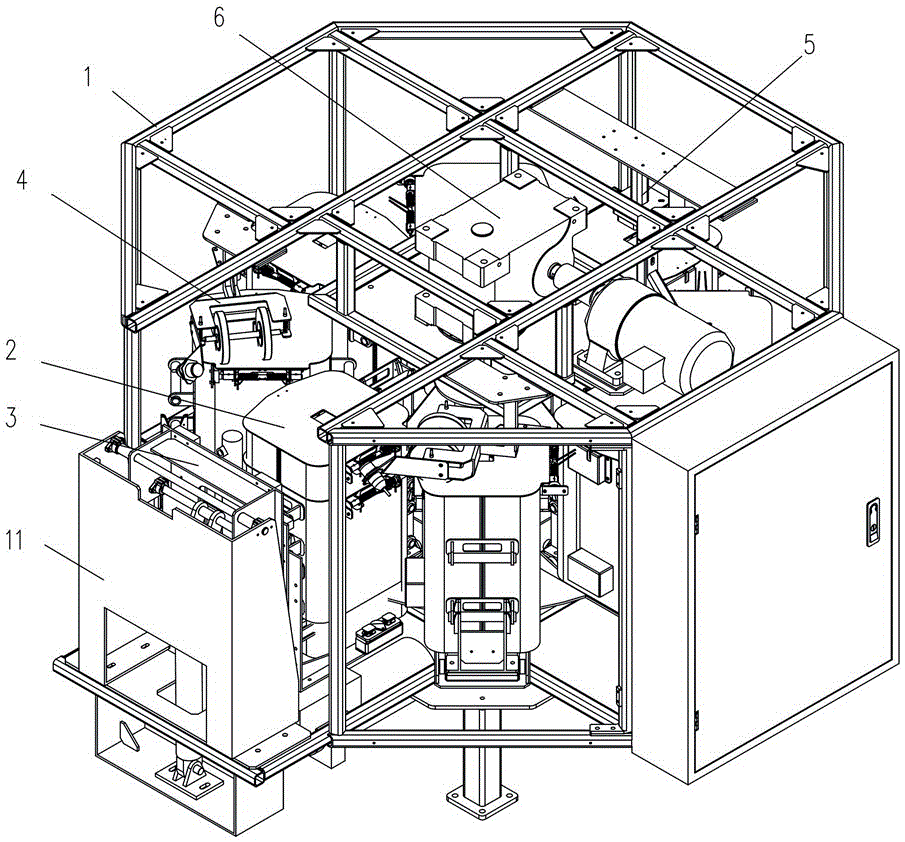

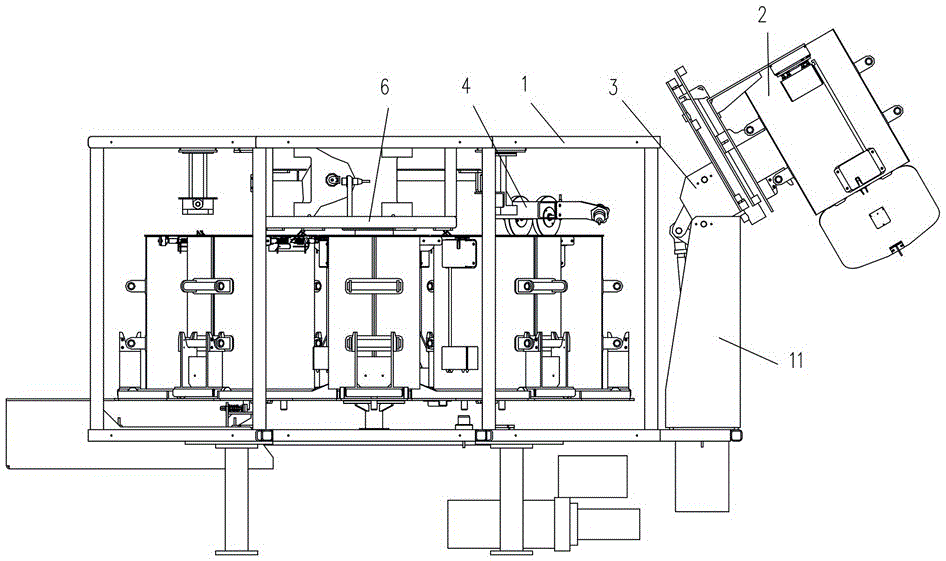

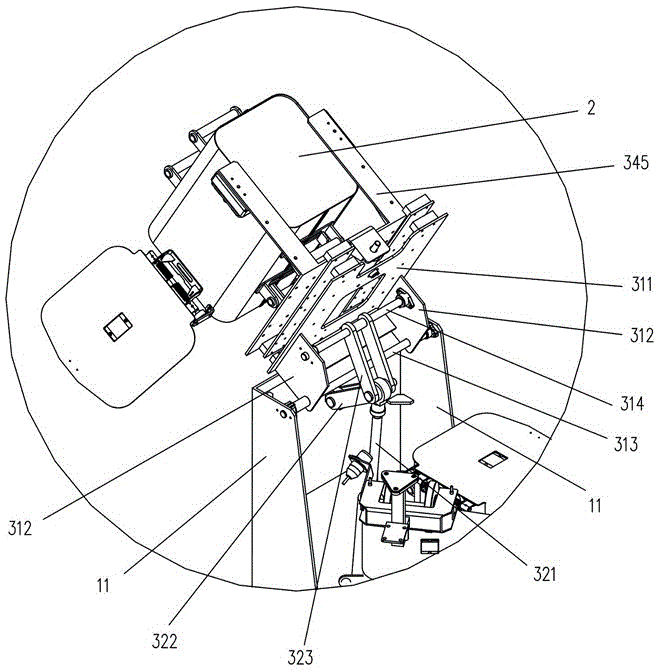

[0039] like Figure 1 to Figure 8 As shown, the present invention provides a sample unloading device for automatic unloading, including a frame 1, and a rotatable turntable mechanism 6 and a plurality of sample storage barrels 2 for collecting samples are arranged in the collection cavity formed by the frame 1 , a plurality of sample storage barrels 2 are arranged on the turntable mechanism 6 and can rotate together with the turntable mechanism 6; the side of the frame 1 is provided with more than one for turning the sample storage barrels 2 outward to the frame 1 for dumping and unloading Overturning unloading mechanism 3, overturning unloading mechanism 3 comprises overturning frame assembly 31, overturning drive assembly 32, lifting drive assembly 33 and extracting assembly 34, and overturning frame assembly 31 is vertically hingedly i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com