2-cyanophenol preparing method

A technology of o-hydroxybenzonitrile and o-hydroxybenzamide, which is applied in the field of preparation of o-hydroxybenzonitrile, can solve problems such as punching and clogging, and achieve the effects of promoting continued reaction, increasing contact area, and shortening reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

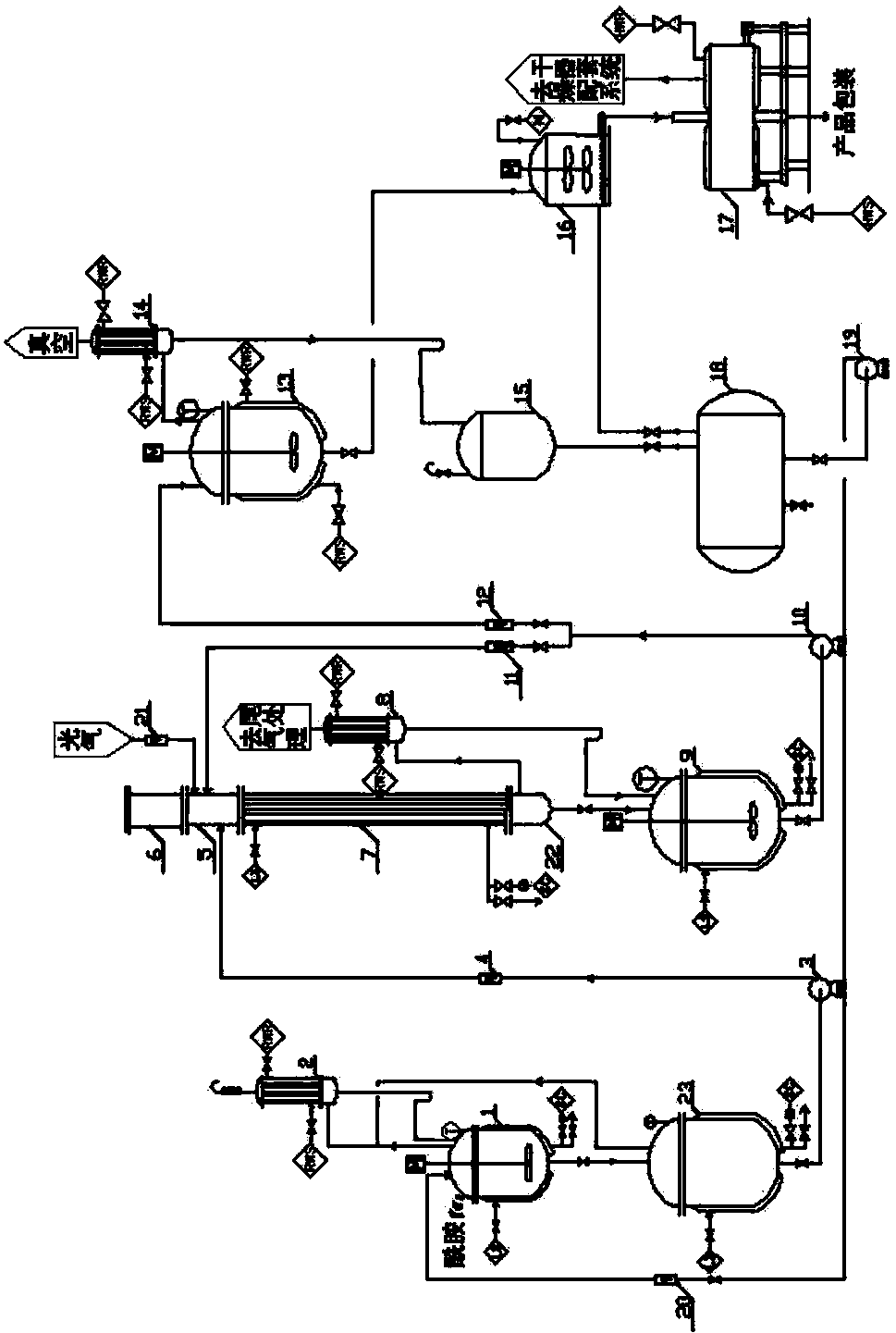

Method used

Image

Examples

Embodiment 1

[0029] In a 2000L glass-lined batching kettle, put 180kg of o-hydroxybenzamide, 0.5kg of catalyst dioxane and 1150L of solvent toluene for batching (1330L in total), turn on the jacket steam and heat to 105°C, stir for 15min, and o-hydroxybenzene After the formamide is completely dissolved in the solvent, the ingredients are put into a 5000L glass-lined storage kettle. Repeat the above process to keep the batching amount in the storage kettle to support extraction. The batching is pumped out with a raw material pump, and the flow rate is 665L / h, and it is input into a raw material mixer, where it is mixed with phosgene with a flow rate of 14700L / h. Control the temperature of the tube pass in the tubular reactor at 100-105°C, and the heat transfer area of the reactant flow is 20m 2 The tube side of the tubular reactor, the gas generated by the reaction passes through the gas-liquid separator and condenser, and then goes to the tail gas treatment system. The liquid material e...

Embodiment 2

[0031]In a 2000L glass-lined batching kettle, put 180kg of o-hydroxybenzamide, 0.5kg of catalyst dioxane and 1150L of solvent toluene for batching (1330L in total), turn on the jacket steam and heat to 105°C, stir for 15min, and o-hydroxybenzene After the formamide is completely dissolved in the solvent, the ingredients are put into a 5000L glass-lined storage kettle. Repeat the above process to keep the batching amount in the storage kettle to support extraction. The batching is pumped out with a raw material pump, and the flow rate is 443L / h, and it is input into a raw material mixer, where it is mixed with phosgene with a flow rate of 9800L / h. Control the temperature of the tube pass in the tubular reactor at 100-105°C, and the heat transfer area of the reactant flow is 20m 2 The tube side of the tubular reactor, the gas generated by the reaction passes through the gas-liquid separator and condenser, and then goes to the tail gas treatment system. The liquid material ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com