Beverage bottle dewatering and arranging production line

A beverage bottle and assembly line technology, which is applied in the field of beverage bottle dewatering and alignment assembly line, can solve the problems of increased labor, wet cartons, and easy damage, and achieve the effects of improving automation, drying efficiency, and packing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

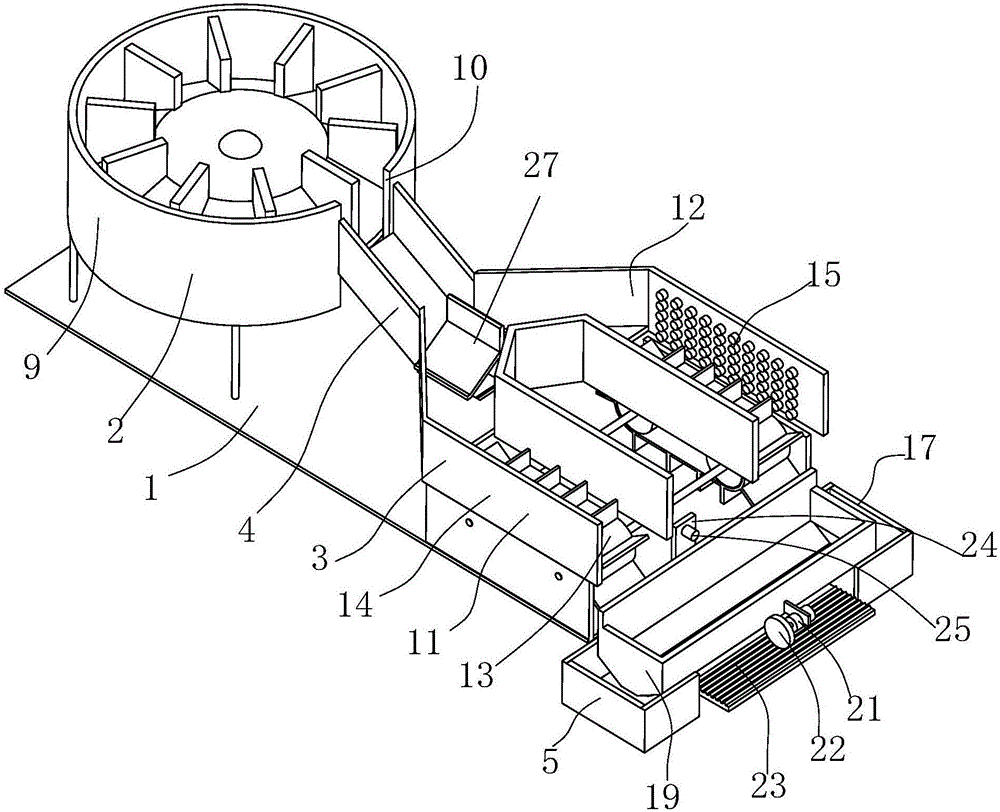

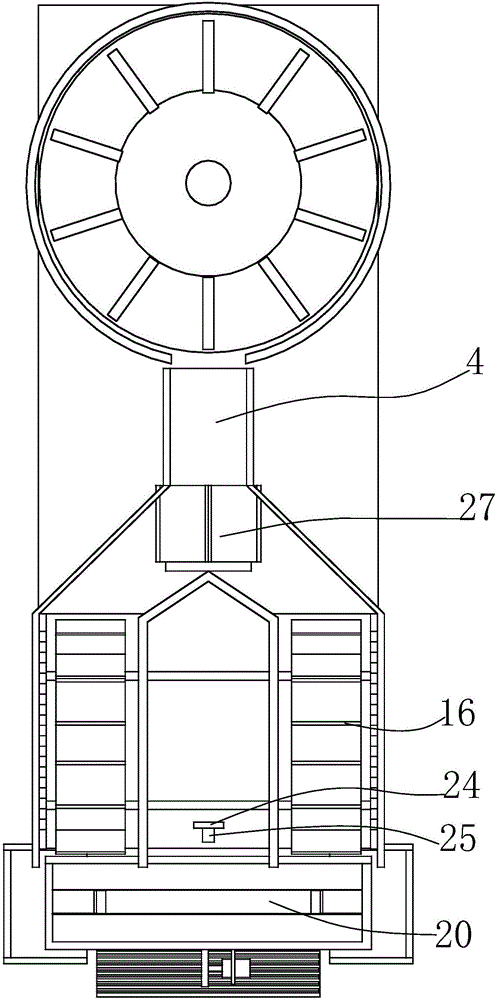

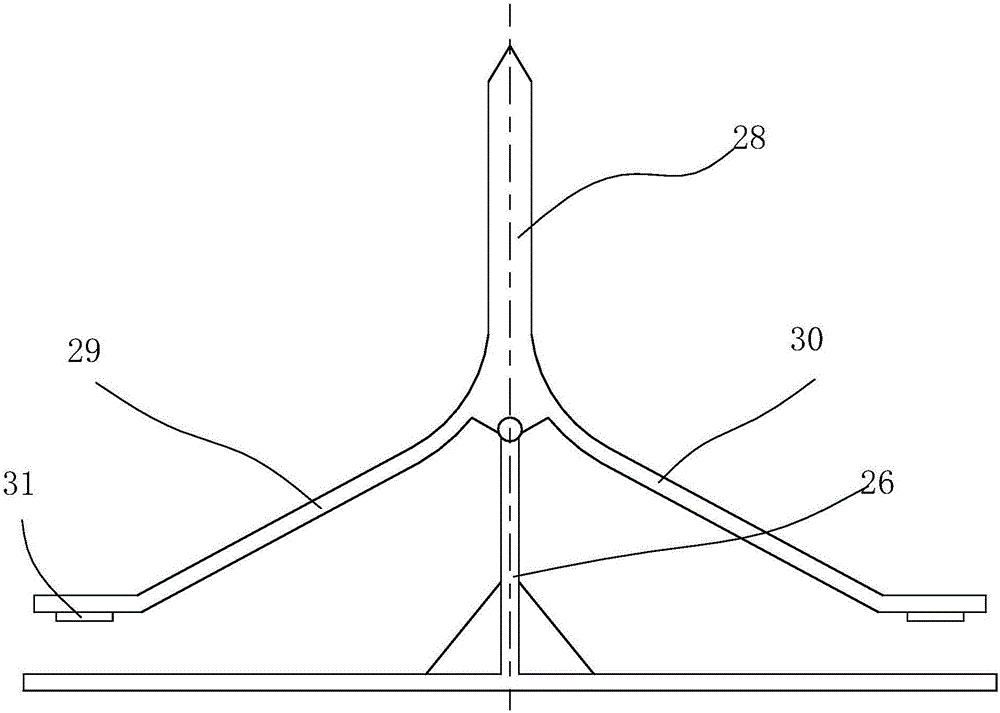

[0024] like Figure 1 to Figure 5 As shown, a beverage bottle dewatering assembly line includes a bottom plate 1, a transfer tray 2 is installed on the rear side of the bottom plate 1, and a wind power dewatering device 3 is installed in the middle of the bottom plate 1, and the wind power dewatering device 3 A feeding bridge plate 4 for conveying beverage bottles is installed between the transfer tray 2, and a beverage bottle regularizing device 5 is installed on the front side of the bottom plate 1.

[0025] The transfer tray 2 includes a No. 1 motor 6 placed vertically. A turntable 7 is installed on the shaft of the No. 1 motor. The outer side of the turntable 7 is inclined downward. Open the partition 8 of the beverage bottle, and the periphery of the turntable 7 is surrounded by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com