Automatic feeding device

An automatic feeding and feeding technology, applied in metal processing and other directions, can solve the problems of unstable workpiece quality, high labor intensity and low work efficiency, and achieve the effect of reducing labor intensity of workers, ensuring health and safety, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

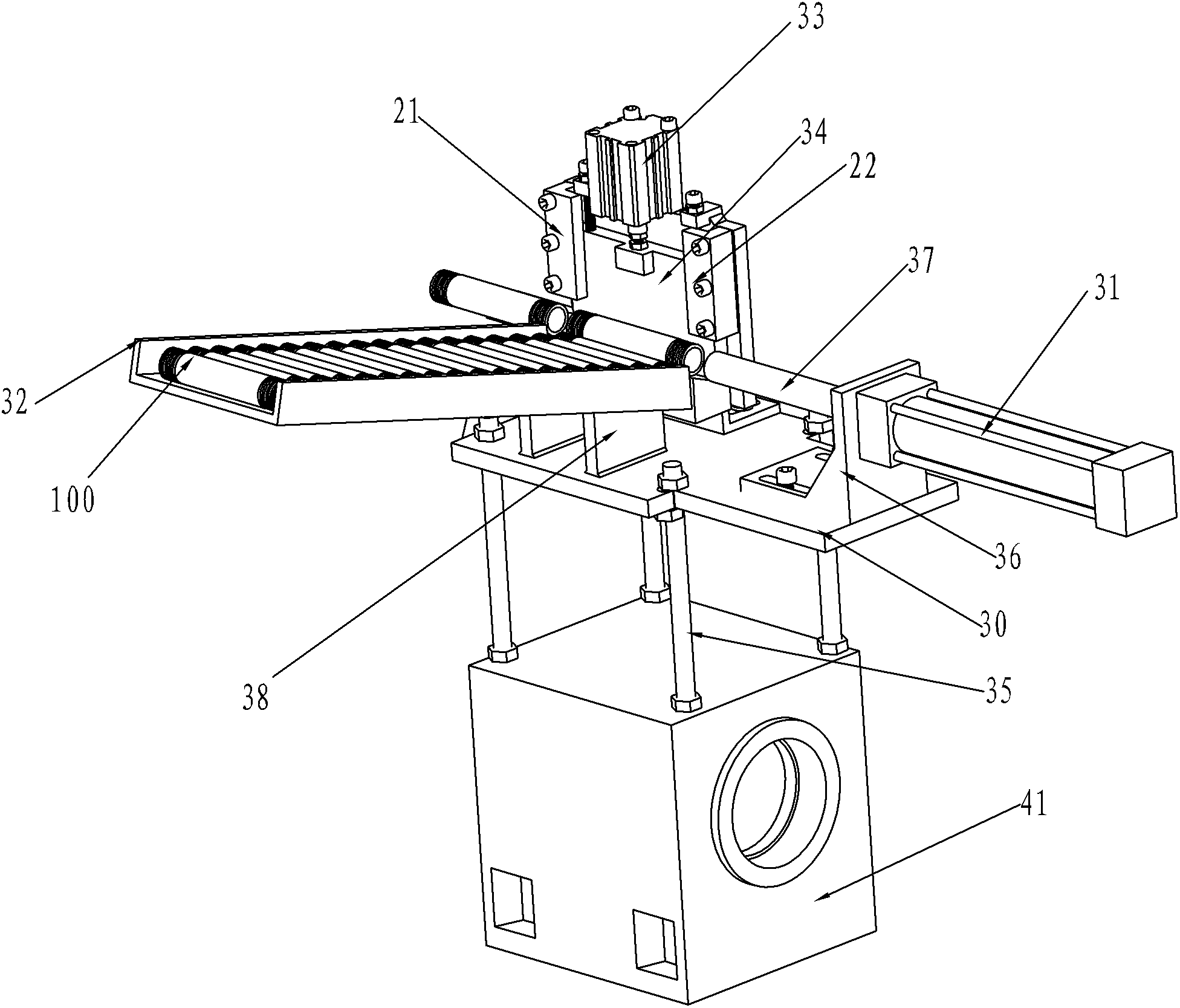

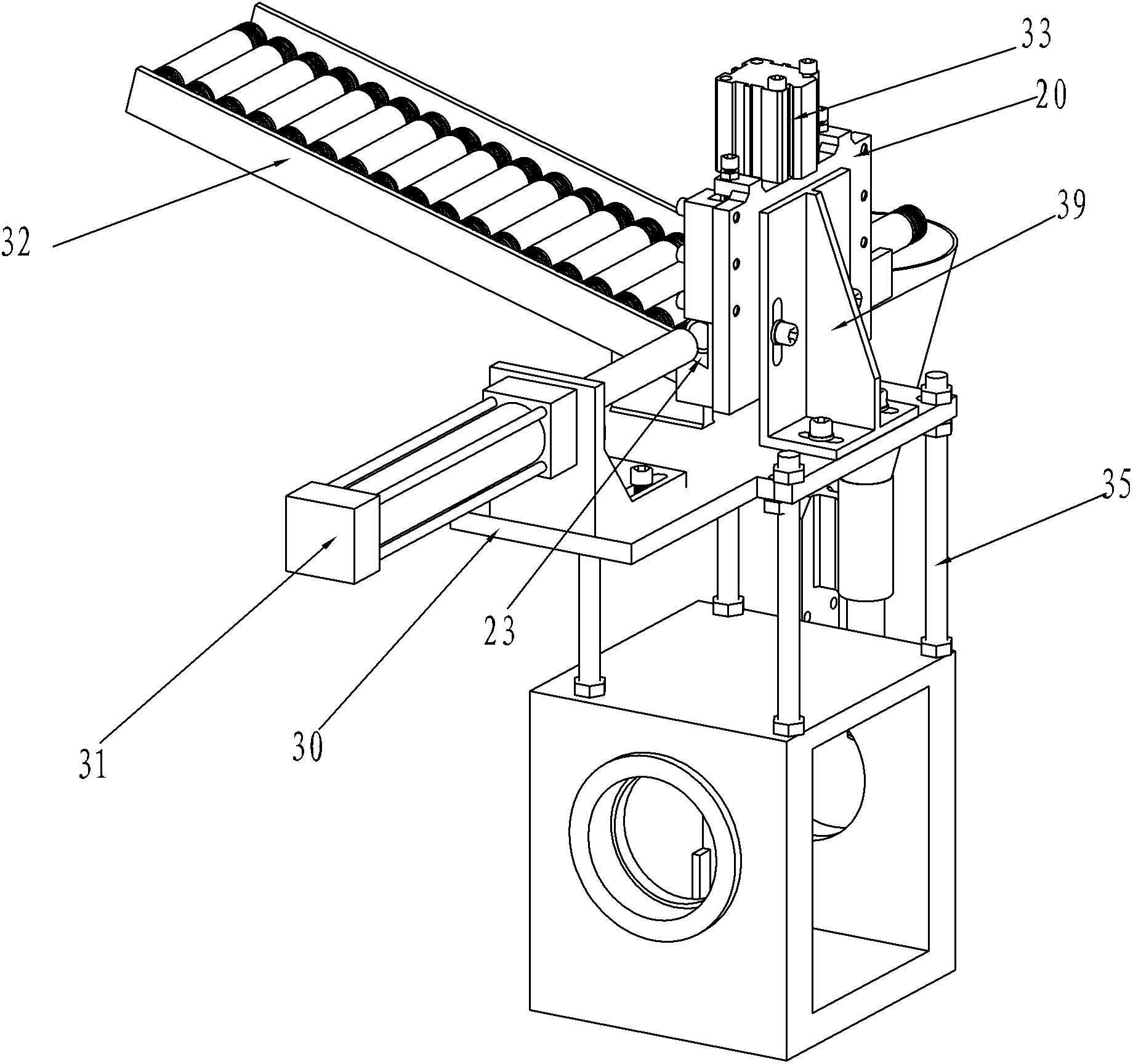

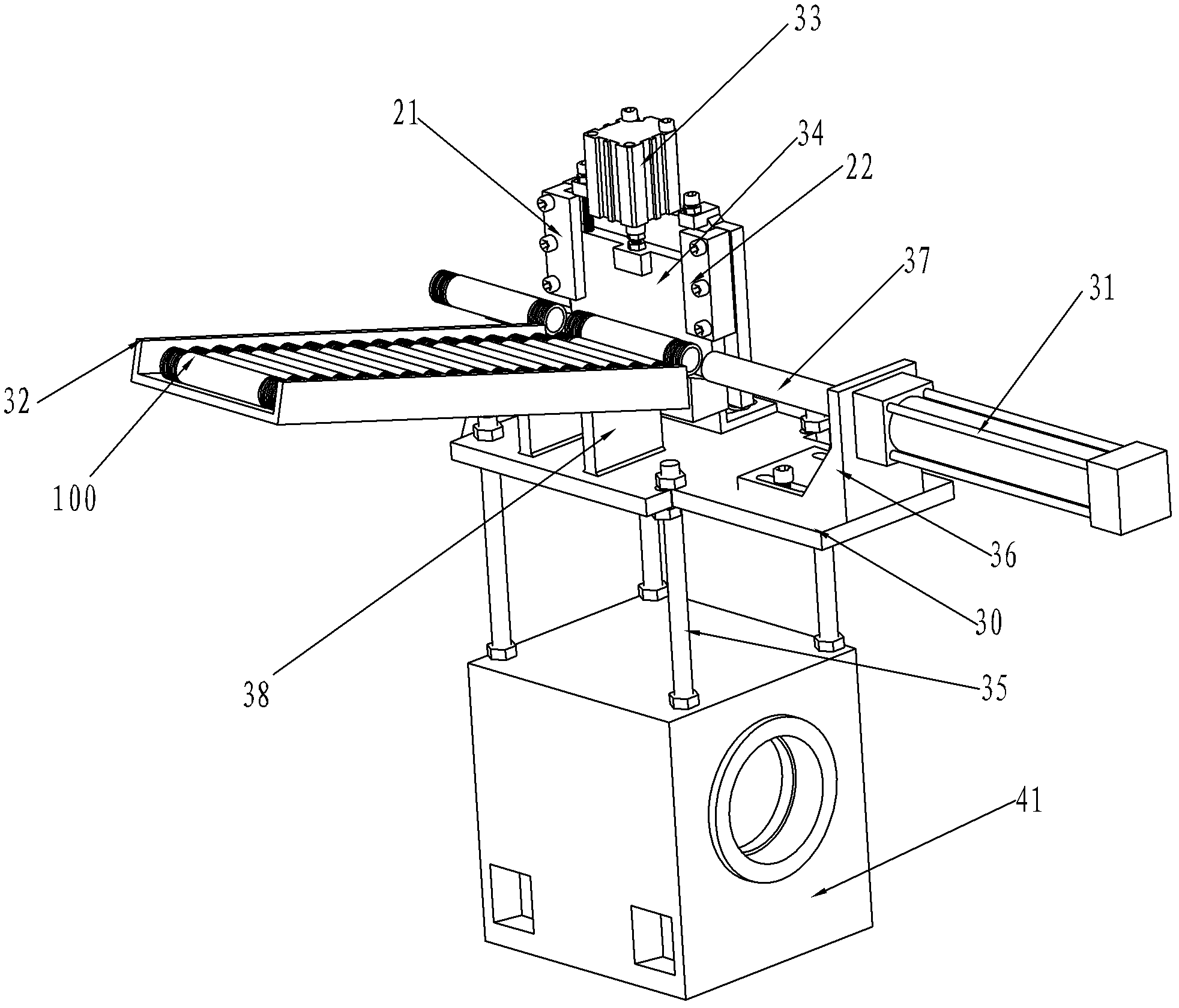

[0013] Such as figure 1 , 2 As shown, the automatic feeding device of the present invention includes a feeding support plate 30, a feeding cylinder 31, a trough 32, a lifting cylinder 33, and a lifting slider 34, and the feeding cylinder fixing seat 36 is installed on the top right end of the feeding supporting plate 30 by screws. The feed cylinder 31 is fixed on the feed cylinder holder 36, the piston rod of the feed cylinder 31 is threadedly connected with the push rod 37, the trough 32 is obliquely welded on the feed support plate 30 by two side plates 38, and the feed support plate 30 passes through Screw fixed slider holder 39, slider holder 20 is fixed on the slider holder 39 by screws, material lifting cylinder 33 is fixed on the top of slider holder 39 by screws, and the piston rod lower end of material lifting cylinder 33 is connected with the material lifting slide. The top of the block 34 is threaded and locked by nuts. The left and right sides of the slider seat 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com