Bearing ring taking-out device for casting

A technology for taking out a device and a bearing ring, applied in the field of mechanical equipment, can solve the problems of high temperature of the bearing ring, poor grasping of the hooking tool and the bearing ring, and falling of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

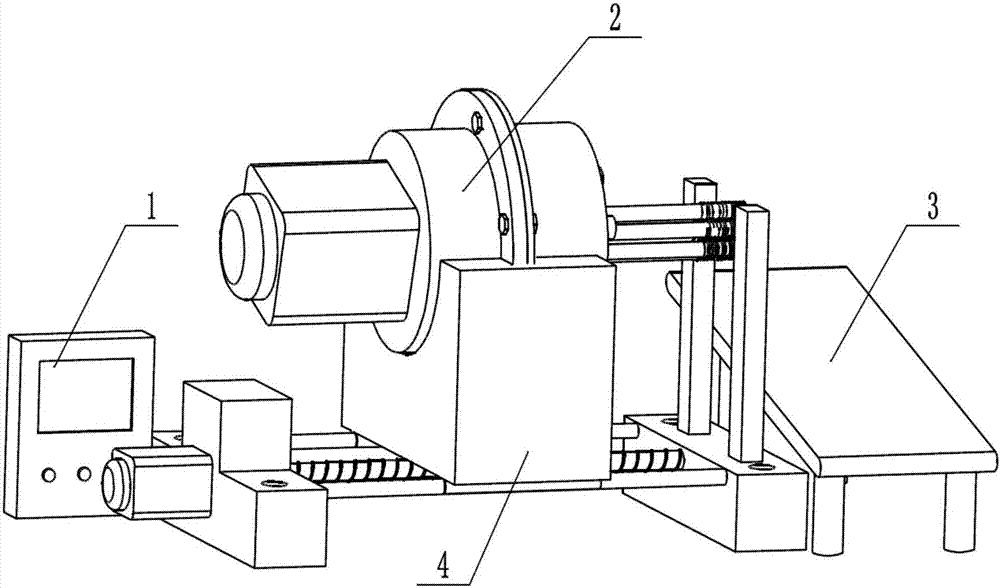

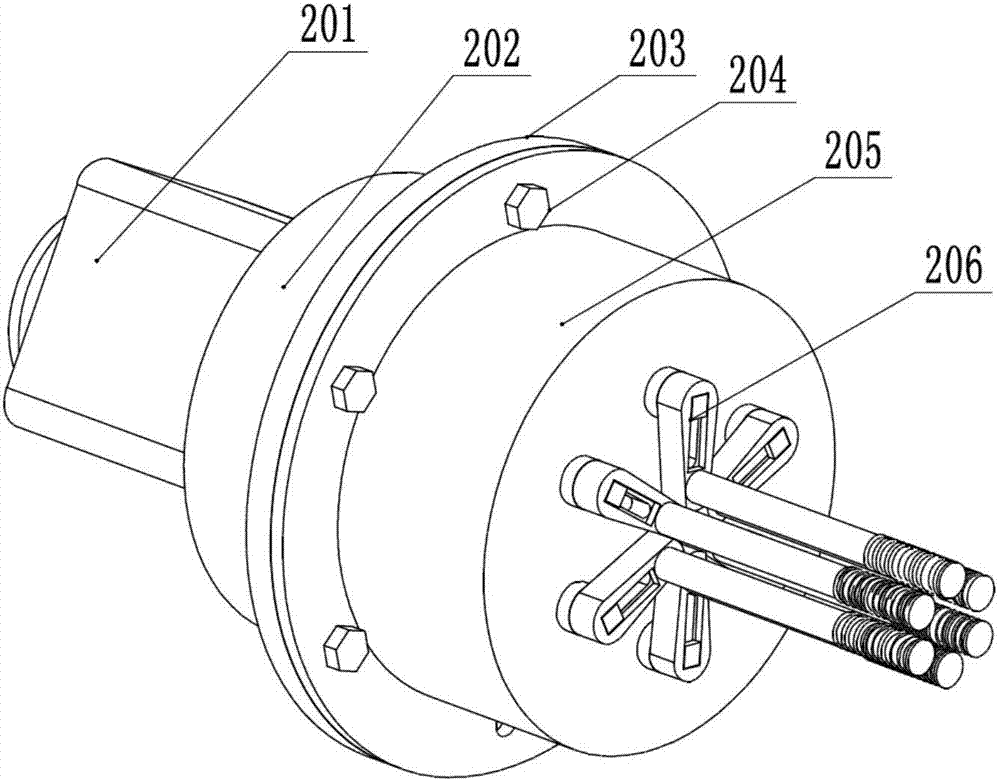

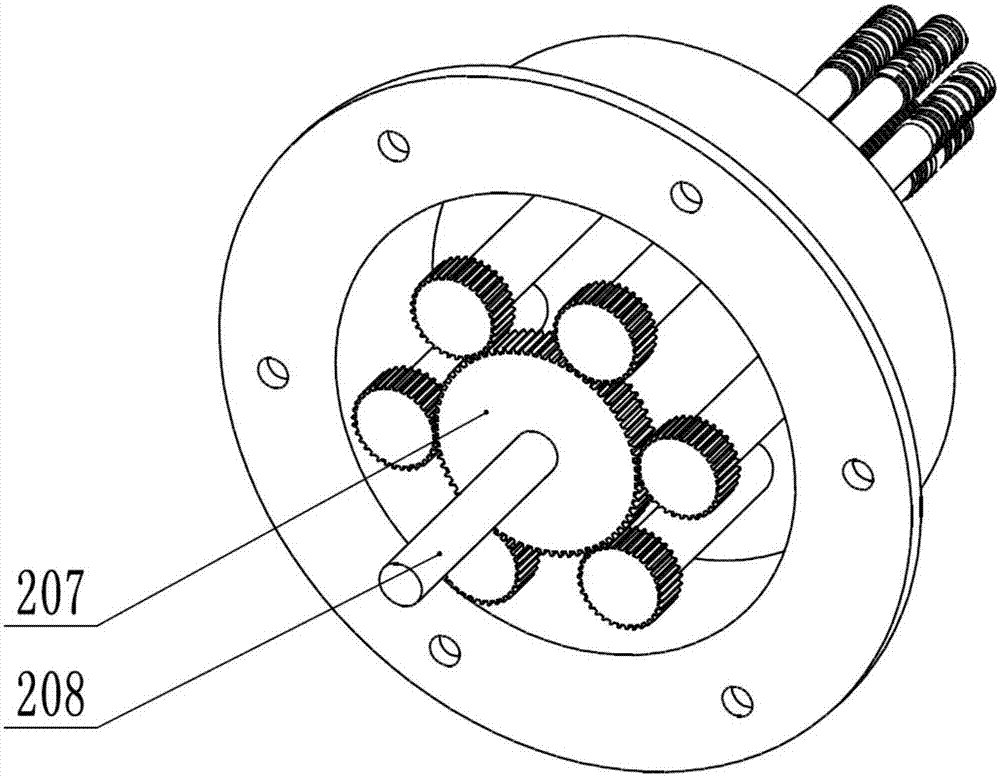

[0017] A bearing ring removal device for casting is composed of a controller 1, a tensioning mechanism 2, a sliding plate 3 and a displacement mechanism 4. The tensioning mechanism 2 includes a tensioning motor 201, a rear shell 202, a flange 203, Flange bolt 204, front shell 205, pull rod mechanism 206, large gear 207 and main shaft 208, described stretching motor 201 is fixedly installed on the rear shell 202, and the end that described front shell 205 and rear shell 202 contacts all is provided with Flange 203, the flange 203 on the front shell 205 and the rear shell 202 is connected and fixed by flange bolts 204, the front shell 205 is provided with a pull rod mechanism 206, and the middle position in the cavity of the front shell 205 is provided with The large gear 207, the large gear 207 is installed on the main shaft 208, the main shaft 208 is keyed to the output shaft of the tension motor 201 through a coupling, the lower end of the front shell 205 and the lower end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com