Scrap cleaning device for engineering machinery machining table board

A mechanical processing platform and engineering machinery technology, applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of cutting errors, inconvenient cleaning, hidden safety hazards, etc., and achieve the effect of not being easy to splash around and cleaning quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

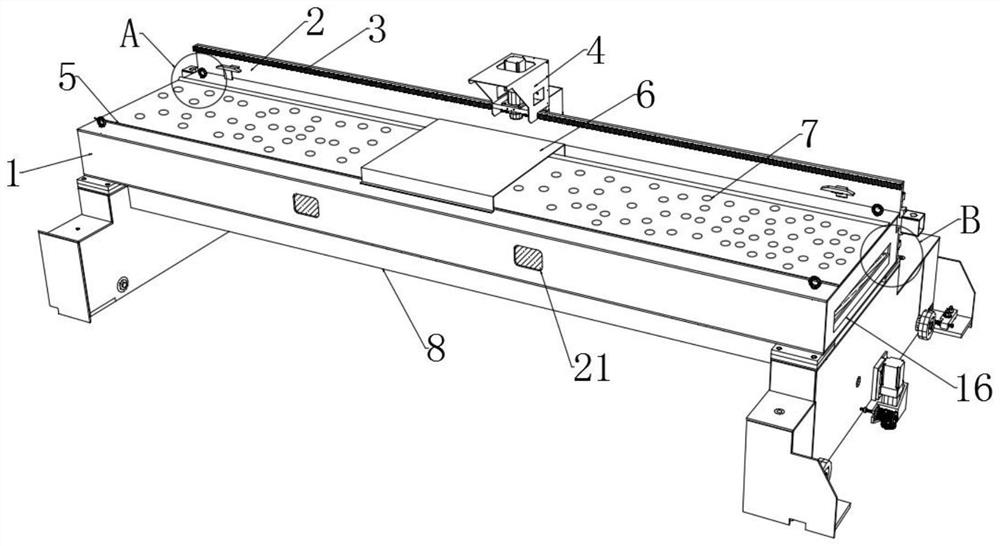

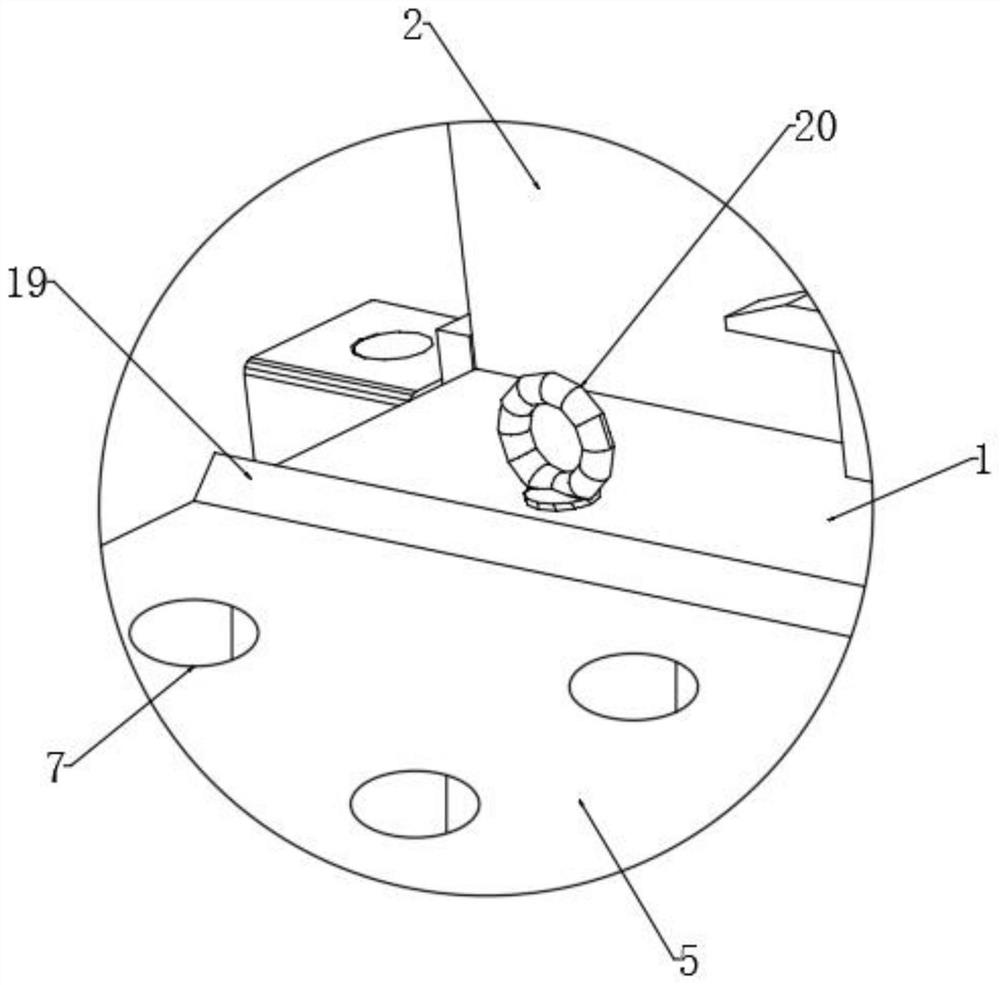

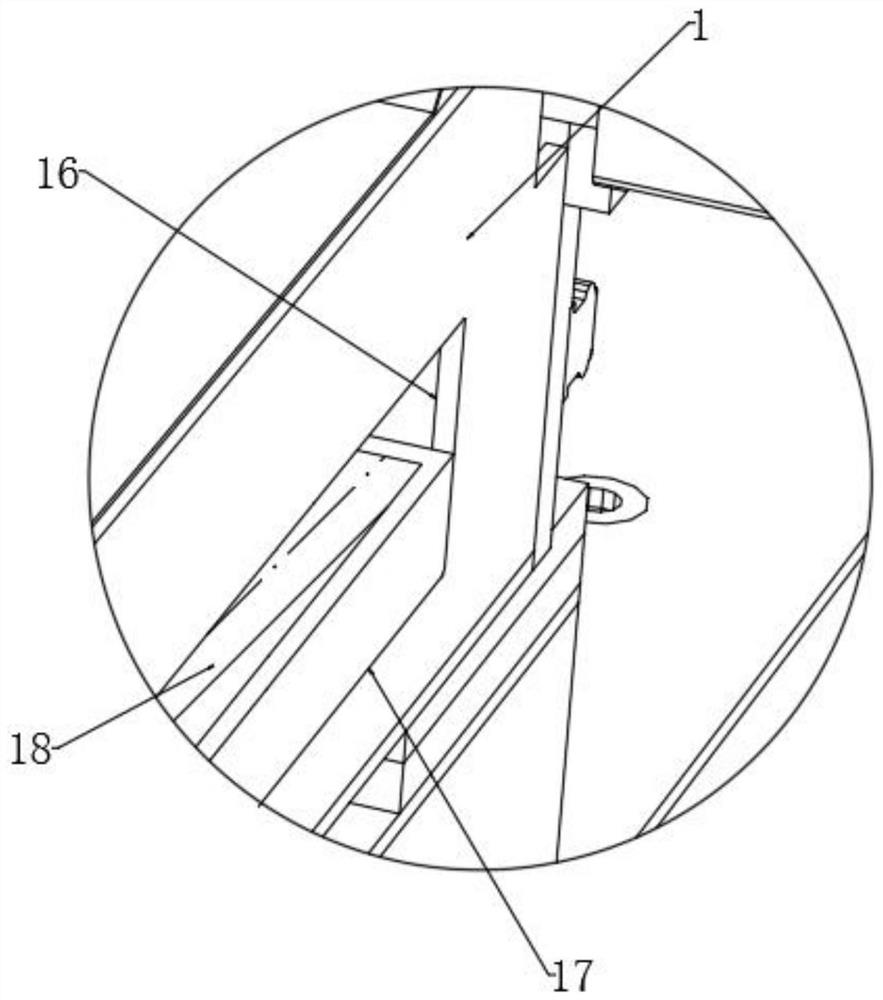

[0040] see Figure 1-6 , a debris cleaning device for engineering machinery processing table tops, comprising a machining platform 1, a fixed baffle 2 is fixedly connected to the upper end of the machining platform 1, and an electric slide rail is installed on the end of the fixed baffle 2 close to the machining platform 1 3. The outer end of the electric slide rail 3 is slidingly connected with a cutting machine 4. Two symmetrical sliding rails 5 are installed on the upper end of the machining platform 1. The inner wall of the sliding rail 5 is slidingly connected to the processing equipment 6. The upper end of the machining platform 1 has multiple excavations. A uniformly distributed through hole 7, the through hole 7 is located between the two sliding rails 5, the lower end of the machining platform 1 is fixedly connected with a protective cover 8, the inner bottom of the protective cover 8 is equipped with an electric heater 9, and the inner wall of the protective cover 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com