Preparation method of nanometer silver powder with particles controllable

A nano-silver powder and particle technology, which is applied in the field of preparation of nano-silver powder, can solve the problems that the production efficiency has not been effectively improved, the method of step-by-step control is cumbersome, and the concentration of the precursor cannot be too high, so as to achieve rapid purification, easy rapid scale-up, The effect of simplifying the post-processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

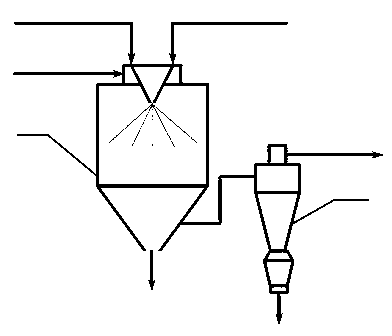

[0027] Such as figure 1 with figure 2 Shown, a kind of preparation method of particle controllable nano-silver powder comprises the following steps,

[0028] (1) Miscible silver nitrate and polyvinylpyrrolidone with water in proportion, after dissolution, the concentration of silver nitrate is 0.02 mol / liter, the concentration of polyvinylpyrrolidone is 0.02 mmol / liter, and the oxidation mixed solution A is obtained;

[0029] (2) Add ascorbic acid, an environmentally friendly, mild and weak reducing agent, into water for stirring and dissolving, then adjust the pH value of the solution to 9 with monomethylamine, and the concentration of the reducing agent is 0.2 mol / liter, and obtain a reducing solution after stirring and dissolving B;

[0030] (3) Pump the oxidized mixed solution A obtained in step (1) and the reduced solution B obtained in step (2) into the spray port at a volume ratio of 1:1, and use hot air with a temperature of 50 °C at a rate of 200 kg / h The speed is...

Embodiment 2

[0033] Such as figure 1 with image 3 Shown, a kind of preparation method of particle controllable nano-silver powder comprises the following steps,

[0034] (1) Miscible silver nitrate and polyvinyl alcohol with water in proportion, after dissolution, the concentration of silver nitrate is 0.045 mol / liter, and the concentration of polyvinyl alcohol is 0.025 mmol / liter, and the oxidation mixed solution A is obtained;

[0035] (2) Add potassium citrate, an environmentally friendly, mild and weak reducing agent, into water for stirring and dissolving, then adjust the pH value of the solution to 11 with ammonia water, in which the concentration of reducing agent is 0.4 mol / liter, and obtain a reducing solution after stirring and dissolving B;

[0036] (3) Pump the oxidized mixed solution A obtained in step (1) and the reduced solution B obtained in step (2) into the spray port at a volume ratio of 1:2, and use hot air with a temperature of 70 °C at a rate of 100 kg / h The speed...

Embodiment 3

[0039] Such as figure 1 with Figure 4 Shown, a kind of preparation method of particle controllable nano-silver powder comprises the following steps,

[0040] (1) Miscible silver nitrate and polyvinylpyrrolidone with water in proportion, after dissolution, the concentration of silver nitrate is 0.05 mol / liter, and the concentration of polyvinylpyrrolidone is 0.015 mmol / liter, and the oxidation mixed solution A is obtained;

[0041] (2) Add environment-friendly, mild and weak reducing agent tannic acid into water for stirring and dissolving, then adjust the pH value of the solution to 11 with a mixed solvent of ammonia water and dimethylamine, wherein the concentration of reducing agent is 0.4 mol / liter, Obtain reducing solution B after stirring and dissolving;

[0042] (3) Pump the oxidized mixed solution A obtained in step (1) and the reduced solution B obtained in step (2) into the spray port at a volume ratio of 2:3, and use hot air at a temperature of 80 °C at a rate of 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com